Is your CNC machine running hotter than usual? That slight warmth creeping into a scorching heat could be a serious warning sign—and it’s not something you can afford to overlook. An overheating spindle isn’t just a minor inconvenience; it’s a signal that something’s wrong, and if ignored, it can lead to damaged components, reduced machining accuracy, costly repairs, or even complete machine failure.

In this guide, we’ll walk you through everything you need to know about CNC spindle overheating—from recognizing the early warning signs to pinpointing the root causes and taking practical steps to fix and prevent it. Whether you’re a machine operator, maintenance technician, or a CNC enthusiast eager to protect your equipment, this is your ultimate resource for keeping your spindle cool, efficient, and long-lasting.

Let’s turn down the heat and keep your production running at peak performance!

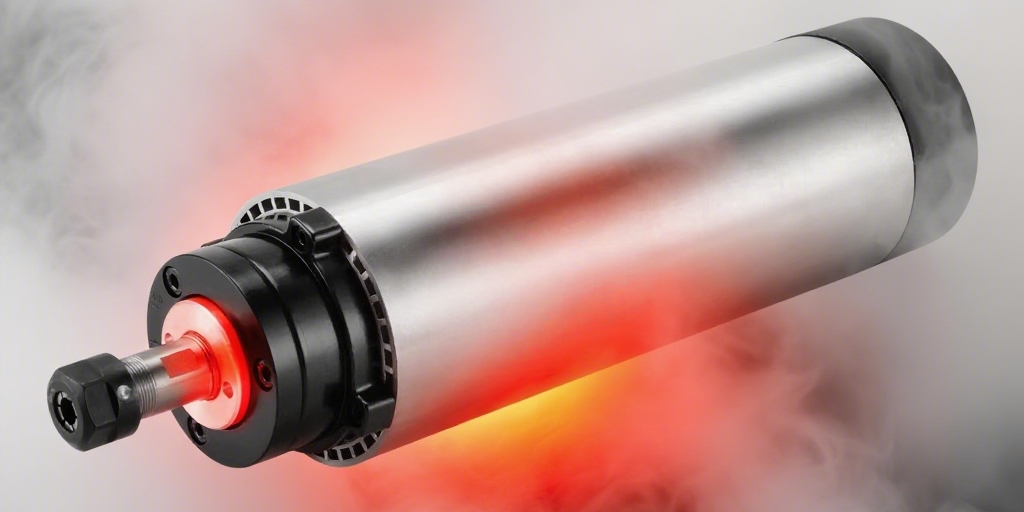

![cnc spindle motor overheating]()

Introduction to CNC Spindle Motors

What Is a CNC Spindle Motor?

At the heart of every CNC machine is its spindle motor. This vital component powers the cutting tools and enables the machine to drill, cut, mill, and shape materials with precision. As the core of the machine’s operation, it controls speed, torque, and overall performance—making its reliability critical to consistent production.

Spindle motors are designed in various sizes, speeds, and power ratings depending on the application, whether it’s woodworking, metalworking, or machining composites. Regardless of the material, the spindle must operate within safe temperature limits to maintain accuracy and longevity.

Think of it like the engine in your car—if it starts running too hot, it’s a warning you can’t ignore. Excessive heat in a spindle can cause bearings to fail, lubrication to break down, and thermal expansion to throw off machining tolerances. A cool-running spindle generally means healthy operation; rising temperatures should prompt immediate attention.

Understanding how the spindle works and what keeps it cool gives you a major advantage when something feels “off.” This includes knowing the role of its bearings, motor windings, cooling systems, and housing—all of which can be affected by overheating and lead to serious performance issues if left unchecked.

Importance of Spindle Health in CNC Machines

Your CNC machine is only as good as its spindle. When a spindle overheats, it’s not just the motor you’re risking; it can lead to bearing damage, warped components, scrapped parts, missed deadlines, and worst of all—costly downtime.

Rising temperatures are often the earliest warning signs. A slightly warm spindle today could turn into a burnt-out motor tomorrow. By monitoring heat levels and addressing the cause early, you can save thousands in repairs and avoid complete spindle replacements.

Also, consider this: an overheating spindle doesn’t suffer alone—it puts extra strain on other parts of your machine, from the drive system to the cooling components. It’s a chain reaction you definitely don’t want to set in motion.

Spindle temperature control is more than just performance—it’s safety, productivity, and profitability all in one. That’s why understanding the causes and prevention of overheating isn’t optional; it’s essential.

The CNC Spindle: Your Machine’s Power Core

The spindle is not just another part—it’s the centerpiece of your CNC machine. When it runs at the right temperature, your operations flow smoothly. When it overheats, everything starts to break down. This component drives cutting tools, shapes your materials, and maintains precision—making its temperature control critical to performance.

The Cost of Spindle Failure

Overheating doesn’t just slow production—it destroys it. Excess heat can cause:

l Bearing failure

l Warped spindle components

l Degraded lubrication

l Scrapped materials

l Missed project deadlines

l Costly emergency repairs

l Unexpected machine downtime

Every minute your spindle runs too hot is money lost. Keeping it cool isn’t optional—it’s essential.

Early Warning Signs

Temperature spikes are often the first sign of trouble. A slightly warm spindle today could be a burnt-out motor tomorrow. Overheating left unchecked can result in:

l Full spindle replacement

l Extended machine downtime

l Damage to other internal components

Catching heat issues early saves money, prevents breakdowns, and keeps production on schedule.

How Overheating Affects Your Entire CNC System

A hot spindle doesn’t just damage itself—it stresses the entire machine.

l Bearings degrade faster

l Lubricants break down

l Drive systems work harder

l Electrical components overheat

l Thermal expansion throws off tool alignment

This chain reaction can lead to system-wide failure. Preventative temperature control is your best defense.

Maximize Machine Lifespan with Regular Temperature Checks

Routine spindle temperature monitoring is essential. Just a few minutes can prevent thousands in repair costs. Schedule regular:

l Thermal imaging inspections

l Coolant system checks

l Airflow and fan maintenance

l Temperature sensor calibration

Prevention always costs less than recovery.

Boosting Productivity Through Cooling Efficiency

A properly cooled spindle cuts cleaner, faster, and more efficiently. This improves:

l Cycle times

l Part quality

l Tool longevity

l Overall machine performance

If you want more parts per hour, start by controlling spindle temperature.

Spindle Cooling = Operator Safety

Overheated spindles aren’t just a mechanical risk—they’re a safety hazard. Excess heat can:

l Cause sudden bearing seizure

l Lead to unexpected tool breakage

l Create erratic machine behavior

Keeping your spindle cool protects both your equipment and your team.

Understand the Heat Signals

Machines speak through temperature changes. Learn to recognize:

l Gradual temperature creep

l Rapid spikes during heavy cuts

l Cooling system inefficiency

l Unusual heat around bearings or housing

Each pattern tells a story—catching it early ensures a safer, more efficient operation.

Extend Tool Life with Temperature Stability

Excess heat shortens tool life. Overheating can cause:

l Dull cutting edges

l Frequent tool changes

l Inaccurate cuts

l Poor surface finishes

A temperature-stable spindle ensures every tool performs at its best.

Common Causes of CNC Spindle Overheating

| Cause | Description |

| Overloading the Spindle | Excessive cutting forces or prolonged operation beyond capacity generates excessive heat, straining the motor and bearings. |

| Poor Lubrication or Lubrication Failure | Inadequate or improper lubrication increases friction in bearings, leading to heat buildup and accelerated wear. |

| Cooling System Inefficiencies | Clogged filters, low coolant levels, or malfunctioning pumps impair heat dissipation in water-cooled systems. |

| High Ambient Temperature | Operating in poorly ventilated or high-temperature environments reduces the spindle’s ability to shed heat. |

| Excessive RPM or Improper Feed Rates | High RPMs or mismatched feed rates increase heat generation and stress components. |

| Worn or Damaged Bearings | Worn bearings create additional friction, generating heat and risking catastrophic failure. |

| Electrical Issues in the Motor | Faulty wiring, voltage fluctuations, or motor malfunctions cause overheating and inefficient operation. |

Overloading the Spindle

Overloading occurs when the spindle is forced to operate beyond the performance limits specified by the manufacturer. This can happen in several ways:

Cutting overly hard or dense materials

For example, machining hardened steel or exotic alloys with a spindle designed for softer materials like aluminum or wood. The increased resistance generates more torque demand, leading to greater heat buildup.

Taking excessively deep cuts

A deep pass removes more material per revolution, requiring more cutting force. This not only increases the load on the spindle motor but also creates more friction at the tool-workpiece interface.

Using overly high feed rates

When the feed rate is too fast for the spindle speed and tool capability, the cutting edge is forced to plow through material instead of cleanly slicing it. This produces excess vibration, stress, and heat.

The combination of these factors puts mechanical stress on the spindle bearings, motor windings, and drive components. Over time, this can lead to:

Accelerated bearing wear from excess radial and axial loads.

Thermal expansion of internal parts, which may cause misalignment or increased friction.

Electrical overload of the spindle motor, risking insulation breakdown and winding damage.

In severe cases, overloading can cause the spindle to trip on thermal overload protection, stall during operation, or suffer permanent damage to the motor and bearings.

Best Practice: Always match your cutting parameters—material type, spindle speed, feed rate, and depth of cut—to the spindle’s rated specifications. Using proper tooling and ensuring sharp cutting edges can also reduce the load significantly.

Poor Lubrication or Lubrication Failure

The spindle’s bearings and other moving components rely heavily on proper lubrication to function smoothly. Lubrication serves two critical purposes: reducing friction between metal surfaces and helping dissipate heat generated during operation.

When lubrication is insufficient, contaminated, or entirely absent, several problems can arise:

Insufficient lubrication

If the spindle does not receive enough grease or oil, the metal-to-metal contact increases, generating excessive heat and accelerating wear.

Contaminated lubrication

Dirt, metal shavings, or moisture in the lubricant can act as abrasives, scratching bearing surfaces and impeding smooth rotation.

Lubrication leaks or neglect

Over time, seals can fail, or maintenance schedules may be overlooked, leading to a gradual loss of lubricant. Without proper lubrication, friction increases rapidly.

The consequences of poor lubrication include:

Rapid heat buildup – Excessive friction converts mechanical energy into heat, raising spindle temperature quickly.

Bearing wear and damage – Friction erodes bearing surfaces, which can lead to pitting, scoring, or even bearing seizure.

Spindle failure – In extreme cases, the bearings can lock up entirely, causing the spindle to stop suddenly and potentially damaging the motor and other components.

Best Practice: Regularly check lubrication levels, ensure the use of manufacturer-recommended grease or oil, and replace contaminated lubricant promptly. Routine maintenance and inspection of seals and bearings can prevent most lubrication-related spindle overheating issues.

Cooling System Inefficiencies

A CNC spindle generates significant heat during operation, and an effective cooling system is essential to maintain safe operating temperatures. Spindles may use air cooling or liquid cooling, but both rely on unobstructed circulation to dissipate heat.

Problems that reduce cooling efficiency include:

Blocked vents or dirty filters

Dust, debris, or metal shavings can clog air intakes or exhausts, restricting airflow and reducing heat dissipation.

Clogged coolant passages

In liquid-cooled systems, mineral deposits, chips, or oil residues can obstruct the flow of coolant, preventing it from absorbing and carrying away heat.

Faulty pumps or fans

Mechanical failure in fans, pumps, or flow sensors can stop coolant circulation or airflow entirely, allowing temperatures to rise rapidly.

When the cooling system cannot remove heat efficiently, several issues occur:

Overheating of bearings and motor windings – Excessive temperatures accelerate wear and can damage insulation.

Thermal expansion and misalignment – Uneven heating can cause spindle components to expand at different rates, affecting precision and increasing friction.

Premature spindle failure – Persistent overheating can shorten spindle life or trigger thermal shutdowns to prevent catastrophic damage.

Best Practice: Maintain the cooling system regularly—clean air filters and vents, flush and replace coolant as recommended, and inspect pumps and fans for proper operation. Ensuring unobstructed and effective cooling is crucial for spindle longevity and reliable machining performance.

High Ambient Temperature

Even when a spindle is properly maintained and all systems are functioning correctly, high ambient temperatures in the workshop can cause overheating. Spindles rely on a temperature difference between themselves and the surrounding environment to dissipate heat, so if the air around the machine is already warm, cooling efficiency is reduced.

Factors that contribute to this problem include:

Poor ventilation

Stagnant air prevents heat from escaping the workspace, reducing the effectiveness of air-cooled spindles or fans.

Lack of climate control

Without air conditioning or proper airflow, workshops can reach temperatures that exceed the spindle’s designed operating range.

Extended production runs

Long periods of continuous operation in a hot environment allow heat to accumulate, even with active cooling systems.

Consequences of high ambient temperature include:

Reduced cooling efficiency – The spindle cannot shed heat as effectively, causing its temperature to rise faster than normal.

Thermal stress on components – Bearings, motor windings, and other sensitive parts are more prone to wear and failure when exposed to sustained high temperatures.

Possible thermal shutdown – Many spindles have built-in thermal protection; excessive ambient heat can trigger shutdowns, interrupting production.

Best Practice: Ensure adequate workshop ventilation, consider air conditioning or forced-air systems for hotter environments, and monitor spindle temperature during extended runs. Even small improvements in airflow and cooling can significantly reduce overheating risks.

Excessive RPM or Improper Feed Rates

Operating a spindle at high rotational speeds (RPM) without properly adjusting the feed rate for the material and cutting tool can create excessive heat. The spindle and tool must work in harmony: the material removal rate, spindle speed, and feed rate all need to match to ensure efficient cutting.

Problems caused by mismatched speeds and feeds include:

Excessive RPM with low feed rates

The cutting tool rubs against the material rather than slicing it cleanly, generating friction and heat.

Too high feed rates for the given spindle speed

The tool may dig into the material too aggressively, placing extra load on the spindle and causing rapid temperature rise.

Inefficient cutting

Incorrect combinations of speed and feed lead to poor chip formation, which increases resistance and friction, further heating the spindle and tool.

The consequences of these issues include:

Spindle overheating – Increased friction and load elevate spindle temperature, potentially triggering thermal protection or causing permanent damage.

Tool wear and failure – Cutting tools dull faster under inefficient cutting conditions, which in turn increases friction and heat.

Reduced machining accuracy – Heat-induced expansion of the spindle or workpiece can compromise precision, affecting surface finish and tolerances.

Best Practice: Always calculate appropriate spindle speed and feed rates based on material type, tool geometry, and depth of cut. Using manufacturer guidelines or CAM software recommendations can help prevent overheating and maximize both spindle life and machining quality.

Worn or Damaged Bearings

Bearings are critical components in a CNC spindle, supporting rotation and ensuring smooth, precise motion. When bearings become worn, damaged, or improperly installed, they generate additional friction and vibration, both of which contribute to heat buildup.

Common causes of bearing issues include:

Normal wear over time

Bearings naturally degrade with prolonged use, especially under high loads or continuous operation.

Contamination

Dust, chips, or moisture can enter the bearing, causing pitting, scoring, or corrosion.

Improper installation or alignment

Misaligned bearings create uneven loads, increasing friction and heat.

Consequences of worn or damaged bearings include:

Increased heat generation – Friction from degraded bearings raises spindle temperature, which can accelerate wear in other components.

Excessive vibration – Vibration affects machining accuracy, leading to poor surface finish and dimensional errors.

Higher risk of spindle failure – If bearing damage is severe, the spindle may seize, trip thermal protection, or suffer permanent mechanical damage.

Best Practice: Regularly inspect spindle bearings for signs of wear or damage, maintain proper lubrication, and replace bearings according to manufacturer recommendations. Ensuring smooth bearing operation is essential to prevent overheating and maintain machining precision.

Electrical Issues in the Motor

The spindle motor relies on a stable electrical supply and properly functioning internal components to operate efficiently. Electrical problems—such as voltage imbalances, faulty windings, or short circuits—can cause the motor to draw excessive current, which generates heat inside the motor itself.

Common electrical issues include:

Voltage imbalances

Unequal voltage across motor phases increases current draw and internal resistance, producing additional heat.

Faulty or damaged windings

Worn insulation, shorted turns, or open circuits can reduce motor efficiency and raise operating temperatures.

Loose connections or faulty drives

Poor electrical connections or malfunctioning VFDs (Variable Frequency Drives) can create spikes or irregular currents, stressing the motor.

Consequences of electrical issues include:

Rapid heat buildup – Excess current generates heat in the motor windings, which can quickly exceed safe operating limits.

Motor insulation failure – Prolonged overheating can damage insulation, leading to short circuits or permanent motor failure.

Reduced spindle lifespan – Continuous electrical stress accelerates wear on bearings and other mechanical components, compounding the overheating problem.

Best Practice: Regularly inspect electrical connections, monitor current and voltage levels, and ensure the VFD or drive system is functioning correctly. Correcting electrical imbalances early can prevent motor overheating and costly spindle damage.

Signs and Symptoms of CNC Spindle Overheating

Recognizing the early warning signs of spindle overheating is crucial for preventing severe damage and costly downtime. Here are the most common indicators:

Unusual Noises

Grinding, squealing, or rattling sounds often indicate that bearings are under excessive stress or that lubrication has failed. As heat builds up, metal components expand and bearings lose their smooth operation, creating friction noises. These sounds are a clear signal that the spindle is experiencing thermal stress and should be checked immediately.

Thermal Shutdowns

Many modern CNC spindles are equipped with temperature sensors that trigger automatic shutdowns when temperatures exceed safe limits. While this feature protects the machine, repeated or frequent thermal shutdowns are a red flag that your spindle is consistently overheating. Ignoring these shutdowns can lead to permanent motor or bearing damage.

Reduced Spindle Performance

Overheating can directly affect machining performance. You may notice decreased cutting precision, slower spindle speeds, or difficulty maintaining feed rates. Heat causes expansion of critical components, reduces bearing efficiency, and may increase vibration—all of which compromise accuracy and reduce the overall effectiveness of your machine.

Visible Discoloration or Burning Smell

Extreme heat can cause metal components or insulation materials to discolor. If you notice bluish or brownish hues on the spindle housing, motor, or bearings, it’s a sign of prolonged high temperatures. A burning smell is another serious indicator that internal parts, such as windings or lubrication, may be damaged. These symptoms require immediate attention to prevent catastrophic failure.

By paying close attention to these signs, operators can catch overheating issues early, prevent costly repairs, and extend the lifespan of their CNC spindle.

Step-by-Step Guide to Preventing cNc Spindle Overheating

Monitor Spindle Load

Always operate the spindle within its rated capacity. Avoid pushing it too hard with aggressive cuts, deep passes, or high feed rates. Overloading creates excessive friction and heat, which can rapidly damage the spindle.

Maintain Proper Lubrication

Regularly check and maintain lubrication for spindle bearings. Ensure that the correct type and amount of lubricant is used, and replace it as needed. Contaminated or insufficient lubrication increases friction and accelerates overheating.

Inspect and Maintain Cooling Systems

Ensure that your spindle’s cooling system—whether air-cooled or liquid-cooled—is functioning properly. Clean air vents, replace filters, check coolant levels, and ensure fans or pumps are working efficiently. A well-maintained cooling system is critical for temperature control.

Control Ambient Temperature

Keep the workshop environment cool and well-ventilated. High ambient temperatures make it harder for cooling systems to dissipate heat, especially during long production runs. Air conditioning or proper ventilation can help maintain safe operating temperatures.

Adjust RPM and Feed Rates Appropriately

Optimize spindle speed and feed rates based on the material, tooling, and machining operation. Running at very high RPMs without adjusting feeds can generate unnecessary heat, while too slow or inefficient feeds can create friction and stress.

Regularly Inspect Bearings and Spindle Components

Check bearings, shafts, and mounting hardware for signs of wear, misalignment, or damage. Worn or damaged bearings increase friction, vibration, and heat buildup. Replace any parts showing signs of wear before they cause overheating.

Monitor Electrical Health of the Motor

Ensure that the spindle motor receives stable voltage and current. Electrical issues, such as shorted windings or voltage imbalances, can cause excessive internal heat. Routine electrical inspections help prevent sudden overheating.

Implement Temperature Monitoring

Use thermal sensors or infrared cameras to monitor spindle temperature during operation. Early detection of rising temperatures allows you to take corrective action before serious damage occurs.

Schedule Routine Preventive Maintenance

Create a maintenance schedule that includes vibration analysis, thermal imaging, lubrication checks, and spindle alignment inspections. Preventive maintenance is far less costly than emergency repairs and ensures consistent spindle performance.

Train Operators to Recognize Warning Signs

Educate operators on the signs of overheating, including unusual noises, reduced performance, discoloration, and burning smells. Prompt response to early indicators prevents major failures.

Following these steps consistently can significantly reduce the risk of spindle overheating, extend the life of your CNC machine, and maintain consistent machining quality.

Advanced Tips for Spindle Longevity

Using Spindle Load Monitoring Systems

Installing sensors that monitor spindle load in real-time can provide early warnings of potential issues. These systems track torque, current, and temperature, alerting operators to abnormal conditions before they cause serious damage. Early detection helps prevent overheating, mechanical stress, and unexpected downtime.

Choosing the Right Spindle for the Job

Selecting a spindle with sufficient power, speed, and cooling capacity for the intended material and cutting operation is crucial. Using an underpowered spindle for demanding tasks can lead to frequent overloads, excessive heat, and reduced lifespan. Matching spindle specifications to the workload ensures consistent performance and reliability.

Upgrading to Better Cooling Solutions

For high-demand operations, consider upgrading to more effective cooling systems. Water-cooled spindles or advanced hybrid cooling technologies can maintain lower operating temperatures than standard air-cooled units. Enhanced cooling reduces thermal stress on bearings and motor windings, improving both spindle life and machining precision.

Diagnosing Electrical vs. Mechanical Causes of CNC Spindle Overheating

Signs of Electrical Issues

Spindle overheating can stem from electrical problems, often tied to the spindle motor or its control systems, such as a Variable Frequency Drive (VFD). These issues may cause excessive heat due to improper power delivery or component failure.

Watch for:

l Inconsistent RPMs or torque under load, indicating potential VFD or motor control issues.

l Sudden power drops, which can strain the motor and generate heat.

l Overheating of the spindle motor, often detectable by touch or thermal imaging.

l Burnt smells or discolored wiring, suggesting electrical arcing or short circuits.

Use a multimeter to check voltages and amperage for irregularities. Thermal imaging can pinpoint hot spots on the motor or control board. If you're not experienced with electrical diagnostics, consult a professional. Poor grounding or worn brushes (in brushed motors) can also contribute to overheating and erratic performance.

Signs of Mechanical Failures

Mechanical issues are a common cause of spindle overheating, often due to friction or improper alignment in components like bearings, shafts, or collets. These problems typically produce excessive heat alongside other symptoms.

Common red flags include:

l Grinding or knocking noises during spindle operation, indicating worn bearings or misaligned components.

l Vibration in the Z-axis or spindle head, which increases friction and heat.

l Physical wear on collets, tool holders, or motor mounts, leading to inefficient operation and overheating.

If your CNC machine has condition monitoring sensors, review vibration or temperature logs for spikes, which signal mechanical issues. Routine inspections, such as checking for loose fasteners or worn gears, can catch problems early.

Mechanical failures often develop gradually, so proactive maintenance is key to preventing overheating and costly repairs.

Tools and Techniques for CNC Spindle Overheating Diagnosis

Using a Stethoscope or Vibration Analyzer

When a CNC spindle overheats, diagnostic tools can help identify the root cause with precision. A mechanic’s stethoscope is a simple yet effective tool for pinpointing issues. By placing the probe on different parts of the spindle housing, you can listen for abnormal sounds, such as grinding or humming, that may indicate friction or component wear contributing to overheating.

l Stethoscope: Amplify sounds from the motor, bearings, or gearbox. If excessive noise or vibration is detected near the bearings, it suggests friction or wear causing heat buildup.

l Vibration Analyzer: These devices measure vibration amplitude and frequency, identifying imbalances, misalignments, or worn components that generate heat. Advanced sensors can detect subtle issues before they lead to significant overheating.

Pairing these tools with smartphone apps for sound recording or frequency analysis allows you to log and track data over time. This supports predictive maintenance, helping you address overheating issues before they escalate.

Thermal Imaging and Temperature Profiling

Thermal imaging is a critical tool for diagnosing spindle overheating. Infrared cameras detect hot spots, revealing overheating bearings, motor windings, or friction in the spindle shaft. A quick scan can identify problem areas without dismantling the machine.

l Thermal Cameras: Look for bright red or white areas on the thermal display, indicating temperatures above normal operating conditions. For example, a hot bearing suggests inadequate lubrication or wear.

l Temperature Profiling: Use software to compare current temperature readings against a baseline “healthy” profile. Spikes in temperature logs from condition monitoring sensors can confirm overheating trends.

Combining thermal imaging with vibration analysis and temperature profiling provides a comprehensive approach to diagnosing overheating. This is particularly effective in busy shop environments where multiple machines run simultaneously, making it harder to isolate heat-related issues. Regular use of these tools enables early detection and prevents costly spindle failures.

How to Fix Common CNC Spindle Overheating Issues

Replacing or Re-greasing Bearings

Bearings are a frequent cause of spindle overheating due to friction from wear or inadequate lubrication. Check your machine’s manual to identify the bearing type (sealed or open) and maintenance requirements.

l Re-greasing Open Bearings: If the bearings are open, apply high-quality, manufacturer-recommended grease using a precision grease gun. Avoid overpacking, as excess grease can increase friction and heat. Run the spindle at low RPM after greasing to ensure even distribution, then monitor temperature with a thermal camera or sensor to confirm reduced heat output.

l Replacing Sealed Bearings: Sealed bearings typically require replacement. Disassemble the spindle housing carefully, using a bearing puller if needed, and replace with OEM-specified bearings. After installation, run the spindle at low RPM to settle the bearings, then use a thermal imaging tool or temperature sensor to verify normal operating temperatures.

Post-repair, check vibration and temperature logs to ensure the issue is resolved. Overheating caused by bearings often stems from neglect, so regular maintenance is critical.

Realigning the Spindle Shaft

Misalignment in the spindle shaft can cause excessive friction, leading to overheating, especially at high speeds. Proper alignment reduces heat and extends component life.

l Alignment Tools: Use a dial indicator or laser alignment kit to measure shaft runout at low RPM. If runout exceeds the manufacturer’s tolerance, realignment is necessary.

l Realignment Process: Loosen the spindle mount and reseat it carefully. For advanced CNC machines, adjust alignment shims or recalibrate software settings as needed. Inspect the toolholder, collet, and chuck for wear or debris, as these can introduce misalignment and increase heat.

l Post-Alignment Checks: After realignment, clean all components thoroughly and test the spindle under load. Use thermal imaging or temperature sensors to confirm that overheating has been mitigated.

Document temperature and vibration readings after repairs to establish a new baseline. Regular alignment checks and toolholder maintenance will help prevent overheating and maintain smooth, efficient spindle operation.

When to Call a Professional for CNC Spindle Overheating

Knowing Your Limits

Even experienced CNC operators should recognize when spindle overheating issues require professional expertise. While you can address basic maintenance like re-greasing bearings or cleaning toolholders, complex problems—such as internal motor failure, spindle cartridge damage, or advanced electrical faults—demand specialized skills.

Call a professional if:

l Basic fixes (e.g., re-greasing bearings, realigning the shaft, or checking electrical connections) don’t resolve overheating.

l You notice persistent high temperatures despite normal operation, suggesting deeper issues like motor winding failure or VFD malfunctions.

l Diagnostic tools (thermal imaging, vibration analyzers) show anomalies you can’t interpret or fix.

Professionals have advanced diagnostic equipment, such as high-precision thermal scanners or specialized spindle testing rigs, and expertise with various spindle designs. Hiring a pro isn’t admitting defeat—it’s a smart move to protect your machine’s performance and longevity.

Cost vs. Benefit of Professional Repairs

The cost of professional spindle repair can seem high, but attempting complex fixes without the right skills or tools often leads to bigger problems. Mishandling components, like improperly installing bearings or misaligning the spindle, can escalate a $500 repair into a $5,000 replacement.

Benefits of professional service include:

l Expert Diagnostics: Technicians can pinpoint issues like hidden electrical faults or internal friction that standard shop tools might miss.

l Warranties: Most professional repairs come with guarantees, ensuring long-term reliability.

l Minimized Downtime: Many services offer expedited repairs to get your machine back online quickly.

l Increased Resale Value: A documented service history from professionals enhances your CNC machine’s market value.

Before tackling a suspected major issue yourself, weigh the cost of professional repair against the value of your machine’s uptime and precision. In most cases, the expertise and peace of mind are well worth the investment.

How Environmental Factors Affect CNC Spindle Overheating

Humidity, Dust, and Temperature

The environment in your CNC shop significantly impacts spindle health and can contribute to overheating. These factors can exacerbate friction, degrade components, and disrupt proper operation.

l Humidity: High humidity can cause condensation inside the spindle housing, leading to rust or corrosion on bearings and other components. This increases friction, generating excess heat and potentially causing premature failure.

l Dust and Particulate Matter: In environments like woodshops or metal-grinding facilities, dust can infiltrate the spindle motor. When mixed with grease, dust forms an abrasive compound that wears down bearings and seals, increasing friction and heat buildup.

l Temperature Swings: Cold temperatures thicken grease, reducing its lubricating effectiveness and causing higher friction and heat. In hot conditions, thermal expansion can misalign the spindle shaft, and lubricants may degrade faster, leading to overheating. Extreme heat can also stress motor windings, contributing to elevated temperatures.

Mitigation Strategies:

l Install dust collectors and air filtration systems to minimize particulate infiltration.

l Use climate control systems to maintain stable humidity and temperature levels.

l Store spare parts and lubricants in clean, dry, temperature-controlled environments.

l Regularly inspect and clean spindle components to prevent dust buildup and ensure proper lubrication.

Machine Placement and Vibration Isolation

The physical placement of your CNC machine can influence spindle overheating by amplifying vibrations or heat transfer from external sources.

l Uneven Surfaces: Machines on uneven floors may experience misalignment, causing the spindle to work harder and generate more heat. Vibrations from an unstable base can also increase friction in bearings and other components.

l Proximity to Other Equipment: Placing a CNC machine near heavy machinery, such as presses or lathes, can introduce external vibrations that stress the spindle, leading to increased heat from friction or misalignment.

l Heat Sources: Machines placed near heat-generating equipment or in direct sunlight may experience higher ambient temperatures, exacerbating spindle overheating.

Mitigation Strategies:

l Ensure the machine is level using a precision bubble level or laser level to minimize misalignment-related heat.

l Install vibration isolation mounts or dampers under the CNC to absorb external vibrations and reduce stress on the spindle.

l Position the machine away from heavy equipment or heat sources to avoid vibration transfer through the floor or elevated ambient temperatures.

l Use thermal barriers or enclosures to shield the machine from external heat sources.

By controlling environmental factors and optimizing machine placement, you can reduce spindle overheating, improve operational efficiency, and extend the lifespan of your CNC equipment. Regular monitoring with thermal imaging or temperature sensors can help detect early signs of environment-related issues.

Manufacturer Recommendations You Shouldn’t Ignore for CNC Spindle Overheating

Reading the Manual Thoroughly

Skipping the CNC spindle manual is a costly mistake. It’s packed with critical information tailored to your spindle model, including specifications for operating temperatures, lubrication schedules, compatible coolants, and maintenance procedures. Ignoring these details can lead to overheating and long-term damage.

l Key Details: The manual specifies the correct lubrication type (e.g., oil mist, packed grease, or self-lubricating ceramic bearings), cooling requirements, and torque settings. Using the wrong lubricant or coolant can increase friction and heat buildup.

l Maintenance Guidelines: Follow instructions for cleaning, bearing maintenance, and component preload to prevent excessive heat from improper setup or wear.

l Troubleshooting Tips: The manual often includes error codes or temperature thresholds to help diagnose overheating issues early.

Print and laminate key maintenance pages for quick reference in your shop. This ensures you’re following manufacturer guidelines to keep temperatures in check and avoid costly repairs.

Following Load and Speed Guidelines

Pushing a spindle beyond its recommended load or RPM limits is a common cause of overheating. Overloading or overspeeding generates excessive heat, stresses components, and accelerates wear.

l Load Limits: Exceeding the spindle’s torque or cutting load capacity can cause motor strain, leading to overheating and potential warping of the shaft or damage to bearings.

l Speed Limits: Running the spindle above its rated RPM increases friction in bearings and generates excessive heat, risking motor winding failure or lubricant breakdown.

l Monitoring Tools: Use your CNC controller’s software to track real-time spindle load, speed, and temperature. Many systems allow you to set alarms for exceeding safe thresholds, helping prevent overheating.

Best Practices:

l Stick to the manufacturer’s specified RPM and load limits to minimize heat generation.

l Regularly check cooling systems (e.g., air or liquid cooling) to ensure they’re functioning as per the manual’s recommendations.

l Monitor temperature logs via condition sensors or thermal imaging to catch deviations early.

Adhering to these guidelines reduces heat-related stress, prevents overheating, and extends your spindle’s lifespan, keeping your CNC machine running smoothly and efficiently.

Conclusion

Overheating in your CNC spindle is a clear warning sign that demands attention. Whether it’s caused by worn bearings, misalignment, electrical faults, or environmental factors, excessive heat signals underlying issues that can escalate if ignored. Left unchecked, overheating can lead to component failure, costly repairs, and significant downtime.

By mastering diagnostic tools like thermal imaging, vibration analyzers, and stethoscopes, and adhering to manufacturer guidelines for maintenance, load, and speed, you can catch problems early and keep your spindle running efficiently. Environmental controls and proper machine placement further reduce the risk of heat-related issues.

Your spindle is the heart of your CNC machine. Protect it with proactive care, and it will reward you with reliable, long-lasting performance.

FAQs

What is the ideal operating temperature for a CNC spindle?

Most spindles operate optimally between 40°C and 60°C (104°F–140°F), but consult the manufacturer’s specifications.

How often should I lubricate my spindle?

Lubrication frequency depends on usage and manufacturer guidelines, typically every 500–1,000 operating hours.

Can overheating cause permanent damage?

Yes, prolonged overheating can damage bearings, motors, or other components, leading to costly repairs or replacements.

Is water cooling better than air cooling?

Water cooling is more effective for high-speed or heavy-duty applications, but air cooling is simpler and sufficient for lighter tasks.

What’s the average lifespan of a CNC spindle?

With proper maintenance, spindles can last 10,000–20,000 operating hours, depending on usage and conditions.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu