I CNC machine hi a tlangpui aia a lum zawk em? Chu lumna lum tak, khaw lum takah chuan a lumna tlemte chu vaukhânna chhinchhiahna lian tak a ni thei a—chu chu i ngaihthah theih tûr thil a ni lo bawk. Overheating spindle hi harsatna tenau tak mai a ni lo va; Thil dik lo a awm tih signal a ni a, ngaihthah a nih chuan components chhia, machining accuracy tihtlem, siamthat man to tak tak, a nih loh leh machine failure kimchang tak pawh a thlen thei a ni.

He guide-ah hian CNC spindle overheating chungchanga hriat tur zawng zawng kan kalpui ang che—a bul ṭanna chhinchhiahnate hriat aṭanga a bul ṭanna chiang taka hriat theihna leh siam ṭhat leh ven theihna tura hmalakna tangkai tak takte kan kalpui ang. Machine operator emaw, maintenance technician emaw, i hmanrua humhim duhtu CNC ngainatute emaw pawh ni ila, hei hi i spindle cool, efficient, leh rei tak daih thei tur atana i resource awmchhun a ni.

A lumna chu tihhniam la, i production chu peak performance-ah kalpui zel ang u!

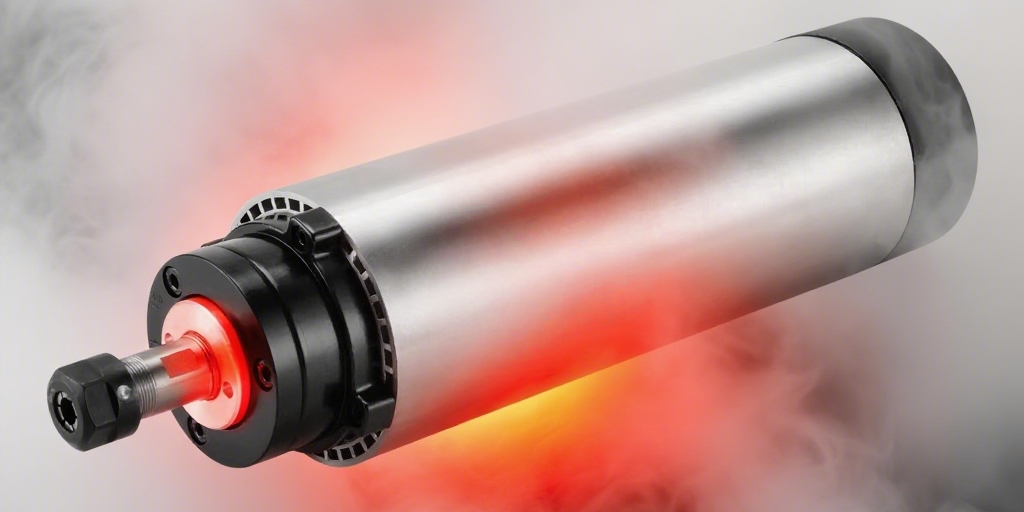

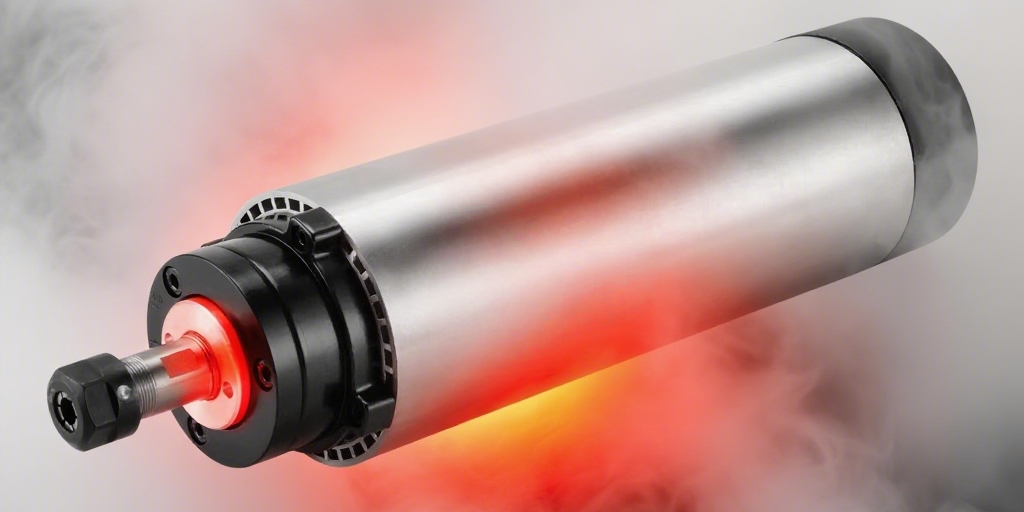

CNC Spindle Motors chungchang inhriattirna .

CNC spindle motor tih hi eng nge ni?

CNC machine zawng zawng bulpui ber chu a spindle motor a ni. He vital component hian cutting tools te chu a tichak a, machine chu a drill, cut, mill, leh shape materials te chu precision takin a siam thei a ni. Machine hnathawh bulpui ber a nih angin, speed, torque, leh overall performance te a control a—a rintlakna chu consistent production atana pawimawh tak a ni.

Spindle motor hi a hman dan azirin size hrang hrang, speed, leh power rating hrang hranga siam a ni a, thingpui lumna emaw, metalworking emaw, machining composite emaw pawh nise. Material chu eng pawh ni se, spindle chu a dikna leh a dam rei theihna turin temperature limit him tak chhungah a thawk tur a ni.

I car chhunga engine ang maiin han ngaihtuah teh—a lum lutuk tan chuan i ngaihthah theih loh tur vaukhânna a ni. Spindle-a lum lutuk chuan bearings a tichhia thei a, lubrication a tichhia thei a, thermal expansion hmangin machining tolerances a paih chhuak thei bawk. Cool-running spindle tih awmzia chu a tlangpuiin hrisel taka hnathawh tihna a ni a; Temperature sang chho zel hian ngaihven nghal vat tur a ni.

Spindle hnathawh dan hriatthiamna leh a lum zel dan hriatthiamna chuan thil engemaw a hriat chuan advantage lian tak a pe che 'off.' Hei hian a bearings, motor windings, cooling systems, leh housing te chanvo hriat a huam a—chu zawng zawng chu overheating avanga nghawng a nei thei a, performance issue lian tak tak a thlen theih a, chu chu check loha dah a nih chuan a nghawng thei a ni.

CNC machine-a spindle health pawimawhzia .

I CNC machine chu a spindle ang chauh a tha. Spindle a lum lutuk chuan i motor risk mai mai a ni lo; Bearing damage, warped components, scrapped parts, missed deadlines, leh a chhe ber ber—a man tlawm ber—a man tlawm ber—a ti thei a ni.

Temperature sang chho zel hi vaukhânna chhinchhiahna hmasa ber a ni fo ṭhîn. Vawiin hian spindle lum deuh mai chu naktuk hian burnt-out motor-ah a chang thei ang. Heat level enfiah leh a chhan ngaihtuah hmasak hian siamthatna tur sang tam tak i humhim thei a, spindle thlakna tur kimchang i pumpelh thei bawk.

Tin, hei hi ngaihtuah bawk ang che: overheating spindle hian a mah chauhin a tuar lo—i machine hmun dang, drive system atanga cooling components thlengin extra strain a dah a ni. Chain reaction a ni a, motion-a set duh lo tak tak a ni.

Spindle temperature control hi performance chauh ni lovin a tam zawk a ni—a himna, productivity, leh profitability zawng zawng chu pakhatah a awm vek a ni. Chuvangin, a chhan hriatthiam leh a lum lutuk venna chu duhthlan tur a ni lo; A pawimawh hle mai.

CNC spindle: i machine power core .

Spindle hi a dang chauh a ni lo—i CNC machine-a centerpiece a ni. Temperature dik taka a kal chuan i hnathawh dan chu a kal tluang hle. A lum lutuk chuan engkim a chhe tan ta. He component hian cutting tools a khalh a, i materials a siam a, precision a vawng reng bawk—a temperature control chu performance atana pawimawh tak a ni.

Spindle failure man a to .

Overheating hian production a ti slow mai mai lo—a tichhia a ni. A lum lutuk chuan:

l bearing a hlawhchham .

L Warped Spindle Components 1000 a awm bawk.

l Lubrication tihchhiat .

l Scrapped Materials .

L Project hun tawp dawnah a tlai tawh.

l Emergency siamthatna man to tak tak .

l beisei loh machine downtime .

Minute tin i spindle a lum lutuk chu pawisa hloh a ni. A lum vawn hi duhthlan tur a ni lo—a pawimawh hle.

A hmaa vaukhânna chhinchhiahnate .

Temperature spike hi harsatna chhinchhiahna hmasa ber a ni fo thin. Vawiina spindle lum deuh mai chu naktuk hian burnt-out motor a ni thei ang. Overheating left unchecked a nih chuan hetiang hian a awm thei ang:

l Full Spindle thlak danglamna .

l Machine downtime tihzauh a ni.

l Internal component dangte chhiatna .

Catching Heat Issues A tir lamah chuan sum a humhim a, a chhe lo tur a veng a, a siam chhuah hun tur pawh a tikhawtlai bawk.

Overheating hian i CNC system pumpui a nghawng dan .

Hot spindle hian a mah chauh a tichhia lo—machine pumpui a stress a ni.

l Bearings a chhe rang zawk .

l Lubricant te chu a chhe vek a ni.

L Drive Systems ah hian a thawkrim zawk .

L Electrical Components A lum lutuk .

l Thermal expansion chuan tool alignment a paih chhuak.

He chain reaction hian system-wide failure a thlen thei a ni. Preventative temperature control hi i defense tha ber a ni.

Machine lifespan a tam thei ang bera awm theihna tur a ni.

Routine spindle temperature monitoring neih a pawimawh hle. Minute tlemte chauh hian repair man sang tam tak a veng thei a ni. Schedule Regular:

l Thermal Imaging enfiahna .

L Coolant System tih a ni a, a hnuaia mi ang hian a ni.

L airflow leh fan enkawl dan .

L Temperature sensor calibration 1000 a awm bawk.

Invenna hian recovery aiin a man a tlawm zawk fo thin.

efficiency hmanga productivity tihpun . Cooling

Spindle lum taka tihlum chuan a tifai a, a tifai a, a ti rang zawk a, a tha zawk bawk. Hei hian a ti tha zawk:

l Cycle hun 10.1.

l part quality .

l Hmanrua dam rei theihna .

l Machine performance zawng zawng a thawk thei ang .

Darkar khata part tam zawk i duh chuan spindle temperature control hmangin tan la rawh.

Spindle Cooling = Operator himna tur .

Overheated spindles hi mechanical risk mai a ni lo—safety hazard a ni. A lum lutuk chuan:

l A chhan chu a man nghal zat a ni.

l chuan beisei loh hmanrua a tichhia a ni.

l Machine hmanga nungchang dik lo siam .

I spindle cool taka vawn hian i hmanrua leh i team te a venghim vek a ni.

Heat signals te hrethiam rawh .

Machine te hian temperature inthlak danglamna hmangin thu an sawi thin. Hriat dan zir rawh:

l A lumna chu a zau zauh zauh a.

l rapid spikes a awm laiin a cut nasa hle.

l Cooling system a thawk tha lo .

l Bearings emaw housing emaw vel a lumna danglam tak .

Pattern tin hian thawnthu pakhat a sawi a—a hma taka man chuan hnathawh him zawk, awlsam zawk a siam thei a ni.

Tool life chu temperature stability neiin a tizau thei bawk.

Heat tam lutuk hian tool life a ti tawi zawk. Overheating hian a thlen thei:

l Dull cutting edges .

l Hmanraw hman fo thin .

l A dik lo .

l Surface finish tha lo .

Temperature-stable spindle hian tool tin hian a tha ber berah an thawk thei tih a tichiang a ni.

CNC spindle overheating chhan tlangpui a awm

| chhan |

sawifiahna . |

| Spindle a overload . |

Cutting force tam lutuk emaw, capacity kaltlanga hun rei tak hnathawh emaw chuan lum lutuk a siam a, motor leh bearings a ti na hle. |

| Lubrication tha lo emaw lubrication a chhiat loh chuan . |

Lubrication tling lo emaw, dik lo emaw chuan bearings-ah friction a tipung a, chu chuan heat buildup leh accelerated wear a thlen thin. |

| Cooling system a that lohna . |

Filter clogged, coolant level hniam, emaw pump tha lo tak tak te hian water-cooled system-a heat dissipation a tichhe thei a ni. |

| A chhehvel boruak lum lutuk . |

Ventilated tha lo emaw, boruak sang lo tak emawa hnathawh hian spindle-in lumna a chhuah theihna a ti tlem a ni. |

| RPM tam lutuk emaw feed rate dik lo emaw . |

RPM sang emaw feed rate inmil lo emaw chuan heat generation leh stress components a tipung a ni. |

| Bearings chhe tawh emaw, chhe tawh emaw . |

Bearings chhe tawh chuan friction dang a siam belh a, heat a siam a, catastrophic failure a thlen thei bawk. |

| Motor chhunga electrical issue awm te . |

Wiring dik lo, voltage inthlak danglam emaw motor malfunction emaw hian a lum lutuk a, a thawk tha lo hle bawk. |

Spindle a overload .

Overloading hi spindle chu a siamtuin a tarlan performance limits aia tam a thawh tir a nih chuan a thleng thin. Hei hi kawng hrang hrangin a thleng thei a ni:

Thil harsa lutuk emaw, thil dense lutuk emaw tan .

Entirnan, machining hardened steel emaw exotic alloys emaw hmangin spindle hmangin aluminum emaw thing ang chi thil nem zawk atan siam a ni. Resistance tihpun hian torque demand a siam tam zawk a, hei hian heat buildup nasa zawk a thlen a ni.

Cut thuk lutuk lak .

Deep pass chuan revolution khatah material tam zawk a paih chhuak a, cutting force tam zawk a mamawh a ni. Hei hian spindle motor-a load a tipung mai bakah tool-workpiece interface-ah friction tam zawk a siam bawk.

Feed rate sang lutuk hmangin .

Feed rate chu spindle speed leh tool capability atan a rang lutuk chuan, cutting edge chu faina slicing ai chuan material plow through a ngai a ni. Hei hian vibration tam lutuk, stress leh heat a siam chhuak thin.

Heng thilte inzawmkhawm hian spindle bearings, motor windings, leh drive components te chu mechanical stress a siam a ni. Hun a kal zel a, hei hian:

bearing wear chak zawk . Radial leh axial load tam lutuk atanga

thermal expansion of internal parts, chu chuan misalignment emaw friction tihpun emaw a thlen thei.

electrical overload , insulation breakdown leh winding damage hlauhawmna. Spindle motor atanga

A nasat lutuk chuan overloading hian spindle chu thermal overload protection-ah a trip thei a, a hman laiin a stall thei a, a nih loh leh motor leh bearings-ah a tichhia reng thei bawk.

A tha ber: I cutting parameters—material type, spindle speed, feed rate, leh cut depth of cut—te chu spindle-a rated specification-te nen inmil tir fo ang che. Tooling dik tak hman leh sharp cutting edges enkawl hian load nasa takin a tihtlem thei bawk.

Lubrication tha lo emaw lubrication a chhiat loh chuan .

Spindle’s bearings leh moving component dangte chu a hnathawh dan tur dik taka thawk turin lubrication dik takah an innghat nasa hle. Lubrication hian thil pawimawh tak pahnih a thawk a, chungte chu metal surface inkara inhnaih lohna tihtlem leh hnathawh laiin heat siam chhuah tihbo (dissipate heat) te a ni.

Lubrication a tlem a, a bawlhhlawh a, a nih loh leh a awm loh chuan harsatna engemaw zat a awm thei:

Lubrication tling lo .

Spindle hian grease emaw oil emaw a dawn tlem chuan metal-to-metal contact a pung a, lum lutuk a siam a, wear a ti chak bawk.

Lubrication bawlhhlawh .

Lubricant-a bawlhhlawh, metal shavings, emaw moisture emaw hian abrasives angin hna a thawk thei a, bearing surface a scratch thei a, smooth rotation a tikhawlo thei bawk.

Lubrication leak emaw neglect emaw .

Hun a kal zel a, seal te chu a hlawhchham thei a, a nih loh leh maintenance schedule pawh ngaihthah theih a ni a, chu chuan lubricant a hloh zauh zauh thei a ni. Lubrication dik tak awm lovin friction a pung chak hle.

Lubrication tha lo avanga a rah chhuah chu:

Rapid Heat Buildup – Friction tam lutuk hian mechanical energy chu lumnaah a chantir a, spindle temperature a tisang rang hle.

Bearing wear leh damage – friction hian bearing surface a ti chhe a, chu chuan pitting, scoring, emaw bearing seizure pawh a thlen thei.

Spindle failure – A nasat lutuk chuan bearings te chu a lock vek thei a, chu chuan spindle chu a ti tawp nghal a, motor leh a component dangte pawh a tichhia thei a ni.

A tha ber: Lubrication level enfiah fo la, siamtuin a rawn rawt grease emaw oil emaw hman a nih leh nih loh enfiah la, lubricant bawlhhlawh chu thlak nghal rawh. Seal leh bearings enkawl leh enfiah dan pangngai chuan lubrication nena inzawm spindle overheating issue tam zawk a veng thei a ni.

Cooling system a that lohna .

CNC spindle hian hnathawh laiin lumna nasa tak a siam a, operating temperature him taka awm theihna turin cooling system tha tak a pawimawh hle bawk. Spindle hian a hmang thei a air cooling emaw liquid cooling emaw , mahse an pahnih hian unobstructed circulation-ah an innghat a, chu chuan a lumna a ti bo thei a ni.

Cooling efficiency tihtlem thei harsatna te chu:

vents block emaw filter bawlhhlawh emaw .

Dust, debris, emaw metal shavings emaw hian boruak ei emaw, exhaust emaw a tikhawlo thei a, boruak kal theihna a tikhawtlai a, heat dissipation a ti tlem thei bawk.

Coolant kalkawng a clogged te .

Liquid-cooled system-ah chuan mineral deposit, chips, emaw oil residue emaw chuan coolant luang chu a tikhawlo thei a, chu chuan a la lut thei lo va, a lumna a phur thei lo bawk.

Pump emaw fans emaw chhia .

Fans, pump emaw flow sensor-a mechanical failure hian coolant circulation emaw airflow emaw a titawp vek thei a, hei hian temperature a tisang rang thei hle.

Cooling system hian heat a remove tha thei lo a nih chuan issue engemaw zat a awm a:

Bearing leh motor windings a lum lutuk – Temperature tam lutuk hian wear a ti chak a, insulation a tichhia thei bawk.

Thermal expansion leh misalignment – uneven heating hian spindle components te chu rate hrang hrangin a tizau thei a, precision leh friction tihpunna a nghawng thei bawk.

Premature spindle failure – persistent overheating hian spindle life a ti tawi thei a, a nih loh leh thermal shutdown a trigger thei a, chu chuan chhiatna nasa tak a thlen thei lo.

Best Practice: Cooling system chu enkawl reng rawh—air filter leh vents te tifai la, coolant chu a recommend angin flush la, thlak la, pump leh fans te chu a hnathawh dan tur dik leh hman loh enfiah rawh. Spindle dam rei leh machining performance rintlak tak neih theihna turin unobstructed leh effective cooling enkawl hi a pawimawh hle.

A chhehvel boruak lum lutuk .

Spindle chu uluk taka enkawl a nih a, system zawng zawng a thawk tha vek lai pawhin, boruak lum lutuk chuan a lum lutuk thei a ni. workshop-a Spindle hian anmahni leh a chhehvel boruak inkar boruak lum leh vawt inthlauhna (temperature difference) a rinchhan a, chuvangin machine chhehvel boruak chu a lum tawh a nih chuan cooling efficiency a tlahniam a ni.

He harsatna thlentu thilte chu:

Ventilation tha lo .

Stagnant air hian heat hian workspace atanga a tlanchhuah loh nan a veng a, air-cooled spindles emaw fans emaw te thatna a ti tlem bawk.

Climate control awm lohna .

Air conditioning emaw, boruak kal dan tur dik lo emaw awm lovin, workshop-ah chuan spindle-a designed operating range aia sang temperature a thleng thei a ni.

Extended production run 10 a awm bawk.

Hun rei tak chhung boruak lum takah hna thawh chhunzawm zel a nih avangin active cooling system hmang pawhin lumna a pung thei a ni.

Ambient temperature sang lutuk avanga a rah chhuah te chu:

Reduced Cooling Efficiency – Spindle hian a lumna a chhuah thei lo va, a temperature chu a tlangpui aia rangin a tisang thei a ni.

Components-a thermal stress – bearings, motor windings, leh sensitive part dangte chu boruak lum leh vawt sang zel a awm chuan a chhe zawk a, a hlawhchham bawk.

Thermal shutdown awm thei – spindle tam takah chuan thermal protection built-in a awm a; Ambient heat tam lutuk hian shutdown a tichhuak thei a, production a titawp thei bawk.

Best Practice: Workshop ventilation tha tak neih theih nan, boruak lum zawk tan air conditioning emaw forced-air system ngaihtuah la, extended runs neih laiin spindle temperature enfiah bawk ang che. Airflow leh cooling lama hmasawnna tlemte pawh hian overheating risk nasa takin a tihziaawm thei a ni.

RPM tam lutuk emaw feed rate dik lo emaw .

Rotational speed sang (RPM)-a spindle hman dan tur chu material leh cutting tool atana feed rate dik taka siam that loh chuan heat nasa lutuk a siam thei a ni. Spindle leh tool hian inrem takin hna a thawk tur a ni: Material removal rate, spindle speed, leh feed rate te chu efficient cutting neih theih nan a inmil vek tur a ni.

Speed leh feed inmil lo avanga harsatna awmte chu:

RPM tam lutuk leh feed rate hniam .

Cutting tool hian a slicing ai chuan material chu a rub a, a faiin a rub a, friction leh heat a siam a ni.

Spindle speed pek tawh tan feed rate sang lutuk .

He hmanrua hian a thil siamah hian nasa lutukin a lai lut thei a, chu chuan spindle-ah extra load a dah thei a, temperature sang tak a tisang thei bawk.

A hlawk lo hle .

Speed leh feed inkawp dik lo hian chip formation tha lo a thlen a, chu chuan resistance leh friction a tipung a, spindle leh tool a ti lum zual bawk.

Heng thilte avanga thil thlengte chu:

Spindle Overheating – Friction leh load sang hian spindle temperature a tisang a, hei hian thermal protection a thlen thei a, a chhe reng thei bawk.

Tool wear leh failure – cutting tools dull fast faster under inefficient cutting conditions, chu chuan friction leh heat a tisang leh bawk.

Reduced Machining Accuracy – Spindle emaw workpiece emaw heat-induced expansion hian precision a tichhe thei a, surface finish leh tolerances a nghawng thei.

Best Practice: Material type, tool geometry, leh depth of cut hmanga spindle speed leh feed rates dik tak chhut thin ang che. Manufacturer guidelines emaw CAM software recommendation emaw hman hian overheating a veng thei a, spindle life leh machining quality te pawh a ti tam thei hle.

Bearings chhe tawh emaw, chhe tawh emaw .

Bearings hi CNC spindle-a thil pawimawh tak a ni a, rotation a thlawp a, a kal tluang leh a dik tak a nih theih nan a pui bawk. Bearings te chu a chhe tawh a, a chhe tawh a, a dik lo a nih chuan , an friction leh vibration additional an siam a, chungte chuan heat buildup a thlen thei a ni.

Bearing issue awm chhan tlangpui chu:

Hun kal zelah normal wear .

Bearings te hi naturally degrade in hun rei tak hman a ni a, a bik takin high loads emaw continuous operation hnuaiah a ni.

Thil bawlhhlawh .

Dust, chips, emaw moisture emaw chu bearing-ah a lut thei a, pitting, scoring, emaw corrosion emaw a thlen thei bawk.

Installation emaw alignment emaw dik lo .

Misaligned bearings hian load inang lo a siam a, friction leh heat a tipung bawk.

Bearing chhe tawh emaw, chhe tawh emaw avanga a rah chhuah chu:

Heat generation tihpun – degraded bearings atanga friction hian spindle temperature a tisang a, chu chuan component dang a wear a ti chak thei a ni.

Vibration tam lutuk – vibration hian machining accuracy a nghawng a, chu chuan surface finish tha lo leh dimensional error a thlen thin.

Spindle failure hlauhawmna sang zawk – Bearing damage a nasat chuan spindle hian a man thei a, thermal protection a nei thei a, a nih loh leh permanent mechanical damage a tuar thei bawk.

Best Practice: Spindle bearings te chu a chhe emaw, a chhe emaw a awm leh awm loh enfiah fo la, lubrication dik tak enkawl la, a siamtute rawtna angin bearings thlak rawh. Machining precision a lum lutuk loh nan leh machining precision a awm loh nan bearing operation mumal tak neih a pawimawh hle.

Motor chhunga electrical issue awm te .

Spindle motor hian electrical supply nghet tak leh internal components tha taka a thawh theih nan a innghat a, chu chuan a thawk tha thei hle. Electrical problems— ang chi voltage imbalances, faulty windings, emaw short circuit te —chuan motor chuan current tam lutuk a siam thei a, chu chuan motor chhung ngeiah pawh lumna a siam thei a ni.

Electrical lama harsatna awm tlangpui te chu:

Voltage inthlauhna a awm lo .

Motor phase hrang hranga voltage inang lo chuan current draw leh internal resistance a tipung a, additional heat a siam bawk.

Windings dik lo emaw, chhia emaw .

Insulation chhe tawh, shorted turn, emaw open circuit te hian motor efficiency a ti tlem thei a, operating temperature a tisang thei bawk.

Connection loose emaw drive chhia emaw .

Electrical connection tha lo emaw, VFD (variable frequency drives) tha lo emaw chuan spike emaw, irregular current emaw a siam thei a, chu chuan motor chu a ti stress thei a ni.

Electrical chungchanga harsatna awm thei te chu:

Rapid Heat Buildup – Excess current hian motor windings ah heat a siam a, chu chuan safe operating limits a pel nghal vat thei.

Motor insulation failure – Hun rei tak a lum lutuk hian insulation a tichhia thei a, short circuit emaw motor failure permanent emaw a thlen thei.

Reduced Spindle Lifespan – Electrical stress chhunzawm zel chuan bearing leh mechanical component dangte a ti chak a, hei hian overheating problem a tizual a ni.

Practice tha ber: Electrical connection enfiah fo la, current leh voltage level te enfiah thin la, VFD emaw drive system chu a thawk tha em tih enfiah thin ang che. Electrical imbalances siamthat hmasak hian motor a lum lutuk lo thei a, spindle a tichhia thei bawk.

CNC spindle a lum lutuk chhinchhiahna leh a lan chhuah dan .

Spindle overheating-a vaukhânna chhinchhiahna hmasa ber hriat chu chhiatna nasa tak leh downtime man to tak venna atan a pawimawh hle. Hengte hi a hman tlanglawn ber berte chu an ni:

Thil danglam tak tak thawm .

Grinding, squealing, emaw rattling sound te hian bearings te hi stress nasa lutuk hnuaia awm emaw, lubrication a hlawhchham emaw tih a tilang fo thin. Heat a lo pung zel a, metal components a zau a, bearings te chuan an smooth operation an hloh a, friction noise a siam a ni. Heng sound te hi spindle hian thermal stress a tawk tih hriattirna chiang tak a ni a, enfiah nghal tur a ni.

Thermal shutdown 10 a awm.

Tunlai CNC spindle tam takah chuan temperature sensor hmanga thuam a ni a, chu chuan temperature-in safe limit a pelh chuan automatic shutdown a thlen thei a ni. He feature hian machine a humhim laiin, thermal shutdown repeated emaw, frequent emaw chu red flag a ni a, i spindle chu a lum lutuk reng a ni. Heng shutdown te hi ngaihthah hian permanent motor emaw bearing emaw a tichhia thei a ni.

Spindle performance tih tlem a ni.

Overheating hian machining performance a nghawng nghal thei a ni. Cutting precision tlahniam, spindle speed slow zawk, emaw feed rates vawn that harsatna i hmu thei bawk. Heat hian critical components a tizau a, bearing efficiency a ti tlem a, vibration a tipung thei bawk—chu zawng zawng chuan accuracy a tichhe a, i machine effectiveness zawng zawng a ti tlem thei bawk.

Hmuh theiha inthlak danglamna emaw, kang rim emaw .

Khaw lum lutuk hian metal component emaw insulation material emaw a ti danglam thei. Spindle housing, motor, emaw bearings-a bluish emaw brownish hues i hmuh chuan hun rei tak chhung temperature sang tak a awm tihna a ni. A rim kang chu a chhunga thil awmte, winding emaw, lubrication emaw ang chite chu a chhiat phah thei tih tilangtu lian tak dang a ni bawk. Heng symptoms te hi catastrophic failure ven nan ngaihven nghal a ngai a ni.

Heng chhinchhiahnate hi ngun taka ngaihven a nih chuan, operator-te chuan boruak lum lutuk chu an man hmasa thei a, siamthatna man to tak tak an veng thei a, an CNC spindle dam chhung pawh an ti rei thei bawk.

CNC spindle overheating venna tur step-by-step guide

Spindle load enkawl dan .

Spindle chu a rated capacity chhungah operate fo thin ang che. Aggressive cuts, deep passes, emaw feed rate sang tak tak hmanga nawr nasat lutuk loh tur. Overloading hian friction leh heat nasa lutuk a siam a, chu chuan spindle chu rang takin a tichhia thei a ni.

Lubrication dik tak vawng reng rawh .

Spindle bearings awm leh awm loh enfiah leh enkawl reng thin ang che. Lubricant chi leh a zat dik tak hman a nih leh nih loh enfiah la, a tul angin thlak leh rawh. Lubrication bawlhhlawh emaw, tling tawk lo emaw chuan friction a tipung a, a lum lutuk a ti chak bawk.

Cooling system te enfiah leh enkawl dan .

I spindle-a cooling system—air-cooled emaw, liquid-cooled emaw pawh ni se—a thawk ṭha em tih enfiah rawh. Air vents tifai la, filter thlak la, coolant level check la, fans emaw pump emaw a thawk tha em tih enfiah rawh. Cooling system enkawl tha tak chu temperature control nan a pawimawh hle.

A chhehvel boruak lum leh vawt control .

Workshop boruak chu a lum leh boruak tha tak a awm reng tur a ni. Ambient temperature sang tak hian cooling system tan chuan lumna tihbo a ti harsa zawk a, a bik takin production run rei tak neih laiin a ti harsa zawk a ni. Air conditioning emaw, boruak luh dan dik emaw chuan hnathawh temperature him tak a vawng reng thei a ni.

RPM leh feed rates te chu a remchan dan angin siamrem theih a ni .

Material, tooling, leh machining operation hmanga spindle speed leh feed rates siam that. RPM sang tak takah chuan feed siamrem loha tlan chuan a tul lo heat a siam thei a, chutih laiin feed slow lutuk emaw, hlawk lo lutuk emaw chuan friction leh stress a siam thei bawk.

Bearings leh spindle components te enfiah fo thin ang che .

Bearings, shafts, leh mounting hardware te chu a chhe tawh em tih te, a misalignment te, a chhiatna te emaw a awm leh awm loh enfiah thin ang che. Bearing chhe tawh emaw, chhe tawh emaw chuan friction, vibration, leh heat buildup a tipung a ni. A chhe lutuk tih lanna part eng pawh chu a lum lutuk hmain thlak leh tur a ni.

Motor electrical health enfiah .

Spindle motor hian stable voltage leh current a dawng ngei ngei tur a ni. Electrical issues, shorted windings emaw voltage imbalances emaw ang chi te hian a chhunga lum lutuk a thlen thei a ni. Routine electrical inspection hian a lum lutuk loh nan a pui thin.

Temperature enkawlna kalpui dan tur .

thermal sensor emaw infrared camera emaw hmangin a hnathawh laiin spindle temperature enfiah thin ang che. Temperature sang chho hmasa ber hmuhchhuah hian chhiatna nasa tak a thlen hmain siamthatna tur a ti thei a ni.

Schedule routine preventive maintenance .

Vibration analysis, thermal imaging, lubrication check, leh spindle alignment inspection te pawh huam tel maintenance schedule siam rawh. Preventive maintenance hi emergency repairs aiin a man a tlawm zawk hle a, spindle performance mumal tak a awm theih nan a enkawl bawk.

Train operator te chuan warning sign hriat theihna tur .

Operator-te chu a lum lutuk chhinchhiahnate chu zirtir la, chutah chuan thawm danglam tak tak, an thawh dan tihtlem, rawng danglam, leh rim kang te pawh a tel. Early indicator-te chhanna rang tak chuan hlawhchhamna lian tham a veng thei a ni.

Heng step te zawm zel hian spindle overheating hlauhawmna nasa takin a tihziaawm thei a, i CNC machine dam chhung a ti rei thei a, machining quality mumal tak a vawng reng thei bawk.

Spindle dam rei theihna tur advanced tips .

Spindle load monitoring system hmanga

spindle load chu real-time-a enfiah thei sensor dah chuan thil awm thei turte hriattirna hmasa ber a pe thei a ni. Heng system-te hian torque, current, leh temperature te an track a, operator-te chu chhiatna nasa tak an thlen hmain dinhmun pangngai lo an hriattir thin. A hmaa hmuhchhuah hian a lum lutuk, mechanical stress leh beisei loh downtime a veng thei a ni.

Hna atana spindle dik thlan chu

spindle, power, speed, leh cooling capacity tling tak neia thlan chu a pawimawh hle a, cutting operation pawh a pawimawh hle. Hna thawh tur mamawh tak takte tana underpowered spindle hman hian overload tam tak a thlen thei a, a lum lutuk a, a dam rei lo thei bawk. Spindle specification te chu workload nena inmil tir hian performance leh rintlakna inang tlang a siam a ni.

Upgrading to better cooling solutions

for high-demand operations, cooling system tha zawka upgrade ngaihtuah rawh. Water-cooled spindles emaw advanced hybrid cooling technology hmangin standard air-cooled unit aiin operating temperature a hniam zawk thei a ni. Enhanced cooling hian bearing leh motor winding-a thermal stress a tihziaawm a, spindle life leh machining precision pahnih a ti tha bawk.

CNC spindle a lum lutuk vanga electrical vs. mechanical causes hriat theihna.

Electrical lama harsatna awmte chhinchhiahna .

Spindle overheating hi electrical problem atanga lo chhuak a ni thei a, a tam zawkah chuan spindle motor emaw a control system emaw, variable frequency drive (VFD) ang chi te nen a inzawm a ni. Heng thilte hian power delivery dik lo emaw, component failure emaw avanga lum lutuk a thlen thei a ni.

A lo kal zel a:

l Load hnuaia RPM emaw torque emaw inconsistent , VFD emaw motor control chungchanga harsatna awm thei te tarlanna.

L Sudden Power a tla thla a , chu chuan motor a ti na thei a, a lum thei bawk.

l Spindle motor a lum lutuk , touch emaw thermal imaging hmanga hmuh theih a nih fo.

l A rim emaw, wiring rawng danglam tak emaw a rim a , electrical arcing emaw short circuit emaw a awm tih a tilang.

Multimeter hmangin voltage leh amperage te chu a dik lo em tih enfiah tur a ni. Thermal imaging hmang hian motor emaw control board emaw a hot spot awm te chu a chiang thei hle. Electrical diagnostics lama tawnhriat nei lo i nih chuan professional zawt la. Grounding tha lo emaw brush chhe tawh (brushed motor-a) emaw hian overheating leh erratic performance a thlen thei bawk.

Mechanical failures chhinchhiahna .

Mechanical issues hi spindle overheating thlentu a ni tlangpui a, hei hi bearings, shafts, emaw collets ang chi components-a friction emaw improper alignment emaw vang a ni fo thin. Heng harsatnate hian a tlangpuiin symptom dang nen lum lutuk a siam chhuak thin.

Red flag hman tlanglawn tak takte chu:

l thawm ri bengchheng emaw, knock emaw, bearings chhe tawh emaw, misaligned components emaw a lantir. Spindle operation laiin

l vibration chu Z-axis emaw spindle head ah emaw a ni a , chu chuan friction leh heat a tipung a ni.

l Collets, tool holder, emaw motor mount-a taksa incheina , a hnathawh that lohna leh a lum lutuk theihna tur.

I CNC machine-in condition monitoring sensor a neih chuan, spike-te tan vibration emaw temperature logs emaw chu enfiah la, chu chuan mechanical issues a signal a ni. Routine inspection, loose fastener emaw gear chhe tawh emaw enfiah ang chi te hian harsatna a thlen hma thei a ni.

Mechanical failures hi a lo awm zauh zauh fo thin a, chuvangin proactive maintenance hi a lum lutuk leh siamthatna man to lutuk venna atan a pawimawh hle.

CNC spindle overheating diagnosis atana hmanrua leh technique hman dan

Stethoscope emaw vibration analyzer emaw hmangin .

CNC spindle overheat a nih chuan diagnostic tools hian a bulpui ber chu precision nen a hriat theih nan a pui thei a ni. Mechanic’s Stethoscope hi thil chiang tak tak, mahse a tangkai tak a ni a, thil chiang tak tak a ni. Probe chu spindle housing hmun hrang hranga dahin, aw pangngai lo, grinding emaw humming emaw, friction emaw component wear contributing to overheating emaw a lantir thei tih i ngaithla thei ang.

l Stethoscope : Motor atanga aw ri te, bearings te, gearbox te chu amplify rawh. Bearings bulah hian ri tam lutuk emaw, vibration emaw a awm tih hmuhchhuah a nih chuan friction emaw wear emaw a awm tih a tilang a, chu chuan heat buildup a thlen thei a ni.

l vibration Analyzer : Heng hmanrua te hian vibration amplitude leh frequency an teh a, imbalances, misalignment, emaw worn components te chu heat siamtu an ni tih an hmuchhuak a. Sensor hmasawn tak takte chuan thil chiang lo tak tak, a lum lutuk a thlen hmain an hre thei a ni.

Heng tools te hi smartphone apps nen pairing a, sound recording emaw frequency analysis emaw hmangin hun kal zelah data log leh track theih a ni. Hei hian predictive maintenance a support a, overheating issues te chu a escalate hmain a sutkian tir thin.

Thermal Imaging leh Temperature Profiling te pawh a awm bawk.

Thermal imaging hi spindle overheating diagnose na atana hmanraw pawimawh tak a ni. Infrared camera hian hot spot a hmuchhuak a, chu chuan bearings lum lutuk, motor windings emaw, spindle shaft-a friction emaw a pholang a ni. Quick scan hian machine tihchhiat lohvin harsatna awmna hmun a hre thei a ni.

l Thermal Cameras : Thermal display-ah hian hmun dum emaw, a dum emaw a awm a, chu chuan hnathawh dan pangngai aia lumna a tarlang a ni. Entirnan, hot bearing hian lubrication emaw wear emaw tling lo a nih thu a sawi.

l Temperature Profiling : Tuna temperature chhiar dan leh baseline 'healthy' profile nena khaikhin nan software hmang rawh. Condition monitoring sensor atanga temperature logs spike te hian overheating trends a nemnghet thei a ni.

Thermal imaging leh vibration analysis leh temperature profiling te inzawmkhawm hian overheating diagnosing tih dan kimchang tak a pe a ni. Hei hi a bik takin dawr busy tak tak, machine tam tak a ruala kal thinna hmunah a tangkai hle a, hei hian heat-related issues isolate a harsa zawk a ni. Heng hmanrua te hi hman fo hian a hmaa hmuhchhuah theihna a siam a, spindle failure man to tak tak a veng thei bawk.

Common CNC spindle overheating issues siam that dan tur .

Bearings thlak emaw, re-greasing emaw .

Bearings hi spindle overheating a ni fo thin a, chu chu wear atanga friction emaw, lubrication tling lo emaw a nih vang a ni. Bearing type (sealed emaw open emaw) leh maintenance mamawh hriat theih nan i machine manual kha en la.

l Re-greasing Open Bearings : Bearings te chu a inhawng a nih chuan precision grease gun hmangin grease quality sang tak, manufacturer-recommended hmang la. Overpacking hi pumpelh rawh, grease tam lutuk hian friction leh heat a tipung thei a ni. Spindle chu greasing hnuah rpm hniam takah run la, even distribution a awm theih nan, chutah chuan thermal camera emaw sensor hmangin temperature chu enfiah la, heat output tihtlem a nih leh nih loh enfiah rawh.

l Sealed bearings thlak : Sealed bearings ah hian a tlangpuiin thlak a ngai thin. Spindle housing chu uluk takin then la, a tul chuan bearing puller hmangin OEM-a siam bearing hmangin thlak leh rawh. Install zawhah spindle chu rpm hniam takah run la, bearings te chu settle la, chutah chuan thermal imaging tool emaw temperature sensor emaw hmangin operating temperature pangngai te chu a dik leh dik loh enfiah rawh.

Post-repair, vibration leh temperature logs te enfiah la, a chinfel theih nan. Bearings avanga overheating hi ngaihsak lohna atanga lo chhuak a ni fo thin a, chuvangin regular maintenance hi a pawimawh hle.

Spindle shaft chu realigning a ni.

Spindle shaft-a misalignment hian friction nasa lutuk a thlen thei a, a bik takin speed sang takah chuan a lum lutuk thei. Alignment dik tak chuan lumna a ti tlem a, component dam chhung a ti rei bawk.

l Alignment hmanrua : RPM hniam taka shaft runout tehna atan dial indicator emaw laser alignment kit emaw hmang ang che. Runout hian a siamtu tolerance a pelh chuan realignment a ngai a ni.

l Realignment Process : Spindle mount chu phelh la, uluk takin reseat rawh. Advanced CNC machine tan chuan alignment shims emaw a tul angin software settings te recalibrate emaw theih a ni. Toolholder, collet, leh chuck te chu a chhe emaw a chhe emaw a awm leh awm loh enfiah la, hengte hian misalignment a thlen thei a, lumna a tipung thei bawk.

l Post-alignment checks : Realignment zawhah component zawng zawng chu uluk takin tifai la, spindle chu load hnuaiah test rawh. Thermal imaging emaw temperature sensor emaw hmangin overheating chu tihziaawm a nih thu a nemnghet a ni.

Baseline thar din turin siamthat hnua temperature leh vibration reading te chu document rawh. Regular alignment check leh toolholder enkawl hian a lum lutuk tur a veng thei ang a, spindle operation awlsam leh tha tak a vawng reng thei bawk ang.

CNC spindle overheating atan professional koh hun tur .

I huam chin hriat chian .

CNC operator tawnhriat ngah tak takte pawhin spindle overheating issue-ah professional expertise an mamawh hunah an hriat a ngai. Basic maintenance chu bearings ropui tak tak emaw, tihfai nana hmanrua emaw ang chi i hmachhawn thei laiin, harsatna khirh tak tak—internal motor failure, spindle cartridge chhiatna, emaw, electrical faults advanced te ang chi—chuan specialized skills a tisang thei a ni.

Professional call a nih chuan:

l Basic fixes (eg, bearings re-greasing, shaft realigning, emaw electrical connection check) te chu a lum lutuk lo.

l Operation pangngai nei mahse temperature sang tak persistent i hmu a, hei hian motor winding failure emaw VFD malfunctions ang chi thil thuk zawk a awm tih a tilang.

l Diagnostic tools (thermal imaging, vibration analyzer) te hian anomalies i hrilhfiah theih loh leh i siam that theih loh a lantir a.

Professional-te chuan diagnostic equipment hmasawn tak tak an nei a, chu chu high-precision thermal scanner emaw specialized spindle testing rigs emaw, spindle design hrang hrang hmanga thiamna an nei a ni. Pro hiring hian hnehna a pawm lo—i machine performance leh dam rei theihna humhim tura hmalakna fing tak a ni.

Cost vs. Professional repairs atanga hlawkna .

Professional spindle siamthat man hi a sang hlein a lang thei a, mahse thiamna leh hmanrua dik tak nei lo complex fix tum chuan harsatna lian zawk a thlen fo thin. Mishandling components, bearings dik lo taka dah emaw, spindle dik lo emaw ang chi hian $500 repair chu $5,000 replacement-ah a escalate thei a ni.

Professional service hlawkna te chu:

l Expert Diagnostics : Technician-te chuan electrical fault thup emaw, standard shop tools-in a hmuh loh theih tur internal friction emaw ang chi thilte chu an hmu thei a ni.

L Warranties : Professional repair tam zawkah chuan guarantee a awm a, hun rei tak chhunga rintlak a nih theih nan a ni.

l Minimized Downtime : Service tam tak chuan i machine chu online-a rang taka an rawn let leh theih nan repairs rang tak an pe a.

l Resale value tihpun : Professional-te hnen atanga service history documented chuan i CNC machine market value a ti sang a.

Major issue nia rinhlelh chu nangmah ngeiin i hmachhawn hmain, professional repair man chu i machine uptime leh precision hlutna nen teh hmasa phawt ang che. A tam zawkah chuan thiamna leh rilru thlamuanna hi investment tling tak a ni.

Environmental factors te hian CNC spindle overheating a nghawng dan .

Humidity, leivut leh boruak lum leh vawt .

I CNC dawr chhunga boruak hian spindle health a nghawng nasa hle a, overheating a thlen thei bawk. Heng thilte hian friction a tizual thei a, components a tichhe thei a, hnathawh dan tur dik tak a tibuai thei bawk.

L Humidity : Humidity sang tak hian spindle housing chhungah condensation a thlen thei a, chu chuan bearings leh component dang dangah rust emaw corrosion emaw a thlen thei a ni. Hei hian friction a tipung a, heat tam lutuk a siam a, premature failure a thlen thei bawk.

L Dust leh Particulate Matter : Woodshop emaw metal-grinding facility ang chi environment-ah chuan leivut hian spindle motor chhungah a lut thei a ni. Grease nena an inhmeh chuan dust hian abrasive compound a siam a, chu chuan bearing leh seal a ti chhe a, friction leh heat buildup a tipung a ni.

L Temperature Swings : Khaw lum hian grease a ti thick a, a lubricating effectiveness a ti tlem a, friction leh heat sang zawk a thlen bawk. Hot condition-ah chuan thermal expansion hian spindle shaft chu a misalign thei a, lubricants pawh a chhe rang zawk thei a, a lum lutuk thei bawk. Khaw lum lutuk hian motor windings a stress thei bawk a, temperature sang tak a thlen thei bawk.

Mitigation strategy te: 1.1.

l Dust collector leh air filtration system te chu particulate infiltration tih tlem nan dah rawh.

l Climate control system hmang la, humidity leh temperature level nghet tak neih theih nan.

l Spare part leh lubricant te chu hmun fai, vawt, temperature-a control theihah dah tur a ni.

l Dust buildup awm loh nan leh lubrication dik tak neih theih nan spindle components te chu enfiah leh tihfai fo thin ang che.

Machine dah leh vibration isolation .

I CNC machine physical placement hian spindle overheating a nghawng thei a, pawn lam atanga vibrations emaw heat transfer emaw amplifying a ni.

l Uven Surfaces : Floor inang lo tak takah chuan machine-te chuan misalignment an tawk thei a, chu chuan spindle chu a thawkrim zawk a, lumna a siam tam zawk thei bawk. Unstable base atanga vibrations hian bearings leh component dangte friction a tipung thei bawk.

L Hmanraw dang hnaih : CNC machine chu machine rit tak tak, press emaw lathes emaw bulah dah chuan pawn lam vibrations a rawn luh tir thei a, chu chuan spindle chu a stress a, chu chuan friction emaw misalignment emaw atanga lumna a tipung thei a ni.

l Heat Sources : Machine-te chuan heat-generating equipment hnaih emaw, ni êng direct-a dah emaw chuan boruak lumna sang zawk a tawk thei a, chu chuan spindle a ti lum lutuk a ni.

Mitigation strategy te: 1.1.

l Misalignment nena inzawm heat tih tlem nan precision bubble level emaw laser level emaw hmangin machine chu level a nih leh nih loh enfiah rawh.

l CNC hnuaia vibration isolation mounts emaw dampers emaw dah la, pawn lam vibration absorb la, spindle-a stress tihziaawm rawh.

l Machine chu hmanraw rit tak tak emaw, lumna hmun emaw atanga hla takah dah la, chu chuan floor kal tlanga vibration transfer emaw, ambient temperature sang emaw a awm loh nan.

l Machine chu pawn lam lumna atanga venhim nan thermal barrier emaw enclosure emaw hmang rawh.

Environmental factors control leh machine placement optimize hmang hian spindle overheating a tihtlem thei a, operational efficiency a ti tha thei a, i CNC equipment te dam chhung pawh i ti rei thei bawk. Thermal imaging emaw temperature sensor hmanga enkawl fo chuan boruak nena inzawm thil chhinchhiahna hmasa ber hriat theihna a siam thei a ni.

CNC spindle overheating atan chuan siamtute rawtna i ngaihthah loh tur a ni.

Manual ngun taka chhiar .

CNC spindle manual skip hi thil tihsual man to tak a ni. I spindle model nena inmil information pawimawh tak tak nen a khat a, operating temperature, lubrication schedule, coolants inmil, leh maintenance procedure hrang hrangte specification te pawh a awm bawk. Heng chipchiar tak takte ngaihthah hian a lum lutuk leh hun rei tak chhunga chhiatna a thlen thei a ni.

l Key Details : Manual hian lubrication type dik tak (eg, oil mist, packed grease, emaw self-lubricating ceramic bearings), cooling mamawh, leh torque setting te a tarlang a. Lubricant dik lo emaw coolant emaw hman hian friction leh heat buildup a tipung thei a ni.

l Maintenance Guidelines : Heat tam lutuk setup emaw wear emaw a awm loh nan tihfai, bearing maintenance, leh component preload tih dan tur zawm tur a ni.

l Troubleshooting Tips : Manual-ah hian error code emaw, temperature threshold emaw a awm fo thin a, chu chuan overheating issues te chu a hmain a hriat theih nan a pui thin.

I dawrah awlsam taka reference theih turin key maintenance pages print leh laminate rawh. Hei hian boruak lum leh vawt inthlak danglam zel tur leh siamthatna man to tak tak awm loh nan siamtute kaihhruaina i zawm tih a tichiang a ni.

Load leh speed kaihhruaina zawm .

Spindle chu a recommended load emaw rpm limits aia tam a nih chuan a lum lutuk a, a lum lutuk a ni. Overloading emaw overspeeding emaw hian lum lutuk a siam a, components a stress a, wear a ti chak bawk.

L Load Limits : Spindle torque emaw cutting load capacity aia tam chuan motor a ti na thei a, chu chuan a lum lutuk a, shaft emaw bearings tihchhiat emaw a thlen thei bawk.

L Speed Limits : A rated RPM aia sang spindle run hian bearings-ah friction a tipung a, lum lutuk a siam a, motor winding failure emaw lubricant breakdown emaw a thlen thei.

L Monitoring Tools : I CNC controller software hmangin real-time spindle load, speed leh temperature te chu track la. System tam tak chuan threshold him tak tak pelh theihna tur alarm set theihna a siam a, chu chuan overheating a veng thei a ni.

Thil tih dan tha ber berte:

l Heat generation tih tlem nan a siamtuin a tarlan RPM leh load limits te chu stick rawh.

l Cooling system (eg, air emaw liquid cooling) te chu manual-in a rawt angin an thawk tha em tih enfiah fo thin ang che.

l Condition sensor emaw thermal imaging hmanga temperature logs te chu deviation te man hmasa turin enfiah thin ang che.

Heng kaihhruainate zawm hian heat-related stress a tihziaawm a, a lum lutuk tur a veng a, i spindle dam chhung a ti rei a, i CNC machine chu a kal tluang a, a ti tha bawk.

Tawpna

I CNC spindle-a overheating hi ngaihven a ngai tih hriattirna chiang tak a ni. Bearings chhe tawh vang emaw, misalignment emaw, electrical fault emaw, environmental factors emaw avanga lo awm a nih pawhin, ngaihthah a nih chuan a lo zual zel thei tur thil awmsa heat signal tam lutuk. Left unchecked, overheating hian component a tichhia thei a, repairs man to tak tak a thlen thei a, downtime nasa tak a thlen thei bawk.

Thermal imaging, vibration analyzer, leh stethoscope ang chi diagnostic tools thiam tak tak te, leh maintenance, load, leh speed atana siamtute kaihhruaina zawm te hian harsatna i man hma thei a, i spindle chu a kal tha thei bawk. Environmental control leh machine dah dan dik tak chuan heat-related issues awm theihna a ti tlem lehzual a ni.

I spindle hi i CNC machine thinlung a ni. Proactive care hmangin humhim la, chu chuan rintlak, hun rei tak chhunga hnathawh theihna a pe ang che.

FAQS 1000 a ni.

CNC spindle atan hian eng operating temperature tha ber nge awm ang?

Spindle tam zawk hi 40°C leh 60°C (104°F–140°F) inkarah a tha berin an thawk a, mahse a siamtute specifications en rawh.

Ka spindle hi engzat nge ka lubricate ang?

Lubrication frequency hi hman dan leh siamtute kaihhruainaah a innghat a, a tlangpuiin operating hour 500–1,000 danah a innghat a ni.

Overheating hian chhiatna nghet tak a thlen thei em?

Ni e, hun rei tak a lum lutuk chuan bearings, motor, a nih loh leh component dang a tichhia thei a, chu chuan siamthatna emaw, thlak danglamna emaw man to tak tak a thlen thei a ni.

Tui lum hi air cooling aiin a tha zawk em?

Tui lum hi high-speed emaw heavy-duty emaw hmanna atan a tha zawk a, mahse air cooling hi a awlsam zawk a, hna light zawk atan chuan a tawk bawk.

CNC spindle pakhat dam rei zawng chu engzat nge ni ang?

Maintenance dik tak nen chuan spindle te hi hman hun chhung darkar 10,000–20,000 chhung a daih thei a, hman dan leh a awm dan azirin a awm thei bawk.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu