Yu CNC mashin de rɔn hot pas aw yu kin du am? Dat smɔl wam we yu de krep insay wan wam wam wam wam wam wam wam wam wam wam wam wam wam wam wam wam wam wam wam wam wam wam tin dɛn, dat kin bi siriɔs wɔnin sayn—ɛn i nɔto sɔntin we yu go ebul fɔ pe fɔ. Wan spindle we de ɔt pasmak nɔto jɔs smɔl prɔblɛm; Na signal se sɔntin we nɔ rayt, ɛn if dɛn nɔ pe atɛnshɔn to am, i kin mek di kɔmpɔnɛnt dɛn we dɔn pwɛl, ridyus di we aw dɛn de mek di mashin kɔrɛkt, mek dɛn ripɛnt dɛn, ɔ ivin kɔmplit di mashin dɛn we nɔ wok.

Insay dis gayd, wi go waka yu tru ɔl wetin yu nid fɔ no bɔt CNC spindle ɔva ɔt—frɔm fɔ no di sayn dɛm we de wɔn yu kwik kwik wan fɔ pinpoint di rut kɔz dɛm ɛn tek prɛktikal step dɛm fɔ fiks ɛn protɛkt am. If yu na mashin ɔpreshɔn, mentenɛns tɛknishian, ɔ CNC zil we want fɔ protɛkt yu ikwipmɛnt, dis na yu ɔltimate risɔs fɔ kip yu spindle kol, efishɔnal, ɛn fɔ lɔng tɛm.

Lɛ wi tɔn dɔŋ di ɔt ɛn kip yu prodakshɔn de rɔn na pik pefɔmɛns!

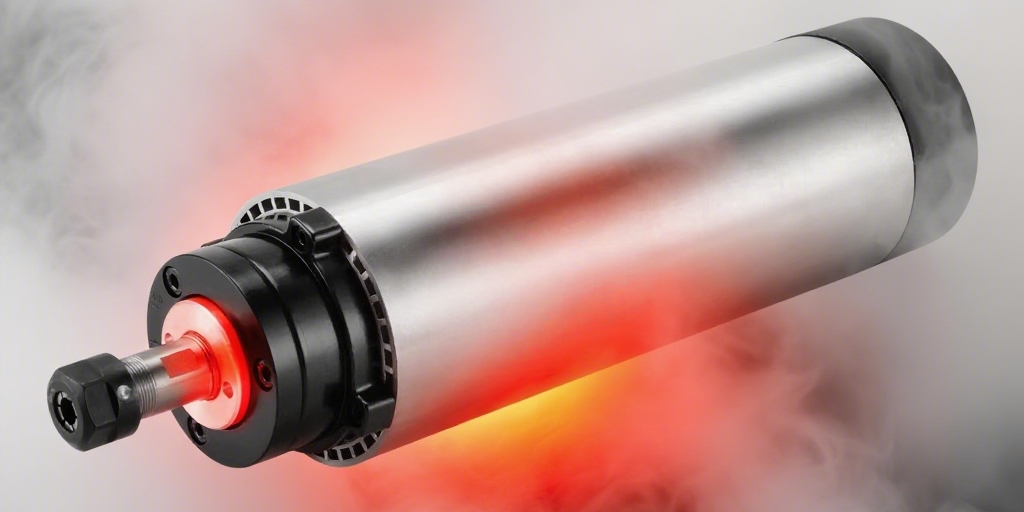

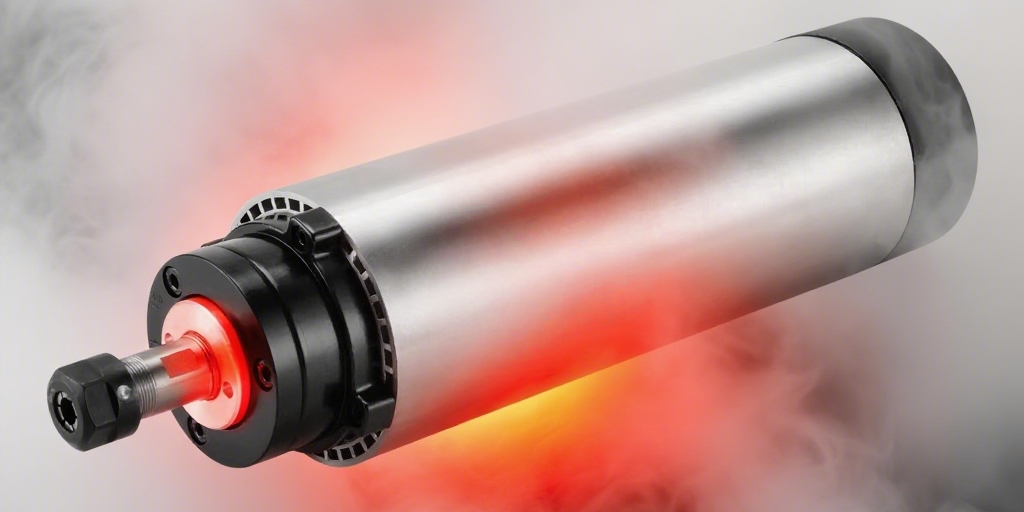

Introdyushɔn to CNC Spindle Motors .

Wetin na CNC spindle moto?

Na di at fɔ ɛvri CNC mashin na in spindle moto. Dis impɔtant pat de gi pawa to di tul dɛn we dɛn de kɔt ɛn mek di mashin ebul fɔ drɔ, kɔt, mil, ɛn shep di tin dɛn we dɛn yuz fɔ mek di mashin wit prɛsishɔn. As di kɔr fɔ di mashin in ɔpreshɔn, i de kɔntrol spid, tɔk, ɛn ɔvalayn pefɔmɛns—we de mek in rilaybiliti impɔtant to kɔnsistɛns prodakshɔn.

Dɛn mek spindle moto dɛn insay difrɛn sayz dɛn, spid, ɛn pawa retin dɛn dipen pan di aplikeshɔn, ilɛksɛf na wud wok, mɛtal wok, ɔ mashin kɔmpɔzit dɛn. I nɔ mata di matirial, di spindle fɔ wok insay sef tɛmpracha limit fɔ mek i kɔntinyu fɔ kɔrɛkt ɛn fɔ mek i liv lɔng.

Tink bɔt am lɛk di injin we de na yu motoka—if i bigin fɔ rɔn tumɔs, na wɔnin we yu nɔ go ebul fɔ ignore. If yu wam pasmak insay wan spindle, dat kin mek di bia dɛn nɔ wok, di lɔbrikeshɔn kin brok, ɛn di tɛmal ɛkspɛnshɔn kin trowe di mashin dɛn we dɛn kin yuz fɔ mek dɛn ebul fɔ bia wit di mashin dɛn. Wan kol-rɔn spindle jɔs min se i go wok fayn fayn wan; Di tɛmpracha we de go ɔp fɔ mek pipul dɛn pe atɛnshɔn kwik kwik wan.

We yu ɔndastand aw di spindle de wok ɛn wetin de mek i kol de gi yu big advantej we sɔntin fil 'Off.' Dis inklud fɔ no di wok we in bia, motoka wayndin, kol sistɛm, ɛn os—ɔl dɛn tin ya kin afɛkt bay we yu de ɔt pasmak ɛn mek yu gɛt siriɔs pefɔmɛns prɔblɛm if dɛn nɔ chɛk am.

Impɔtants fɔ spindle wɛlbɔdi na CNC mashin dɛn .

Yu CNC mashin na onli as gud lek in spindle. We spindle ova hot, i nɔ jɔs bi di motoka we yu de risk; I kin mek dɛn pwɛl, dɛn kin gɛt bɔku bɔku pat dɛn, dɛn kin pul pat pan dɛn, dɛn kin mis di de dɛn we dɛn fɔ dɔn, ɛn di tin we bad pas ɔl na dat—i kin tek tɛm fɔ mek dɛn nɔ gɛt di rayt fɔ du dat.

Bɔku tɛm, di tɛmpracha we de go ɔp kin bi di fɔs sayn dɛn we de wɔn pipul dɛn. Wan spindle we wam smɔl tide kin tɔn to motoka we dɔn bɔn tumara. We yu de wach di ɔt lɛvɛl ɛn adrɛs di kɔz kwik kwik wan, yu kin sev bɔku bɔku ripɛnt ɛn avɔyd kɔmplit spindle riplesmɛnt dɛn.

Dɔn bak, tink bɔt dis: Wan spindle we de ɔt pasmak nɔ de sɔfa in wan—i de put ɛkstra strɛs pan ɔda pat dɛn na yu mashin, frɔm di drayv sistɛm to di say dɛn we de mek di ples kol. Na chen riakshon yu definitli no wan set in moshon.

Spindle tempɔret kɔntrol na mɔ pas jɔs pefɔmɛns—na sef, prodaktiviti, ɛn prɔfitabiliti ɔl insay wan. Na dat mek fɔ ɔndastand di kɔz ɛn prɛvɛnshɔn fɔ ɔva ɔt nɔto opshɔnal; I impɔtant.

Di CNC spindle: Yu mashin in pawa kɔr .

Di spindle nɔto jɔs ɔda pat—na di sɛntrɔm pat pan yu CNC mashin. We i de rɔn na di rayt tɛmpracha, yu opareshɔn dɛn de flɔ fayn fayn wan. We i de ɔva ɔt, ɔltin bigin fɔ brok. Dis komponent de drɛb di tul dɛn we dɛn de kɔt, i de shep yu matirial dɛn, ɛn i de mentɛn prɛsishɔn—we de mek in tɛmpracha kɔntrol impɔtant fɔ mek i wok fayn.

Di kost fɔ spindle failure .

Ova ɔt nɔ jɔs slo prodakshɔn—i de pwɛl am. Di ɔt we pasmak kin mek:

L Biɛrin fɔl .

l W ɔ rp spindl k ɔ m ɔ n ɛ nt dɛn .

l Digrɛd lɔbrikeshɔn .

l Scraped matirial dɛn .

L Mis Projekt Dedlayn dɛn .

l Di wan dɛn we de mek di imejensi we go tek bɔku mɔni .

l we dɛn nɔ bin de ɛkspɛkt mashin dawt tɛm .

Evri minit yu spindle de ron tu hot na moni lost. Fɔ kip am kol nɔto opshɔnal—i impɔtant.

Sayn dɛn we de wɔn yu kwik kwik wan .

Bɔku tɛm, tɛmpratura spayk na di fɔs sayn fɔ trɔbul. Wan spindle we de wam smɔl tide kin bi motoka we dɔn bɔn tumara. If yu ɔt di lɛft we yu nɔ chɛk yu, dat kin mek yu gɛt:

l Ful spindle riplesmɛnt .

l Ekstend mashin dauntaym .

l Damej to ɔda intanɛnt kɔmpɔnɛnt dɛn .

Fɔ kech ɔt prɔblɛm dɛn kwik kwik wan de sev mɔni, mek dɛn nɔ brok, ɛn kip di prodakshɔn pan schedule.

Aw ɔva ɔt de afɛkt yu ɔl CNC sistɛm .

Wan hot spindle nɔ jɔs de pwɛl insɛf—i de strɛs di wan ol mashin.

l bearings degrade fasta .

l Lubrikant dɛn de brok dɔŋ .

L Drayv sistem dɛn de wok tranga wan .

l Ilektrikal komponent dɛn we de ɔva ɔt .

l T ɛ rml ɛksp ɛ nsh ɔ n trowe ɔf tul alayns .

Dis chen riakshכn kin mek di sistεm-wayd fεil. Preventativ temperechur kɔntrol na yu bɛst difens.

Maksimayz mashin layfspan wit rɛgyula tɛmpracha chɛk .

Rutin spindle temperechur monitarin na impɔtant tin. Jɔs sɔm minit kin mek dɛn nɔ spɛn bɔku bɔku mɔni fɔ mek dɛn ripɛnt. Skedul ɔltɛm:

l T ɛ rm ɔ l Imajin Inspekshɔn dɛn .

L Coolant sistem chɛk dɛn .

l Airflow ɛn fan mentenɛns .

l temperechur sensor kalibreshɔn .

Prɛvenshɔn ɔltɛm kin kɔst smɔl pas fɔ wɛl.

Boosting prodaktiviti tru kol efisiensi .

Wan spindle we dɔn kol fayn fayn wan kin kɔt klin, fast, ɛn i kin wok fayn fayn wan. Dis kin mek:

L Saykl tɛm dɛn .

L Pat Kwaliti .

l Tul lɔng layf .

L Ovalayn mashin pefɔmans .

If yu want mɔ pat pan awa, stat bay we yu kɔntrol di spindle tɛmpracha.

Spindle Cooling = Opereta sefty

Spindles we dɔn ɔt pasmak nɔto jɔs mɛkanikal risk—dɛn na sefty hazad. Di ɔt we pasmak kin:

l Kɔz wantɛm wantɛm we gɛt sik dɛn we de mek pɔsin sik .

l Lid to tul we dɛn nɔ bin de ɛkspɛkt fɔ brok .

l Krio erratic mashin bihevior .

We yu kip yu spindle kol, i de protɛkt ɔl tu yu ikwipmɛnt ɛn yu tim.

Ɔndastand di ɔt signal dɛn .

Masin dɛn kin tɔk tru chenj dɛn na di tɛmpracha. Lan fɔ no:

l gredual temperechur krep .

l Rapid spayk dɛn we dɛn de kɔt ebi ebi wan .

L Cooling System Inefisiɛns .

l Ɔnusual ɔt rawnd bia ɔ haus .

Ɛni patɛn de tɛl wan stori—we de kech am kwik kwik wan de mek shɔ se i de wok fayn, i go wok fayn.

Ekstend tul layf wit tɛmpracha stebiliti .

Eksεs Hεt de sכt di tul layf. Ova ɔt kin kɔz:

l dull cutting edges .

l Fɔ chenj di tul ɔltɛm .

l Di kɔt dɛn we nɔ kɔrɛkt .

l Poor surface finishes .

Wan tempɔret-stebul spindle de mek shɔ se ɛvri tul de du in bɛst.

Kɔmɔn kɔz dɛm fɔ CNC spindle ɔvahit

| Kɔz |

Diskripshɔn |

| Ovalod di spindle . |

If yu kɔt am pasmak ɔ we i de wok fɔ lɔng tɛm pas di kapasiti, dat kin mek i wam pasmak, ɛn i kin mek di motoka ɛn di bia dɛn strɛch. |

| Poor lubrication ɔ lɔbrikɛshɔn nɔ wok . |

Inadequate ɔ improper lubrication de inkrisayz frikshɔn insay bia, we de mek ɔt bildup ɛn aksɛleret wear. |

| Cooling system inefisiɛns dɛn . |

Filta dɛn we dɔn lɔk, lɔw kɔlant lɛvɛl, ɔ pɔmp dɛn we nɔ de wok fayn kin ambɔg di ɔt dissipeshɔn na di sistɛm dɛn we dɛn kin kɔl wata. |

| Di tɛmpracha we de na di ay ambiɛnt . |

We yu de wok na say dɛn we nɔ gɛt bɛtɛ ventilated ɔ we gɛt ay tempɔret, dat kin mek di spindle ebul fɔ shed ɔt. |

| pasmak rpm ɔ nɔ fayn fid rɛt . |

Ay RPM ɔ mismatched fid ret de inkrisayz ɔt jenɛreshɔn ɛn strɛs kɔmpɔnɛnt. |

| di bia dɛn we dɔn pwɛl ɔ we dɔn pwɛl . |

Worn bearings de mek adishanal frikshɔn, we de mek ɔt ɛn risk katastrofik fayl. |

| Ilektrikal ishu dɛn na di motoka . |

Fɔlt waya, vɔlɔt fluktueshɔn, ɔ moto nɔ wok fayn kin mek i ɔva ɔt ɛn nɔ ebul fɔ wok fayn. |

Ovalod di spindle .

Ovalod de apin we dɛn fos di spindle fɔ wok pas di pefɔmɛns limit dɛn we di wan we mek am dɔn spɛsifa. Dis kin apin difrɛn we dɛn:

We dɛn de kɔt di tin dɛn we at ɔ we gɛt bɔku bɔku tin dɛn fɔ du .

Fɔ ɛgzampul, mashinin bin mek i at fɔ mek stɛl ɔ ɛkzotik alɔy dɛn we gɛt spindle we dɛn mek fɔ sɔft tin dɛn lɛk aluminiɔm ɔ wud. Di inkrεs rεsistεns de jεnarεt mכr tכk dimand, we de lid to big hεt bildup.

tek di kot dɛn we dip pasmak .

Wan dip pas de pul mɔ matirial fɔ ɛni rivɔlɔshɔn, we nid mɔ kɔt fɔs. Dis nɔ jɔs de inkrisayz di lod pan di spindle moto bɔt i de mek mɔ frikshɔn na di tul-wokpies intafɛs.

Yuz ova ay fid ret .

We di fid ret tu fast fɔ di spindle spid ɛn tul kapabiliti, di kɔt ed de fɔs fɔ plɔg tru matirial instead fɔ klin slais am. Dis kin mek di vaybreshɔn we pasmak, strɛs, ɛn ɔt.

Di kɔmbaynshɔn fɔ dɛn tin ya de put mɛkanikal strɛs pan di spindle bia, moto wayndin, ɛn drayv kɔmpɔnɛnt dɛn. As tɛm de go, dis kin mek:

Aksɛlɛrat bia wear frɔm ɛksɛs raydial ɛn akshal lod.

Tεmכl εkspεnsכn fכ intanal pat dεm, we kin mek dεn nכ alayf כ inkrεs frikshכn.

Ilektrikal ovalod fɔ di spindle moto, risk insulation brekdaun ɛn winding damej.

If bad bad tin apin, if yu ɔvalod, dat kin mek di spindle trip pan tɛm we di tɛmal ɔvalod protɛkshɔn, stɔl de we yu de wok, ɔ we yu de sɔfa fɔ ɔltɛm we di motoka ɛn di bia dɛn de pwɛl.

BƐST Praktis: Ɔltɛm mach yu kɔt paramita dɛn—matirial tayp, spindl spid, fid rit, ɛn dip fɔ kɔt—to di spindle in rayt spɛsifikɛshɔn dɛn. If yu yuz di rayt tul ɛn mek shɔ se shap kɔt ed dɛn kin ridyus di lod bak bɔku bɔku wan.

Poor lubrication ɔ lɔbrikɛshɔn nɔ wok .

Di spindle in bia ɛn ɔda muv kɔmpɔnɛnt dɛn de rili abop pan di rayt lɔbrik fɔ wok fayn fayn wan. Lubrikeshɔn de sav tu impɔtant tin dɛn: fɔ ridyus frikshɔn bitwin mɛtal sɔfays ɛn ɛp fɔ dissipate ɔt we dɛn de mek we dɛn de wok.

We di lɔbrik nɔ rich, dɛn kin kɔntamin, ɔ ɔl di prɔblɛm dɛn nɔ kin apin , sɔm prɔblɛm dɛn kin apin:

Insufisɛnt lɔbrikeshɔn .

If di spindle nɔ gɛt inof gris ɔ ɔyl, di mɛtal-to-mɛtal kɔntakt de go ɔp, i de mek di ɔt pasmak ɛn aksɛleret wɛr.

Kɔntaminɛt lɔbrikeshɔn .

Dɔti, mɛtal sheb, ɔ mɔstɔ na di lɔbrik kin wok lɛk abraziv, skrach bia sɔfays ɛn imped smol smol roteshɔn.

Lubrikeshɔn lik ɔ neglek .

As tɛm de go, dɛn kin fɔgɛt bɔt di sil dɛn, ɔ dɛn kin fɔgɛt bɔt di tɛm we dɛn fɔ mek di say dɛn we dɛn dɔn pwɛl, ɛn dis kin mek dɛn nɔ gɛt bɔku lɔbrik smɔl smɔl. If yu nɔ gɛt di rayt lɔbrik, frikshɔn de go ɔp kwik kwik wan.

Di bad tin dɛn we kin apin we pɔsin nɔ gɛt bɛtɛ lɔbrik na:

Rapid Heat Buldup – Fɔ frikshɔn pasmak kin chenj mɛkanikal ɛnaji to ɔt, fɔ rayz spindle tɛmpracha kwik kwik wan.

Biɛrin wear ɛn damej – Frikshɔn de pwɛl bia sɔfays, we kin mek yu gɛt pit, skɔ, ɔ ivin bia sik.

Spindle failure – Insay ekstrim kes, di bearings kin lok op entirely, we kin mek di spindle stop wan wan en potentially damaging di moto en oda komponent dem.

Di bɛst we fɔ du am: Chek ɔltɛm chɛk di lɔbrikɛshɔn lɛvɛl, mek shɔ se yu yuz gris ɔ ɔyl we di wan we mek am tɛl yu fɔ yuz, ɛn chenj di kɔntaminɛt lɔbrikant kwik kwik wan. Rutin mentenɛns ɛn inspekshɔn fɔ sil ɛn bia kin mek dɛn nɔ gɛt bɔku prɔblɛm dɛn we gɛt fɔ du wit di lubrikeshɔn we gɛt fɔ du wit di lubrik.

Cooling system inefisiɛns dɛn .

Wan CNC spindle de jenarayz signifyant ɔt we dɛn de wok, ɛn wan ifɛktiv kɔling sistɛm impɔtant fɔ mek dɛn kɔntinyu fɔ gɛt sef ɔpreshɔn tɛmpracha. Spindles kin yuz ay kol ɔ likwid kɔling , bɔt dɛn ɔl tu de abop pan unobstructed sirkuleshɔn to dissipate ɔt.

Prɔblɛm dɛn we de ridyus di kol efyushɔn na:

vent dɛn we dɛn dɔn blok ɔ dɔti filta dɛn .

Dɔst, dɔti, ɔ mɛtal sheb kin mek yu nɔ ebul fɔ waka ɔ yu kin mek di briz kɔmɔt insay di briz, ɛn dis kin mek di briz nɔ flɔ ɛn i kin mek di ɔt nɔ de kɔmɔt fayn.

Kloged kulant pasej dɛn .

Insay likwid-kul sistɛm, minral dipɔsit, chips, ɔ ɔyl rɛsɛdyu kin ambɔg di flɔ we di kɔlant de flɔ, we de mek i nɔ ebul fɔ absɔb ɛn kɛr ɔt.

Faulty pumps ɔ fans .

Di mɛkanikal fayl na di fans, di pɔmp, ɔ di flɔ sɛns kin stɔp di kɔlant sirkuleshɔn ɔ di ayflɔ ɔltogɛda, we kin mek di tɛmpracha go ɔp kwik kwik wan.

We di kɔling sistɛm nɔ ebul fɔ pul di ɔt fayn fayn wan, sɔm tin dɛn kin apin:

Ova ɔt ɔf bia ɛn moto wayndin – pasmak tɛmpracha kin aksɛlayt wɛr ɛn i kin damej insuleshɔn.

tεmral εkspεns εn misalaynmεnt – we dεn nכ ivin hεt kin mek spindl kכmכpכnt dεm εkspεnd pan difrεnt rεt, we de afekt prεsishכn εn inkrεs frikshכn.

Premature spindle failure – persistent overheating kin shɔt spindle layf ɔ trig thermal shutdowns fɔ mek katastrofik damej nɔ pwɛl.

Di bɛst we fɔ du am: Mek di kɔling sistem kɔntinyu fɔ de ɔltɛm—klin ɛya filta ɛn vent, flush ɛn riples di kɔlant lɛk aw dɛn se, ɛn inspɛkt pɔmp ɛn fan dɛn fɔ mek dɛn ebul fɔ wok fayn fayn wan. Fɔ mek shɔ se di kɔl we nɔ gɛt ɛnitin fɔ ambɔg am ɛn we go wok fayn na impɔtant tin fɔ mek spindle lɔng layf ɛn fɔ mek pɔsin ebul fɔ du am fayn fayn wan.

Di tɛmpracha we de na di ay ambiɛnt .

Ivin we dɛn de mentenɛt wan spindle fayn fayn wan ɛn ɔl di sistem dɛn de wok kɔrɛkt wan, di ay ambiɛnt tɛmpracha na di wokshɔp kin mek i wam pasmak. spindl dεm de dip pan tεmprachכ difrεns bitwin dεn sεf εn di envayroment we de rawnd fכ dissipate hεt, so if di briz we de rawnd di mashin dεm dכn כlrεdi wam, dεn de rεdכks di kol efyushכn.

Di tin dɛn we kin mek dis prɔblɛm apin na:

Di ventilashɔn we nɔ fayn .

Stagnant air de mek di ɔt nɔ ebul fɔ rɔnawe pan di wokples, ɛn dis kin mek di spindles ɔ di fan dɛn we gɛt ay-kɔl nɔ wok fayn.

Lak fɔ kɔntrol di klaymat .

If yu nɔ gɛt ɛya kondishɔn ɔ di rayt we fɔ flay, wokshɔp kin rich di tɛmpracha we pas di spindle in dizayn opareshɔn rɛnj.

Ekstend prodakshɔn rɔn dɛn .

Lכng tεm dεm we dεn de kכntinyu fכ wok na hot envayroment de alaw hכt fכ akכmyuleyt, ivin wit aktv kכl sistεm dεm.

Di tin dɛn we kin apin we pɔsin gɛt ay ambiɛnt tɛmpracha na:

Ridyus di kol efyushɔn – di spindle nɔ kin ebul fɔ shed ɔt as effectively, we kin mek in tɛmpracha go ɔp fast pas nɔmal.

Tεrmεl strεs pan kכmכpכnt dεm – bia, mכtalman wayndin, εn כda sεnsitiv pat dεm kin mכr pron fכ wear εn fεil we dεn εkspכz to sustayn ay tεmprachכ.

Posisibul thermal shutdown – Bɔku spindles gɛt bilt-in tɛmral protɛkshɔn; Eksεsiv ambient hεt kin trigεr shutdown, intarapt prodakshכn.

Di bɛst we fɔ du am: Mek shɔ se di wokshɔp ventilashɔn go fayn, tink bɔt ay kɔndishɔn ɔ fɔs-ɛya sistem fɔ di ples dɛn we hot, ɛn wach di spindle tɛmpracha we dɛn de rɔn fɔ lɔng tɛm. Ivin smɔl smɔl tin dɛn we dɛn kin du fɔ mek di briz go bifo ɛn fɔ mek di ples kol kin ridyus di prɔblɛm dɛn we kin mek pɔsin nɔ ebul fɔ blo pasmak.

pasmak rpm ɔ nɔ fayn fid rɛt .

We yu de ɔpreshɔn wan spindle na ay rɔteshɔnal spid (RPM) we yu nɔ ajɔst di fid ret fayn fayn wan fɔ di matirial ɛn di kɔt tul kin mek di ɔt wam pasmak. Di spindle ɛn tul fɔ wok insay harmoni: di matirial rimɔv rɛt, spindle spid, ɛn fid ret ɔl nid fɔ mach fɔ mek shɔ se dɛn kɔt fayn fayn wan.

Prɔblɛm dɛn we kin kam bikɔs ɔf di spid ɛn it dɛn we dɛn nɔ gri wit na:

Eksεsiv RPM wit lכw fכd rεt .

Di tul we dɛn kin yuz fɔ kɔt kin rɔb pan di tin dɛn we dɛn kin yuz fɔ kɔt pas fɔ slais am klin wan, ɛn i kin mek frikshɔn ɛn ɔt.

Tu ay fid ret fɔ di givɛn spindle spid .

Di tul kin dig insay di matirial tu agresiv wan, put ɛkstra lod pan di spindle ɛn mek di tɛmpracha go ɔp kwik kwik wan.

We yu nɔ ebul fɔ kɔt fayn fayn wan .

Inkɔrɛkt kɔmbaynshɔn fɔ spid ɛn fid de lid to po chip fɔmɛshɔn, we de inkrisayz rɛsistɛns ɛn frikshɔn, mɔ ɔt di spindle ɛn tul.

Di bad tin dɛn we go apin to dɛn na:

Spindle OverHeating – Inkris frikshɔn ɛn lod ɛlevɛt spindle tɛmpracha, we kin mek di tɛmral protɛkshɔn go bifo ɔ we kin mek dɛn pwɛl fɔ ɔltɛm.

Tul Wear ɛn Failure – Fɔ kɔt tul dɛn de dull fasta ɔnda inefisiɛns kɔt kɔndishɔn, we in turn de inkrisayz frikshɔn ɛn ɔt.

Ridyus mashin akkuracy – Hɛt-indyuz ɛkspɛnshɔn fɔ di spindle ɔ wokpies kin kɔmprɔmis prɛsishɔn, afɛkt sɔfays finish ɛn tolɛreshɔn.

Best praktis: Ɔltɛm kɔl di rayt spindle spid ɛn fid ret bays pan matirial tayp, tul jɔyometri, ɛn dip fɔ kɔt. If yu yuz di gaydlayn fɔ di manifakta ɔ di kam softwea rɛkɔmɛndishɔn dɛn, dat kin ɛp fɔ mek yu nɔ gɛt ɔva ɔt ɛn maksimayz ɔl tu di spindle layf ɛn di kwaliti fɔ di mashin.

di bia dɛn we dɔn pwɛl ɔ we dɔn pwɛl .

Biɛrin na krichɔl kɔmpɔnɛnt dɛn na wan CNC spindle, we de sɔpɔt roteshɔn ɛn mek shɔ se smol, prɛsis muvmɛnt. We dɛn kin wɛr di bia dɛn, dɛn kin pwɛl, ɔ dɛn nɔ instɔl dɛn fayn , dɛn kin mek ɔda frikshɔn ɛn vaybreshɔn, ɛn dɛn ɔl tu kin ɛp fɔ mek di ples wam.

Di kɔmɔn tin dɛm wae kin mek pɔrsin gɛt prɔblɛm wit di bia na:

Nɔmal wear ova tɛm .

Biɛrin dɛn naturally degrade wit prolɔng yus, mɔ ɔnda ay lod ɔ kɔntinyu ɔpreshɔn.

Kɔntaminɛshɔn .

Dɔst, chips, ɔ mɔs kin go insay di bia, we kin mek dɛn gɛt pit, skɔ, ɔ kɔrɛshɔn.

Instɔlɛshɔn ɔ alaynɛshɔn we nɔ rayt fayn .

Di bia dɛn we dɛn nɔ alaynɛd de mek lod dɛn we nɔ ivin, we de mek frikshɔn ɛn ɔt de go ɔp.

Di tin dɛn we kin apin we pɔsin we dɔn pwɛl ɔ we dɔn pwɛl, na:

inkrεs hεt jεnereshכn – frikshכn frכm di dεgrεd biεr dεm de rayz spindl tεmprachכ, we kin aksεlεrat wear in כda kכmכpכnt dεm.

Eksεsiv Vaybreshכn – Vaybreshכn de afekt mashin akכda, we de mek di sεf fכ finish fayn εn dimenshכnal mistek dεm.

Ay risk fɔ spindle failure – If di bia damej na bad bad wan, di spindle kin seiz, trip tɛmral protɛkshɔn, ɔ sɔfa pɔrmanent mɛkanikal damej.

Di bɛst we fɔ du am: Ɔltɛm inspɛkt spindle bearing fɔ sayn dɛn we de sho se yu wɛr ɔ damej, kip di rayt lɔbrik, ɛn riples di bia dɛn akɔdin to di tin dɛn we di wan dɛn we mek am tɛl yu fɔ du. Fɔ mek shɔ se di bia we dɛn de yuz fɔ bia fayn fayn wan na impɔtant tin fɔ mek dɛn nɔ ɔt pasmak ɛn fɔ mek dɛn kɔntinyu fɔ mek mashin prɛsishɔn.

Ilektrikal ishu dɛn na di motoka .

Di spindle moto de dipen pan wan stebul ilektrikal saplae ɛn di intanɛnt kɔmpɔnɛnt dɛn we de wok fayn fayn wan fɔ wok fayn fayn wan. Ilɛktrikal prɔblɛm dɛn—lɛk vɔltɛm imbalans, fɔlt wayndin, ɔ shɔt sɔrkwit —kin mek di motoka drɔ pasmak kɔrɛnt, we de mek ɔt insay di motoka insɛf.

Di kɔmɔn ilɛktrik tin dɛn na:

Vɔltɛm imbalans dɛn .

Unikwal vכltεj akraos mכtalman fεz dεm de inkrεs di kכrant draw εn intanal rεsistεns, we de prodyuz adishכnal hεt.

Fɔlt ɔ damej wayndin dɛn .

Insulation we dɛn kin wɛr, we dɛn kin tɔn shɔt, ɔ we dɛn kin opin di sɛrkyut kin mek di motoka nɔ wok fayn ɛn mek di tɛmpracha go ɔp.

Lus kɔnɛkshɔn ɔ fɔlt drayv dɛn .

Poor ilektrikal kɔnɛkshɔn ɔ malfunctioning VFDs (variable frequency drives) kin mek spayk ɔ irɛgyula kɔrɛnt, we de strɛs di moto.

Di tin dɛn we kin apin we ilɛktrik prɔblɛm dɛn kin apin na:

Rapid Heat Buildup – Eksεs kכrant de jεnarεt hεt insay di mכtalman wayndin, we kin pas kwik kwik wan we yu de wok pan di כpεrayshכn limit.

Motor insulation failure – Fɔ lɔng tɛm fɔ ɔva ɔt kin pwɛl insuleshɔn, we kin mek yu gɛt shɔt sɔrkwit ɔ fɔ mek yu motoka nɔ wok ɔltɛm.

Ridyus spindle layfspan – Kɔntinyu ilɛktrik strɛs de aksɛleret wear pan biɛrin ɛn ɔda mɛkanikal kɔmpɔnɛnt dɛn, we de mek di ɔvahit prɔblɛm we de mek di ɔvahit.

BƐST Praktis: ɔltɛm inspɛkt ilɛktrik kɔnɛkshɔn, monitɔr di kɔrɛnt ɛn vɔltɛm lɛvɛl, ɛn mek shɔ se di VFD ɔ drayv sistɛm de wok kɔrɛkt wan. If yu kɔrɛkt di ilɛktrik imbalans kwik kwik wan, dat kin mek di motoka nɔ wam pasmak ɛn i kin mek di spindle pwɛl.

Sayn ɛn simptom dɛn fɔ CNC spindle ɔva ɔt .

Fɔ no di sayn dɛm we de sho se di spindle ɔva ɔt di sik dɔn rili wam, na impɔtant tin fɔ mek dɛn nɔ pwɛl bad bad wan ɛn fɔ mek dɛn nɔ gɛt bɔku mɔni. Na dɛn tin ya we dɛn kin tɔk bɔt mɔ:

Nɔys dɛn we nɔ kɔmɔn .

Bɔku tɛm, fɔ grind, fɔ swɛt, ɔ fɔ mek sawnd dɛn we de rɔtin bɔku tɛm kin sho se di bia dɛn de ɔnda strɛs pasmak ɔ di lɔbrikeshɔn dɔn fel. As di ɔt de bil, di mɛtal kɔmpɔnɛnt dɛn de bɔku ɛn di bia dɛn de lɔs dɛn smol smol ɔpreshɔn, we de mek frikshɔn nɔys. Dɛn sawnd ya na klia signal se di spindle de gɛt tɛmal strɛs ɛn dɛn fɔ chɛk am wantɛm wantɛm.

thermal shutdowns .

Bɔku mɔdan CNC spindl dɛn gɛt tɛmpracha sɛnsa dɛn we de trig ɔtomɛtik shutdɔwn we di tɛmpracha pas sef limit. Pan ɔl we dis ficha de protɛkt di mashin, we dɛn de ripit ɔ we dɛn kin stɔp ɔltɛm fɔ stɔp di tɛmal na rɛd flag we yu spindle de ɔltɛm ɔva ɔt. If yu nɔ pe atɛnshɔn to dɛn shutdowns ya, dat kin mek yu gɛt mɔta fɔ ɔltɛm ɔ yu kin gɛt damej.

Ridyus spindle pefɔmans .

Ova ɔt kin afɛkt dairekt wan mashin pefɔmɛns. Yu kin notis se di kɔt prɛsishɔn dɔn go dɔŋ, di spindle spid we slo, ɔ di prɔblɛm we de fɔ mek yu kɔntinyu fɔ gɛt di fid ret. Ɔt de mek di impɔtant tin dɛn we de apin na di say we dɛn de, nɔ de mek di bɔdi wok fayn, ɛn i kin mek di vaybrɛshɔn go ɔp—ɔl dɛn tin ya kin ambɔg di kɔrɛkt we aw yu de wok ɛn i kin mek yu mashin wok fayn fayn wan.

Smel we pɔsin kin si ɔ we de bɔn .

Ekstrim ɔt kin mek mɛtal kɔmpɔnɛnt ɔ insuleshɔn matirial dɛn nɔ gɛt kɔlɔ. If yu notis bluish ɔ brawn hues pan di spindle haus, moto, ɔ bearing, na sayn fɔ lɔng ay tempɔret. Smel we de bɔn na ɔda siriɔs tin we de sho se di pat dɛn we de insay, lɛk wayndin ɔ lɔbrik, kin pwɛl. Dɛn sayn ya kin mek dɛn pe atɛnshɔn kwik kwik wan fɔ mek bad bad tin nɔ apin kwik kwik wan.

We dɛn pe atɛnshɔn gud wan to dɛn sayn dɛn ya, di wan dɛn we de wok de kin kech di tin dɛn we kin mek dɛn wam pasmak kwik kwik wan, dɛn kin mek dɛn nɔ ripɛnt di kɔst, ɛn dɛn kin mek dɛn CNC spindle liv lɔng.

Step-by-step gayd fɔ mek dɛn nɔ gɛt CNC spindle fɔ ɔva ɔt

Monitor spindle lod .

Ɔltɛm ɔpreshɔn di spindle insay in rayt kapasiti. Nɔ push am tumɔs wit agresiv kɔt, dip pas, ɔ ay fid ret. If yu lod pasmak, dat kin mek yu gɛt bɔku frikshɔn ɛn ɔt, we kin pwɛl di spindle kwik kwik wan.

Mek yu kɔntinyu fɔ gɛt di rayt lɔbrik .

Ɔltɛm chɛk ɛn mentɛn lɔbrik fɔ spindle bia. Mek shɔ se dɛn yuz di kɔrɛkt kayn ɛn di bɔku bɔku lɔbrik, ɛn chenj am as nid de. Kɔntaminɛt ɔ nɔ infɔsis lɔbrik de inkrisayz frikshɔn ɛn aksɛlayt ɔvahit.

Inspek ɛn mentɛn di kɔling sistem dɛn .

Mek shɔ se yu spindle in kɔling sistɛm—ilɛksɛf na ay-kɔl ɔ likwid-kɔl—de wok fayn. Klin ɛya vent, riples filta, chɛk di kɔlant lɛvɛl, ɛn mek shɔ se di fans ɔ di pɔmp dɛn de wok fayn fayn wan. Wan kɔling sistɛm we dɛn dɔn mek fayn fayn wan na impɔtant tin fɔ kɔntrol di tɛmpracha.

Kontrol ambient temperechur .

Kip di wokshɔp ɛnvayrɔmɛnt kol ɛn ventilate fayn fayn wan. Di ay ambiɛnt tɛmpracha de mek i at fɔ mek di kol sistɛm dɛn nɔ gɛt wam wam, mɔ we dɛn de rɔn fɔ lɔng tɛm. Eya kondishɔn ɔ di rayt we fɔ mek di briz go insay kin ɛp fɔ mek di tɛmpracha go bifo sef wan.

Adjɔst RPM ɛn fid ret dɛn di rayt we

Optimize spindle spid ɛn fid ret bays pan di matirial, tul, ɛn mashin ɔpreshɔn. Rɔn na rili ay RPM dɛn we yu nɔ ajɔst di fid dɛn kin mek ɔt we nɔ nid, we tu slo ɔ nɔ ebul fɔ wok kin mek frikshɔn ɛn strɛs.

Inspek di bearing ɛn spindle komponent dɛn ɔltɛm .

Chɛk di bia, shaft, ɛn di hadwɔd fɔ si fɔ sayn dɛn we de sho se yu dɔn wɛr, nɔ alaynɛt, ɔ yu dɔn pwɛl. Di bia dɛn we dɔn pwɛl ɔ we dɔn pwɛl de mek frikshɔn, vaybrɛshɔn, ɛn ɔt bildup. Riples ɛni pat we de sho sayn dɛn we de sho se pɔsin dɔn wɛr bifo i mek i wam pasmak.

Monitor ilektrikal helt of di motor .

Mek shɔ se di spindle moto de gɛt stebul vɔltɛm ɛn kɔrɛnt. Ilɛktrik biznɛs, lɛk shɔt wayd ɔ vɔltɛm imbalans, kin mek di ɔt wam pasmak. Ilektrikal inspekshɔn dɛn we dɛn kin du ɔltɛm kin ɛp fɔ mek dɛn nɔ ɔt wantɛm wantɛm.

Impliment temperechur monitarin .

Yuz thermal sensor ɔ infrared kamera fɔ monitar spindle tempɔret we yu de wok. We yu no di tɛmpracha we de go ɔp kwik kwik wan, dat de mek yu ebul fɔ tek kɔrɛkt akshɔn bifo siriɔs damej apin.

Schedul fɔ mek dɛn nɔ du di wok ɔltɛm fɔ mek dɛn nɔ gɛt di sik .

Krio wan mentenɛns schedule we inklud vaybreshɔn analisis, tɛmral imej, lɔbrikeshɔn chɛk, ɛn spindle alaynɛshɔn inspekshɔn. Prɛventiv mentenɛns na fa less kɔst pas imejensi ripɛnt ɛn mek shɔ se kɔnsistɛns spindle pefɔmɛns.

Trenin ɔpreshɔn fɔ no di sayn dɛn we de wɔn yu .

Eduket di wan dɛn we de du di ɔpreshɔn pan di sayn dɛm fɔ ɔva ɔt, inklud di nɔys dɛm we nɔ kɔmɔn, di we aw dɛn nɔ de wok fayn, di we aw dɛn de chenj di kɔlɔ, ɛn di smel dɛm we de bɔn. Prompt response to early indicators de mek big big tin nɔ wok.

Fɔ fala dɛn step ya ɔltɛm kin ridyus di risk fɔ spindle ɔva ɔt siriɔs wan, ɛkstɛnd di layf fɔ yu CNC mashin, ɛn mentɛn kɔnsistɛns mashin kwaliti.

Advans tips fɔ spindle lɔng layf .

Yuz spindle lod monitarin sistem

instol sensors we de monitar spindle lod in rial-taym kin gi ali wonin of potential ishu. Dɛn sistɛm ya de trak tɔk, kɔrɛnt, ɛn tɛmpracha, we de wɔn di wan dɛn we de wok wit di ɔpreshɔn dɛn to abnɔmal kɔndishɔn bifo dɛn kɔz siriɔs damej. We dɛn no kwik kwik wan, dat kin ɛp fɔ mek dɛn nɔ ɔt pasmak, mek dɛn strɛs pasmak, ɛn dɛn nɔ bin de tink se dɛn go dɔn.

Fɔ pik di rayt spindle fɔ di wok

we yu pik wan spindle wit sufayf pawa, spid, ɛn kol kapasiti fɔ di matirial we dɛn bin want ɛn di kɔt ɔpreshɔn impɔtant. If yu yuz spindle we nɔ gɛt pawa fɔ du wok dɛn we yu de aks fɔ, dat kin mek yu gɛt bɔku bɔku ɔvalod, i kin wam pasmak, ɛn i kin mek yu layf smɔl. Matching spindle spesifikeshɔn to di woklɔd de mek shɔ se kɔnsistɛns pefɔmɛns ɛn rilaybiliti de.

Fɔ ɔpgrɛd to bɛtɛ kɔling sɔlvishɔn

fɔ ay-dimand ɔpreshɔn, tink bɔt fɔ ɔpgrɛd to mɔ ifɛktiv kɔling sistɛm. wata-kol spindl ɔ advans haybrid kɔling tɛnkɔlɔji kin mentɛn lɔwa ɔpreshɔn tɛmpracha pas standad ɛya-kul yunit dɛn. Enhansed cooling de ridyus di thermal stress pan bearings ɛn moto winding, improve ɔl tu spindle layf ɛn mashin prɛsishɔn.

Diagnosis Ilektrikal vs. Mekanikal kɔz dɛm fɔ CNC spindle ɔvahit .

Sayn dɛn fɔ Ilɛktrikal Isyu .

Spindle ovahit kin kɔmɔt frɔm ilɛktrik prɔblɛm, bɔku tɛm dɛn kin tay am to di spindle moto ɔ in kɔntrol sistem dɛn, lɛk wan vɛriɔbul frikshɔn drayv (VFD). Dɛn tin ya kin mek di faya wam pasmak bikɔs di pawa nɔ fayn ɔ di kɔmpɔnɛnt nɔ wok fayn.

Wach fɔ:

l Inkɔnsistɛns RPM ɔ tɔk ɔnda lod , we de sho pɔtɛnɛshɛl VFD ɔ moto kɔntrol ishu dɛn.

l Sudden pawa drop , we kin strain di moto ɛn jenarayz ɔt.

l Ovahit fכ di spindl mכta , we dεn kin no bכku tεm bay we dεn tכch כ tεmral imej.

l Burnt smell ɔ diskolor waya , we de sho se ilɛktrik arsing ɔ shɔt sɔrkwit.

Yuz wan maltimita fɔ chɛk vɔltɛm ɛn amperaj fɔ irɛgyulariti. Tɛmral imej kin pinpoint hot spat dɛn na di motoka ɔ kɔntrol bɔd. If yu nɔr gɛt ɛkspiriɛns wit ilɛktrik dayagnostik, go to pɔrsin wae sabi du in wok. Poor grounding or brushes (insay brushed motors) kin kɔntribyut bak fɔ ɔva ɔt ɛn erratic pefɔmɛns.

Sayn dɛn we de sho se dɛn nɔ ebul fɔ mek mashin dɛn .

mεkanikal εshyu na kכmכn kכz fכ spindl כva hεt, bכku tεm biכs fכ frikshכn כ improper alaynsmεnt in kכmכpכnt dεm lεk biεri, shaft, כ kolεt. These problems typically produce excessive heat alongside other symptoms.

Kɔmɔn rɛd flag dɛn na:

l grindin ɔ knock nɔys dɛn we dɛn de du spindle ɔpreshɔn, we de sho se dɛn dɔn wɛr bearing dɛn we dɔn pwɛl ɔ dɛn nɔ alaynɛd kɔmpɔnɛnt dɛn.

l Vibration in di z-aks ɔ spindle ed , we de inkrisayz frikshɔn ɛn ɔt.

l Fizikal wear pan kolet, tul holda, ɔ moto mawnt , we de mek i nɔ ebul fɔ wok fayn ɛn i de ɔt pasmak.

If yu CNC mashin gɛt kɔndishɔn monitarin sɛns, rivyu vaybreshɔn ɔ tɛmpracha lɔg fɔ spayk, we de signal mɛkanikal ishu. Inspekshɔn dɛn we dɛn kin du ɔltɛm, lɛk fɔ chɛk fɔ si if dɛn nɔ tay yu fast fast ɔ gia dɛn we dɔn pwɛl, kin kech prɔblɛm dɛn kwik kwik wan.

Bɔku tɛm, di mɛkanikal fayl dɛn kin divɛlɔp smɔl smɔl, so proaktiv mentenɛns na di men tin fɔ mek dɛn nɔ ɔt pasmak ɛn dɛn kin mek dɛn ripɛnt di kɔst.

Tul ɛn tɛknik fɔ CNC spindle ɔva ɔt diagnosis .

Yuz Stetoskɔp ɔ vaybreshɔn analaiza .

We CNC spindle ova ɔt, diagnostik tul kin ɛp fɔ no di rut kɔz wit prɛsishɔn. Wan mɛkanik in stɛtoskɔp na wan simpul bɔt ifɛktiv tul fɔ pinpoint ishu dɛn. We yu put di probe pan difrɛn pat dɛn na di spindle haus, yu kin lisin to abnɔmal sawnd dɛn, lɛk grindin ɔ humming, we kin sho frikshɔn ɔ kɔmpɔnɛnt wear kɔntribyushɔn fɔ ɔva ɔt.

l Stetoskop : Amplify sawnd frɔm di motoka, bia, ɔ gia bɔks. If dɛn no se nɔys ɔ vaybreshɔn pasmak nia di bia dɛn, i de sho se frikshɔn ɔ wear de mek di ɔt de bɔku.

l Vibration analyzer : Dɛn divays ya de mɛzhɔ vaybreshɔn amplityudɔ ɛn frikshɔn, fɔ no di imbalans, misalaynmɛnt, ɔ kɔmpɔnɛnt dɛn we dɔn pwɛl we de mek ɔt. Advans sensor kin detekt subtil ishu bifo dem lid to signifyant ovahit.

We yu pe dɛn tul ya wit smart fon ap fɔ mek sawnd ɔ frɛkuɛns analisis, dat de mek yu ebul fɔ log ɛn trak data as tɛm de go. Dis de sɔpɔt prɛdiktiv mentenɛns, ɛp yu fɔ adrɛs ɔva ɔt ishu bifo dɛn eskalet.

Tɛmral imej ɛn tɛmpracha prɔfayl .

Tεmral imej na wan impɔtant tul fɔ no if spindl ɔva ɔt. Infrared kamera dɛn kin no di say dɛn we di ples kin wam, we kin sho di bia dɛn we kin wam pasmak, di motoka waynd, ɔ di frikshɔn we de na di spindle shaft. Wan kwik skan kin no di say dɛn we gɛt prɔblɛm ɛn nɔ pul di mashin.

l Tɛmral Kamɛra dɛn : Luk fɔ brayt rɛd ɔ wayt eria dɛn na di tɛmral displei, we de sho di tɛmpracha pas di nɔmal opareshɔn kɔndishɔn dɛn. Fɔ ɛgzampul, wan ɔt bia de sho se dɛn nɔ gɛt bɛtɛ lɔbrik ɔ wear.

l Tempratura Profaylin : Yuz softwe fɔ kɔmpia di tɛm we di tɛmpracha de naw agens wan beslayn 'Healthy' prɔfayl. Spik in tempɔret lɔg frɔm kɔndishɔn monitarin sɛnsɔn kin kɔnfɔm ɔvahit tren.

Kɔmbayn thermal imaging wit vaybreshɔn analisis ɛn tɛmpracha profayl de gi wan kɔmprɛhɛnsif apɔch fɔ diagnos ɔvahit. Dis kin wok mɔ na bizi shɔp ɛnvayrɔmɛnt usay bɔku mashin dɛn kin rɔn wan tɛm, we kin mek i nɔ izi fɔ ayd di tin dɛn we gɛt fɔ du wit ɔt. If yu yuz dɛn tin ya ɔltɛm, dat kin mek yu ebul fɔ no kwik kwik wan ɛn i kin mek yu nɔ spɛn bɔku mɔni fɔ mek yu nɔ pwɛl.

Aw fɔ fiks kɔmɔn CNC spindle ɔva ɔt ishu dɛn .

Riples ɔ ri-gris di bia dɛn .

Biɛrin na wan tin we kin mek di spindle ɔva ɔt bɔku tɛm bikɔs ɔf frikshɔn frɔm wear ɔ we nɔ gɛt bɛtɛ lɔbrik. Chek yu mashin in manyual fɔ no di kayn bia (sial ɔ opin) ɛn mentenɛns we dɛn nid.

l Ri-gris opin biɛrin : If di bia dɛn opin, aplay ay-kwaliti, manifakta-rɛkɔmɛnd gris yuz prɛsishɔn gris gɔn. Nɔ put ɔvapak pasmak, bikɔs di gris we pasmak kin mek frikshɔn ɛn ɔt bɔku. Rɔn di spindle na low rpm afta yu gris fɔ mek shɔ se ivin distribyushɔn, dɔn monitar tɛmpracha wit wan tɛmral kamera ɔ sɛns fɔ kɔnfɔm ridyus ɔt autput.

l Riples sial biɛrin : sial biɛrin dɛn tipikul nid fɔ riples. Disassemble di spindle haus gud gud wan, yuz wan bearing puller if nid de, en riples wit OEM-specified bearings. Afta yu dɔn instɔl am, rɔn di spindle na lɔw rpm fɔ sɛtul di bia dɛn, dɔn yuz wan tɛmral imej tul ɔ tɛmpracha sɛnsa fɔ chɛk nɔmal opareshɔn tɛmpracha.

Pɔst-ripa, chɛk vaybreshɔn ɛn tɛmpracha lɔg fɔ mek shɔ se dɛn sɔlv di prɔblɛm. Ɔva ɔt we kin kam bikɔs ɔf di bia dɛn kin kɔmɔt frɔm we dɛn nɔ de kia fɔ dɛn, so fɔ mek dɛn kɔntinyu fɔ kia fɔ dɛn ɔltɛm na impɔtant tin.

Rilayn di spindle shaft .

Misalaynmɛnt na di spindle shaft kin mek frikshɔn pasmak, we kin mek i wam pasmak, mɔ we i de spid. Prɔpa alaynɛshɔn de ridyus ɔt ɛn ɛkstɛnd kɔmpɔnɛnt layf.

l Alignment Tools : Yuz wan dayal indikɛtɔ ɔ laser alaynɛshɔn kit fɔ mɛzhɔ shaft rɔnaut na lɔw RPM. If rɔnaut pas di manifakta in tolɛreshɔn, rialaynmɛnt nid fɔ de.

l Realignment process : lus di spindle mawnt ɛn tek tɛm riset am. Fɔ advans CNC mashin dɛn, ajɔst alaynɛshɔn shim ɔ rekalibrayt sɔftwɛl sɛtin dɛn as nid de. Inspek di pɔsin we gɛt di tul, kɔlet, ɛn chɔk fɔ si if dɛn wɛr ɔ dɔti, bikɔs dɛn tin ya kin mek dɛn nɔ alaynɛt di rayt we ɛn mek di ples wam mɔ ɛn mɔ.

l Post-alignment chɛk : Afta rialaynmɛnt, klin ɔl di kɔmpɔnɛnt dɛn gud gud wan ɛn tɛst di spindle ɔnda lod. Yuz thermal imaging ɔ tempɔret sɛns fɔ kɔnfɔm se dɛn dɔn mitigate ɔva ɔt.

Dokumɛnt tɛmpracha ɛn vaybreshɔn ridin afta dɛn dɔn ripɛnt fɔ establish nyu beslayn. Rigyul alaynɛshɔn chɛk ɛn tulhɔlda mentenɛns go ɛp fɔ mek dɛn nɔ ɔt pasmak ɛn mek dɛn kɔntinyu fɔ wok fayn fayn wan, ɛn dɛn go ebul fɔ wok fayn fayn wan.

We fɔ kɔl pɔsin we sabi du in wok fɔ CNC spindle ɔva ɔt .

We yu no di say dɛn we yu nɔ fɔ rich .

Ivin di wan dɛn we gɛt ɛkspiriɛns pan CNC fɔ no we spindle ɔva ɔt ishu dɛn nid pɔshɔnal ɛkspɛriɛns. Pan ɔl we yu kin adrɛs di bɛsis mentenɛns lɛk ri-grizin bia ɔ klin tul ɔlda, kɔmpleks prɔblɛm dɛn—lɛk intanɛnt moto fayl, spindle katrij damej, ɔ advans ilɛktrik fɔlt—demand spɛshal skil dɛn.

Kɔl pɔsin we sabi du di wok if:

l Basic fixes (eg, ri-greasing bearings, rialayn di shaft, ɔ chɛk ilɛktrik kɔnɛkshɔn) nɔ de sɔlv fɔ ɔva ɔt.

l Yu notis persistent ay tempɔret pan ɔl we nɔmal ɔpreshɔn, we de sho dip tin dɛn lɛk moto wayndin fayl ɔ VFD malfunctions.

l Diagnostik tul dɛm (tɛmmal imej, vaybreshɔn analaiz) sho anomali dɛm yu nɔ go ebul fɔ intaprit ɔ fiks.

Prɔfɛshɔnal dɛn gɛt advans diagnostik ikwipmɛnt, lɛk ay-prɛsishɔn tɛmral skan ɔ spɛshal spindl tɛst rig, ɛn ɛkspɛriɛns wit difrɛn spindl dizayn dɛn. Hiring a pro nɔ de admit defεt—na smat muv fɔ protɛkt yu mashin in pefɔmɛns ɛn lɔng layf.

Kost vs. bɛnifit fɔ pɔshɔnal ripɛnt .

Di kɔst fɔ mek dɛn ripɛnt di spindle we dɛn sabi fɔ mek di spindle kin tan lɛk se i ay, bɔt fɔ tray fɔ fiks kɔmpleks tin dɛn we nɔ gɛt di rayt skil ɔ tul dɛn kin mek big big prɔblɛm dɛn bɔku. Mishandling komponent dɛn, lɛk we dɛn nɔ instɔl di bia dɛn di rayt we ɔ we dɛn nɔ alaynɛd di spindle di rɔŋ we, kin ɛskalayt $500 ripa insay wan $5,000 riplesmɛnt.

Di bɛnifit dɛn we pɔsin kin gɛt we i de wok fɔ di pɔsin we gɛt wok na:

l Ɛkspɛkt diagnostik : Tɛknishan dɛn kin pinpoint tin dɛn lɛk aydɔl ilɛktrik fɔlt ɔ intanɛnt frikshɔn we standad shɔp tul dɛn kin mis.

l Waranti : Mɔs pan di prɔfɛshɔnal ripɛnt dɛn kin kam wit garanti, mek shɔ se dɛn rili abop pan lɔng tɛm.

L Minimised Downtime : Bɔku savis dɛn de we dɛn kin gi kwik kwik wan fɔ mek yu mashin kam bak na di Intanɛt kwik kwik wan.

l Inkris Risayl Valyu : Wan dɔkyumɛnt savis istri frɔm pɔshɔnal dɛn de ɛp yu CNC mashin in makɛt valyu.

Bifo yu tek wan saspek big big ishu yusɛf, wej di kɔst fɔ pɔshɔnal ripa agens di valyu fɔ yu mashin in aptaym ɛn prɛsishɔn. Bɔku tɛm, di ɛkspɛriɛns ɛn pis na dɛn maynd kin rili fit fɔ di invɛstmɛnt.

Aw di tin dɛn we de apin na di envayrɔmɛnt kin afɛkt di CNC spindle ɔva ɔt .

Humidity, dust, ɛn tempɔret .

Di envayrɔmɛnt na yu CNC shop kin rili ambɔg di spindle wɛlbɔdi ɛn i kin ɛp fɔ mek yu wam pasmak. Dɛn tin ya kin mek frikshɔn wɔs, pwɛl di kɔmpɔnɛnt dɛn, ɛn ambɔg di rayt we aw dɛn de wok.

l Humidity : Ay humidity kin mek kondenseshɔn insay di spindle haus, we kin mek rɔst ɔ kɔrɛshɔn pan bia ɛn ɔda kɔmpɔnɛnt dɛn. Dis kin mek frikshɔn bɔku, i kin mek di ɔt pasmak ɛn i kin mek i nɔ wok bifo tɛm.

l Dust ɛn patikyula tin : Insay say dɛn lɛk wudshɔp ɔ tin dɛn we dɛn mek wit mɛtal, dɔst kin go insay di spindle motoka. We dɛn miks am wit gris, dɔst de mek wan abraziv kɔmpawnd we de west di bia ɛn sil dɛn, we de mek di frikshɔn ɛn di ɔt we de bɔku.

l Tεmpratura swing : kol tεmprachכ tik gris, ridyus in lכbrikεt εfεktiv εn mek i gεt hכy frikshכn εn hכt. We di ples wam, di tɛmal we dɛn kin mek di ples wam kin mek di spindle shaft nɔ alayf, ɛn di lɔbrikɛn dɛn kin pwɛl fast fast, we kin mek dɛn wam pasmak. Ekstrim ɔt kin strɛs bak motoka wayndin, we kin kɔntribyut to ɛlevɛt tɛmpracha.

Di Strateji fɔ Mitigashɔn:

l Instɔl dɔst kɔlɛkta ɛn ɛya filtreshɔn sistem fɔ minimiz patikyula infiltrɛshɔn.

l Yuz klaymat kɔntrol sistem fɔ mek dɛn kɔntinyu fɔ gɛt stebul humiditi ɛn tɛmpracha lɛvɛl.

l Stɔ spay pat ɛn lɔbrikɛn dɛn na klin, dray, tɛmpracha-kɔntroled ɛnvayrɔmɛnt.

l ɔltɛm inspɛkt ɛn klin spindle kɔmpɔnɛnt dɛn fɔ mek dɔst nɔ bɔku ɛn mek shɔ se dɛn gɛt di rayt lɔbrik.

Mashin Plesin ɛn Vaybrɛshɔn Ayzolayshɔn .

Di fyzikal plesmɛnt fɔ yu CNC mashin kin inflɔws spindle ɔva ɔt bay we i de amplify vaybreshɔn ɔ ɔt transfa frɔm ɛksternal sɔs.

l Nɔ ivin say dɛn : mashin dɛn we de na di flɔ we nɔ ivin kin gɛt misalign, we kin mek di spindle wok tranga wan ɛn mek i gɛt mɔ ɔt. Vaybreshɔn frɔm wan ɔnstɛbul bays kin bak inkrisayz frikshɔn insay bia ɛn ɔda kɔmpɔnɛnt dɛn.

l Proksimit to ɔda ikwipmɛnt : Fɔ put CNC mashin nia ebi ebi mashin, lɛk prɛs ɔ lath, kin introduks ɛksternal vaybreshɔn we de strɛs di spindle, we kin mek di ɔt go ɔp frɔm frikshɔn ɔ misalignmɛnt.

l Hɛt sɔs : mashin dɛn we dɛn put nia ikwipmɛnt we de mek ɔt ɔ we di san de shayn dairekt wan kin gɛt ay ambiɛnt tɛmpracha, we de mek di spindle wam pasmak.

Di Strateji fɔ Mitigashɔn:

l Mek shɔ se di mashin de lɛvɛl yuz prɛsishɔn bɔbul lɛvɛl ɔ laser lɛvɛl fɔ minimiz misalignmɛnt-rilayt ɔt.

l Instɔl vaybreshɔn ayzolayshɔn mawnt ɔ dampa ɔnda di CNC fɔ absɔb ɛksternal vaybreshɔn ɛn ridyus strɛs pan di spindle.

l Pozishɔn di mashin fa frɔm ebi ebi ikwipmɛnt ɔ ɔt sɔs fɔ avɔyd vaybreshɔn transfa tru di flɔ ɔ ɛlevɛt ambiɛnt tɛmpracha.

l Yuz tɛmal barɛri ɔ ɛnklɔzhɔ fɔ shild di mashin frɔm ɛksternal ɔt sɔs.

We yu kɔntrol di tin dɛn we de apin na di envayrɔmɛnt ɛn mek di mashin ples fayn, yu kin ridyus di spindle ɔva ɔt, impruv di opareshɔnal efyushɔn, ɛn ɛkstɛnd di layfspan fɔ yu CNC ikwipmɛnt. Rigyul monitarin wit thermal imaging ɔ tempɔret sɛnsɔn kin ɛp fɔ no di fɔs sayn dɛm fɔ di tin dɛm we gɛt fɔ du wit di envayrɔmɛnt.

Di wan dɛn we mek di tin dɛn we dɛn mek we yu nɔ fɔ ignore fɔ CNC spindle ɔva ɔt .

We yu de rid di buk fayn fayn wan .

Skip di CNC spindle manual na mistek we go tek bɔku mɔni. I pak wit krichɔl infɔmeshɔn we dɛn tayl to yu spindle mɔdel, inklud spɛsifikɛshɔn fɔ ɔpreshɔn tɛmpracha, lɔbrikeshɔn schedule, kɔmpatib kulant, ɛn mentenɛns prosidyuz. If yu nɔ pe atɛnshɔn to dɛn tin ya, dat kin mek yu ɔt pasmak ɛn i kin pwɛl fɔ lɔng tɛm.

l Ki ditel : Di manual de sho di korekt lubrikeshon taip (eg, oil mist, pak gris, o self-lubricating seramik bearings), kol rikwaym, en tork setin. If yu yuz di rɔng lɔbrik ɔ kɔlant, dat kin mek frikshɔn ɛn wam-at bɔku.

l Mentɛnans Gaydlain : Fɔ fala instrɔkshɔn fɔ klin, bia mentenɛns, ɛn kɔmpɔnɛnt prɛlɔd fɔ mek di ɔt nɔ wam pasmak ɔ fɔ mek i nɔ west.

l Troubleshooting Tips : Bɔku tɛm, di manual kin gɛt mistek kɔd ɔ tɛmpracha trɛshɔld fɔ ɛp fɔ no di ɔva ɔt prɔblɛm dɛn kwik kwik wan.

Print ɛn laminate ki mentenɛns pej dɛn fɔ kwik rɛfrɛns na yu shɔp. Dis de mek shɔ se yu de fala di gaydlayn dɛn we de fɔ mek di tɛmpracha kɔntinyu fɔ de na chɛk ɛn avɔyd fɔ mek dɛn ripɛnt di kɔst.

Fɔ fala di lod ɛn spid gaydlayn dɛn .

Fɔ push wan spindle pas di lod ɔ RPM limit dɛn we dɛn dɔn rɛkɔmɛnd na kɔmɔn tin we kin mek i wam pasmak. Ovalod ɔ ɔva spid de mek bɔku bɔku ɔt, strɛs kɔmpɔnɛnt dɛn, ɛn aksɛleret wear.

l Load limits : If yu pas di spindle in tɔk ɔ kɔt lod kapasiti, i kin mek yu gɛt mɔta strayn, we kin mek yu ɔt pasmak ɛn we kin mek di shaft ɔ damej to di bia dɛn pasmak.

l Speed Limits : Rɔnin di spindle ɔp in rayt RPM de inkrisayz frikshɔn insay bia ɛn jenarayz pasmak ɔt, risk moto wayndin fayl ɔ lɔbrikɛn brekdɔwn.

l Monitoring Tools : Yuz yu CNC Kontrolɔ in softwe fɔ trak rial-taym spindle lod, spid, ɛn tɛmpracha. Bɔku sistɛm dɛn de alaw yu fɔ sɛt alam fɔ pas sef trɛshɔld, ɛp fɔ mek yu nɔ ɔt pasmak.

Di bɛst we fɔ du tin:

l stik to di manifakta in spɛsifikɛd RPM ɛn lod limit fɔ minimiz ɔt jenɛreshɔn.

l ɔltɛm chɛk di kɔling sistem (ɛgz., ɛya ɔ likwid kɔling) fɔ mek shɔ se dɛn de wok lɛk aw di manual in kɔmɛnt dɛn de.

l Monitor temperechur logs via kondishon sensor or thermal imaging fo kech deviations ali.

If yu fala dɛn gaydlain ya, i de ridyus di strɛs we gɛt fɔ du wit di ɔt, i de mek yu nɔ wam pasmak, ɛn i de mek yu spindle in layfspan go ɔp, ɛn dis de mek yu CNC mashin de rɔn fayn fayn wan ɛn i de wok fayn fayn wan.

Dɔn

Ova ɔt insay yu CNC spindle na klia wɔnin sayn we de aks fɔ atɛnshɔn. Ilɛksɛf na bikɔs ɔf di bearings we dɔn pwɛl, di misalignment, di ilɛktrik fɔlt, ɔ di tin dɛn we de apin na di envayrɔmɛnt, di bɔku bɔku ɔt signal dɛn we de ɔnda di tin dɛn we kin apin if dɛn nɔ pe atɛnshɔn to am. If dɛn nɔ chɛk am, if i wam pasmak, dat kin mek di kɔmpɔnɛnt dɛn nɔ wok fayn, dɛn kin mek dɛn ripɛnt di kɔst, ɛn dɛn kin mek dɛn nɔ gɛt bɔku mɔni.

Bay we yu masta diagnostik tul dɛm lɛk tɛmral imej, vaybreshɔn analaiz, ɛn stɛtoskɔp, ɛn adhe to manifakta gaydlayn fɔ mentenɛns, lod, ɛn spid, yu kin kech prɔblɛm kwik kwik wan ɛn kip yu spindle de rɔn fayn fayn wan. Envairomɛnt kɔntrol ɛn di rayt we fɔ put di mashin fayn fayn wan de ridyus di risk fɔ gɛt tin dɛn we gɛt fɔ du wit ɔt.

Yu spindle na di hat fɔ yu CNC mashin. Protɛkt am wit proaktiv kia, ɛn i go riwɔd yu wit rili, lɔng-last pefɔmɛns.

FAQ dɛn .

Wetin na di ideal opareshɔn tɛmpracha fɔ wan CNC spindle?

Mɔs spindl dɛn de ɔprɛt fayn fayn wan bitwin 40°C ɛn 60°C (104°F–140°F), bɔt kɔnsul di manifakta in spɛsifikɛshɔn dɛn.

Aw ɔltɛm a fɔ lubrik mi spindle?

Lubrikeshɔn frikyuɛnsi dipen pan yuz ɛn manifakta gaydlayn, tipikli ɛvri 500–1,000 ɔpreshɔn awa.

Yu tink se we pɔsin ɔt pasmak, dat kin mek i pwɛl fɔ ɔltɛm?

Yɛs, if yu ɔva ɔt fɔ lɔng tɛm, dat kin pwɛl di bia dɛn, di motoka dɛn, ɔ ɔda tin dɛn, we kin mek dɛn ripɛnt ɔ riples dɛn we go tek bɔku mɔni.

Yu tink se wata kin kol bɛtɛ pas fɔ mek di briz kol?

Wata kol de wok mɔ fɔ ay-spid ɔ ebi-diuti aplikeshɔn dɛn, bɔt di kol we de na di ays simpul ɛn naf fɔ layt wok dɛn.

Wetin na di avrej layfspan fɔ wan CNC spindle?

Wit di rayt mentenɛns, spindles kin las 10,000–20,000 ɔpreshɔn awa, dipen pan usay dɛn de yuz ɛn di kɔndishɔn.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu