Ðe wò CNC-mɔ̃a le dzo dam wu alesi wònɔna ɖaa? Dzoxɔxɔ sue ma si le gegem ɖe dzoxɔxɔ si nu sẽ me ate ŋu anye nuxlɔ̃amedzesi vevi aɖe—eye menye nusi dzi nàte ŋu aŋe aɖaba aƒui o. Menye nu sue aɖe koe wònye be woatsɔ awɔ nusi me dzoxɔxɔ si gbɔ eme le o; Enye dzesi be nane gblẽ, eye ne woŋe aɖaba ƒu edzi la, ate ŋu ahe akpa siwo gblẽ vɛ, mɔ̃ɖaŋununya ƒe nyateƒetoto dzi aɖe akpɔtɔ, woaɖɔe ɖo le ga geɖe me, alo mɔ̃a ƒe gbagbã keŋkeŋ gɔ̃ hã.

Le mɔfiame sia me la, míazɔ wò to nusianu si wòle be nànya tso CNC spindle ƒe dzoxɔxɔ si gbɔ eme ŋu me—tso dzesidede nuxlɔ̃amedzesi gbãtɔwo dzi va ɖo nusiwo gbɔ wòtso ƒe kewo dzi kpɔkpɔ kple afɔɖeɖe ŋutɔŋutɔwo wɔwɔ be woaɖɔe ɖo ahaxe mɔ ɖe enu dzi. Eɖanye mɔ̃ɖaŋudɔwɔƒe, beléle na mɔ̃ɖaŋudɔwɔla, alo CNC ƒe dzonɔamemetɔ si di vevie be yeakpɔ wò dɔwɔnuwo ta o, esiae nye wò dɔwɔnu vevitɔ si ana wò spindle nafa, wòawɔ dɔ nyuie, eye wòanɔ anyi eteƒe nadidi.

Mina míaɖe dzoxɔxɔa dzi akpɔtɔ eye míayi edzi anɔ dɔ wɔm le dɔwɔwɔ ƒe kɔkɔƒe!

CNC spindle motors ƒe ŋgɔdonya .

Nukae nye CNC spindle motor?

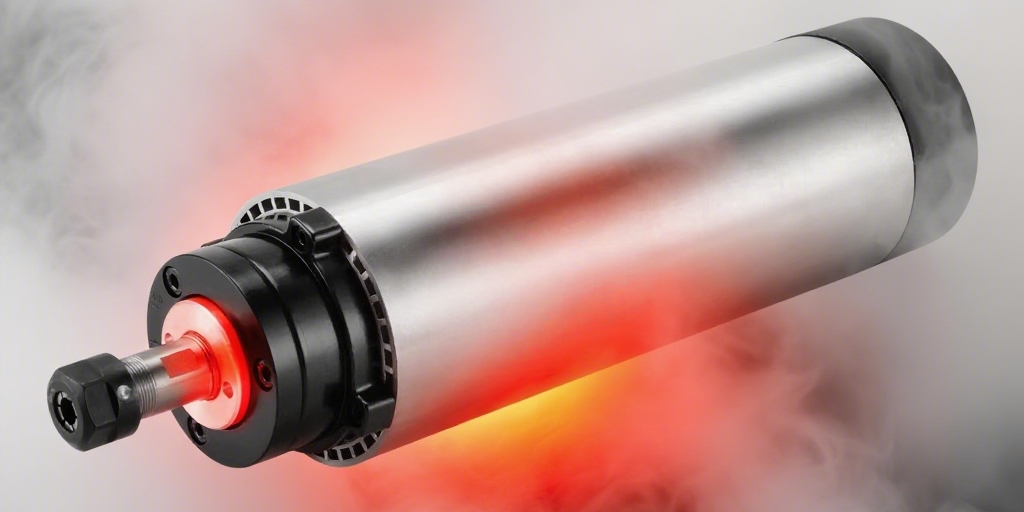

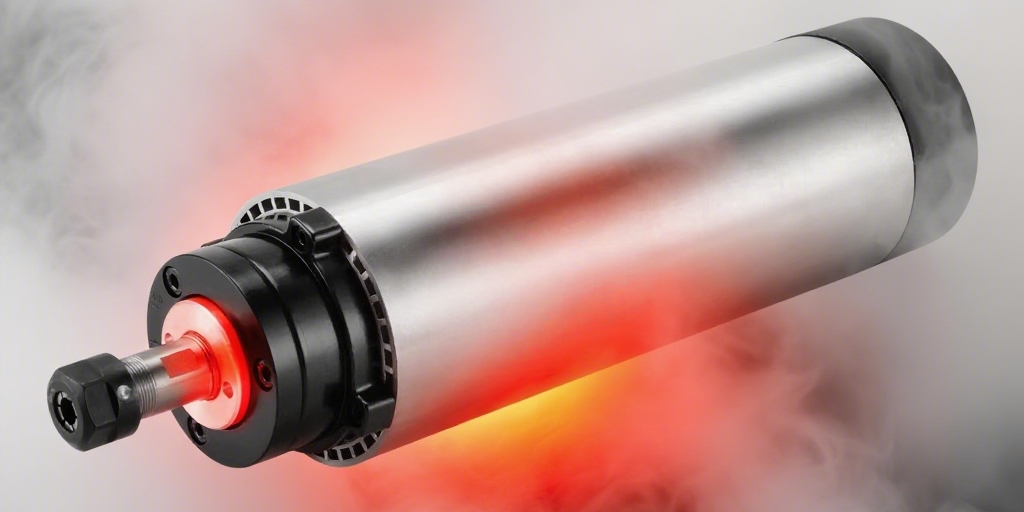

Le CNC mɔ̃ ɖesiaɖe ƒe dzime la, eƒe spindle motor. Akpa vevi sia naa ŋusẽ lãɖeɖedɔwɔnuwo eye wònana mɔ̃a te ŋu kua nu, lãa nu, ƒoa nu, eye wòwɔa nu pɛpɛpɛ. Abe mɔ̃a ƒe dɔwɔwɔ ƒe akpa vevitɔ ene la, ekpɔa duƒuƒu, torque, kple dɔwɔwɔ bliboa dzi—si wɔnɛ be kakaɖedzi si le eŋu la le vevie ŋutɔ na ewɔwɔ si mewɔa tɔtrɔ o.

Wotrɔ asi le spindle motors ŋu le lolome, duƒuƒu, kple ŋusẽ ƒe dzidzedzekpɔkpɔ vovovowo me le alesi wozãnɛ nu, eɖanye atikpakpa, gaŋutinunya, alo mɔ̃ɖaŋunu siwo wotsɔ wɔa nu vovovowoe o. Eɖanye nuka kee wotsɔ wɔe o, ele be spindle la nawɔ dɔ le dzoxɔxɔ si le dedie ƒe seɖoƒewo me be wòalé nyateƒetoto kple agbenɔƒe didi me ɖe asi.

Bu eŋu abe mɔ̃ si le wò ʋu me ene—ne edze duƒuƒu gɔme akpa la, enye nuxlɔ̃ame si dzi màte ŋu aŋe aɖaba aƒui o. Dzoxɔxɔ si gbɔ eme le spindle me ate ŋu ana bearings nado kpo nu, amisisi na wògbã, eye dzoxɔxɔ ƒe kekeɖenudɔwɔwɔ natsɔ mɔ̃wo ƒe mɔɖeɖewo aƒu gbe. Zi geɖe la, spindle si me fa miamiamia la fia be woawɔ dɔ na ame le lãmesẽ me; Ele be dzoxɔxɔ si le dzidzim ɖe edzi nahe amewo ƒe susu vɛ enumake.

Alesi spindle wɔa dɔe gɔmesese kple nusi na wòfa la naa viɖe gã aɖe wò ne nane se le eɖokui me be 'off.' Esia lɔ akpa si eƒe bearings, motor windings, cooling systems, kple housing wɔna ɖe eme nyanya ɖe eme—siwo katã ate ŋu akpɔ ŋusẽ ɖe wo katã dzi to dzoxɔxɔ si gbɔ eme me eye wòahe dɔwɔwɔ ƒe nya veviwo vɛ ne wogblẽe ɖi.

Vevienyenye si le spindle ƒe lãmesẽ ŋu le CNC mɔ̃wo me .

Wò CNC mɔ̃a nyo abe eƒe spindle ene ko. Ne spindle xɔ dzo akpa la, menye mɔ̃ si nèle afɔku me koe wònye o; Ate ŋu ana ame nagblẽ nu le ame ŋu, eƒe akpa aɖewo natro, akpa siwo woɖe ɖa, ɣeyiɣi mamlɛ siwo meto o, kple esiwo vɔ̃ɖi wu—ɣeyiɣi si woatsɔ atɔ te woe.

Zi geɖe la, dzoxɔxɔ si le dzidzim ɖe edzi nyea nuxlɔ̃amedzesi gbãtɔwo. Spindle si me dzoxɔxɔ le vie egbea ate ŋu atrɔ azu mɔ̃ si wotɔ dzoe etsɔ. Ne èlé ŋku ɖe dzoxɔxɔ ƒe agbɔsɔsɔ ŋu eye nèkpɔ nusi gbɔ wòtso gbɔ kaba la, àte ŋu adzra ga geɖe ɖo le nuwo ɖɔɖɔɖo me eye nàƒo asa na aŋekotokua ɖɔliɖɔli bliboe.

Azɔ hã, bu esia ŋu kpɔ: dzoxɔxɔ si gbɔ eme ƒe ʋuƒo mekpea fu o—edea agba wò mɔ̃a ƒe akpa bubuwo dzi geɖe wu, tso ʋukuku ƒe ɖoɖoa dzi va ɖo fafa ƒe akpawo dzi. Enye kɔsɔkɔsɔ ƒe nuwɔna si mèdi be yeaɖo ɖe ʋuʋu me o godoo.

Spindle ƒe dzoxɔxɔ dzi kpɔkpɔ menye dɔwɔwɔ dzro ko o—enye dedienɔnɔ, dɔwɔwɔ, kple viɖekpɔkpɔ katã le ɖeka me. Esia tae nusiwo gbɔ dzoxɔxɔ si gbɔ eme tsona kple mɔxexe ɖe enu gɔmesese menye tiatiawɔblɔɖe o; Ele vevie ŋutɔ.

CNC Spindle: Wò mɔ̃a ƒe ŋusẽ ƒe nu vevi .

Menye akpa bubu aɖe koe spindle la nye o—enye wò CNC-mɔ̃a ƒe titina. Ne ele du dzi le dzoxɔxɔ si sɔ nu la, wò dɔwɔwɔwo sina nyuie. Ne dzoxɔxɔa nu sẽ akpa la, nusianu dzea gbagbã gɔme. Akpa sia ʋãa dɔwɔnu siwo wotsɔ lãa nu, trɔa asi le wò nuwo ŋu, eye wòléa eƒe dzoxɔxɔ dzi kpɔkpɔ me ɖe asi pɛpɛpɛ—si wɔnɛ be eƒe dzoxɔxɔ dzi kpɔkpɔ le vevie ŋutɔ na dɔwɔwɔ.

ga si woatsɔ awɔ spindle ƒe gbagbã .

Menye ɖeko dzoxɔxɔ si gbɔ eme nana be wowɔa nu blewu ko o—egblẽa nu le eŋu. Dzoxɔxɔ si sɔ gbɔ ate ŋu ana:

l bearing ƒe kpododonu .

l warped spindle ƒe akpa aɖewo .

L Amisisi si gblẽ .

l Nu siwo woɖe ɖa .

l Dɔa ƒe ɣeyiɣi mamlɛtɔ siwo meto ŋuwò o .

l Dzadzraɖo kpata siwo xɔa ga geɖe .

l Mɔ̃ si womele mɔ kpɔm na o ƒe dɔwɔwɔ ƒe ɖiɖi .

Le miniti ɖesiaɖe me la, wò spindle la ƒua du akpa la nye ga si bu. Menye ame ŋutɔ ƒe tiatiae wòfa o—ele vevie.

Nuxlɔ̃ame ƒe dzesi siwo woxɔna kaba .

Zi geɖe la, dzoxɔxɔ ƒe ʋuʋudediwoe nyea kuxi ƒe dzesi gbãtɔ. Spindle si me dzoxɔxɔ le vie egbea ate ŋu anye mɔ̃ si wotɔ dzoe etsɔ. Dzoxɔxɔ si gbɔ eme si wogblẽ ɖi si dzi womelé ŋku ɖo o ate ŋu ana:

l full spindle ɖɔliɖɔli .

l Mɔ̃ si keke ɖe enu ƒe anyidzedze .

l Nusiwo gblẽ le ememe nu bubuwo ŋu .

Dzoxɔxɔ ƒe nyawo léle ɖe asi kaba ɖea ga dzi kpɔtɔna, xea mɔ na gbagbã, eye wònana wowɔa nu le ɖoɖo nu.

Alesi dzoxɔxɔ si gbɔ eme kpɔa ŋusẽ ɖe wò CNC ɖoɖo bliboa dzi .

Menye ɖeko spindle dzodzoe gblẽa nu le eɖokui ŋu ko o—etea gbe ɖe mɔ̃ bliboa dzi.

l bearings dzi ɖena kpɔtɔna kabakaba wu .

L Amiwo ƒe gbagbã .

L Ʋukuku ƒe ɖoɖowo wɔa dɔ sesĩe wu .

l Elektrikŋusẽ ƒe akpawo Dzoxɔxɔ si gbɔ eme .

l Dzoxɔxɔ ƒe kekeɖenudɔwɔwɔ ƒua gbe tso dɔwɔnu ƒe ɖoɖo nu .

Kɔsɔkɔsɔ ƒe nuwɔna sia ate ŋu ana woawɔ ɖoɖo bliboa ƒe kpododonu. Dzoxɔxɔ dzi kpɔkpɔ si xea mɔ ɖe enue nye wò ametakpɔnu nyuitɔ kekeake.

Maximize mɔ̃ ƒe agbenɔƒe kple dzoxɔxɔ ƒe dodokpɔ edziedzi .

Spindle ƒe dzoxɔxɔ dzi kpɔkpɔ edziedzi le vevie ŋutɔ. Aɖabaƒoƒo ʋɛ aɖewo ko ate ŋu axe mɔ ɖe ga akpe geɖe nu le edzadzraɖo ƒe gazazãwo me. Ðoɖowɔɖi edziedzi:

l Dzoxɔxɔ ƒe nɔnɔmetatawo me dzodzro .

l Coolant system ƒe dodokpɔwo .

l Yameʋu ƒe sisi kple fesrewo dzi kpɔkpɔ .

l Dzoxɔxɔdzidzenu ƒe dzidzenu .

Mɔxexe ɖe dɔlélea nu ƒe asi medea esi wògahaya o ɣesiaɣi.

Dɔwɔwɔ ɖe edzi to fafa ƒe dɔwɔwɔ nyuie me .

Spindle si wofa nyuie la ɖea dzadzɛnyenyemɔ̃a dzi kpɔtɔna, ewɔa dɔ kabakaba wu, eye wòwɔa dɔ nyuie wu. Esia nyona ɖe edzi:

l Ɣeyiɣi ƒe ɣeyiɣiwo .

l Akpa ƒe nyonyome .

l Dɔwɔnu ƒe agbenɔƒe didi .

l Mɔ̃ bliboa ƒe dɔwɔwɔ .

Ne èdi akpa geɖe wu le gaƒoƒo ɖeka me la, dze egɔme kple spindle ƒe dzoxɔxɔ dzi ɖuɖu.

Spindle Cooling = Dɔwɔƒe ƒe Dedienɔnɔ .

Menye mɔ̃ɖaŋununya ƒe afɔku koe spindle siwo xɔ dzo akpa nye o—wonye dedienɔnɔ ƒe afɔku. Dzoxɔxɔ si gbɔ eme ate ŋu:

l hea bearing seizure vɛ zi ɖeka .

l kplɔa ame yia dɔwɔnu ƒe gbagbã si womele mɔ kpɔm na o gbɔ .

l Wɔ mɔ̃ si mewɔa tɔtrɔ o ƒe nuwɔna .

Wò spindle fafɛ nana kpɔa wò dɔwɔnuwo kple wò ƒuƒoƒoa siaa ta.

Se dzoxɔxɔ ƒe dzesiwo gɔme .

Mɔ̃wo ƒoa nu to dzoxɔxɔ ƒe tɔtrɔ me. Srɔ̃ alesi nàde dzesii:

l Dzoxɔxɔ ƒe ʋuʋu vivivi .

l Spikes kabakaba le lãɖeɖe sesẽwo me .

l Cooling system ƒe dɔmawɔmawɔ nyuie .

l Dzoxɔxɔ si mebɔ o ƒo xlã bearings alo xɔwo .

Kpɔɖeŋu ɖesiaɖe gblɔa ŋutinya aɖe—eléle kaba kpɔa egbɔ be wowɔa dɔ le dedie wu, si wɔa dɔ nyuie wu.

Keke dɔwɔnu ƒe agbenɔƒe ɖe enu kple dzoxɔxɔ ƒe liƒo .

Dzoxɔxɔ si sɔ gbɔ wu nana dɔwɔnu ƒe agbenɔƒe nɔa kpuie. Dzoxɔxɔ si gbɔ eme ate ŋu ana:

L ƒe nutsotso siwo me mekɔ o .

l Dɔwɔnu ƒe tɔtrɔ enuenu .

l Lãɖeɖe siwo mesɔ o .

l Anyigbamama ƒe nuwuwu manyomanyowo .

Spindle si te ŋu nɔa te ɖe dzoxɔxɔ nu la kpɔa egbɔ be dɔwɔnu ɖesiaɖe wɔa dɔ le eƒe nɔnɔme nyuitɔ kekeake me.

Nusiwo gbɔ CNC spindle ƒe dzoxɔxɔ si gbɔ eme tsona zi geɖe

| Nusi gbɔ wòtso ƒe |

numeɖeɖe . |

| Agbatsɔtsɔ le spindle la dzi . |

Lãɖeɖe ƒe ŋusẽ siwo gbɔ eme alo dɔwɔwɔ ɣeyiɣi didi wu ŋutete nana dzoxɔxɔ si gbɔ eme, si wɔnɛ be mɔ̃a kple bearingwo tena ɖe wo dzi. |

| Amisisi alo amisisi ƒe kpododonu manyomanyo . |

Amisisi si mesɔ o alo esi mesɔ o nana be ʋuʋudedi le bearings me dzina ɖe edzi, si wɔnɛ be dzoxɔxɔa nu sẽna ɖe edzi eye wòvuvuna kabakaba. |

| Cooling system ƒe dɔmawɔmawɔ nyuie . |

Filter siwo xe, fafanu ƒe agbɔsɔsɔ si bɔbɔ, alo pɔmpi siwo mewɔa dɔ nyuie o gblẽa nu le dzoxɔxɔ ƒe kaka ŋu le tsifamɔ̃wo me. |

| Yame ƒe dzoxɔxɔ si kɔkɔ ŋutɔ . |

Dɔwɔwɔ le nuto siwo me ya mele nyuie o alo esiwo me dzoxɔxɔ le ŋutɔ me ɖea dzoxɔxɔ si le spindle la ƒe ŋutete dzi kpɔtɔna. |

| RPM si gbɔ eme alo nuɖuɖu ƒe agbɔsɔsɔ si mesɔ o . |

RPM siwo sɔ gbɔ alo nuɖuɖu ƒe agbɔsɔsɔ si mesɔ o dzia dzoxɔxɔ kple nuteɖeamedzi ƒe akpawo ɖe edzi. |

| Bearing siwo wodo alo esiwo gblẽ . |

Bearings siwo wodo la hea ʋuʋudedi bubuwo vɛ, si hea dzoxɔxɔ vɛ eye wòdea afɔku me be kpododonu gã aɖe nado kpo nu. |

| Elektrikŋusẽ ƒe nyawo le mɔ̃a me . |

Ka siwo gblẽ, elektrikŋusẽ ƒe tɔtrɔ, alo mɔ̃a ƒe dɔmawɔmawɔ nyuie nana dzoxɔxɔ si gbɔ eme eye mewɔa dɔ nyuie o. |

Agbatsɔtsɔ le spindle la dzi .

Agbatsɔtsɔ fũ dzɔna ne wozi spindle la dzi be wòawɔ dɔ wu dɔwɔwɔ ƒe seɖoƒe siwo adzɔha la gblɔ. Esia ate ŋu adzɔ le mɔ geɖe nu:

Nusiwo sesẽ akpa alo esiwo le ʋeʋẽm la ɖeɖe .

Le kpɔɖeŋu me, mɔ̃wɔwɔ ɖe gakpo si sesẽ alo akɔbli si mebɔ o ŋu kple aŋenu si wowɔ na nusiwo fa wu abe aluminum alo ati ene. Tsitretsitsi si dzi ɖe edzi la hea torque didi geɖe vɛ, si wɔnɛ be dzoxɔxɔa nu sẽna ɖe edzi.

Lãɖeɖe siwo me goglo akpa xɔxɔ .

To goglo aɖe ɖea nu geɖe ɖa le tɔtrɔ kpata ɖesiaɖe me, si bia ŋusẽ geɖe wu. Menye ɖeko esia dzia agba si le spindle motor la dzi ɖe edzi ko o, ke enaa friction geɖe wu hã le dɔwɔnu-dɔdaƒe ƒe ƒomedodoa me.

Nuɖuɖu ƒe agbɔsɔsɔ si sɔ gbɔ akpa zazã .

Ne nuɖuɖu ƒe tsɔtsɔme le du dzi akpa na spindle ƒe duƒuƒu kple dɔwɔnu ƒe ŋutete la, wozia lãɖeɖe ƒe nugbɔ dzi be wòaƒã nu to nu me tsɔ wu be wòatsoe dzadzɛ. Esia naa ʋuʋudedi, nuteɖeamedzi, kple dzoxɔxɔ si gbɔ eme.

Nu siawo ƒe ƒuƒoƒo dea mɔ̃ɖaŋununya ƒe nuteɖeamedzi dzi, mɔ̃a ƒe ʋuƒo, kple ʋua ƒe akpa aɖewo. Le ɣeyiɣi aɖe megbe la, esia ate ŋu ana:

kabakaba bearing do tso radial kple axial agba siwo sɔ gbɔ wu.

Dzoxɔxɔ ƒe kekeɖenudɔwɔwɔ le akpa siwo le eme ŋu, si ate ŋu ana woawɔ nu ɖe ɖoɖo nu alo woadzi ɖe edzi.

Elektrikŋusẽ ƒe agbɔsɔsɔ fũ le spindle motor la me, afɔku be woaxe mɔ ɖe nusiwo xea mɔ na dzoxɔxɔ kple nusiwo gblẽ le wo ŋu ƒe gbegblẽ ŋu.

Le nɔnɔme sesẽwo me la, agbatsɔtsɔ fũ ate ŋu ana spindle la nazɔ ɖe dzoxɔxɔ ƒe agba si wu tsɔtsɔ ta, atɔ nu le dɔwɔwɔ me, alo agblẽ nu le mɔ̃a kple bearings ŋu tegbee.

Nu nyuitɔ kekeake: Tsɔ wò lãɖeɖe ƒe nɔnɔmewo sɔ kple wo nɔewo ɣesiaɣi—nu ƒomevi, spindle ƒe duƒuƒu, nuɖuɖu ƒe tsɔtsɔme, kple lãɖeɖe ƒe goglome—sɔ kple spindle ƒe nɔnɔme siwo woɖo ɖi. Dɔwɔnu nyuiwo zazã kple kakaɖedzi nana be lãɖeɖe ɖaɖɛwo hã ate ŋu aɖe agbaa dzi akpɔtɔ ŋutɔ.

Amisisi alo amisisi ƒe kpododonu manyomanyo .

Spindle ƒe bearings kple akpa bubu siwo le ʋuʋum la nɔa te ɖe amisisi nyuie dzi vevie be wòawɔ dɔ nyuie. Amisisi wɔa dɔ vevi eve: ga siwo le anyigba dome ƒe ʋuʋu dzi ɖeɖe kpɔtɔ kple kpekpeɖeŋu nana dzoxɔxɔ si dona le dɔwɔwɔ me.

Ne amisisi mesɔ gbɔ o, woƒo ɖii, alo mele eme kura o , kuxi geɖe ate ŋu ado mo ɖa:

Amisisi si mesɔ gbɔ o .

Ne ami alo ami mesɔ gbɔ ɖe spindle la me o la, ga kple ga ƒe kadodoa dzina ɖe edzi, si wɔnɛ be dzoxɔxɔ si gbɔ eme dona eye wòvuvuna kabakaba.

Amisisi si me dɔlékuiwo le .

Ðiƒoƒo, ga lũhɛwo, alo tsi si le amia me ate ŋu awɔ dɔ abe nusiwo wotsɔna ƒoa nu ene, aƒo bearing ƒe akpawo eye wòaxe mɔ na tɔtrɔ bɔbɔe.

Amisisi ƒe sisi alo ɖekematsɔleme .

Le ɣeyiɣi aɖe megbe la, woate ŋu aŋe aɖaba aƒu nutrenuwo dzi, alo woate ŋu aŋe aɖaba aƒu beléle na wo ƒe ɖoɖowɔɖiwo dzi, si ana ami nabu vivivi. Ne womesi ami nyuie o la, ʋuʋudedi dzina ɖe edzi kabakaba.

Nusiwo dona tso amisisi na ame nyuie o dometɔ aɖewoe nye:

Dzoxɔxɔ ƒe ƒoƒo kabakaba – Friction si gbɔ eme trɔa mɔ̃ŋusẽ wòzua dzoxɔxɔ, ekɔa spindle ƒe dzoxɔxɔ ɖe dzi kabakaba.

Bearing wear and damage – Friction erodes bearing surfaces, si ate ŋu ana woado do, aɖo dzesi, alo bearing seizure gɔ̃ hã.

Spindle failure – le nɔnɔme siwo gbɔ eme me la, bearings ateŋu axe keŋkeŋ, si ana spindle la natɔ kpata eye wòate ŋu agblẽ nu le motor la kple akpa bubuwo ŋu.

Nu nyuitɔ kekeake: Kpɔ amisisi ƒe agbɔsɔsɔ edziedzi, kpɔ egbɔ be wozã ami alo ami si dɔwɔƒea kafu, eye nàɖɔli ami si me dɔlékuiwo le enumake. Beléle na nutrenuwo kple bearingwo edziedzi kple wo me dzodzro ate ŋu axe mɔ ɖe amisisi ƒe akpa gãtɔ si do ƒome kple ami ƒe dzoxɔxɔ fũ akpa nu.

Cooling system ƒe dɔmawɔmawɔ nyuie .

CNC spindle naa dzoxɔxɔ gã aɖe dona le dɔwɔwɔ me, eye fafamɔ̃ nyui aɖe le vevie ŋutɔ be woalé dzoxɔxɔ si le dedie me ɖe asi. Spindles ate ŋu azã ya fafɛ alo tsi fafɛ , gake wo ame evea siaa ɖoa ŋu ɖe ʋu ƒe sisi si me mɔxexe aɖeke mele o ŋu be dzoxɔxɔ nakaka.

Kuxi siwo ɖea fafa ƒe dɔwɔwɔ nyuie dzi kpɔtɔna dometɔ aɖewoe nye:

yaƒoƒomɔ̃ siwo woxe mɔ na alo filter ƒoɖiwo .

Ke, gbeɖuɖɔ, alo ga lũhɛwo ate ŋu axe ya si woxɔna alo ya si dona le eme, si xea mɔ na ya ƒe sisi kple dzoxɔxɔ ƒe kaka dzi ɖeɖe kpɔtɔ.

Fafamɔ̃ siwo xe mɔ .

Le tsi-fafɛ ɖoɖowo me la, mineral deposits, chips, alo ami ƒe nugbagbeviwo ate ŋu axe mɔ na fafanu ƒe sisi, si ana be wòagaxɔ dzoxɔxɔ ahatsɔe adzoe o.

Pɔmpi alo Fan siwo gblẽ .

Mɔ̃ɖaŋununya ƒe kpododonu le fesrewo, pɔmpiwo, alo sisi ƒe sensorwo me ate ŋu atɔ te fafanu ƒe tsatsam alo ya ƒe sisi keŋkeŋ, si ana dzoxɔxɔ nayi dzi kabakaba.

Ne fafamɔ̃a mete ŋu ɖe dzoxɔxɔ ɖa nyuie o la, nya geɖewo dzɔna:

Bearings kple motor windings ƒe dzoxɔxɔ fũu akpa – dzoxɔxɔ si gbɔ eme nana be wòvuvuna kabakaba eye ate ŋu agblẽ nu le insulation ŋu.

Dzoxɔxɔ ƒe kekeɖenudɔwɔwɔ kple masɔmasɔ – Dzoxɔxɔ si mesɔ o ateŋu ana spindle ƒe akpawo nakeke ɖe enu le agbɔsɔsɔ vovovowo me, si akpɔ ŋusẽ ɖe nusiwo sɔ pɛpɛpɛ kple ʋuʋudedi si le dzidzim ɖe edzi dzi.

Spindle ƒe kpododonu kaba – dzoxɔxɔ si nɔa anyi ɖaa ate ŋu ana spindle ƒe agbenɔƒe nadidi ɖe edzi alo aʋã dzoxɔxɔ ƒe nutsitsi be wòaxe mɔ ɖe nusiwo gblẽ nu le ame ŋu nu.

Nu nyuitɔ kekeake si nàwɔ: Na fafamɔ̃a nanɔ anyi edziedzi—Yafamɔ̃wo kple yadoƒewo, akɔ fafanu ŋu eye nàɖɔlii abe alesi wokafui ene, eye nàlé ŋku ɖe pɔmpiwo kple yaƒomɔ̃wo ŋu be woawɔ dɔ nyuie hã. Kakaɖedzi nana be fafa si mexe mɔ na o eye wòwɔa dɔ nyuie le vevie ŋutɔ na spindle ƒe agbenɔƒe didi kple mɔ̃ɖaŋununya ƒe dɔwɔwɔ si ŋu kakaɖedzi le.

Yame ƒe dzoxɔxɔ si kɔkɔ ŋutɔ .

Ne wodzra spindle ɖo nyuie eye ɖoɖoawo katã le dɔ wɔm nyuie gɔ̃ hã la, yame ƒe dzoxɔxɔ si kɔkɔ le dɔwɔƒea ate ŋu ana dzoxɔxɔ si gbɔ eme nado. Spindles ɖoa ŋu ɖe dzoxɔxɔ ƒe vovototo si le woawo ŋutɔ kple nuto si ƒo xlãe dome ŋu be dzoxɔxɔ nakaka, eyata ne ya si ƒo xlã mɔ̃a xɔ dzo xoxo la, fafa ƒe ŋutete dzi ɖena kpɔtɔna.

Nusiwo na kuxi sia le eme dometɔ aɖewoe nye:

Ya nyui aɖeke mele ame ŋu o .

Ya si tsi anyi xea mɔ na dzoxɔxɔ be wòagasi le dɔwɔƒea nu o, si ɖea ya si wotsɔ ƒoa yae alo yaƒomɔ̃wo ƒe dɔwɔwɔ dzi kpɔtɔna.

Yame ƒe nɔnɔme dzi kpɔkpɔ ƒe anyimanɔmanɔ .

Ne yaƒoƒomɔ̃ alo ya ƒe sisi nyuie meli o la, dɔwɔƒewo ate ŋu aɖo dzoxɔxɔ si wu alesi wowɔa dɔ le spindle la ƒe dɔwɔwɔ ƒe didime nu.

Extended production runs .

Dɔwɔwɔ atraɖii ɣeyiɣi didi le teƒe si dzoxɔxɔ le na dzoxɔxɔ te ŋu ƒoa ƒu, ne fafamɔ̃ siwo le dɔ wɔm gɔ̃ hã.

Nusiwo dona tso yame ƒe dzoxɔxɔ si sɔ gbɔ me dometɔ aɖewoe nye:

Fafa ƒe dɔwɔwɔ nyuie dzi ɖe kpɔtɔ – Spindle la mate ŋu akɔ dzoxɔxɔ nyuie o, si wɔnɛ be eƒe dzoxɔxɔ dzina ɖe edzi kabakaba wu alesi wònɔna ɖaa.

Dzoxɔxɔ ƒe nuteɖeamedzi le akpa vovovoawo ŋu – bearings, motor windings, kple akpa bubu siwo sea veve la te ŋu dona bɔbɔe eye wodoa kpo nu wu ne wodo wo ɖe dzoxɔxɔ gã si nɔa anyi ɖaa me.

Dzoxɔxɔ ƒe nutsitsi si ate ŋu anɔ anyi – dzoxɔxɔ takpɔkpɔ le spindle geɖewo me; Dzoxɔxɔ si gbɔ eme ate ŋu aʋã ame be wòatsi, si ana woawɔ nu.

Nu nyuitɔ kekeake: Kpɔ egbɔ be ya nyui aɖe le dɔwɔƒea, bu yaƒoƒo alo ya si wozi ɖe ame dzi ƒe ɖoɖowo ŋu na nuto siwo me dzoxɔxɔ le, eye nàlé ŋku ɖe spindle ƒe dzoxɔxɔ ŋu le duƒuƒu didiwo me. Ya ƒe sisi kple fafa ƒe ŋgɔyiyi suesuesuewo gɔ̃ hã ate ŋu aɖe afɔku siwo le dzoxɔxɔ si gbɔ eme me dzi akpɔtɔ ŋutɔ.

RPM si gbɔ eme alo nuɖuɖu ƒe agbɔsɔsɔ si mesɔ o .

Spindle zazã le tɔtrɔ ƒe duƒuƒu kɔkɔwo me (RPM) evɔ womatrɔ asi le nuɖuɖu ƒe agbɔsɔsɔme ŋu nyuie na nusi wotsɔ wɔe o eye dɔwɔnu si wotsɔ lãa nu ate ŋu ana dzoxɔxɔ si gbɔ eme nado. Ele be spindle kple dɔwɔnua nawɔ dɔ le ɖekawɔwɔ me: ele be nusiwo wotsɔ ɖea nu me, spindle ƒe duƒuƒu, kple nuɖuɖu ƒe tsɔtsɔme katã sɔ be woakpɔ egbɔ be wolã wo nyuie.

Kuxi siwo tso duƒuƒu kple nuɖuɖu siwo mesɔ o gbɔ dometɔ aɖewoe nye:

RPM si gbɔ eme si me nuɖuɖu ƒe agbɔsɔsɔme le sue .

Dɔwɔnu si wotsɔ lãa nu la ƒoa nu ɖe nusi wotsɔ wɔe ŋu tsɔ wu be wòatsoe dzadzɛ, si wɔnɛ be ʋuʋudedi kple dzoxɔxɔ dona.

Nuɖuɖu ƒe agbɔsɔsɔme si kɔkɔ akpa na spindle ƒe duƒuƒu si wona .

Dɔwɔnua ate ŋu aku nu me sesĩe akpa, atsɔ agba bubu ade lãgbalẽgoloa dzi eye wòana dzoxɔxɔa nadzi ɖe edzi kabakaba.

Lãɖeɖe si mewɔa dɔ nyuie o .

Duƒuƒu kple nuɖuɖu ƒe ƒuƒoƒo si mesɔ o hea chip wɔwɔ nyuie vɛ o, si wɔnɛ be tsitretsitsi kple ʋuʋudedi dzina ɖe edzi, si naa dzoxɔxɔnamɔ̃a kple dɔwɔnua gadzina ɖe edzi.

Nya siawo me tsonuawo dometɔ aɖewoe nye:

Spindle ƒe dzoxɔxɔ si gbɔ eme – Friction kple agba si dzina ɖe edzi ƒe dzidziɖedzi le spindle ƒe dzoxɔxɔ ŋu, si ate ŋu aʋã dzoxɔxɔ takpɔkpɔ alo agblẽ nu tegbee.

Dɔwɔnu ƒe vuvu kple eƒe kpododonu – Dɔwɔnu siwo wotsɔ lãa nu kabakaba le lãɖeɖe ƒe nɔnɔme siwo mewɔa dɔ nyuie o me, si hã dzia ʋuʋudedi kple dzoxɔxɔ ɖe edzi.

Mɔ̃wɔwɔ ƒe nyateƒetoto dzi ɖe kpɔtɔ – dzoxɔxɔ si hea spindle alo dɔwɔwɔ ƒe akpa si nye dzoxɔxɔ vɛ ate ŋu agblẽ nu le nusiwo le pɛpɛpɛ ŋu, si akpɔ ŋusẽ ɖe anyigba ƒe nɔnɔme kple mɔɖeɖewo dzi.

Nuwɔna Nyuitɔ: Ɣesiaɣi la, bu akɔnta le spindle ƒe duƒuƒu kple nuɖuɖu ƒe agbɔsɔsɔ si sɔ ŋu le nusiwo wotsɔ wɔe ƒe ƒomevi, dɔwɔnu ƒe nɔnɔme, kple woƒe goglome nu. Mɔ̃ɖaŋudɔwɔƒe ƒe mɔfiamewo alo CAM kɔmpiuta dɔwɔɖoɖowo ƒe aɖaŋuɖoɖowo zazã ate ŋu akpe ɖe ame ŋu be woaxe mɔ ɖe dzoxɔxɔ si gbɔ eme nu eye wòana spindle ƒe agbenɔƒe kple mɔ̃ɖaŋununya ƒe nyonyome siaa nadzi ɖe edzi.

Bearing siwo wodo alo esiwo gblẽ .

Bearings nye nu vevi siwo le CNC spindle me, si doa alɔ tɔtrɔ kple kakaɖedzi nana be ʋuʋu nyuie, si sɔ pɛpɛpɛ. Ne bearingwo vuvu, gblẽ, alo woda wo ɖe teƒe si mesɔ o , wonana wogawɔa ʋuʋudedi kple ʋuʋudedi bubuwo, eye wo ame evea siaa kpena ɖe dzoxɔxɔ ŋu.

Nusiwo gbɔ bearing nyawo tsona zi geɖe dometɔ aɖewoe nye:

Nuwuwu si sɔ le ɣeyiɣi aɖe megbe .

Bearings gblẽna le dzɔdzɔme nu ne wozãe ɣeyiɣi didi, vevietɔ le agba gãwo te alo dɔwɔwɔ atraɖii.

Ðiƒoƒo .

Ke, chips, alo tsidzadza ate ŋu age ɖe bearing la me, si ana do, ƒoƒo, alo xɔdzo.

ɖoɖo si mesɔ o alo ɖoɖowɔwɔ ɖe ɖoɖo nu .

Bearing siwo mesɔ o la hea agba siwo mesɔ o vɛ, si wɔnɛ be ʋuʋudedi kple dzoxɔxɔ dzina ɖe edzi.

Bearing siwo wovuvu alo esiwo gblẽ la me tsonuawo dometɔ aɖewoe nye:

Dzoxɔxɔ ƒe dzidziɖedzi – Friction from degraded bearings doa spindle ƒe dzoxɔxɔ ɖe dzi, si ate ŋu ana nu bubuwo nado kabakaba.

Vibration si sɔ gbɔ akpa – Vibration kpɔa ŋusẽ ɖe mɔ̃ɖaŋununya ƒe nyateƒetoto dzi, si hea anyigba ƒe nɔnɔme ƒe nuwuwu nyuie kple didime ƒe vodadawo vɛ.

Afɔku si lolo wu le spindle ƒe gbagbã ŋu – ne bearing ƒe nugbegblẽ nu sẽ la, spindle ate ŋu axɔ, trip thermal protection, alo fu le mɔ̃ɖaŋununya ƒe gbegblẽ tegbee ta.

Nu nyuitɔ kekeake: Kpɔ spindle bearings edziedzi ɖa be dzesiwo le eŋu be evuvu alo gblẽ hã, lé amisisi nyuie ɖe asi, eye nàɖɔli bearings le adzɔnuwɔƒea ƒe aɖaŋuɖoɖowo nu. Kakaɖedzitɔe be bearing dɔwɔwɔ nyuie le vevie be woaxe mɔ ɖe dzoxɔxɔ fũ nu eye woalé mɔ̃ɖaŋununya ƒe dɔwɔwɔ pɛpɛpɛ me ɖe asi.

Elektrikŋusẽ ƒe nyawo le mɔ̃a me .

Spindle motor la ɖoa ŋu ɖe elektrikŋusẽnamɔ̃ si li ke kple ememe ƒe akpa siwo le dɔ wɔm nyuie ŋu be woawɔ dɔ nyuie. Elektrikŋusẽ ƒe kuxiwo—abe elektrikŋusẽ ƒe dadasɔmakpɔmakpɔ, yaƒoƒo siwo gblẽ, alo ʋuƒo kpuiwo ene—ate ŋu ana mɔ̃a nahe elektrikŋusẽ si gbɔ eme, si naa dzoxɔxɔ dona le mɔ̃a ŋutɔ me.

Elektrikŋusẽnya siwo bɔ dometɔ aɖewoe nye:

Voltage ƒe masɔmasɔwo .

Voltage si mesɔ o le motor phases me dzia current draw kple ememe tsitretsitsi ɖe edzi, si wɔnɛ be dzoxɔxɔ bubuwo dona.

Windings siwo gblẽ alo esiwo gblẽ .

Nusiwo wotsɔna xea mɔ na dzoxɔxɔ, tɔtrɔ kpuiwo, alo nutome sue siwo le ʋuʋu ɖi ate ŋu aɖe mɔ̃a ƒe dɔwɔwɔ nyuie dzi akpɔtɔ eye wòana dzoxɔxɔ si le dɔwɔwɔ me nadzi ɖe edzi.

Kadodo siwo me mekɔ o alo ʋu siwo gblẽ .

Elektrikŋusẽ ƒe kadodo gbegblẽ alo VFD siwo mewɔa dɔ nyuie o (trɔtrɔ ƒe ʋuʋudediwo) ate ŋu awɔ ʋuʋudediwo alo elektrikŋusẽ si mewɔa dɔ edziedzi o, si ate ɖe mɔ̃a dzi.

Elektriknyawo me tsonuawo dometɔ aɖewoe nye:

Dzoxɔxɔ ƒe dzidziɖedzi kabakaba – elektrikŋusẽ si sɔ gbɔ nana dzoxɔxɔ nɔa mɔ̃a ƒe ʋuʋudediwo me, si ate ŋu agbɔ dɔwɔwɔ ƒe seɖoƒe si le dedie ŋu kabakaba.

Motor Insulation Failure – Dzoxɔxɔ si gbɔ eme didi ate ŋu agblẽ nu le nusiwo xea mɔ na dzoxɔxɔ ŋu, si ana mɔ̃ kpuiwo alo mɔ̃a nado kpo nu tegbee.

Spindle ƒe agbenɔƒe dzi ɖeɖe kpɔtɔ – Elektrikŋusẽ ƒe nuteɖeamedzi si yia edzi la nana bearingwo kple mɔ̃ɖaŋunu bubuwo ƒe akpa aɖewo dona kabakaba, si wɔnɛ be dzoxɔxɔ si gbɔ eme ƒe kuxia dzina ɖe edzi.

Nu nyuitɔ kekeake: Kpɔ elektrikkadodowo ɖa edziedzi, lé ŋku ɖe elektrikŋusẽ ƒe agbɔsɔsɔ kple elektrikŋusẽ ƒe sesẽme ŋu, eye nàkpɔ egbɔ be VFD alo ʋukuku ƒe ɖoɖoa le dɔ wɔm nyuie. Elektrikŋusẽ ƒe masɔmasɔwo ɖɔɖɔɖo kaba ate ŋu axe mɔ na mɔ̃a ƒe dzoxɔxɔ fũ kple spindle ƒe gbegblẽ si xɔa ga geɖe.

Dzesiwo kple dzesiwo le CNC spindle ƒe dzoxɔxɔ si gbɔ eme ŋu .

Dzesi siwo fia be spindle ƒe dzoxɔxɔ si gbɔ eme ƒe nuxlɔ̃ame kaba ƒe dzesiwo le vevie ŋutɔ be woaxe mɔ ɖe nusiwo gblẽna vevie kple ɣeyiɣi si woatsɔ awɔ dɔ le wo ŋu si xɔa ga geɖe nu. Nufianu siwo bɔ wue nye esi:

toɣliɖeɖe siwo mebɔ o .

Gbeɖiɖi siwo le ƒoƒom, wo ƒoƒo, alo wo ƒoƒo ɖe wo nɔewo ŋu ɖee fia zi geɖe be bearingwo le nuteɖeamedzi si gbɔ eme me alo be amisisi do kpo nu. Ne dzoxɔxɔ le dzidzim ɖe edzi la, ga ƒe akpa aɖewo kekena eye bearingwo megawɔa dɔ nyuie o, si wɔnɛ be toɣliɖeɖe siwo le ʋuʋum la nɔa anyi. Gbeɖiɖi siawo nye dzesi si me kɔ be spindle la le dzoxɔxɔ ƒe nuteɖeamedzi me tom eye ele be woalé ŋku ɖe eŋu enumake.

Dzoxɔxɔ ƒe nutsitsidɔ .

Wodea dzoxɔxɔdzidzenu siwo nana wotsia wo ɖokui nu ne dzoxɔxɔa wu seɖoƒe si le wo ɖokui si la le egbegbe CNC-kplu geɖe me. Togbɔ be nɔnɔme sia kpɔa mɔ̃a ta hã la, dzoxɔxɔ ƒe nutsitsi enuenu alo enuenu nyea aflaga dzĩ si wò spindle la xɔna ɣesiaɣi. Ne woŋe aɖaba ƒu nutsitsidɔ siawo dzi la, ate ŋu ana mɔ̃ alo bearing nagblẽ nu le eŋu tegbee.

Spindle ƒe dɔwɔwɔ dzi ɖe kpɔtɔ .

Dzoxɔxɔ si gbɔ eme ate ŋu akpɔ ŋusẽ ɖe mɔ̃wɔwɔ ƒe dɔwɔwɔ dzi tẽ. Àte ŋu ade dzesi lãɖeɖe pɛpɛpɛ, spindle ƒe duƒuƒu blewu, alo nuɖuɖu ƒe agbɔsɔsɔ dzi kpɔkpɔ sesẽ. Dzoxɔxɔ nana akpa veviwo kekena ɖe enu, eɖea bearing ƒe dɔwɔwɔ nyuie dzi kpɔtɔna, eye ate ŋu ana ʋuʋudedi nadzi ɖe edzi—siwo katã gblẽa nu le nu ŋu pɛpɛpɛ eye wòɖea wò mɔ̃a ƒe dɔwɔwɔ bliboa dzi kpɔtɔna.

Amadede ƒe tɔtrɔ si wokpɔna alo ʋeʋẽ lilili si wokpɔna .

Dzoxɔxɔ si gbɔ eme ate ŋu ana ga ƒe akpa aɖewo alo nusiwo wotsɔ xea mɔ na dzoxɔxɔ ƒe amadede natrɔ. Ne ède dzesi amadede siwo le blɔ alo esiwo ƒe amadede nye aŋutiɖiɖi le spindle housing, motor, alo bearings dzi la, ke enye dzesi be dzoxɔxɔ si nɔa anyi didi. Ʋeʋẽ si le bibim hã nye nu vevi bubu si fia be akpa siwo le eme, abe ʋuʋudedi alo amisisi ene, ate ŋu agblẽ. Dzesi siawo bia be woalé ŋku ɖe eŋu enumake be woaxe mɔ ɖe kpododonu gã aɖe nu.

Ne dɔwɔlawo lé ŋku ɖe dzesi siawo ŋu nyuie la, woate ŋu alé dzoxɔxɔ si gbɔ eme ƒe nyawo ɖe asi kaba, axe mɔ ɖe nuwo ɖɔɖɔɖo si xɔa ga geɖe nu, eye woadidi woƒe CNC-kplu ƒe agbenɔƒe ɖe edzi.

Mɔfiame afɔɖeɖe ɖesiaɖe si woatsɔ axe mɔ ɖe CNC spindle ƒe dzoxɔxɔ fũ nu .

Monitor spindle ƒe agba .

Wɔ spindle la ŋudɔ ɣesiaɣi le eƒe ŋutete si woɖo nɛ me. Ƒo asa na etutu sesĩe akpa to lãɖeɖe sesẽwo, mɔ siwo dzi nàto goglo, alo nuɖuɖu ƒe agbɔsɔsɔ si sɔ gbɔ me. Agbatsɔtsɔ fũu akpa nana ʋuʋudedi kple dzoxɔxɔ si gbɔ eme, si ate ŋu agblẽ nu le lãgbalẽgoloa ŋu kabakaba.

Lé amisisi nyuie ɖe asi .

Kpɔ amisisi ɖa edziedzi eye nàlé be na spindle bearings. Kpɔ egbɔ be wozã ami ƒomevi si sɔ kple agbɔsɔsɔ si sɔ, eye nàɖɔlii ne ehiã. Amisisi si me dɔlékuiwo le alo esi mesɔ gbɔ o nana be ʋuʋudedi dzina ɖe edzi eye wònana dzoxɔxɔ si gbɔ eme la nu sẽna ɖe edzi.

Kpɔ fafamɔ̃wo ɖa eye nàlé be na wo .

Kpɔ egbɔ be wò spindle ƒe fafamɔ̃—eɖanye ya fafɛ alo tsi fafɛ o—le dɔ wɔm nyuie. Yadoƒe dzadzɛwo, ɖɔlia nusiwo wotsɔna ƒoa yae, léa ŋku ɖe fafanu ƒe agbɔsɔsɔme ŋu, eye wòkpɔa egbɔ be yaƒomɔ̃ alo pɔmpiwo le dɔ wɔm nyuie. Fafamɔ̃ si ŋu wodzra ɖo nyuie le vevie ŋutɔ na dzoxɔxɔ dzi kpɔkpɔ.

Control Ambient Temperature .

Na dɔwɔƒea ƒe nɔnɔme nafa eye ya naƒo ɖe eme nyuie. Yame ƒe dzoxɔxɔ si nu sẽna nana wòsesẽna na fafamɔ̃wo be woakaka dzoxɔxɔ, vevietɔ le ɣeyiɣi didi siwo wowɔna me. Yameʋuɖoɖo alo yaƒoƒo nyuie ate ŋu akpe ɖe ame ŋu be dzoxɔxɔ si le eme nanɔ dedie.

Trɔ asi le rpm kple nuɖuɖu ƒe agbɔsɔsɔme ŋu wòasɔ .

Optimize spindle duƒuƒu kple nuɖuɖu ƒe agbɔsɔsɔme si wotu ɖe nusiwo wotsɔ wɔe, dɔwɔnuwo, kple mɔ̃ɖaŋudɔwɔwɔ dzi. Duƒuƒu le rpm siwo kɔkɔ ŋutɔ me evɔ womatrɔ asi le nuɖuɖuwo ŋu o ate ŋu ana dzoxɔxɔ si mehiã o nado, gake nuɖuɖu siwo le blewu akpa alo esiwo mewɔa dɔ nyuie o ate ŋu ahe ʋuʋudedi kple nuteɖeamedzi vɛ.

Kpɔ bearings kple spindle components edziedzi .

Kpɔ bearings, shafts, kple mounting hardware ɖa be dzesi siwo ɖee fia be wodo, woƒe nɔnɔme mesɔ o, alo wogblẽ hã. Bearing siwo wodo alo esiwo gblẽ la dzia ʋuʋudedi, ʋuʋudedi, kple dzoxɔxɔ ƒe dzidziɖedzi ɖe edzi. Tsɔ akpa ɖesiaɖe si ɖe dzesi siwo fia be wovuvu la ɖɔ li hafi woahe dzoxɔxɔ si gbɔ eme vɛ.

Kpɔ elektrikŋusẽ ƒe lãmesẽ si le mɔ̃a ŋu ɖa .

Kpɔ egbɔ be spindle motor la xɔ elektrikŋusẽ si li ke kple elektrikŋusẽ. Elektrikŋusẽ ƒe nyawo, abe ʋuƒo siwo le kpuie alo elektrikŋusẽ ƒe dadasɔmakpɔmakpɔ ene, ate ŋu ana dzoxɔxɔ si gbɔ eme nanɔ eme. Elektrikŋusẽ me dzodzro edziedzi kpena ɖe ame ŋu be wòaxe mɔ na dzoxɔxɔ si gbɔ eme kpata.

Dɔwɔwɔ ƒe dzoxɔxɔ dzi kpɔkpɔ .

Zã dzoxɔxɔdzidzenuwo alo fotoɖemɔ̃ siwo me dzoxɔxɔ mele o nàtsɔ alé ŋku ɖe spindle ƒe dzoxɔxɔ ŋu le dɔwɔwɔ me. Dzoxɔxɔ si le dzidzim ɖe edzi ƒe dzedze kaba wɔnɛ be nàte ŋu awɔ ɖɔɖɔɖo hafi agblẽ nu le ŋuwò vevie.

Ðoɖowɔɖi si wowɔna edziedzi be woatsɔ axe mɔ ɖe enu .

Wɔ beléle na xɔa ƒe ɖoɖowɔɖi si me ʋuʋudedi me dzodzro, dzoxɔxɔ ƒe nɔnɔmetatawo, amisisi ƒe dodokpɔwo, kple spindle alignment inspections le. Mɔxexe ɖe enu ƒe beléle na xɔa mexɔ asi kura o wu nuwo ɖɔɖɔɖo kpata eye wòkpɔa egbɔ be spindle ƒe dɔwɔwɔ nɔa anyi ɖaa.

Ketekedɔwɔlawo be woade dzesi nuxlɔ̃amedzesiwo .

Wofiaa nu dɔwɔla siwo le dzoxɔxɔ si gbɔ eme ƒe dzesiwo ŋu, siwo dometɔ aɖewoe nye toɣliɖeɖe siwo mebɔ o, dɔwɔwɔ dzi ɖe kpɔtɔ, woƒe amadede trɔna, kple ʋeʋẽ siwo le bibim. Nyaŋuɖoɖo kaba ɖe dzesi gbãtɔwo ŋu xea mɔ na kpododonu gãwo.

Afɔɖeɖe siawo dzi wɔwɔ ɣesiaɣi ate ŋu aɖe afɔku si le spindle ƒe dzoxɔxɔ fũu akpa me dzi akpɔtɔ ŋutɔ, ana wò CNC mɔ̃a ƒe agbenɔƒe nadidi ɖe edzi, eye wòalé mɔ̃ɖaŋununya ƒe nyonyome si nɔa anyi ɖaa me ɖe asi.

Aɖaŋuɖoɖo Deŋgɔwo na Spindle Agbenɔƒe didi .

Zã spindle agba dzikpɔkpɔ ɖoɖowo

ɖoɖo sensor siwo léa ŋku ɖe spindle agba le ɣeyiɣi ŋutɔŋutɔ me ate ŋu ana nuxlɔ̃ame kaba tso nya siwo ate ŋu ado mo ɖa. Nuɖoanyi siawo léa ŋku ɖe torque, current, kple dzoxɔxɔ ŋu, si wɔnɛ be dɔwɔlawo xlɔ̃a nu tso nɔnɔme siwo mesɔ o ŋu hafi wogblẽa nu vevie. Ekpɔkpɔ kaba kpena ɖe ame ŋu be dzoxɔxɔ si gbɔ eme, mɔ̃ɖaŋununya ƒe nuteɖeamedzi, kple ɣeyiɣi si womele mɔ kpɔm na o nagage ɖe eme o.

Tiatia si sɔ na dɔ si woawɔ

atsɔ atia aŋenu si me ŋusẽ, duƒuƒu, kple fafa ƒe ŋutete si sɔ le na nusi woɖo be woawɔ kple eɖeɖedɔa le vevie ŋutɔ. Spindle si ŋu ŋusẽ mele o zazã hena dɔ siwo biaa nu geɖe wɔwɔ ate ŋu ana agbawo nasɔ gbɔ enuenu, dzoxɔxɔ si gbɔ eme, eye woaɖe ame ƒe agbenɔƒe dzi akpɔtɔ. Spindle ƒe nɔnɔme siwo sɔ kple dɔwɔwɔ ƒe agba la nana be dɔwɔwɔ kple kakaɖedzi nɔa anyi ɖaa.

Ne ètrɔ asi le fafa ƒe kuxiwo gbɔ kpɔnu siwo nyo wu ŋu

na dɔ siwo wobia tso ame si vevie la, bu eŋu kpɔ be yeawɔ asitɔtrɔ le fafamɔ̃ siwo wɔa dɔ nyuie wu ŋu. Tsi-fafɛ spindles alo deŋgɔ hybrid fafa mɔ̃ɖaŋununya ate ŋu alé dɔwɔwɔ ƒe dzoxɔxɔ si bɔbɔ wu standard ya-fafɛ units. Fafa si wodo ɖe ŋgɔ ɖea dzoxɔxɔ ƒe nuteɖeamedzi dzi kpɔtɔna le bearings kple motor windings ŋu, si wɔnɛ be spindle ƒe agbenɔƒe kple mɔ̃ɖaŋununya siaa nyona ɖe edzi.

Elektrikŋusẽ ƒe dzesi kple mɔ̃ siwo hea CNC spindle ƒe dzoxɔxɔ si gbɔ eme vɛ .

Elektriknyawo ƒe dzesiwo .

Spindle ƒe dzoxɔxɔ si gbɔ eme ate ŋu atso elektrikŋusẽ ƒe kuxiwo gbɔ, eye zi geɖe la, woblanɛ ɖe spindle motor alo eƒe control systems ŋu, abe variable frequency drive (VFD) ene. Nya siawo ate ŋu ahe dzoxɔxɔ si gbɔ eme vɛ le ŋusẽ si mesɔ o alo eƒe akpa aɖewo ƒe gbegblẽ ta.

Kpɔe ɖa be:

l Inconsistent RPMs alo torque le agba te , si fia be VFD alo mɔ̃ dzi ɖuɖu ƒe nyawo ate ŋu anɔ anyi.

l Kabakaba ƒe ŋusẽ ɖiɖina , si ate ŋu agbã mɔ̃a eye wòana dzoxɔxɔ nado.

l Spindle motor ƒe dzoxɔxɔ fũ akpa , si woate ŋu ade dzesii zi geɖe to asikaka ame ŋu alo dzoxɔxɔ ƒe nɔnɔmetatawo ɖeɖe me.

l Dzobibi ƒe ʋeʋẽ alo wiring siwo ƒe amadede trɔ , si fia be elektrikŋusẽ ƒe arcing alo short circuits.

Zã multimeter nàtsɔ akpɔ voltages kple amperage hena madzɔmadzɔnyenye. Dzoxɔxɔ ƒe nɔnɔmetatawo ate ŋu ade dzesi teƒe siwo dzoxɔxɔ le le mɔ̃a alo mɔ̃a dzi kpɔnu la ŋu. Ne mènya nu tso elektrikŋusẽ didi ŋu o la, ke bia dɔnyala aɖe. Grɔs alo brɔs siwo womedo nyuie o (le mɔ̃ siwo wotsɔ brɔs wɔe me) hã ate ŋu ana dzoxɔxɔ si gbɔ eme kple dɔwɔwɔ si mewɔa tɔtrɔ o hã nado.

Mɔ̃ɖaŋununya ƒe kpododonu ƒe dzesiwo .

Mɔ̃ɖaŋununya ƒe nyawo nye nusi gbɔ spindle ƒe dzoxɔxɔ si gbɔ eme tsona zi geɖe, zi geɖe la, le ʋuʋudedi alo alesi wowɔa nu ɖe wo nɔewo ŋu le mɔ si mesɔ o nu le akpawo abe bearing, shafts, alo collets ene me. Zi geɖe la, kuxi siawo nana dzoxɔxɔ si gbɔ eme kpena ɖe dzesi bubuwo ŋu.

Aflaga dzĩ siwo bɔ dometɔ aɖewoe nye:

l Toɣliɖeɖewo ƒoƒo alo ƒoƒo le spindle ƒe dɔwɔwɔ me, si fia bearings siwo vuvu alo akpa siwo mesɔ o.

l Vibration le Z-axis alo spindle ta , si dzia ʋuʋudedi kple dzoxɔxɔ ɖe edzi.

l Ŋutilã ƒe awudodo le collets, dɔwɔnulénuwo, alo motor mounts , si hea dɔwɔwɔ nyuie kple dzoxɔxɔ si gbɔ eme vɛ.

Ne wò CNC mɔ̃a le nɔnɔme dzi kpɔkpɔ sensorwo, to ʋuʋudedi alo dzoxɔxɔ ƒe nuŋlɔɖiwo me na spikes, si fiaa mɔ̃ɖaŋunyawo. Dzodzro siwo wowɔna edziedzi, abe nusiwo wotsɔ blaa nu alo gear siwo wovuvu ene ƒe ŋkuléle ɖe wo ŋu, ate ŋu ahe kuxiwo vɛ kaba.

Zi geɖe la, mɔ̃wo ƒe dɔmawɔmawɔ nyuie va nɔa anyi vivivi, eyata beléle na wo do ŋgɔe nye nu vevi aɖe si ana woaxe mɔ ɖe dzoxɔxɔ si gbɔ eme nu eye woaɖɔ wo ɖo le ga geɖe me.

Dɔwɔnuwo kple mɔnuwo na CNC spindle ƒe dzoxɔxɔ si gbɔ eme ƒe dzesiwo didi .

Stethoscope alo Vibration Analyzer zazã .

Ne CNC spindle xɔ dzo akpa la, dɔwɔnu siwo wotsɔ dea dzesi nu ate ŋu akpe ɖe ame ŋu wòade dzesi nusi gbɔ wòtso pɛpɛpɛ. Mɔ̃ɖaŋudɔwɔla ƒe nuƒomɔ̃ nye dɔwɔnu bɔbɔe aɖe si wɔa dɔ nyuie hena nyawo ɖeɖe ɖe go. Ne ètsɔ nusi wotsɔna dzroa nu me la da ɖe spindle-xɔa ƒe akpa vovovowo dzi la, àte ŋu aɖo to gbeɖiɖi siwo mesɔ o, abe nututu alo humming ene, si ate ŋu afia be friction alo component wear si kpena ɖe dzoxɔxɔ si gbɔ eme ŋu.

l Stethoscope : Amplify gbeɖiɖiwo tso mɔ̃a, bearings, alo gearbox. Ne wokpɔ toɣliɖeɖe si gbɔ eme alo ʋuʋu le bearingawo gbɔ la, efia be ʋuʋudedi alo vuvu si hea dzoxɔxɔ ƒe dzidziɖedzi vɛ.

l Vibration Analyzer : Mɔ̃ siawo dzidzea ʋuʋudedi ƒe sesẽme kple eƒe tsɔtsɔme, si dea dzesi dadasɔmasɔmasɔ, masɔmasɔ, alo akpa siwo doa dzoxɔxɔ. Sensor deŋgɔwo ate ŋu ade dzesi nya siwo menya kpɔna dzea sii bɔbɔe o hafi woahe dzoxɔxɔ si gbɔ eme ŋutɔ vɛ.

Dɔwɔnu siawo tsɔtsɔ kpe ɖe smartphone dɔwɔɖoɖowo ŋu hena gbeɖiɖi ƒe nuŋɔŋlɔ alo frequency analysis na nète ŋu ŋlɔa nyatakakawo ɖe agbalẽ me heléa ŋku ɖe wo ŋu le ɣeyiɣi aɖe megbe. Esia doa alɔ beléle na nusiwo wogblɔ ɖi, si kpena ɖe ŋuwò nèkpɔa dzoxɔxɔ si gbɔ eme gbɔ hafi wodoa ŋusẽe.

Dzoxɔxɔ ƒe nɔnɔmetatawo kple dzoxɔxɔ ƒe nɔnɔmetatawo .

Dzoxɔxɔ ƒe nɔnɔmetatawo ɖeɖe nye dɔwɔnu vevi aɖe si wotsɔ dea dzesi spindle ƒe dzoxɔxɔ si gbɔ eme. Fotoɖemɔ̃ siwo me dzoxɔxɔ mele o dea dzesi teƒe siwo dzoxɔxɔ le, si ɖea dzoxɔxɔ si gbɔ eme ƒe bearingwo, mɔ̃a ƒe ʋuʋu, alo ʋuʋudedi le spindle-ʋuƒoa me fiana. Ne wowɔ numekuku kabakaba la, ate ŋu ade dzesi teƒe siwo kuxiwo le evɔ womaɖe mɔ̃a ɖa o.

l Dzoxɔxɔ ƒe fotoɖemɔ̃wo : Di teƒe siwo le dzĩ alo ɣi siwo klẽna le dzoxɔxɔ ƒe ɖeɖefia la dzi, si fia dzoxɔxɔ si wu dɔwɔwɔ ƒe nɔnɔme siwo sɔ. Le kpɔɖeŋu me, dzoxɔxɔ si me dzoxɔxɔ le ɖee fia be ami alo evuvu si mesɔ o.

l Dzoxɔxɔ ƒe nɔnɔmetatawo : Zã kɔmpiutadziɖoɖowo nàtsɔ atsɔ dzoxɔxɔ ƒe nuxexlẽ siwo li fifia asɔ kple gɔmedzedze 'healthy' profile. Dzoxɔxɔ ƒe nuŋlɔɖi siwo tso nɔnɔme dzi kpɔkpɔ ƒe sensorwo me ƒe dzidziɖedzi ate ŋu aɖo kpe dzoxɔxɔ si gbɔ eme ƒe nɔnɔmewo dzi.

Dzoxɔxɔ ƒe nɔnɔmetatawo tsɔtsɔ ƒo ƒui kple ʋuʋudedi me dzodzro kple dzoxɔxɔ ƒe nɔnɔmetatawo nana mɔnu si me kɔ nyuie le dzoxɔxɔ si gbɔ eme didi me. Esia wɔa dɔ nyuie ŋutɔ le fiase siwo me amewo sɔ gbɔ ɖo le afisi mɔ̃ geɖe zɔna le le ɣeyiɣi ɖeka me, si wɔnɛ be wòsesẽna be woaɖe nya siwo ku ɖe dzoxɔxɔ ŋu la ɖe vovo. Dɔwɔnu siawo zazã edziedzi wɔnɛ be woate ŋu ade dzesi wo kaba eye wòxea mɔ na spindle ƒe gbagbã si xɔa ga geɖe.

Alesi woaɖɔ CNC spindle ƒe dzoxɔxɔ si gbɔ eme ƒe nyawo ɖo .

Bearings ɖɔliɖɔli alo ami yeye .

Bearings nye nusi gbɔ spindle ƒe dzoxɔxɔ si gbɔ eme tsona enuenu le ʋuʋudedi si tso vuvu alo amisisi si mesɔ gbɔ o ta. Kpɔ wò mɔ̃a ƒe mɔfiamegbalẽa me be nàkpɔ bearing ƒomevi (si wotre alo ʋu) kple beléle na edzi ƒe nudidiwo.

l Ami gbadzɛ siwo le ʋuʋu ɖi : Ne bearings la le ʋuʋu ɖi la, zã ami ƒe tu si sɔ pɛpɛpɛ, tsɔ ami si ƒe nyonyome de ŋgɔ, si dɔwɔƒea kafu. Ƒo asa na agbatsɔtsɔ fũ, elabena ami si sɔ gbɔ ɖe eme ate ŋu ana ʋuʋudedi kple dzoxɔxɔ nadzi ɖe edzi. Ƒu du le ʋuƒoa me le rpm si le bɔbɔe me le amisisi vɔ megbe be nàkpɔ egbɔ be womae gɔ̃ hã, emegbe nàtsɔ dzoxɔxɔ fotoɖemɔ̃ alo sensor alé ŋku ɖe dzoxɔxɔ ŋu be nàɖo kpe dzoxɔxɔ si dzi ɖe kpɔtɔ dzi.

l replacing sealed bearings : Zi geɖe la, bearing siwo wotre la hiã be woaɖɔli wo. Tsɔ spindle-xɔa ɖa nyuie, zã bearing puller ne ehiã, eye nàtsɔ bearings siwo OEM gblɔ la aɖɔli wo. Ne èɖoe vɔ la, tsɔ spindle la le rpm si bɔbɔ me be nàtsɔ aɖo bearings la dzi, emegbe nàzã dzoxɔxɔ ƒe nɔnɔmetata alo dzoxɔxɔdzidzenu atsɔ aɖo kpe dɔwɔwɔ ƒe dzoxɔxɔ si sɔ dzi.

Le edzadzraɖo vɔ megbe la, lé ŋku ɖe ʋuʋudedi kple dzoxɔxɔ ŋuti nuŋlɔɖiwo ŋu be nàkpɔ egbɔ be wokpɔ nyaa gbɔ. Zi geɖe la, dzoxɔxɔ si gbɔ eme si bearingwo hena vɛ la tsoa ɖekematsɔleme gbɔ, eyata beléle na wo edziedzi le vevie ŋutɔ.

Gbugbɔgaɖoɖo ɖe spindle ƒe ʋuƒoa ŋu .

Afɔdzideƒe ƒe ʋuƒoa ƒe akpa si mesɔ o ate ŋu ana ʋuʋudedi si gbɔ eme nado, si ana dzoxɔxɔa naxɔ dzo akpa, vevietɔ le duƒuƒu sesĩe me. Ðoɖo nyuie ɖea dzoxɔxɔ dzi kpɔtɔna eye wònana akpa aɖewo nɔa agbe.

l Dɔwɔnu siwo wotsɔna ɖoa nuwo ɖe ɖoɖo nu : Zã dial indicator alo laser alignment kit nàtsɔ adzidze shaft runout le rpm si le bɔbɔe me. Ne runout wu alesi adzɔha la ɖe mɔ ɖe eŋu la, ehiã be woagbugbɔ aɖoe ɖe ɖoɖo nu.

l Realignment process : Ðe asi le spindle mount la ŋu eye nàgbugbɔe aɖoe nyuie. Le CNC mɔ̃ deŋgɔwo gome la, trɔ asi le shim siwo sɔ ɖe ɖoɖo nu ŋu alo nàgbugbɔ aɖo kɔmpiutadziɖoɖowo ƒe ɖoɖowo ɖe ɖoɖo nu alesi wòhiãe. Dzro dɔwɔnu, collet, kple chuck me be do alo gbeɖuɖɔ hã le eme, elabena esiawo ate ŋu ahe masɔmasɔ vɛ eye wòana dzoxɔxɔ nadzi ɖe edzi.

l Post-alignment checks : Ne ègbugbɔ ɖo wo ɖe ɖoɖo nu vɔ la, kɔ akpaawo katã ŋu nyuie eye nàdo spindle la kpɔ le agba te. Zã dzoxɔxɔ ƒe nɔnɔmetatawo alo dzoxɔxɔdzidzenuwo nàtsɔ aɖo kpe edzi be woɖe dzoxɔxɔ si gbɔ eme dzi kpɔtɔ.

Ŋlɔ dzoxɔxɔ kple ʋuʋudedi ƒe nuxexlẽwo ɖi le edzadzraɖo vɔ megbe be woaɖo gɔmedzedze yeye aɖe anyi. Ðoɖowɔwɔ ɖe nuwo ŋu edziedzi kple dɔwɔnuwo dzi kpɔkpɔ akpe ɖe ŋuwò nàxe mɔ ɖe dzoxɔxɔ si gbɔ eme nu eye wòalé spindle ƒe dɔwɔwɔ nyuie, si wɔa dɔ nyuie la me ɖe asi.

Ɣekaɣie woayɔ dɔnyala aɖe na CNC spindle ƒe dzoxɔxɔ si gbɔ eme .

Wò seɖoƒewo nyanya .

Ele be CNC dɔwɔla bibiwo gɔ̃ hã nakpɔe adze sii ne spindle ƒe dzoxɔxɔ si gbɔ eme ƒe nyawo bia be woawɔ dɔnyala bibiwo ƒe nunya. Togbɔ be àte ŋu akpɔ beléle na nu veviwo abe bearing siwo me ami gbugbɔgaɖɔɖo le alo dɔwɔnu siwo wotsɔna kɔa nu ŋu ene hã la, kuxi sesẽwo—abe mɔ̃a ƒe dɔmawɔmawɔ nyuie le ememe, spindle cartridge ƒe gbegblẽ, alo elektrikŋusẽ ƒe vodada deŋgɔwo ene—bia aɖaŋu tɔxɛwo.

Yɔ dɔnyala aɖe ne:

l Gɔmedzedze ƒe ɖɔɖɔɖowo (le kpɔɖeŋu me, bearings gbugbɔgaɖɔɖo, shaft la gbugbɔgaɖo, alo elektrik kadodowo me toto) mekpɔa dzoxɔxɔ si gbɔ eme gbɔ o.

l Èdea dzesi dzoxɔxɔ si nɔa anyi ɖaa togbɔ be wowɔa dɔ le mɔ si sɔ nu hã, si fia be nya siwo de to wu abe mɔ̃a ƒe ƒoƒo ƒe kpododonu alo VFD ƒe dɔmawɔmawɔ nyuie ene.

l Dɔwɔnu siwo wotsɔ dia dɔléle (dzoxɔxɔ ƒe nɔnɔmetatawo, vibration analyzers) ɖea nusiwo mesɔ o fiana siwo màte ŋu aɖe gɔme alo aɖɔ wo ɖo o.

Dɔwɔnu deŋgɔwo le dɔnyala bibiwo si, abe dzoxɔxɔnukpɔmɔ̃ siwo wɔa dɔ pɛpɛpɛ alo spindle dodokpɔ ƒe ʋuƒo tɔxɛwo ene, kple nunya si le spindle ƒe nɔnɔme vovovowo ŋu. Pro a pro isn’t admitting devence—enye afɔɖeɖe si me nunya le be nàkpɔ wò mɔ̃a ƒe dɔwɔwɔ kple agbenɔƒe didi ta.

Gazazã vs. viɖe si le eŋutinunyalawo ƒe nuwo ɖɔɖɔɖo ŋu .

Ga si wozãna ɖe spindle dzadzraɖodɔ ŋu ate ŋu adze abe ɖe wòle kɔkɔm ene, gake zi geɖe la, woate kpɔ be woaɖɔ nuwo ɖo siwo sesẽ aɖaŋu alo dɔwɔnu nyuiwo manɔmee hea kuxi gãwo vɛ. Nusiwo ŋu womewɔa naneke le o, abe bearingwo dede nyuie alo spindle la mesɔ o ene, ate ŋu ana woaɖɔ dɔlar 500 ɖo wòazu dɔlar 5,000 si woatsɔ aɖɔlii.

Viɖe siwo le dɔnyala ƒe subɔsubɔdɔ ŋu dometɔ aɖewoe nye:

L Eŋutinunyala Diagnostics : Mɔ̃ɖaŋudɔwɔlawo ate ŋu ade dzesi nyawo abe elektrikŋusẽ ƒe vodada ɣaɣlawo alo ememe ʋuʋudedi siwo fiase me dɔwɔnu siwo wozãna ɖaa ate ŋu ato ene.

l Warranies : Dɔnyala ƒe dzadzraɖo akpa gãtɔ va kple kakaɖedziwo, si kpɔa egbɔ be kakaɖedzi le eŋu ɣeyiɣi didi.

l Ɣeyiɣi si woɖe ɖe vovo : Subɔsubɔdɔ geɖewo naa nuwo ɖɔɖɔɖo kabakaba be woagbugbɔ wò mɔ̃a aɖo ɖe Internet dzi kaba.

l Dzidziɖedzi gbugbɔdzra ƒe asixɔxɔ : Subɔsubɔ ŋutinya si woŋlɔ ɖi tso dɔnyala bibiwo gbɔ doa wò CNC mɔ̃ ƒe asi ƒe asixɔxɔ ɖe ŋgɔ.

Hafi wò ŋutɔ nàkpɔ nya vevi aɖe si wosusu be ele eme la gbɔ la, da ga si woatsɔ adzra ɖo ɖe dɔnyala bibiwo ŋu la kpɔ le asixɔxɔ si le wò mɔ̃a ƒe ɣeyiɣi si nèzãna kple esi sɔ pɛpɛpɛ ŋu. Zi geɖe la, nunya kple susu ƒe akɔdzeanyi sɔ na gadede asi na amewo nyuie.

Alesi nutome ƒe nɔnɔmewo kpɔa ŋusẽ ɖe CNC spindle ƒe dzoxɔxɔ si gbɔ eme dzi .

Tsi ƒe fafa, ke, kple dzoxɔxɔ .

Nutoa me le wò CNC fiasea me kpɔa ŋusẽ ɖe spindle ƒe lãmesẽ dzi vevie eye ate ŋu akpe ɖe dzoxɔxɔ si gbɔ eme ŋu. Nu siawo ate ŋu ana ʋuʋudedi nagado gã ɖe edzi, agblẽ nu le akpa vovovoawo ŋu, eye woagblẽ dɔwɔwɔ nyuie me.

l Humidity : fafa gã ate ŋu ana condensation le spindle housing la me, si ahe gbeɖuɖɔ alo corrosion ɖe bearings kple akpa bubuwo dzi. Esia nana be ʋuʋudedi dzina ɖe edzi, si wɔnɛ be dzoxɔxɔ si gbɔ eme dona eye wòate ŋu ana ame nado kpo nu kaba.

l Ke kple nusiwo me nu suesuesuewo le : Le nuto siwo le abe atikpowo alo ga-ʋuʋu ƒe dɔwɔƒewo ene me la, ke ate ŋu age ɖe spindle motor la me. Ne wotsɔ ami tsakae la, ke wɔa atike si wotsɔna ƒoa nui si vuvua bearing kple nutrenu, si wɔnɛ be ʋuʋudedi kple dzoxɔxɔ ƒe ƒuƒoƒo dzina ɖe edzi.

l Dzoxɔxɔ ƒe ʋuʋu : Dzoxɔxɔ si fa miamiamia na amia nu sẽna, si ɖea eƒe amisisi ƒe dɔwɔwɔ dzi kpɔtɔna eye wòhea ʋuʋudedi kple dzoxɔxɔ si lolo wu vɛ. Le dzoxɔxɔ ƒe nɔnɔmewo me la, dzoxɔxɔ ƒe keke ɖe enu ate ŋu ana aŋea ƒe ʋuƒoa natrɔ, eye ami ate ŋu agblẽ kabakaba wu, si ana dzoxɔxɔa naxɔ dzo akpa. Dzoxɔxɔ si gbɔ eme ate ŋu ate ɖe mɔ̃a ƒe ʋuƒo dzi hã, si akpe ɖe dzoxɔxɔ si kɔ ŋu.

Nusiwo woatsɔ aɖe edzi akpɔtɔ ƒe mɔnuwo:

l De keƒoɖokuiwo kple ya ƒe ʋuʋu ƒe mɔ̃wo be woaɖe akpa siwo me woɖea nu le ƒe gege ɖe eme dzi akpɔtɔ.

l Zã yame ƒe nɔnɔme dzi kpɔkpɔ ƒe ɖoɖowo nàtsɔ alé fafa kple dzoxɔxɔ ƒe agbɔsɔsɔ si li ke me ɖe asi.

l Dzra akpa aɖewo kple amiwo ɖo ɖe teƒe siwo le dzadzɛ, siwo ƒu, siwo dzi dzoxɔxɔ le.

l Kpɔ spindle ƒe akpawo ɖa edziedzi eye nàkɔ wo ŋu be ke nagaƒo ƒu o eye nàkpɔ egbɔ be amia sɔ nyuie.

Mɔ̃wo ɖoɖo kple ʋuʋu ɖe aga .

Wò CNC mɔ̃a ɖoɖo ŋutɔŋutɔ ate ŋu akpɔ ŋusẽ ɖe spindle ƒe dzoxɔxɔ si gbɔ eme dzi to ʋuʋudedi alo dzoxɔxɔ ƒe tsɔtsɔ tso gotagome dzɔtsoƒewo me.

l Uneven Surfaces : Mɔ̃ siwo le dzisasrã siwo mesɔ o dzi ate ŋu akpɔ woƒe nɔnɔme si mesɔ o, si ana be spindle la nawɔ dɔ sesĩe wu eye wòana dzoxɔxɔ geɖe nado. Ʋuʋu tso gɔmeɖoanyi si meli ke o hã ate ŋu ana ʋuʋudedi nadzi ɖe edzi le bearings kple akpa bubuwo me.

l Te ɖe dɔwɔnu bubuwo ŋu : CNC mɔ̃ dada ɖe mɔ̃ kpekpewo gbɔ, abe agbalẽtamɔ̃wo alo lathes ene, ate ŋu ahe gotagome ʋuʋudedi siwo tea gbe ɖe spindle la dzi vɛ, si ana dzoxɔxɔ nadzi ɖe edzi tso friction alo misalignment me.

l Dzoxɔxɔtsoƒewo : Mɔ̃ siwo woda ɖe dɔwɔnu siwo naa dzoxɔxɔ dzi alo le ɣe ƒe keklẽ tẽ me ate ŋu akpɔ yame ƒe dzoxɔxɔ si kɔkɔ wu, si ana spindle ƒe dzoxɔxɔ si gbɔ eme nagado gã ɖe edzi.

Nusiwo woatsɔ aɖe edzi akpɔtɔ ƒe mɔnuwo:

l Kpɔ egbɔ be mɔ̃a le sɔsɔm to bubble ƒe dzidzenu si sɔ pɛpɛpɛ alo laser ƒe dzidzenu zazã me be nàɖe dzoxɔxɔ si tso misalignment-si me la dzi akpɔtɔ.

l De vibration isolation mounts alo dampers ɖe CNC te be wòaxɔ external vibrations eye nàɖe nuteɖeamedzi dzi akpɔtɔ le spindle la dzi.

l Ðo mɔ̃a ɖe teƒe aɖe tso dɔwɔnu sesẽwo alo dzoxɔxɔtsoƒewo gbɔ be nàƒo asa na ʋuʋudedi ƒe tsɔtsɔ to anyigba alo yame ƒe dzoxɔxɔ si kɔ dzi.

l Zã dzoxɔxɔ ƒe mɔxenuwo alo xɔwo nàtsɔ akpɔ mɔ̃a ta tso dzoxɔxɔtsoƒe siwo tso gota gbɔ.

Ne èɖua nutoa me ƒe nɔnɔmewo dzi eye nètsɔa mɔ̃a ɖoa teƒe nyuitɔ la, àte ŋu aɖe spindle ƒe dzoxɔxɔ si gbɔ eme dzi akpɔtɔ, ana dɔwɔwɔ nyuie nanyo ɖe edzi, eye nàna wò CNC dɔwɔnuwo ƒe agbenɔƒe nadidi ɖe edzi. Ne wotsɔ dzoxɔxɔ ƒe nɔnɔmetatawo alo dzoxɔxɔdzidzenuwo lé ŋku ɖe wo ŋu edziedzi ate ŋu akpe ɖe ame ŋu la, woate ŋu ade dzesi nya siwo ku ɖe nya siwo ku ɖe nutoa me ŋu ƒe dzesiwo kaba.

Adzɔnuwɔƒea ƒe aɖaŋuɖoɖowo mele be nàŋe aɖaba aƒu edzi na CNC spindle ƒe dzoxɔxɔ si gbɔ eme o .

Agbalẽa xexlẽ nyuie .

CNC Spindle ƒe mɔfiamegbalẽa dzi ɖeɖe kpɔtɔ nye vodada si xɔ asi ŋutɔ. Nyatakaka vevi siwo wowɔ ɖe wò spindle ƒe kpɔɖeŋua nu la yɔ eme fũ, siwo dometɔ aɖewoe nye dɔwɔwɔ ƒe dzoxɔxɔ, amisisi ƒe ɖoɖowɔɖiwo, fafanu siwo sɔ, kple beléle na wo ƒe ɖoɖowo. Ne woŋe aɖaba ƒu nya siawo dzi tsitotsito la, ate ŋu ana dzoxɔxɔa naxɔ dzo akpa eye wòagblẽ nu le ame ŋu ɣeyiɣi didi.

l Key Details : Agbalẽa gblɔ amisisi ƒomevi si sɔ (le kpɔɖeŋu me, amikuƒe, ami si wobla ɖe agba me, alo ceramic bearings siwo me woɖea ami le), fafa ƒe nudidiwo, kple torque ƒe ɖoɖowo. Ami alo fafanu si mesɔ o zazã ate ŋu ana ʋuʋudedi kple dzoxɔxɔ nadzi ɖe edzi.

l Beléle na mɔfiamewo : Wɔ ɖe mɔfiame siwo ku ɖe dzadzɛnyenye, bearing beléle na wo, kple component preload dzi be dzoxɔxɔ si gbɔ eme nagatso ɖoɖo alo vuvu madzemadzee o.

L Troubleshooting Tips : Zi geɖe la, vodada ƒe dzesiwo alo dzoxɔxɔ ƒe dzidzenuwo nɔa mɔfiamegbalẽa me be wòakpe ɖe ame ŋu wòakpɔ dzoxɔxɔ si gbɔ eme ƒe nyawo kaba.

Print and laminate key maintenance pages be nàte ŋu akpɔe kaba le wò fiase me. Esia nana nèkpɔa egbɔ be yewɔ ɖe mɔ̃ɖaŋudɔwɔƒea ƒe mɔfiamewo dzi be yealé dzoxɔxɔwo ɖe te eye nàƒo asa na nuwo ɖɔɖɔɖo si xɔa ga geɖe.

Mɔfiame siwo ku ɖe agbatsɔtsɔ kple duƒuƒu ŋu dzi wɔwɔ .

Akɔtaɖonu tutu ɖe eƒe agba alo RPM ƒe seɖoƒe si wokafu dzi nye nusi gbɔ dzoxɔxɔ si gbɔ eme tsona zi geɖe. Agbatsɔtsɔ fũ alo duƒuƒu fũu akpa nana dzoxɔxɔ si gbɔ eme nana ame, etea ɖe akpa aɖewo dzi, eye wònana be nuawo dona kabakaba.

L Agba ƒe Seɖoƒewo : Be woagbɔ spindle ƒe torque alo cutting load capacity ŋu ate ŋu ahe motor strain vɛ, si ana be dzoxɔxɔ si gbɔ eme eye wòate ŋu agblẽ le shaft la ŋu alo wòagblẽ nu le bearings ŋu.

l Duƒuƒu ƒe Seɖoƒewo : Duƒuƒu le spindle la tame le eƒe rpm si woɖo ɖi la dzia friction ɖe edzi le bearings me eye wòhea dzoxɔxɔ si gbɔ eme vɛ, si dea afɔku me be mɔ̃a ƒe ƒoƒo alo ami ƒe gbagbã.

l Dɔwɔnu siwo wotsɔna léa ŋku ɖe nu ŋu : Zã wò CNC-mɔ̃a ƒe kɔmpiutadziɖoɖoa nàtsɔ alé ŋku ɖe ɣeyiɣi ŋutɔŋutɔ ƒe spindle ƒe agba, duƒuƒu, kple dzoxɔxɔ ŋu. Nuɖoanyi geɖe ɖea mɔ na wò be nàɖo ɣlidodowo ɖe dedienɔnɔ ƒe dzidzenu siwo gbɔ eme ta, si kpena ɖe ŋuwò be nàxe mɔ ɖe dzoxɔxɔ si gbɔ eme nu.

Nuwɔna Nyuitɔwo:

l Lé ɖe rpm kple agba ƒe seɖoƒe siwo wogblɔ la ŋu be woaɖe dzoxɔxɔ dzi akpɔtɔ.

l Kpɔ fafamɔ̃wo (le kpɔɖeŋu me, ya alo tsi fafɛ) edziedzi be woakpɔ egbɔ be wole dɔ wɔm abe alesi mɔfiamegbalẽa ƒe aɖaŋuɖoɖowo gblɔe ene.

l Kpɔ dzoxɔxɔ ƒe nuŋlɔɖiwo dzi to nɔnɔme ƒe sensorwo alo dzoxɔxɔ ƒe nɔnɔmetatawo dzi be woalé deviations kaba.

Mɔfiame siawo dzi wɔwɔ ɖea nuteɖeamedzi si tso dzoxɔxɔ gbɔ dzi kpɔtɔna, xea mɔ na dzoxɔxɔ si gbɔ eme, eye wònana wò spindle ƒe agbenɔƒe didi, si wɔnɛ be wò CNC-mɔ̃a nɔa dɔ wɔm nyuie eye wòwɔa dɔ nyuie.

Nyanuwuwuw

Dzoxɔxɔ si gbɔ eme le wò CNC-kplu me nye nuxlɔ̃amedzesi si me kɔ si bia be woalé ŋku ɖe eŋu. Eɖanye bearings siwo wodo, misalignment, elektrikŋusẽ ƒe vodada, alo nusiwo le nutoa me gbɔe wòtso o, dzoxɔxɔ ƒe dzesi siwo gbɔ eme siwo gbɔ nya siwo ate ŋu adzi ɖe edzi ne woŋe aɖaba ƒu wo dzi la gbɔe wòtso. Ne womelé ŋku ɖe eŋu o la, dzoxɔxɔ si gbɔ eme ate ŋu ana akpa aɖewo nado kpo nu, woaɖɔ wo ɖo le ga geɖe me, eye woatɔ te ɣeyiɣi geɖe.

Ne èbi ɖe dɔwɔnu siwo wotsɔ dia dɔlélewo abe dzoxɔxɔ ƒe nɔnɔmetatawo, ʋuʋudedi me dzodzro, kple nuƒomɔ̃wo ene me, kple mɔfiame siwo ku ɖe ewɔlawo ŋu le beléle na wo, agbatsɔtsɔ, kple duƒuƒu ŋu me la, àte ŋu alé kuxiwo kaba eye nàna wò spindle la nanɔ dɔ wɔm nyuie. Nutomedzikpɔkpɔ kple mɔ̃a ɖoɖo nyuie ɖea afɔku si le nya siwo ku ɖe dzoxɔxɔ ŋu me dzi kpɔtɔna ɖe edzi.

Wò spindle nye wò CNC mɔ̃a ƒe dzi. Takpɔe kple beléle do ŋgɔ, eye wòatsɔ dɔwɔwɔ si ŋu kakaɖedzi le, si anɔ anyi ɣeyiɣi didi la aɖo eteƒe na wò.

Nya siwo wobiaa amewo .

Nukae nye dɔwɔwɔ ƒe dzoxɔxɔ nyuitɔ kekeake na CNC spindle?

Spindle akpa gãtɔ wɔa dɔ nyuie le 40°C kple 60°C (104°F–140°F) dome, gake kpɔ amesi wɔe ƒe nɔnɔmewo.

Zi nenie wòle be masi ami na nye spindle?

Amisisi ƒe tsɔtsɔme nɔ te ɖe zazã kple ewɔla ƒe mɔfiamewo dzi, zi geɖe la, dɔwɔwɔ ƒe gaƒoƒo 500–1,000 ɖesiaɖe.

Ðe dzoxɔxɔ si gbɔ eme ate ŋu agblẽ nu le ame ŋu tegbeea?

Ẽ, dzoxɔxɔ si gbɔ eme ɣeyiɣi didi ate ŋu agblẽ nu le bearing, mɔ̃wo, alo nu bubuwo ŋu, si ana woadzra wo ɖo le ga geɖe me alo woaɖɔli wo.

Ðe tsi ƒe fafa nyo wu ya fafɛa?

Tsi ƒe fafa wɔa dɔ nyuie wu na dɔ siwo zɔna kabakaba alo esiwo me wowɔa dɔ sesĩe le, gake ya ƒe fafa le bɔbɔe wu eye wòsɔ gbɔ na dɔ siwo le bɔbɔe wu.

Nukae nye CNC spindle ƒe agbenɔƒe le mama dedie nu?

Ne wodzrae ɖo nyuie la, spindles ate ŋu anɔ anyi 10,000–20,000 dɔwɔwɔ ƒe gaƒoƒo, le zazã kple nɔnɔmewo nu.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu