Ngaba umatshini wakho we-cnc kuphela oshushu kunesiqhelo? Ukuba ukufudumala kancinci kubushushu obutshatileyo kunokuba luphawu olunzulu lwesilumkiso-kwaye ayisiyonto onokuyifumana. Isiphene sokugxeka ayisiyongxaki nje encinci; Ngumqondiso wokuba kukho into engalunganga, kwaye ukuba ingakhathalelwanga, inokukhokelela kwizinto ezonakeleyo, ukuncitshiswa kokuchaneka komatshini, ukulungiswa kweendleko, okanye ukungaphumeleli kwexabiso.

Kulesi sikhokelo, siyakuhamba ngayo yonke into ofuna ukuyazi malunga ne-CNC spindle Grate-ukusuka ekuthatheni iimpawu zesilumkiso kwangethuba ukunika amandla kunye nokuthatha amanyathelo afanelekileyo ukulungisa kunye nokuthintela. Nokuba ungumsebenzi womatshini, uchwepheshe wolondolozo, okanye i-CNC yenzondelelo yokukhusela izixhobo zakho, lo thombo ungumthombo wakho ophambili wokugcina isiphene esipholileyo, esifanelekileyo, kwaye sihlala ixesha elide.

Masibususe ubushushu kwaye sigcine imveliso yakho isebenza kwi-PeAk yokuSebenza!

INTSHAYELELO KWI-CCS Spindle Spindle

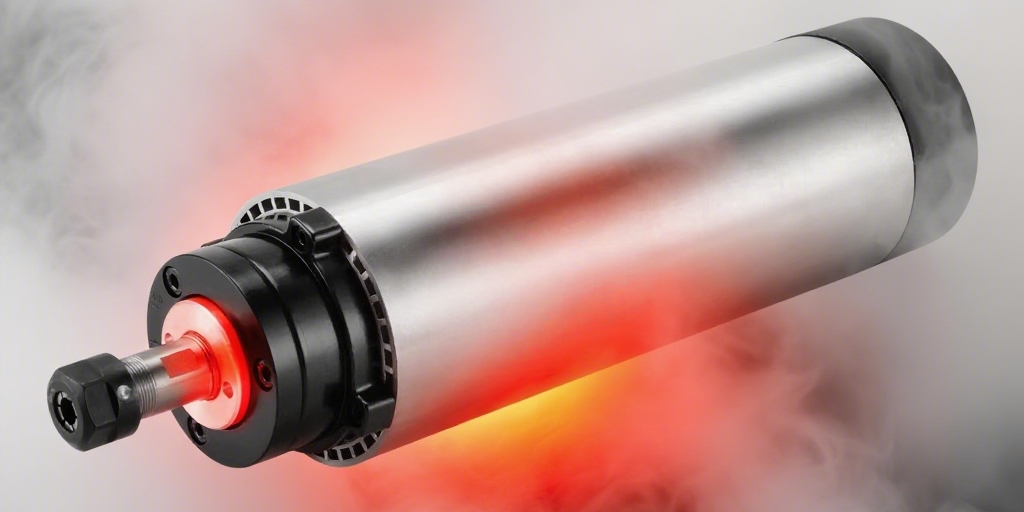

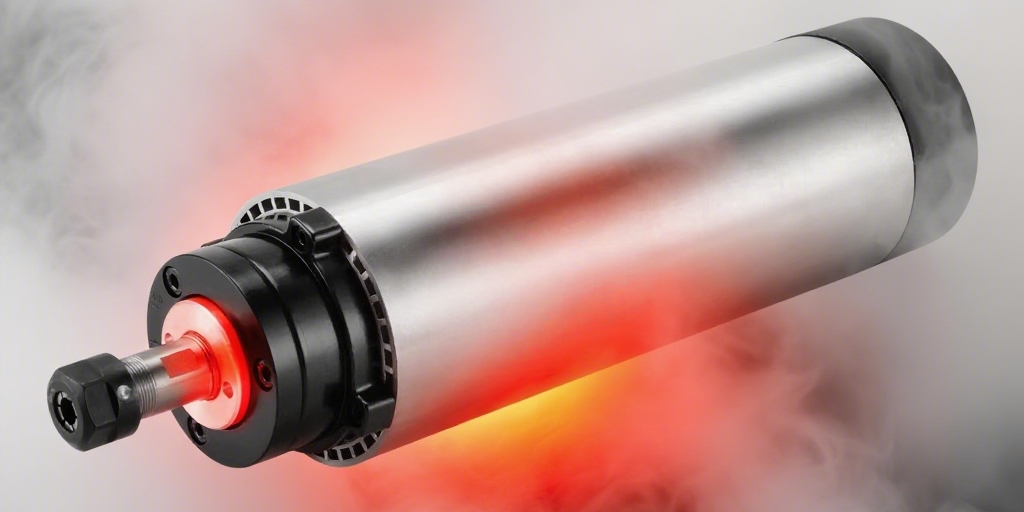

Yintoni imoto ye-cnc spindle?

Entliziyweni yawo onke amatshini we-CNC yimoto yawo ye-spindle. Eli candelo libalulekileyo lixhobisa izixhobo ezisikiweyo kwaye lisebenze ukuba i-fer, cut, imiyo, kunye nezinto zokubonisa ngokuchanekileyo. Njengentloko yokusebenza koomatshini, ilawula isantya, i-torque, kunye nentsebenzo yokuthembeka kwayo ibaluleke kakhulu kwimveliso engaguqukiyo.

I-SPITLE MATOS yenzelwe ubungakanani obahlukeneyo, ngesantya, kunye namandla amandla axhomekeka kwisicelo, nokuba ngabasebenzi, nokuba kukwenza inkcubeko, okanye imingxunya. Nokuba yeyiphi na le nto, isiphene kufuneka sisebenze ngaphakathi kwimida yobushushu ekhuselekileyo yokugcina ukuchaneka kunye nokuzonwabisa.

Cinga ngayo njenge-injini kwimoto yakho-ukuba iqala ukubaleka ishushu kakhulu, sisilumkiso ongakwaziyo ukungahoyi. Ubushushu obugqithisileyo kwi-spile bunokubangela iBherings ukusilela, ukuthambisa ukuqhekeza, kunye nokwandiswa kwe-thermal ukuphosa ubuchwephesha boomatshini. Isiphene esisebenzayo esisebenzayo sithetha ukusebenza okunempilo; Amaqondo obushushu anyukayo kufuneka aqwalasele ngokukhawuleza.

Ukuqonda ukuba i-spindele isebenza njani kwaye yintoni egcina ipholile ikunika ithuba eliphambili xa kukho into evakalelwayo '.

Ukubaluleka kweMpilo ye-SPITELLE kuMatshini we-CNC

Umatshini wakho we-CNC kuphela ulungile njengokukhwaza kwayo. Xa i-spindle igqitha, ayisiyiyo nje imoto oyingozi; Inokukhokelela ekuthatheni umonakalo, izinto ezigcweleyo, iinxalenye ezikrwelelweyo, imihla emileyo ephosiweyo, kwaye eyona imbi kakhulu yexabiso lendleko.

Amaqondo obushushu anyukayo ahlala kwimiqondiso yesilumkiso. Isikhuselo esifudumeleyo namhlanje sinokujika sibe yimoto enyukayo ngomso. Ngokubeka iliso kumanqanaba obushushu kunye nokulungisa isizathu kwangoko, ungasindisa amawaka kulungiswa kwaye uphephe ukutshintshwa ngokupheleleyo.

Kwakhona cinga ngale nto: Isikhonkwane esingapheliyo asibow ' Yindlela yokusabela ngokuqinisekileyo ongafuni ukubekwa kwintshukumo.

Ulawulo lobushushu obutshisayo lungaphezulu kokusebenza nje - kukhuseleko, imveliso, kunye nokwenza inzuzo bonke. Yiyo le nto kutheni kuqonda oonobangela kunye nokuthintela ukugqithisa kungakhethwanga; Ibalulekile.

I-CNC Spindle: Umatshini wakho ophambili

Isiphene asisiyiyo enye indawo - yindawo yokuhlala yomatshini wakho we-CNC. Xa iqhuba ubushushu obulungileyo, ukusebenza kwakho kuyahamba kakuhle. Xa igqitha, yonke into iqala ukuqhekeza. Eli candelo liqhuba izixhobo zokusika, lizilolonge ngezinto zakho, kwaye ligcine ukuchaneka kweqondo lobushushu lokusebenza.

Ixabiso lokungaphumeleli

Ukuxineka ngokungahambiyo ayisiyo indlela yokuhamba-iyayonakalisa. Ubushushu obugqithisileyo bunokubangela:

l ukukhupha ukungaphumeleli

I-LARLEX STOPLE SPIPLE

I- LODRAGED ye- LED

ezikhutshiwe Izinto

I-LFS Procesmes ebekiwe

l Ukulungiswa kwexabiso elingxamisekileyo

l Onddime Downtime

Yonke imzuzu i-spindle yakho ihamba kakhulu yimali elahlekileyo. Ukugcina kupholile akukho ngokuzithandela - kubalulekile.

Iimpawu zesilumkiso kwangoko

Amaqondo obushushu spikes zihlala luphawu lokuqala lwengxaki. Isikhuselo esifudumeleyo esifudumeleyo namhlanje sinokuba yimoto ekhutshiweyo ngomso. I-Traimating eshiyekileyo ingakhokelela:

l ukutshintshwa ngokupheleleyo

I-LARD STADT

Imonakalo kwezinye izinto zangaphakathi

Ukubamba imiba yobushushu bokuqala igcina imali, ithintela ukohlukana, kwaye igcina imveliso yeshedyuli.

Ichaphazela njani inkqubo yakho ye-CNC

Isikhuselo esishushu asizinzilanga nje - igxininisa kumatshini wonke.

Iibhedi ze -l diger deter ngokukhawuleza

I- LOOGCRICS YAYIPHELA

l Drives System System

l Izinto zoMbane ngaphezulu

l Ukwanda kwe-shirm iphosa ulungelelwaniso lwesixhobo

Esi siXesha sokuSebenza sinokukhokelela ekungaphumeleli kwenkqubo. Ulawulo lobushushu bokuthintela yeyona ndlela yakho.

I-Wissepan yomatshini woStoppan ngetshekhi yobushushu rhoqo

Ukubeka iliso kwi-Spinery Spindele Spindele kubalulekile. Imizuzu nje embalwa inokuthintela amawaka eendleko zokulungisa. Ishedyuli rhoqo:

I- LRMAL VICTE

I-LOOLD START SYST

I- Oirflow kunye nesondlo se-fan

I- LAGRAM yobushushu

Uthintelo luhlala luxabisa ngaphantsi kokuchacha.

Ukukhulisa imveliso ngokupholisa ukusebenza kakuhle

I-Spied Spied Spindle icociwe, ngokukhawuleza, kwaye ngokufanelekileyo. Oku kuphucuka:

I-LARCH YAYSP

Inxalenye yomgangatho

l Isixhobo somvity

I L i4 -

Ukuba ufuna iinxalenye ezininzi ngeyure, qala ngokulawula ubushushu obungcolileyo.

Ukupholisa ukupholisa = UKHUSELEKO LOKHUSELEKO

I-spindles evuthiweyo ayisiyomngcipheko kuphela-yingozi yokhuseleko. Ubushushu obukhulu:

I -LONA YOKUZIPHATHA NGOKUGQIBELA

l ukukhokela kwisixhobo esingalindelekanga

l Yenza indlela yokuziphatha yoomatshini

Ukugcina i-spindle yakho ipholile ukhusela zombini izixhobo zakho kunye neqela lakho.

Qonda imiqondiso yobushushu

Oomatshini bathetha ngotshintsho lobushushu. Funda ukwamkela:

Iqondo lokushisa iqondo eliphantsi

I- pikes tikes ngexesha lokusika ubunzima

l Ukupholisa Inkqubo yokungasebenzi kakuhle

l Ubushushu obuqhelekileyo bujikeleze iibherithi okanye izindlu

Ipateni nganye ibalisa ibali-ekuseni iqinisekisa ukusebenza okukhuselekileyo, okufanelekileyo.

Yandisa isiXhobo soBomi kunye nokuzinza kubushushu

Ukugqibela kobushushu bokuyigqibela kwesixhobo sobomi. Unokubangela ukungahambi kakuhle:

I-L Dull ukusika imiphetho

l utshintsho olwenziweyo

l ukunqunyulwa okungachanekanga

I-L Hult Hises

Isiphene esizinzileyo seqondo lobushushu siqinisekisa ukuba zonke izixhobo zenza konke okusemandleni.

Izizathu eziqhelekileyo ze-CNC Spindle

| Grand |

Grate |

| Ukulayisha ngaphezulu kwe-spindle |

Amandla okusika ngokugqithisileyo okanye umsebenzi owexesha oluninzi ngaphaya komthamo ovelisa ubushushu obugqithisileyo, ukhawulezisa iimoto kunye nebheringi. |

| Ukungaphumeleli okungalunganga okanye ukungaphumeleli |

Ukungafaneleki okanye ukungalunganga konyusa ukungqubana eBherlings, okhokelela kwi-SUFGA WAYPOUP kunye nokunxiba okukhawulezileyo. |

| Inkqubo yokungasebenzi kakuhle |

Iifilimu ezivaliweyo, amanqanaba aphantsi athobekileyo, okanye iimpompo zokuziphatha gadalala zizokonakalisa ubushushu kwiinkqubo ezipholileyo. |

| Ubushushu obuphezulu |

Ukusebenza kwiindawo ezingaphantsi kakhulu okanye zobushushu eziphezulu kunciphisa amandla e-spiend yokufumana ubushushu. |

| I-RPM egqithisileyo okanye amaxabiso okutya angalunganga |

I-RPMs ephezulu okanye amaxabiso ezondla ezi-Mismat andanyusa ubushushu kunye nezinto zoxinzelelo. |

| I-on on |

Iibharrings ezinxibileyo zenza imbambano eyongezelelweyo, evelisa ubushushu kunye nokuyibeka emngciphekweni ukusilela kwentlekele. |

| Imiba yombane kwimoto |

I-wiring wiring, ukuguquguquka kwe-voltage, okanye ukungasebenzi kakuhle kweemoto kubangela ukusebenza okungapheliyo kunye nokungabinakho ukusebenza. |

Ukulayisha ngaphezulu kwe-spindle

Ukwenza okugqithisileyo kwenzeka xa i-spile inyanzeliswa ukuba isebenze ngaphaya kwemida yentsebenzo echazwe ngumenzi. Oku kungenzeka ngeendlela ezininzi:

Ukusika iimpahla ezinzima okanye ezinobunzima

Umzekelo, umatshini wentsimbi yentsimbi okanye izabelo ze-inviot ngesiciko esenzelwe izixhobo zokuthambisa njenge-aluminium okanye iinkuni. Ukuchasana nokongezwayo kuvelisa imfuno engaphezulu ye-torque, ekhokelela kulwakhiwo olukhulu lobushushu.

Ukuthatha ukusika ngokunzulu

I-Pass enzulu isusa ngaphezulu kwezinto, ifuna amandla okusika. Oku kungaphunyuli kuphela umthwalo kwinqwelo-mafutha ye-spindle kodwa ikwadala imbambano kwi-Sciences-Internage

Sebenzisa irhafu ephezulu yokutya

Xa inqanaba lokutya likhawuleza kakhulu ukuba libe nesantya se-Spiele kwaye sibanakho isixhobo, umda wokusika unyanzelekile ukuba ulime ngezinto ezisisiseko endaweni yokucheba ngokucocekileyo. Oku kuvelisa ukuntywila okugqithisileyo, uxinzelelo kunye nobushushu.

Ukudityaniswa kwezi zinto kubeka uxinzelelo ngoomatshini kwiibherithi ze-spindle, imipundi yemoto, kunye neqela. Ixesha elingaphezulu, oku kunokukhokelela ku:

Ukukhawulezisa ukunxiba ukusuka kwimithwalo ye-radial kunye ne-axial.

Ukwandiswa kwe-shirm kwiindawo zangaphakathi, ezinokubangela ukungasebenzi kakuhle okanye ukwanda kwengqumbo.

Ukulayishwa kombane kwemoto ye-spindle, ukufaka esichengeni ukuqhekeka komonakalo kunye nomonakalo womoya.

Kwiimeko ezinzima, ukulayisha ngokungaphezulu kunokubangela ukuba i-spindle ihambele ukhuseleko lomthwalo we-thermal, ivenkile ngexesha lokusebenza, okanye ikhathazwe ngokusisigxina kwimoto kunye nebhetri.

Eyona mveliso ilungileyo: Hlala uhambelana nohlobo lweparameter onqumalayo, isantya se-Spiele, ireyithi yokondla, kunye nobunzulu bokusikwa kwe-spindler. Usebenzisa isixhobo esifanelekileyo kunye nokuqinisekisa imiphetho ebukhali nayo inokunciphisa umthwalo.

Ukungaphumeleli okungalunganga okanye ukungaphumeleli

Ibhetri ye-Spiele kunye nezinye izinto ezihambayo zixhomekeke kakhulu kwi-qubrication efanelekileyo ukuze isebenze kakuhle. I-Lubritation isebenza iinjongo ezimbini ezibalulekileyo: Ukunciphisa ukuxabana phakathi kwendawo yentsimbi kunye nokunceda ubushushu obufunyenwe ngexesha lokusebenza.

Xa i-yebrication ayikonelanga, ingcolisekile, okanye ingabikho ngokupheleleyo , iingxaki ezininzi zinokuvela:

Ukunganeli

Ukuba i-spindle ayifumani igrisi eyaneleyo okanye ioyile, ukunxibelelana ngokwesinyithi ukunyuka, ukuvelisa ubushushu obugqithisileyo kunye nokukhawulezisa ukunxiba.

I-conbrication engcolisekileyo

Ukungcola, ukufuduswa kwensimbi, okanye ukufuma kwi-lootha kunokuba kusebenza njengabasetyhini, ukukrazula imiphezulu kunye nokunyanzeliswa kokujikeleziswa okugudileyo.

I-Lubriction iyavuza okanye ukungahoyi

Ixesha elingaphezulu, amatywina anokungaphumeleli, okanye iishedyuli zolondolozo zinokujongwa, zikhokelela ekulahlekelweni ngokuthe ngcembe. Ngaphandle kokuqiniseka okufanelekileyo, ukwanda kwengqumbo ngokukhawuleza.

Iziphumo zokungasebenzi kakuhle zibandakanya:

Ukukhawulezisa ukhawulezisa i- SURD-I-finction egqithileyo iguqula amandla kubushushu, ukukhulisa ubushushu obutshisayo ngokukhawuleza.

Ukunxiba kunye nomonakalo -uxinaniso-filding ethwele umphezulu, onokukhokelela ekuphenduleni, ukufaka amanqaku, okanye ukhathazwe.

Ukungaphumeleli kwi-Spindle -kwiimeko ezigqithisileyo, iibherings zinokuvaleka ngokupheleleyo, zenza ukuba i-spindle iyeke ngequbuliso kwaye ingonakalisi iMoto kunye nezinye izinto.

Eyona mveliso ilungileyo: Jonga rhoqo amanqanaba e-Obritation, qinisekisa ukusetyenziswa kwegrisi ecetyiswayo okanye ioyile, kunye nokutshintsha i-qublicant engcolisekileyo. Ukulungiswa kwesiqhelo kunye nokuhlolwa kwamatywina kunye neebherings kunokunqanda iingxaki ze-suble ezinamagqabi kakhulu.

Inkqubo yokungasebenzi kakuhle

Isiphene se-CNC sivelisa ubushushu obubalulekileyo ngexesha lokusebenza, kwaye inkqubo yokupholisa efanelekileyo kubalulekile ukugcina amaqondo obushushu akhuselekileyo. I-Spindles inokusebenzisa ukupholisa umoya okanye ukupholisa amanzi , kodwa zombini zixhomekeke ekusasazeni okungagungqiyo ukuze kuchithwe ubushushu.

Iingxaki ezinciphisa ukusebenza kakuhle kubandakanya:

I-Vents evaliweyo okanye iifilli ezimdaka

Uthuli, ukutshintshwa kwenkunkuma, okanye i-shavings yensimbi inokuqulatha i-ping air okanye i-Eun Deauns, ithintelo lomoya kunye nokunciphisa ukubekwa kwesondo.

Iipaseji ezipholileyo ezipholileyo

Kwiinkqubo ezipholileyo-ezipholileyo, ii-minerals, iitshipsi, okanye iintsalela zeoyile zinokuthintela ukuhamba kwendlela epholileyo, ukuthintela ukusuka ekufumaneni nasekuthathe ubushushu.

Iimpompo eziphosakeleyo okanye abalandeli

Ukungaphumeleli koomatshini kubalandeli, iimpompo, okanye oosoyer abanokuyeka ukuyeka ukujikeleza okanye umoya ovuthuzayo, ukuvumela amaqondo obushushu anyuke ngokukhawuleza.

Xa inkqubo yokupholisa ayinakususa ubushushu, kuyenzeka imicimbi emininzi:

Ukuxinana kwebheringi kunye neemoto - amaqondo obushushu agqithileyo akhutshiwe kwaye angonakalisa i-intermatiment.

Ukwanda kwe-shirm kunye nokufudumeza okungalinganiyo kunokubangela amacandelo e-spindle ukwandisa amaxabiso ahlukeneyo, echaphazela ukungalunganga kunye nokwandisa ukuxabana kunye nokwandisa ukuxabana nokunyuka kwengqumbo.

ngaphambi kokungasebenzi Ukungaphumeleli

Eyona nto ibalulekileyo: Gcina inkqubo yokupholisa - icocekile rhoqo iifilli kunye nee-chacks, igungxule kwaye iphinde iphoseke ngokuphuculwa njengoko kucetyiswa, kwaye ihlole impompo yokusebenza ngokufanelekileyo. Ukuqinisekisa ukungafakwanga kunye nokupholisa okusebenzayo kubaluleke kakhulu kwi-spievity ye-spindle kunye nendlela ethembekileyo yokuthembeka.

Ubushushu obuphezulu

Naxa i-spindle igcinwa ngokufanelekileyo kwaye zonke iinkqubo zisebenza ngokuchanekileyo, amaqondo obushushu aphezulu kumasifundisane anokubangela ukugxeka. I-Spindles ixhomekeke kumahluko wobushushu phakathi kwazo kunye nendawo engqongileyo yokufumana ubushushu, ke ukuba umoya ojikeleze umatshini sele ushushu, ukusebenza kakuhle kuyancitshiswa.

Izinto ezinegalelo kule ngxaki zibandakanya:

Umoya ohluphekayo

Umoya oqinileyo uthintela ubushushu ekubenileka indawo yokusebenza, ukunciphisa ukusebenza kwe-spile epholileyo ye-moya okanye abalandeli.

Ukunqongophala koLawulo lweMozulu

Ngaphandle kwemeko yomoya okanye umoya ofanelekileyo womoya, oomasifundisane banokufikelela kumaqondo obushushu agqitha kuluhlu lokusebenza kweSpile.

Imveliso eyandisiweyo

Ixesha elide lokusebenza ngokuqhubekayo kwindawo eshushu ivumela ubushushu buqokelele, nokuba neenkqubo ezisebenzayo zokupholisa.

Iziphumo zobushushu obuPhakamileyo zibandakanya:

Ukucuthwa kokupholisa ukusebenza - i-spindle ayinakushenxisa ubushushu ngokusebenza ngokufanelekileyo, ingenzi iqondo lobushushu layo ukuba linyuke ngokukhawuleza.

Uxinzelelo lwe-thermal kumacandelo - ibheri, imipumelelo, kunye nezinye iinxalenye ezinobuthathaka zinengxaki yokunxiba kunye nokusilela xa zivezwa ngamaqondo obushushu aphezulu.

Ukuvalwa kwe-thermal enokubakho -i-spinds ezininzi zakhiwe-kukhuselo lwermati; Ubushushu obugqithisileyo bunokuphelisa ukuvalwa, ukuphazamisa imveliso.

Eyona mveliso ilungileyo: Qinisekisa ukuba ucweyo olwaneleyo locweyo, cinga ngemeko yomoya okanye iinkqubo zomoya ezinyanzelekileyo kwiindawo ezishushu, kunye nokubekwa esweni ubushushu obutshintsho ngexesha lokubaleka. Ngokuphuculwa okuncinci kwi-airflow kunye nokupholisa kunokunciphisa kakhulu umngcipheko wokuhlala.

I-RPM egqithisileyo okanye amaxabiso okutya angalunganga

Ukusebenza isitayile kwizikhephe ezibini zokungasebenzi Isiciko kunye nesixhobo kufuneka sisebenze ngokuvisisana: Inqanaba lokukhupha izinto, isantya se-Spiele, kunye nexabiso lokutya, kunye nexabiso lokutya kufuneka lilinganise ukuqinisekisa ukusikwa ngokufanelekileyo.

Iingxaki ezibangelwa zizindlu ze-mismatorat kunye neendawo zibandakanya:

I-RPM egqithisileyo ngeRhafu yokondla ephantsi

Isixhobo sokusika ihlazo ngokuchasene nezinto endaweni kunokuba siyikhuphele ilusu, ukuvelisa uxinzelelo kunye nobushushu.

Amaxabiso aphezulu yokondla kakhulu kwisantya esinikiweyo

Esi sixhobo sinokumba kwi-ngobukrelekrele kakhulu, sibeka umthwalo owongezelelweyo kwisiciko kwaye sibangela ukuba iqondo lokurabha linyuke.

Ukusika okungasebenziyo

Ukudityaniswa okungachanekanga kwesantya kunye nokondla kukhokelela kwi-Chip engentle, enyusa ukuxhathisa kunye nokuxabana, ukufudumeza isitshizi kunye nesixhobo.

Iziphumo zale micimbi zibandakanya:

Ukutshiza ngokubulala -ukunyusa ubushushu obunqabileyo kwaye kulayishwe iqondo lobushushu obuphakamileyo, kunokubangela ukhuseleko lwe-thermal okanye obangela umonakalo osisigxina.

Isixhobo sokunxiba kunye nokungaphumeleli - izixhobo zokusika izixhobo ezinqamlezayo ngokukhawuleza phantsi kweemeko ezingalunganga zokusika, ezizonyukayo kunyuka ubushushu kunye nobushushu.

Ukucuthwa kokuchaneka komatshini okunciphisa -Ukwandiswa kobushushu kwe-spindle okanye umsebenzi wokusebenza kunokuphawula ngokuchanekileyo, kuchaphazele ukugqiba komgangatho kunye nokuqina.

Eyona mveliso ilungileyo: Soloko ubala isantya esifanelekileyo kunye neRhafu yokondla ngokusekwe kuhlobo lwezinto ezibonakalayo, iJometri yesixhobo, kunye nobunzulu bokusikwa. Sebenzisa izikhokelo zoMvelisi okanye iingcebiso zeSoftware zeSoftware zinokunceda ukukhusela ukugqitha kakhulu kwaye kwandise ubomi obushenxisayo kunye nomgangatho womatshini.

I-on on

Iibheringi zizinto ezibalulekileyo kwi-CNC Spindle, ukuxhasa ukujikeleza nokuqinisekisa ukuhamba okuhle, kuchanekile. Xa iibherings zinxitywe, zonakalisiwe, okanye zifakwe ngokungafanelekanga , zivelisa uxinzelelo olongezelelekileyo kunye nokuntywila, zombini ezinegalelo kulwakhiwo lobushushu.

Unobangela oqhelekileyo wemicimbi ethwele imiba ibandakanya:

Ukunxiba okuqhelekileyo ngokuhamba kwexesha

Iibherings ngokwemvelo zilahlekileyo ngokusetyenziswa ixesha elide, ngakumbi phantsi kwemithwalo ephezulu okanye ukusebenza okuqhubekayo.

Ungcoliseko

Uthuli, i-chips, okanye umswakama ungangena kwizalathiso, ibangela ukuba i-piting, amanqaku, okanye ukukhutshwa.

Ufakelo olungalunganga okanye ulungelelwaniso

Iibherings ezihlelwe zidala imithwalo engalinganiyo, ukwanda kwengqumbo nobushushu.

Iziphumo zokuThunyelwa okanye ezonakeleyo zibandakanya:

Ukonyusa isizukulwana ngompu -ukuntywila kwizinto ezihlanjiweyo kuqhuba ubushushu obutyongiweyo, obunokukhawulezisa ukunxiba kwamanye amacandelo.

Ukuhamba ngokugqithisileyo- Ukuziqhelanisa kuchaphazela ukuchaneka komatshini, kukhokelela ekugqibeleni komgangatho womhlaba kunye neempazamo ezinkulu.

Umngcipheko ophezulu wokungaphumeleli kwe-spindle -Ukuba umonakalo unexhala, i-spile ingabamba, ihamba nokhuseleko lobushushu, okanye ukubandezeleka ngokusisigxina.

Eyona mveliso ilungileyo: vula ibheri ye-spindle yeempawu zokunxiba okanye ukonakala, gcina i-shority efanelekileyo, kwaye ubeke endaweni yezahlulo zomenzi. Ukuqinisekisa ukusebenza kakuhle kw kubalulekile ukuthintela ukugqitha ngokuchanekayo kunye nokugcina ubisi oluchanekileyo.

Imiba yombane kwimoto

Imoto yesitshizi ixhomekeke kubonelelo lombane oluzinzileyo kwaye imisebenzi yangaphakathi esebenzayo yokusebenza ngokufanelekileyo. Iingxaki zombane-ezinjengokungalingani kwe-voltage, imimoya ephosakeleyo, okanye imijikelezo emifutshane -Center -Can ibangela ukuba imoto itsale ngokugqithisileyo, evelisa ubushushu ngaphakathi kwimoto ngokwayo.

Imiba eqhelekileyo yombane ibandakanya:

Ukungalingani kwe-voltage

I-voltage engalinganiyo kuyo yonke imipu kwizigaba ezonyuka ngoku kwaye ukuxhathisa ngaphakathi, ukuvelisa ubushushu ongezelelweyo.

Impazamo

Ukufakelwa kwe-Denen, ukujikajika, okanye ijikelezo ezivulekileyo kunokunciphisa ukusebenza kakuhle kwemoto kunye nokuphakamisa amaqondo obushushu asebenzayo.

Unxibelelwano olukhululekileyo okanye idrivey drives

Unxibelelwano lombane olihlwempu okanye ukungasebenzi kakuhle i-vfds (idrive eguquguqukayo) inokwenza i-spikes okanye imijelo engaqhelekanga, igxininise kwimoto.

Iziphumo zemicimbi yombane ibandakanya:

Ukukhawuleza kweSUFSUKU LOKUGQIBELA -UKUQHUTYELWA NGOKUGQIBELA UKUGCINWA KWEEMPILO ZEEMPindlongo, elinokudlula ngokukhawuleza imida yokusebenza.

Ukungaphumeleli kwi-Tection -Ixesha lokuhlala ixesha elide kunokulimaza i-inshuler, kukhokelela kwimijikelezo emifutshane okanye ukusilela ngokupheleleyo kwemoto.

Ukuncitshiswa kwe-PeSEATAN I-SPIPEAN -Uxinzelelo lombane oluqhubekayo lukhange lunxibe iibherithi kunye nezinye izinto zoomatshini, zidibanisa ingxaki yokugxeka.

Eyona nto ibalulekileyo: Ihlola unxibelelwano lombane, jonga amanqanaba akho e-voltage, kwaye uqinisekise ukuba inkqubo ye-VFD okanye ye-drive isebenza ngokuchanekileyo. Ukulungisa ukungalingani kombane kwangoko kunokuthintela ukonakala kwemoto kunye nomonakalo wexabiso.

Iimpawu kunye neempawu ze-CNC Spindle Grate

Ukuqonda iimpawu zesilumkiso kwangethuba sokupheliswa kwe-spindle spindles kubalulekile ekuthinteleni umonakalo onzima kunye nexabiso leendleko. Nazi ezona zikhombisi ziqhelekileyo:

Ingxolo engaqhelekanga

Ukugaya, ukuncwina, okanye izaziso zokuhambahamba zihlala zibonisa ukuba ibheri iphantsi koxinzelelo olugqithisileyo okanye ukuba i-hlula iphumelele. Njengoko ubushushu buyakha, izinto zentsimbi zandisa kwaye iibherings ziphulukana nokusebenza kwabo ngokutyebileyo, ukudala ingxolo. Ezi zandi zingumqondiso ocacileyo wokuba isitshisi sihlangabezana noxinzelelo lwe-thermal kwaye kufuneka sihlolwe kwangoko.

Ukuvalwa kwe-thermal

Uninzi lwezikhuselo ze-CNC zanamhlanje zixhotyiswe ngamaqondo obushushu obunezilo oluziindawo ezizenzekelayo xa amaqondo obushushu agqitha kwimida ekhuselekileyo. Ngelixa eli nqaku likhusela umatshini, oluphindiweyo okanye rhoqo iflegi ye-thermal i-spile ye-spile yakho iqhubeka igqitha. Ukutyeshela ezi ndawo zinokukhokelela kwisimo semoto esisigxina okanye ukuthwala.

Ukuncitshiswa kweNtsebenzo yeSpeindle

Ukugxeka kunokuchaphazela ngokuthe ngqo ukusebenza kwendlela. Unokuqaphela ukunciphisa ukunqunyulwa, isantya esihamba ngesantya esincinci, okanye ubunzima bokugcina irhafu yokondla. Ubushushu bubangela ukwandiswa kwezinto ezibalulekileyo, kunciphisa ukusebenza ngokukuko, kwaye kunokunyusa ukulungisa-konke okuyinyani kunye nokunciphisa ukusebenza komatshini wakho.

Ukuqinisekiswa okuqinisekileyo okanye ivumba elivuthayo

Ubushushu obugqithisileyo bunokubangela izinto zentsimbi okanye izixhobo zokuthambisa kwi-disclor. Ukuba ubona i-biish okanye i-brownish hies kwizindlu ezifudumeleyo, izithuthi, okanye ebheriyo, luphawu lobushushu obusexesha elide. Iphunga elivuthayo lelinye isalathiso esibi kangangokuba amalungu angaphakathi, njengamamoya okanye i-lbrication, anokonakala. Ezi mpawu zifuna ingqalelo ekhawulezileyo ukuthintela ukusilela kwentlekele.

Ngokunikela ingqalelo kule miqondiso, abaqhubi banokuthi babambe imicimbi ephambeneyo kwangoko, bathintela ukulungiswa kweendleko, kwaye kwandise ixesha lokuphelisa i-CNC yabo le-CNC.

Isikhokelo senyathelo lenyathelo lokuthintela i-CNC Spindle Light

Ukubeka iliso kumthwalo we-spindle

Soloko usebenzisa i-spile ngaphakathi komthamo wayo. Kulumkele ukutyhala nzima kakhulu ngokusika, ukuphumelela okunzulu, okanye irhafu ephezulu yokondla. Ukulayisha ngaphezulu kudala uxinzelelo kakhulu kunye nobushushu, obunokuyonakalisa ngokukhawuleza isifo.

Gcina i-reabrication efanelekileyo

Jonga rhoqo kwaye ugcine inyibilikisi ye-spindlera. Qinisekisa ukuba uhlobo oluchanekileyo kunye nenani le-thabricant lisetyenziswa, kwaye ulitshintshe njengoko kufuneka. Ulungiso olungcolisekileyo okanye olunganyamezeliyo lunyusa ukungqubana kwaye kukhawulezisa ukugcwala.

Hlola kwaye ugcine iinkqubo zokupholisa

Qinisekisa ukuba inkqubo yakho yokupholisa i-spindle - ingaba ipholile ipholile okanye i-wale-ipholile-iyasebenza kakuhle. I-chants yomoya ecocekileyo, faka indawo yeefilitha, jonga amanqanaba apholileyo, kwaye uqinisekise ukuba abalandeli okanye iimpompo zisebenza ngokufanelekileyo. Inkqubo yokupholisa egcinwe kakuhle ibalulekile kulawulo lobushushu.

Ukulawula ubushushu obuNtisha

Gcina imeko yendibano yopholile kwaye ingena kakuhle. Amaqondo obushushu aphezulu awenza kube nzima kwiinkqubo zokupholisa ukuze zichithe ubushushu, ngakumbi ngexesha lokuvelisa ixesha elide. Ukuqulunqwa komoya okanye umoya ofanelekileyo unokunceda ukugcina amaqondo obushushu aqhuba ekhuselekileyo.

Lungisa i-RPM kunye neRireary yondla ngokufanelekileyo

Yenza isantya se-Spindle kunye neRhafu yokondla ngokusekwe kwizixhobo, isixhobo, kunye nokusebenza komatshini. Ukubaleka kwi-RPM ephezulu kakhulu ngaphandle kokuhlengahlengisa ukutya kunokuvelisa ubushushu obungafunekiyo, ngelixa ucotha kakhulu okanye ukona okungalunganga kunokubangela uxinzelelo kunye noxinzelelo.

Ihlala ihlola iibhetri kunye nenxalenye ye-spindle

Jonga iibherings, shaftts, kunye nokunyusa izixhobo ze-hadware. Ukunxiba okanye iibherithi ezonakalisiweyo kunyusa ukungqubana, ukuntywila, kunye nokwakhiwa kobushushu. Faka indawo nawaphi na amalungu abonisa iimpawu zokunxiba ngaphambi kokuba abangele ukugcwala.

Jonga impilo yombane yemoto

Qinisekisa ukuba inqwelo-moya yesitshizi ifumana i-voltage yezinzileyo kwaye ikhoyo ngoku. Imicimbi yombane, njengokuphuthiswa kwemimoya okanye ukungalingani kwe-voltage, kunokubangela ubushushu obukhulu kakhulu. Uvavanyo oluqhelekileyo luNcedo lokuNikela kuthintela ukugxeka ngequbuliso.

Ukusebenza kweliso lobushushu

Sebenzisa iinzwa ze-thermal okanye iikhamera ze-infrared ukubeka iliso kubushushu be-spinded ngexesha lokusebenza. Ukufunyanwa kwangoko kwamaqondo obushushu anyukayo akuvumela ukuba uthathe inyathelo lokulungisa ngaphambi komonakalo omkhulu wenzeka.

Ishedyuli yolondolozo loKhuseleko

Yenza ishedyuli yolondolozo equka uhlalutyo lwe-vibration, ingcinga ye-thermal, itsheki ye-Olbrice, kunye nokuhlolwa konxibelelaniso lwe-spindle. Ulondolozo loKhuseleko lungaphantsi kakhulu kunolungiso olungxamisekileyo kwaye luqinisekise ukusebenza okungaguqukiyo.

Qeqesha abaqhubi ukuba babone iimpawu zesilumkiso

Fundisa abaqhubi kwimiqondiso yokugxeka, kubandakanya ukuqaqamba okungaqhelekanga, ukusebenza okucokisekileyo, ukuguqulelwa, kunye nevumba elivuthayo. Khawuleza uphendule kwizikhombisi zakuqala kuthintela ukusilela okukhulu.

Ukulandela la manyathelo ngokungaguqukiyo kunokunciphisa kakhulu umngcipheko wokutshiza ngokugqithileyo, kwandise ubomi bomatshini wakho we-CNC, kwaye ugcine umgangatho woomatshini ongaguqukiyo.

Iingcebiso eziPhambili ze-Spievity

Sebenzisa iinkqubo zokubeka iliso kwi-spindle

faka izixhobo ezibeka iliso kumthwalo we-spindle ngexesha lokwenyani linokubonelela ngezilumkiso zakuqala imicimbi enokubakho. Ezi nkqubo zilandelela i-Torque, okwangoku, kunye neqondo lokushisa, ukuthobela abaqhubi kwiimeko ezingaqhelekanga ngaphambi kokuba zibangele ukonakala kakhulu. Ukufunyanwa kwangoko kunceda ukuthintela ukugqithisa, uxinzelelo lomatshini, kunye nexesha lokuphumla olungalindelekanga.

Ukukhetha i-spindle elungileyo yokukhetha

i-spile ngamandla awoneleyo, isantya, kunye nokupholisa amandla okwenza izinto ezicetywayo kunye nokusika ukusebenza kubalulekile. Sebenzisa i-Spietleff ekhutshwa phantsi kwemisebenzi yokufumana amandla kunokukhokelela kwixesha elininzi, ubushushu obugqithisileyo, kunye nokuncitshiswa kobomi. Ukutshatisa imigaqo-nkqubo ye-SPIPLE kwilayini yomsebenzi iqinisekisa ukusebenza nokunyaniseka.

Ukuphuculwa kwesisombululo esifanelekileyo sokupholisa ukusebenza

kwimisebenzi ephezulu yokusebenza, kuqwalasela ukuphuculwa kwenkqubo yokupholisa ngakumbi. Itekhnoloji epholileyo epholileyo okanye itekhnoloji yokupholisa i-hybrid inokuthintela amaqondo obushushu asezantsi kuneyunithi epholileyo yomoya. Ukuphucula ukupholisa kunciphisa uxinzelelo lwe-thermal kwiibherithi kunye nokuphucula ubomi obususiweyo kunye nomatshini ngokuchanekileyo.

Ukufumanisa ukubonwa kombane vs.

Iimpawu zemicimbi yombane

Ukupheka ukuya kwi-Spiele kunokwi-stem kwiingxaki zombane, kudla ngokubotshwa kwimoto ye-spindle okanye iinkqubo zayo zokulawula, njenge-drive yedrive yodlelo (VFD). Le micimbi inokubangela ubushushu obukhulu ngenxa yokuhanjiswa kwamandla okanye ukusilela kwemidlalo.

Jonga:

I -LPMS engahambelaniyo okanye i-torque phantsi komthwalo , ebonisa imiba enokubakho ye-VFD okanye yemoto.

I- LORPS yequbuliso ihla , enokuphazamisa ubushushu bezithuthi kwaye zivelise ubushushu.

I- GARTE YOKUGQIBELA YENKQUBO YOKUZIPHATHA , idla ngokufunyanwa nguchuku okanye i-thermal icinga.

Nditshisa ivumba okanye i-wiring ebilisiweyo , iphakamisa imijikelezo yombane okanye imijikelezo emifutshane.

Sebenzisa i-Multeter ukujonga i-voltages kunye nokugcuma kwezitenxo. Imamela ye-thermal inokukhetha amabala ashushu kwibhodi okanye kwiBhodi yoLawulo. Ukuba awunamava ngokuxilonga kombane, nxibelelana nengcali. Ukuphakama okuhlwempuzekileyo okanye iibrashi ezityhutyha (kwi-chestmators) kunokufaka isandla ekusebenzeni kakhulu kunye nokusebenza.

Iimpawu zokusilela koomatshini

Imicimbi yoomatshini sisizathu esiqhelekileyo sokutshiza ngokungxama, rhoqo ngenxa yokuqina okanye ukungqinelana okungafanelekanga kwiindawo ezifana nebheringi, iishafu, okanye iikholeji. Ezi ngxaki zihlala zivelisa ubushushu obugqithisileyo ecaleni kweempawu.

Iiflegi ezibomvu ezixhaphakileyo zibandakanya:

I -Garing okanye inkqonkqoza ingxolo ngexesha lokusebenza kwe-spindle, ebonisa iibherings ezihlangeneyo okanye izinto ezigwenxa.

I- viberation kwi-Z-Axis okanye iNtloko yeSpiele , enyusa ukungqubana nobushushu.

l inxibe ngokwasemzimbeni kwiikholeji, abaphathi bezixhobo, okanye iiNto zemoto , ezikhokelela ekusebenzeni okungapheliyo nokugqithisa.

Ukuba umatshini wakho we-CNC uneendawo zokubeka iliso kwimozulu, uphonononge ukuntywila okanye ukuphononongwa kwengqondo okanye iilogo zeqondo lokushisa le-spikes, le micimbi yoomatshini. Uvavanyo oluqhelekileyo, njengokujonga izithuthi ezikhululekileyo okanye iigiya ezinxungupheleyo, zinokubamba iingxaki kwangoko.

Ukusilela koomatshini kuhlala kuphuhla ngokuthe chu, ke ulondolozo olusebenzayo luphambili ukuthintela ukulungiswa okungapheliyo kunye nexabiso lendleko.

Izixhobo kunye neendlela zobuchule ze-CCC Spindle Gradesis

Sebenzisa i-stethoscope okanye i-ficketion hlaluter

Xa izixhobo ze-CNC zigqithisileyo, izixhobo zokuxilonga zinokunceda ukuchonga unobangela wokuchaneka. I-stethoscope ye-methascope sisixhobo esilula kodwa esisebenzayo semicimbi yokunamabala. Ngokubeka i-Probe yamacandelo ahlukeneyo ezindlu ezinesiphene, unokumamela izandi ezingaqhelekanga, ezinjengokugaya okanye ukubonakalisa i-fanctions okanye into enxibe igalelo kukukhathazeka.

I-L Stethoscope : Yenza izandi ezivela kwimoto, iibheringi, okanye igiyabox. Ukuba ingxolo egqithisileyo okanye i-vibration ifunyenwe kufutshane neebheringi, iphakamisa i-function okanye inxibe i-SURD ALK.

I-L Devibir Davalyire : Ezi zixhobo zilinganisa i-aplication kwaye frequency, ukuchonga ukungalingani, izinto ezibonakalayo, okanye izinto ezinxibileyo ezivelisa ubushushu. Iibhutsi eziphambili zinokubona imiba eqingqiweyo ngaphambi kokuba zikhokelele ekuhambeni kakhulu.

Ukubhatala ezi zixhobo kunye nee-Smartphone Apps zokurekhoda isandi okanye uhlalutyo lwe-frequency ikuvumela ukuba ungene kwaye ulandelele idatha ekuhambeni kwexesha. Oku kuxhasa ukohlwaywa kwangaphambili, kukunceda ujongane nemicimbi yokunyamezela ngaphambi kokuba bawa.

I-thermal icinga kunye neqondo lobushushu

Ingcinga ye-thermal sisixhobo esibalulekileyo sokufumana ukufumanisa ukugcwala. Iikhamera ze-infrared zifumana amabala ashushu, etyhila iibherings ezibonakalayo, imipundi yemoto, okanye i-factions kwishaphu ye-spindle. Iskena esikhawulezayo sinokuchonga iindawo ezinengxaki ngaphandle kokuchitha umatshini.

Iikhamera ze-thermal : jonga iindawo ezibomvu okanye ezimhlophe kwi-thermal ukubonisa, ibonisa amaqondo obushushu ngaphezulu kweemeko eziqhelekileyo zokusebenza. Umzekelo, ukuphazamiseka okutshisayo kucebisa ukungasebenzi okanye ukunxiba.

l Iqondo lobushushu : Sebenzisa isoftware ukuthelekisa ukufundwa kobushushu okwangoku ngokuchasene nesiseko 'iprofayile. I-Spikes kwi-sogs yeqondo lokushishina ukusuka kwi-InsorS of Elisors inokuqinisekisa iindlela zokugxeka.

Ukudibanisa ingcinga ye-thermal ngohlalutyo lokuhamba kunye nokungafihli kubuchule kubonelela ngendlela ebanzi yokuchonga ukufumanisa ukugqithisa. Oku kusebenza ngakumbi kwiindawo zevenkile ezixakekileyo apho oomatshini abaninzi basebenza ngaxeshanye, besenza nzima ukwahlula imiba enxulumene nobushushu. Ukusetyenziswa rhoqo kwezi zixhobo kwenza ukuba kufunyenwe kwangoko kwaye kuthintele ukusilela okugqithisileyo.

Ungalungisa njani iingxaki ze-cnc spindle ezifudukayo

Ukutshintsha okanye ukuphinda-phinde

Iibherings zisizathu esihlala sinesiphene sokutyibilika ngenxa yokuntywila kwi-rantions ukusuka kwi-functions ukusuka kwi-function okanye i-qubrication ye-qubrication. Jonga incwadana yemishini yakho ukuze uchonge uhlobo lwenzuzo (itywinwe okanye ivuliwe) kunye neemfuno zolondolozo.

I -relings evulekileyo : Ukuba iibherings zivulekile, sebenzisa igrisi ephezulu, umthwalo ocetyiswayo usebenzisa i-grey echanekileyo. Kulumkele ukuqaphela, njengoko igrisi engaphezulu inyusa ukungqubana nobushushu. Sebenzisa i-spindle kwi-RPM ephantsi emva kokuba igcwele ikwandiswa, ke ukubeka iliso kwikhamera ye-thermal okanye i-Ensor yokuqinisekisa ukukhutshwa kwemveliso encitshisiweyo.

Ndithatha indawo yokutywinwa etywiniweyo : Iibherings ezitywiniweyo zifuna ukutshintshwa. Ukuqaqamba izindlu ze-spindle ngononophelo, kusetyenziswa i-pullar enesifo sokuqaqamba ukuba iyafuneka, kwaye itshintshe nge-OEMBICS. Emva kokufakwa, qhuba i-spindle nge-RPM ephantsi ukulungisa iibherithi, emva koko sebenzisa isixhobo sokucinga se-Thermal okanye imvakalozwi nezembewu yokuqinisekisa ubushushu obuqhelekileyo bokusebenza.

Ukulungiswa kweposi, jonga ukuntywila kunye neelog zeqondo lokushisa ukuqinisekisa ukuba lo mbandela usonjululwe. Ukuhamba ngokugqithisileyo okubangelwa ziibherisi kuhlala kuyimali ekungakhathalelwanga, ngenxa yoko ukulungiswa rhoqo kubalulekile.

Ukwazisa ishafti ye-spindle

Ukuthathwa ngendlela engeyiyo kwiSpellle Shaft kunokubangela ukungqubana kakhulu, okukhokelela ekulweni kakhulu, ngakumbi kwisantya esiphezulu. Ulungelelwaniso olufanelekileyo lunciphisa ubushushu kwaye lwandisa ubomi bezinto.

Izixhobo zokuNgqinisisa : Sebenzisa inqaku le-DAXOR okanye i-laser yolungelelwaniso ikhithi ukulinganisa ishafti yokuqhuba nge-RPM ephantsi. Ukuba ukuqhuba kuyadlula unyamezelo lomenzi, kunyanzelekile ukuba kunyanzelekile.

- LORD Inkqubo yokuphucula i : Khulula iNtaba yeSpeindle kwaye iphinde iphathe ngononophelo. Ngoomatshini be-CNC oPRD, uhlengahlengiso lwe-shims okanye isoftware kwakhona isoftware njengoko kufuneka. Vavanya umtya wesixhobo, i-collet, kunye ne-chuck yokunxiba okanye inkunkuma, njengoko ezi zinokwazisa ukungalunganga kwaye kwandise ubushushu.

Itshekhi yokulungelelanisa emva kolungelelwaniso : Emva kokuphikiswa, ukucoca zonke izinto ngokuchanekileyo kwaye kuvavanye isitshisi phantsi komthwalo. Sebenzisa ingcinga ye-thermal okanye izilonda zeqondo lobushushu ukuqinisekisa ukuba ukuntywila ngokugqithileyo kuncitshisiwe.

Iqondo lokushisa lexwebhu kunye nokufundwa kwentshukumo emva kokulungiswa kokuseka isiseko esitsha. Itshekhi yolungelelwaniso rhoqo kunye nokugcinwa kwesixhobo

Xa ukufowunela i-CORCH ye-CNC Spindle Grate

Ukwazi imida yakho

Nokuba abaqhubi be-CCC abanamava kufuneka baqonde xa imicimbi yokufunxa ye-spingle ifuna ubuchule obunobuchule. Ngelixa unokuthetha ngokulondolozwa okusisiseko njengokukhula ngokutsha okanye indawo yokucoca, iingxaki ezintsonkothileyo-njengokungaphumeleli kwimoto yangaphakathi, okanye iimpazamo zombane eziphezulu-zifuna izakhono zombane.

Fowunela ingcali ukuba:

I-L EISSINICES (umz.

Ubona amaqondo obushushu aqhubekayo nangona esebenza ngokuqhelekileyo, ephakamisa imiba enzulu efana nemoto yokuphuma komoya okanye ukungasebenzi kakuhle kwe-VFD.

Izixhobo zokuxilonga (i-thermal icinga, i-vibrations yohlalutyo) zibonisa i-anomalies ongenakuguqula okanye ulungise.

Iingcali zinesixhobo esiphezulu sokuxilonga, ezinjengeeskena ezichazayo eziphezulu okanye i-rigs yovavanyo olukhethekileyo, kunye nobuchule kunye nemizobo eyahlukeneyo ye-spindele. Ukuqesha i-pro akvumi ukoyiswa-yimbonakalo ye-smart ukukhusela umsebenzi wakho kunye nobomi bakho.

I-VS VS. Inzuzo yokulungiswa kobungcali

Ixabiso lendlela yokulungiswa kwe-Spindle Geness Lin linokubonakala liphezulu, kodwa lazama ukulungiswa kwezilungiso ngaphandle kwezakhono ezifanelekileyo okanye izixhobo zihlala zikhokelela kwiingxaki ezinkulu. Izinto ezingalunganga, njengebheringi engalunganga okanye ukutyhila i-spindle, inokunyusa i- $ 500 ye- $ 5,000 yokutshintshwa kwe- $ 5,000.

Izibonelelo zenkonzo yobungcali zibandakanya:

I- CORTECROTICS : Iingcali zinokufumana imiba efana neempazamo zombane ezifihliweyo okanye ukuxabana kwangaphakathi kwezixhobo ezisemgangathweni zinokuphoswa.

l Iwaranti : Uninzi lokulungiswa kwengcali luza neziqinisekiso, ukuqinisekisa ukuthembeka kwexesha elide.

I- Dowantime Dowantime : Iinkonzo ezininzi zinikezela ngolungiso lokulungisa ukuze ufumane umatshini wakho kwi-intanethi ngokukhawuleza.

: Ixabiso le-Parler Langa Imbali ebhaliweyo yenkonzo evela kwiingcali iphucula ixabiso lentengiso ye-CNC.

Ngaphambi kokuba ahlawule umbandela omkhulu okrokrelweyo, enobunzima beendleko zokulungiswa ngobuchule ngokuchasene nexabiso lomatshini wakho kunye nokuchaneka. Kwiimeko ezininzi, ubungcali kunye noxolo lwengqondo lufanelekile kutyalo-mali.

Iimpawu zokusibela esisingqongileyo zichaphazela njani ukutshiza kwe-CNC

Umswakazi, uthuli, kunye nobushushu

Imeko engqongileyo kwivenkile yakho ye-CNC ifuthe lempilo kakhulu kwaye inokuba negalelo ekugcwaliseni kakhulu. Ezi zinto zinokwenza mandundu, kwaye zityhutyha izinto ezingcolileyo, kwaye ziphazamise umsebenzi ofanelekileyo.

I- humidity : umswakama ophezulu unokubangela i-progus ngaphakathi kwendlu ye-spindele, ekhokelela kwi-rust okanye i-corosion kwiibherithi kunye nezinye izinto. Oku kukhulisa ukuxabana, ukuvelisa ubushushu obugqithisileyo kunye nokubangela ukungaphumeleli ngaphambi kwexesha.

luthuli namathamsali kunye Xa ixutywe negrisi, uthuli luyi-quasive Complet enxibe iibherithi kunye namatywina, ukwanda kwe-fulls kunye nokwakha ubushushu.

I- swings eshushu : Iqondo lobushushu elibandayo igquba, inciphisa ukusebenza kwempumelelo kwayo kwaye ibangela ukungqubana okuphezulu nobushushu obuphezulu. Kwiimeko ezishushu, ukwanda kwe-shirm kunokungalahlekisi ishafti ye-Spiele, kwaye oobukhari banokude badeka ngokukhawuleza, ekhokelela ekugqityweni. Ubushushu obugqithisileyo bunokuphazamisa ukonakala, igalelo kumaqondo obushushu aphakamileyo.

Amacebo okunciphisa:

faka uthuli kuthuli kunye neenkqubo zomoya zokuzila

l Sebenzisa iinkqubo zolawulo lwemozulu ukugcina ukufumaniswa okuzinzileyo kunye nenqanaba lobushushu.

I-L igcina indawo yokuphumla kunye ne-lebricants kwiindawo ezicocekileyo, ezomileyo, ezilawulayo.

I-L ihlola kwaye icoceke amacandelo acocekileyo ukunqanda ukwakha uthuli kunye nokuqinisekisa ukuba i-abrication efanelekileyo.

Ukubekwa koMatshini kunye nokuHanjiswa kweMibhofi

Ukubekwa kwe-CNC yakho ye-CNC kunokuba nefuthe ekuchitheni i-gelight ngokwenza i-pibences okanye ukutshintshelwa kobushushu ukusuka kwimithombo yangaphandle.

Indawo engalinganiyo : oomatshini kumgangatho ongalinganiyo banokufumana ukungasebenzi kakuhle, kubangela ukuba i-spindle isebenze nzima kwaye ivelise ubushushu obungaphezulu. Iinyikima ezivela kwisiseko esingazinzanga zinokunyusa ukungqubana kwiibhere kunye nezinye izinto.

Isondela kwezinye izixhobo : Ukubeka umatshini we-CNC kufutshane noomatshini abanzima, njengoomatshini bokushicilela okanye amalahle, banokwazisa ukonwaba kwe-sping, okukhokelela kubushushu obungaphezulu okanye ukuntywila gwenxa.

I -LURODS : Oomatshini babekwe kufutshane nezixhobo zokuvelisa ubushushu okanye ukukhanya kwelanga kuya kuba namandla amaqondo aphezulu, ukwandisa ukungcungcutheka kakhulu.

Amacebo okunciphisa:

L ukuqinisekisa ukuba umatshini ulinqanaba usebenzisa inqanaba lokuchaneka kwe-bubble okanye inqanaba le-laser ukunciphisa ubushushu obuhambelana mpazamo.

L ukufaka i-ficking yodwa okanye i-rainders phantsi kwe-CNC ukuze ifumane i-vicketion yangaphandle kwaye inciphise uxinzelelo kwi-spindlele.

l Beka umatshini kude nezixhobo ezinzima okanye imithombo yobushushu ukuthintela ukudluliselwa kwentshukumo kumgangatho okanye kubushushu obuphakamileyo.

Sebenzisa izithintelo ze-thermal okanye iindawo ezivaliweyo ukhuselo umatshini ovela kwimithombo yobushushu yangaphandle.

Ngokulawula izinto zokusingqongileyo kunye nokwenza indawo yokubekwa ngomatshini, unokunciphisa ukugxotha kakhulu, ukuphucula ukusebenza kakuhle, kwaye kwandise ixesha lokuphila kwezixhobo zakho ze-CCC. Ukubeka esweni rhoqo ngenjongo yokuqiniswa kwe-thermal okanye iqondo lokufumanisa ubushushu kunokunceda ekufumaneni iimpawu zakuqala kwimicimbi enxulumene nendalo.

Iingcebiso zomenzi akufuneki zityeshele i-CNC Spindle Grate

Kufundwa ngokucokisekileyo

Ukutsiba incwadana ye-CNC spindle yimpazamo yexabiso. Ipakishwe ngolwazi olubalulekileyo olujolise kwimodeli yakho ye-Spindele, kubandakanya neenkcazo zobushushu bokusebenza, iishedyuli zezinto zezinto ezisebenzayo, ezipholileyo, kunye neenkqubo zokugcina. Ukutyeshela ezi nkcukacha kunokukhokelela kumonakalo ogqithisileyo kunye nexesha elide.

: Iinkcukacha eziphambili Incwadana leyo ichaza uhlobo oluchanekileyo (umz. Sebenzisa ioyile engalunganga okanye okupholileyo kunokunyusa ukugcwala kunye nokwakha ubushushu.

Izikhokelo zolondolozo : Landela imiyalelo yokucoca, ukuthwala ugcino, kunye nezinto ezilayishwe kwangaphambili ukuthintela ubushushu obugqithisileyo kwiseti engalunganga okanye impahla.

I-IT I -PROOSSPHODIOTICTIOTICTETY Iingcebiso : Incwadana yemigaqo idla ngokubandakanya iikhowudi zempazamo okanye iqondo lobushushu lokuncedisa ukunceda ekufumaneni imicimbi yokuqalisa kwangoko.

Printa kunye namaphepha aphambili elungiso kwireferensi ekhawulezayo kwivenkile yakho. Oku kuqinisekisa ukuba ulandela izikhokelo zoMvelisi ukugcina amaqondo obushushu ajonge kwaye uphephe ukulungiswa kwexabiso.

Ukulandela umthwalo kunye nezikhokelo zesantya

Ukutyhala isitshizi ngaphaya komthwalo wakhe ocetyiswayo okanye imida ye-RPM sisizathu esiqhelekileyo sokugxeka. Ukulayisha ngaphezulu okanye ukugqitha okungaphezulu kuvelisa ubushushu obugqithisileyo, i-chadss, kunye nokukhawulezisa ukunxiba.

: Imida yomthwalo Ukudlula kwi-Torque's Torque's Torque okanye umthwalo wokusika umthwalo kunokubangela uxinzelelo lwemoto, okhokelela ekuhambeni nasekufumaneni ishafti okanye umonakalo webhere.

I-LA SPARINGITS : Ukuqhuba i-spindle ngaphezulu kwe-RPM yayo yonyusa ukungqubana kweebherithi kwaye kuvelisa ubushushu obuphezulu, ukusilela komngcipheko wemoto okanye ukonakala komoya.

Izixhobo zokubeka iliso : Sebenzisa isoftware yakho ye-CNC yokuvumela umthwalo wexesha lokwenyani, isantya, kunye neqondo lokushisa. Iinkqubo ezininzi zikuvumela ukuba ubeke iialarm ze-alamu ezikhuselekileyo eziphezulu, nceda ukuthintela ukungahambi kakuhle.

Ezona ndlela zilandelayo:

l intonga kumvelisi we-RPM oqwalaselweyo kunye nemida yomthwalo wokunciphisa ubushushu.

I-L RONI Rind Rai rhoqo iinkqubo zokupholisa (umz., umoya okanye ulwelo lokupholisa) ukuqinisekisa ukuba bayasebenza ngokweengcebiso zencwadi.

l ukubeka iliso kwi-logs yobushushu nge-insers okanye i-thermal icinga ukubamba ukuphambuka kwangoko.

Ukubambelela kwezi zikhokelo kunciphisa uxinzelelo olunxulumene nobushushu, kuthintela ukungahambi kakuhle, kwaye kudlulise umatshini wakho we-spindle, ukugcina umatshini wakho we-CNC ubaleka kakuhle nangokufanelekileyo.

Ukuqukumbela

Ukugcwala kwi-CNC yakho ye-CNC luphawu olucacileyo lwesilumkiso olufunwa ingqalelo. Nokuba ngaba ibangelwe ziibherings ezinxibileyo, ukungahambi kakuhle, iimpazamo zombane, okanye izinto zokusingqongileyo, imiqondiso egqithisileyo, imiba egqithisileyo ephantsi enokuthi inyukele. Ishiywe ingaphenjwanga, ukungahambi kakuhle kunokukhokelela ekungaphumlweni kwemigaqo, ukulungiswa kweendleko kunye ne-Dowantime ebalulekileyo.

Ngokuzibandakanya nezixhobo zokuxilonga njengemifanekiso ye-thermal, i-hlalutshelo lohlalutyo, kunye ne-stethoscopes, kunye nokubambelela kwizikhokelo zolondolozo, umthwalo, ungabamba iingxaki kwangoko kwaye ugcina i-spindles yakho iqhuba kakuhle. Ulawulo lwendalo kunye nokubekwa komatshini ofanelekileyo kunciphisa umngcipheko wemicimbi enxulumene nobushushu.

I-spindle yakho yintliziyo yomatshini wakho we-CNC. Khusela ngononophelo olusebenzayo, kwaye kuya kukuvuza ngentsebenzo ethembekileyo, engapheliyo.

I-FAQS

Leliphi iqondo lobushushu elifanelekileyo le-CNC Spindle?

Uninzi lwee-Spindle lusebenza ngokugqibeleleyo phakathi kwe-40 ° C kunye ne-60 ° C (i-104 ° F)), kodwa funda imigaqo yomenzi.

Ndihlala kangaphi ukuba ndilityhutyha i-spindle yam?

I-Lubrictation Rendation ixhomekeke ekusebenziseni nasekusebenziseni izikhokelo, ngokwesiqhelo zonke iiyure ezingama-500-1,000 zomsebenzi.

Ngaba ukugqitha kakhulu kunokubangela umonakalo osisigxina?

Ewe, ukujonga ixesha elide kunokulimaza ibhetri, i-Motors, okanye ezinye izinto, ezikhokelela kulungiswa ngexabiso okanye ukutshintshwa.

Ngaba ukuphola kwamanzi kungcono kunomoya wokuphola?

Ukupholisa kwamanzi kusebenza ngakumbi kwisantya esiphezulu okanye izicelo ezinzima, kodwa ukupholisa umoya kuyalula kwaye kwanele kwimisebenzi elula.

Nguwuphi owona mndilili wobomi be-cnc spindle?

Ngolungiso oluchanekileyo, izikhuselo zinokuhlala iiyure ezili-10,000-20,000 zokusebenza, kuxhomekeka ekusetyenzisweni nasekusetyenzisweni.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu