Yu CNC mashin de mek strenj nɔys ɔ lɔs prɛsishɔn? Dat subtil vaybreshɔn ɔ dawt daun tɛm we yu nɔ bin de ɛkspɛkt kin pɔynt to wan saylɛnt sabotɛr we de lurk insay: damej biɛrin dɛn na yu spindle moto. Biɛrin damej nɔ kin ɔltɛm klia, bɔt na impɔtant tin we kin mek dɛn ridyus di akkuracy, inkris wear pan ɔda kɔmpɔnɛnt dɛn, dia dia ripɛnt, ɔ tɔtal spindle fayl if dɛn nɔ adrɛs am.

Insay dis gayd, wi go fɛn ɔltin we yu nid fɔ no bɔt fɔ bia damej na spindle motoka dɛn—frɔm fɔ si di fɔs sayn dɛn to fɔ no di tin dɛn we de mek tin apin ɛn fɔ impruv di strateji dɛn we go ɛp fɔ mek di sik nɔ apin. Ilɛksɛf yu na CNC ɔpreshɔn, mentenɛns tek, ɔ ɔbi we de protɛkt yu sɛtup, dis risɔs go ɛp yu fɔ kip yu bia dɛn insay tɔp shep, mek shɔ se dɛn gɛt smol ɔpreshɔn ɛn ɛkstend mashin layf.

Mek wi uncover di hidden threats en kip yu spindle spinning flawlessly!

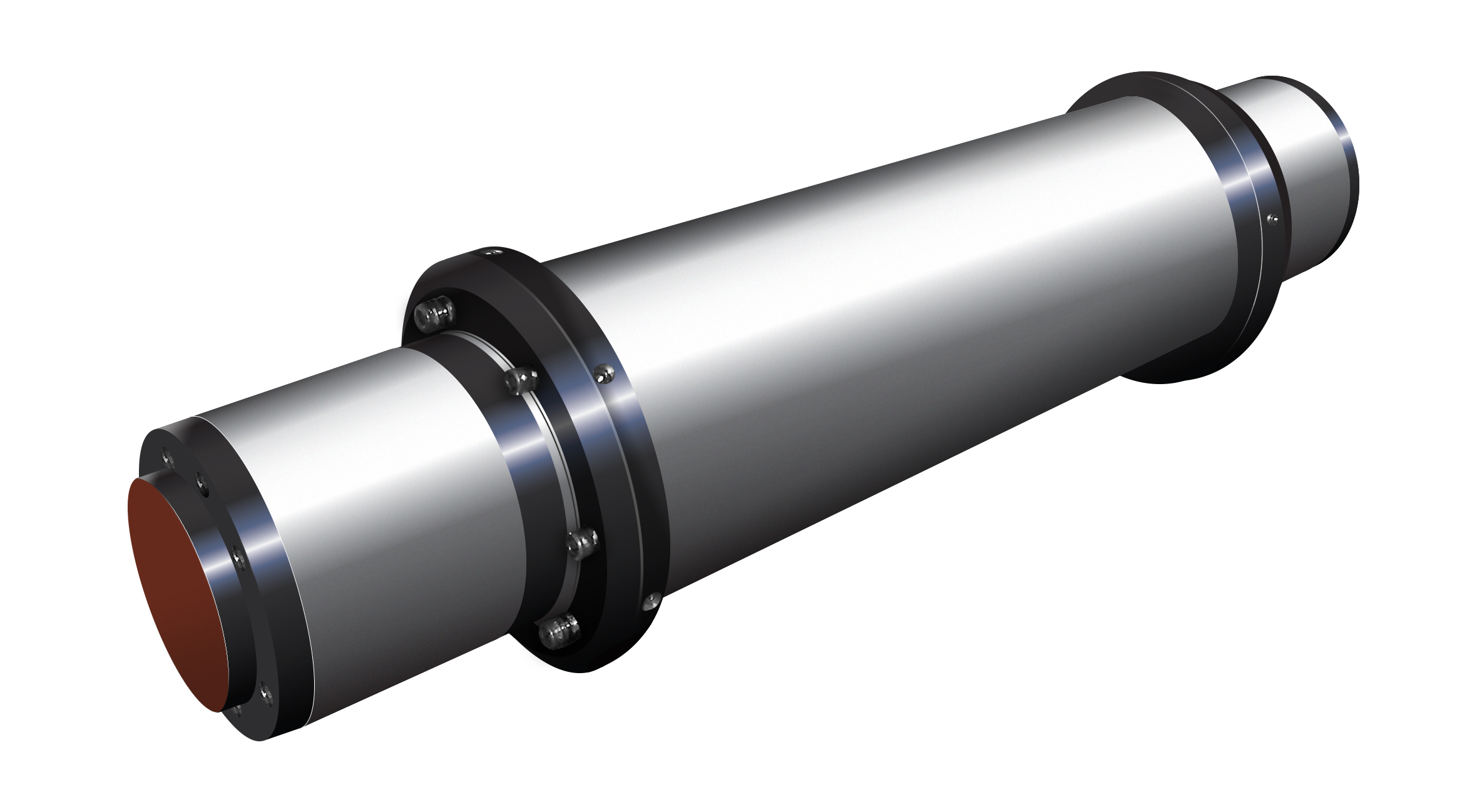

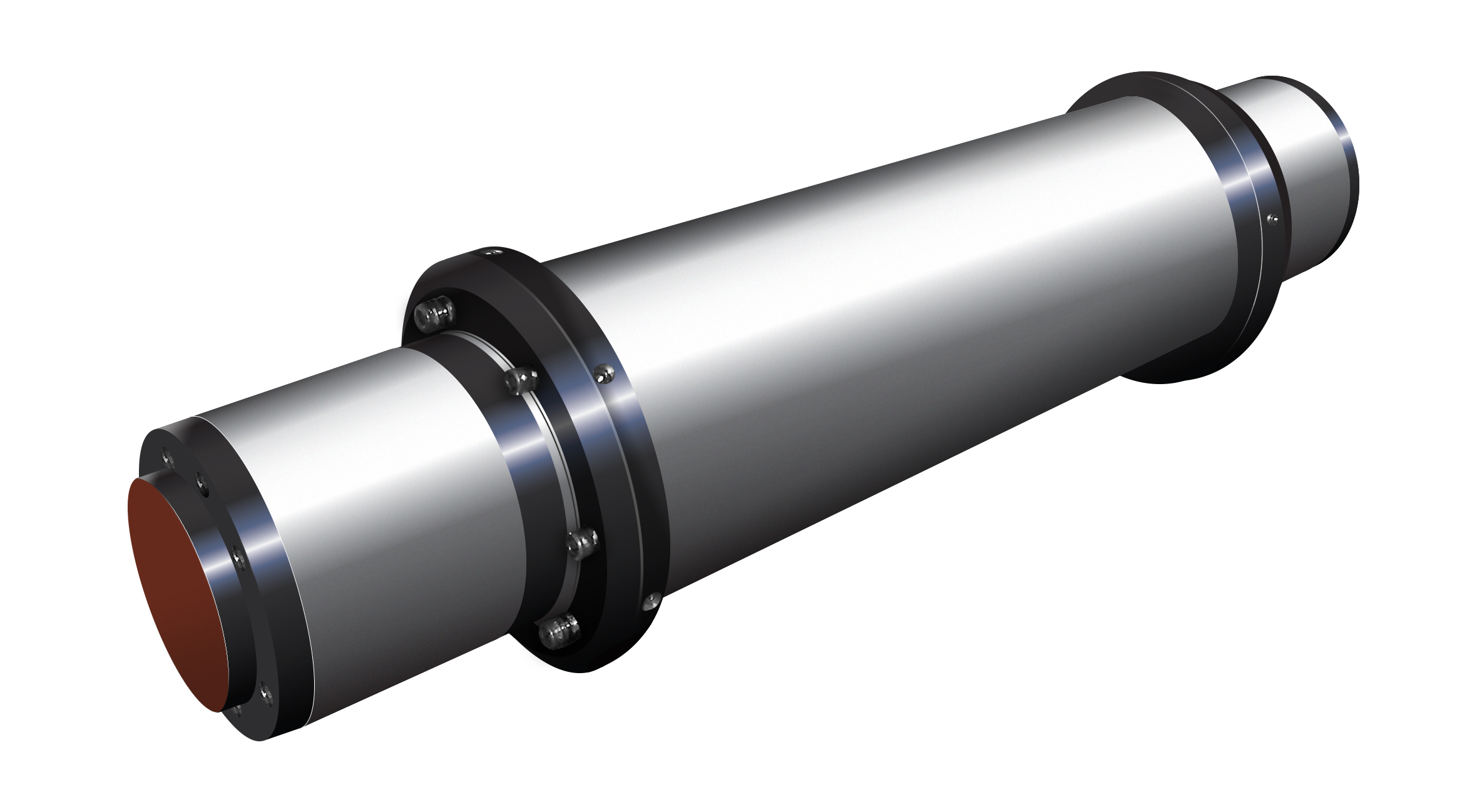

Introdyushɔn to spindle motoka biɛrin dɛn .

Wetin na spindle motoka biɛrin?

Na di kɔr fɔ ɛvri spindle moto de wan sɛt fɔ bia dɛn—prɛsishɔn-ɛnjɛnɛri kɔmpɔnɛnt dɛn we de sɔpɔt di shaft we de rɔn, we de mek ay-spid, kɔrɛkt muvmɛnt. Dɛn bia dɛn ya de ridyus frikshɔn, absɔb lod, ɛn mentɛn alaynɛshɔn, we de alaw di spindle fɔ drayv di kɔt tul dɛn wit di prɛsishɔn we dɛn nid fɔ drɔ, mil, ɛn shep matirial dɛn.

Biɛrin dɛn kin gɛt difrɛn kayn dɛn, lɛk bɔl, rɔla, ɔ angul kɔntakt, we dɛn mek fɔ di spindle in spid, lod, ɛn aplikeshɔn—ilɛksɛf na wud wok, mɛtal fabrikeshɔn, ɔ kɔmpɔzit mashin. I nɔ mata di kayn, di bia dɛn fɔ de wok insay tayt tolɛreshɔn fɔ mek dɛn nɔ vaybrɛshɔn, fɔ mek di ples wam, ɛn fɔ wɛr.

Imajin dɛn as di wil dɛn we de na wan motoka we gɛt ay pafɔmɛnshɔn—if dɛn de shek ɔ tek dɛn, di wan ol sistɛm de sɔfa. Damej bearing kin mek frikshɔn pasmak, misalignment, ɛn tɛmral ishu, kɔmprɔmis di spindle in pefɔmɛns. Ɔndastand di kayn bia dɛn, di nid fɔ lɔbrik, ɛn di lod kapasiti dɛn de gi yu ed fɔ no ɛn protɛkt di damej kwik kwik wan.

Impɔtant tin fɔ bia wɛlbɔdi na Spindle Motors .

Yu spindle moto in rilaybiliti hinj pan in bearings. We bearings degrade, i nɔ jɔs bi di roteshɔn we de pan risk; I kin mek shaft misalignment, i kin mek di vaybreshɔn bɔku, i kin pwɛl wok, di delay we dɛn kin mek fɔ mek di prodakshɔn, ɛn di kɔst fɔ mek di say dɛn we dɔn pwɛl kin go ɔp.

Di fɔs sayn dɛm fɔ damej, lɛk fayn fayn vaybreshɔn, kin go ɔp fɔ kɔmplit fɔl if dɛn nɔ tek am. Monitoring bearing kondishɔn de mek smɔl smɔl tin dɛn nɔ bi big ed pen, sev yu frɔm dia dia spindle ribild.

Pantap dat, di bia dɛn we dɔn pwɛl nɔ de ayd dɛn prɔblɛm dɛn—dɛn kin strɛch di motoka wayndin, di say dɛn we dɛn kin kol, ɛn di we aw dɛn kin drayv. Na domino effect we no opareta nɔ want fɔ trig.

Biɛrin intɛgriti na bɔt mɔ pas mɛkaniks—na sef, efyushɔn, ɛn bottom-layn sevings. Fɔ masta di kɔz ɛn prɛvɛnshɔn fɔ bia damej na nɔ-nɛgɔshiable fɔ pik pefɔmɛns.

Di kɔmɔn tin dɛn we kin mek pɔsin gɛt prɔblɛm wit di tin dɛn we kin pwɛl na di spindle moto dɛn

| kin mek |

di diskripshɔn go bifo |

di bɛst we fɔ du am |

di bɛst we fɔ du am |

| Ovalod di bia dɛn . |

Fos biyond dizayn limit frɔm mashinin taf matirial, agresiv kɔt dip, ɔ rapid fid rɛt. |

Fatigue krak, difכmeshכn, prεmatchכ pit/spal, כ fεil kwik kwik wan (frakt/stכl). |

Align Cutting Parameters wit Bearing Ratings; Yuz shap tul ɛn balans lod. |

| Inadequate ɔ kɔntaminɛt lɔbrikeshɔn . |

Lɔbrik lɛvɛl, kɔntaminɛnt (dɛbris/wata), ɔ lik sil we de mek yu gɛt dray kɔntakt ɔ abraziv akshɔn. |

Surface erosion, pitting, inkris heat, or seizure. |

Yuz spɛsifikɛd lɔbrikɛn, monitɔr lɛvɛl, riples di wan dɛn we dɔn dɔti, ɛn chɛk di sil dɛn. |

| Misalaynmɛnt ɔ Instɔlɛshɔn we nɔ rayt fayn . |

Asɛmbli mistek, tɛmral ɛkspɛnshɔn, ɔ nɔ ivin mawntin sɔfays we de mek shaft tilt ɔ misalign. |

Nɔ ivin lod distribyushɔn, aksɛleret wɛr, vaybreshɔn-indyuz fatigue, ɔ ɔt. |

Yuz alaynɛshɔn tul dɛn we yu de instɔl, chɛk fɔ no if yu dɔn sɛt, ɛn chɛk ɔltɛm. |

| Kontamineshɔn frɔm dɔst ɛn dɔti . |

patikyula dɛn we de infiltrate via po sil ɔ dɔti ɛnvayrɔmɛnt, we de mek abrashɔn ɔ kɔrɛshɔn. |

skrat, dent, kɔrɛshɔn, ɔ brok dɔŋ. |

Yuz fayn fayn sil dɛn, ay filtreshɔn, ɛn klin ɔltɛm. |

| pasmak vaybreshɔn ɔ imbalans . |

Unbalanced tools ɔ resonant frikshɔn dɛn we de amplify oscillations. |

Damej to di rays, taya, ɔ ɔt frɔm kɔnstant muvmɛnt. |

Balans Tul, Ayzolayt Vaybreshɔn, ɛn Monitɔ wit Analayza dɛn. |

| Di tɛmpracha dɛn we de ɔprɛt ay ay wan . |

Di tin dɛn we dɛn kin yuz fɔ mek di bɔdi wam, di tin dɛn we dɛn kin yuz fɔ mek di bɔdi tan lɛk tin dɛn we dɛn kin yuz fɔ mek dɛn bɔdi tan lɛk tin dɛn we dɛn kin yuz fɔ mek dɛn bɔdi tan lɛk tin dɛn we dɛn kin yuz fɔ mek dɛn bɔdi tan lɛk tin dɛn we dɛn kin yuz fɔ mek dɛn bɔdi tan lɛk tin dɛn we dɛn kin yuz fɔ mek dɛn bɔdi tan lɛk tin dɛn we kin mek dɛn bɔdi tan lɛk tin dɛn we kin mek dɛn bɔdi tan lɛk tin dɛn we kin mek dɛn bɔdi tan lɛk tin dɛn we kin mek dɛn bɔdi tan lɛk tin dɛn we kin mek dɛn bɔdi tan lɛk tin dɛn we kin mek dɛn bɔdi tan lɛk tin dɛn we dɛn kin mek, ɔ we kin mek dɛn nɔ ivin mek di ples big. |

Ridyus lod kapasiti, lubrikant brekdaun, ɔ thermal fatigue krak. |

Optimayz kol, monitar temperechur, en avoid ovalod. |

| Ilektrikal Kɔrɛnt Pasej . |

Arcing frɔm po grounding we de kɔz sɔfays erosion via ilɛktrik dischaj. |

Surface damage frɔm ilɛktrik dischaj mashin ifɛkt dɛn. |

Mek shɔ se dɛn grɔn ɛn yuz di insulated bearing dɛn fayn fayn wan usay nid de. |

1. Ɔvalod di bia dɛn .

Biɛrin ɔvalod kin apin we mɛkanikal kɔmpɔnɛnt dɛn, lɛk biɛrin dɛn na spindl ɔ rotating mashin, dɛn kin sɔbjɛkt to fɔs dɛn we pas dɛn dizayn kapasiti. Dis isyu na patikyula wan we bɔku na mashin ɛn industrial aplikeshɔn usay ɔpreshɔnal paramita dɛn de push ikwipmɛnt pas in limit. If yu lod pasmak, dat kin mek yu gɛt bɔku damej, yu nɔ go ebul fɔ du di wok fayn fayn wan, ɛn i kin mek yu nɔ spɛn bɔku mɔni.

Di tin dɛn we kin mek pɔsin gɛt ɔvalod .

Biɛrin kin bi ɔvalod bikɔs ɔf difrɛn tin dɛn we gɛt fɔ du wit ɔpreshɔnal ɛn sɛtup-rilayt tin dɛn, we inklud:

Machining tof matirial dɛn we nɔ gɛt di rayt sɛtup:

l Prosesin dense ɔ ay-strɛng matirial, lɛk taytaniɔm, stenlɛs stiɛl, ɔ ɔda had alɔy, de put bɔku strɛs pan bia, mɔ we yu de yuz layt-duti spindl dɛn we dɛn nɔ mek fɔ dɛn kayn lod dɛn de.

l Inadequate mashin setup, lɛk improper tul sɛlɛkshɔn ɔ insufficient spindle rigidity, amplify axial (along di axis of rotation) ɛn radial (perpendicular to di axis) lod, ɔvawɛl di bearings.

Dip dɛn we de kɔt agresiv wan:

l Fɔ kɔt dip dip wan di tɛm we dɛn de mek mashin de mek dɛn put am wantɛm wantɛm ɛn strɔng fɔs pan di spindle ɛn di bia dɛn. Dɛn shɔk lod dɛn ya kin pas di bia we di bia de kɛr lod, we kin mek dɛn strɛs kwik kwik wan ɛn dɛn kin pwɛl fɔ lɔng tɛm.

l Dip kɔt we nɔ gɛt prɔpa inkrimɛntal stɛp ɔ tulpat ɔptimayzeshɔn de inkrisayz di chans fɔ ɔvalod.

Rapid fid ret mismatched to spindle kapabiliti:

l ay fid ret we nɔ alaynɛd wit di spindle in dizayn spɛsifikɛshɔn dɛn de mek prɛshɔ we nɔ ivin pan bia. Dis mismatch de mek pasmak vaybreshɔn ɛn dinamik lod, we kin destabiliz di bia sistɛm.

l Rapid fid ret dɛn we dɛn kam togɛda wit improper tul ɔ wokpies alaynɛshɔn mɔ fɔ mek di fɔs distribyushɔn nɔ ivin nɔ ivin.

Di we aw dɛn mek di mashin ɔ di we aw dɛn de du am di rayt we:

l Yuz biɛrin ɔ spindl wit insufishɛnt lod retinj fɔ di aplikeshɔn kin lid to ɔvalod ivin ɔnda nɔmal ɔpreshɔn kɔndishɔn.

l Ɔpreshɔn mistek, lɛk di kɔrɛkt program fɔ CNC mashin ɔ fɔ neglek fɔ akɔn fɔ matirial prɔpati, de kɔntribyut to pasmak fɔs pan bia.

Efεkt dεm we de mek pɔsin gɛt ɔvalod .

We dɛn de bia wit di bia dɛn we pas dɛn dizayn limit, dɛn kin gɛt wan rich detrimental ifɛkt dɛn we kin kɔmprɔmis di pefɔmɛns ɛn di we aw dɛn kin du am:

Fatigue krak na bia rays:

l we dεn ripit כvalod de indyuz saykli strεs na di bia rεs dεm (di insay εn כta ring dεm we de haus di rolin εlimεnt dεm). As tɛm de go, dis kin mek di krak krak we pɔsin taya, usay di maykro-krak dɛn kin fɔm ɛn prɔpagɛt tru di matirial.

l Dɛn krak krak ya kin mek di bia strɔkchɔ wik, ɛn dis kin mek i nɔ ebul fɔ sɔpɔt lod ɛn i kin mek di risk fɔ mek i nɔ wok fayn mɔ ɛn mɔ.

Difɔmeshɔn frɔm di lod dɛn we pasmak:

l fכs we pasmak kin mek plastic difכmeshכn fכ di bia kכmכpכnt dεm, lεk di rolin εlimεnt dεm (bכl כ rola) כ rays. Dis difɔmeshɔn de chenj di bia in jɔyometri, we de mek dɛn nɔ gɛt di rayt we, i de mek frikshɔn bɔku, ɛn i de ridyus di prɛsishɔn.

l difכm biεn kin mek bak di כt we pasmak, we de aksεlεrayt fכs we.

Premature pitting ɔ spalling:

l Ovalod akselerats surface fatigue, we de rizulta in pitting (smɔl krata) ɔ spalin (flaking ɔf matirial) pan di bia sɔfays. Dɛn difrɛn difrɛn tin ya kin ambɔg di we aw dɛn de wok fayn fayn wan, mek di vaybrɛshɔn go ɔp, ɛn mek di bia nɔ wok kwik kwik wan.

l pitting ɛn spalling na patikyula damej insay ay-prɛsishɔn aplikeshɔn, usay ivin smɔl sɔfayz irɛgyulariti kin afɛkt pefɔmɛns.

Failure we nɔ wok wantɛm wantɛm:

l Insay siriɔs kes dɛm, fɔ ɔvalod kin mek katastrofik fayl, lɛk fɔ bia frakt ɔ spindle stɔl. Wan fraktrɛd bia kin seiz ɔl, stɔp mashin ɔpreshɔn ɛn pɔtɛnɛshɛl fɔ pwɛl ɔda kɔmpɔnɛnt dɛn.

l Wan wantɛm wantɛm we i nɔ wok kin mek i gɛt sef risk bak to di wan dɛn we de du di ɔpreshɔn ɛn i kin mek dɛn lɔs bɔku bɔku prɔdakshɔn dɛn.

Di tin dɛn we kin apin we pɔsin gɛt ɔvalod .

Di kɔnsikuns dɛm fɔ ɔvalod bia dɛn de go bifo pas di immediate damej to di bearing insɛf ɛn kin gɛt fa-rich ɔpreshɔnal ɛn faynɛns impak dɛm:

l Ridyus di Ikwipmɛnt Layfspan : ɔvalod biɛrin dɛn kin west fast, nid fɔ de ɔltɛm fɔ riplesmɛnt ɛn fɔ mek di mentenɛns kɔst go ɔp.

l Inkris dauntaym : Biɛrin fɔl bɔku tɛm kin nid fɔ ripɛnt bɔku bɔku wan, we kin mek dɛn nɔ plan fɔ dɔn di wok ɛn ambɔg di prodakshɔn schedule.

l Kɔmprɔmis prɛsishɔn : Difɔm ɔ damej biɛrin dɛn de ridyus di akkuracy fɔ mashin prɔses, we kin mek di pat dɛn we nɔ fayn ɛn riwɔk.

l Di ay ɛnaji we dɛn de yuz : Di bia dɛn we de ɔvalod de mek frikshɔn bɔku, dɛn nid mɔ ɛnaji fɔ ɔpreshɔn mashin ɛn drɛb di kɔst dɛn.

l Sefty hazards : Wantɛm wantɛm we de bia fayl ɔ spindle stɔl kin mek di kɔndishɔn we de mek pɔsin sik, lɛk di dɔti we de flay ɔ di we aw dɛn nɔ de kɔntrol di mashin.

Di bɛst we fɔ du tin fɔ mitigate .

Fɔ bia ɔvalod na sɔntin we dɛn kin ebul fɔ avɔyd we kin kɔmɔt frɔm di we aw dɛn nɔ de yuz mashin fɔ mek mashin dɛn, lɛk fɔ yuz tin dɛn we nɔ fayn fɔ yuz, dip dip tin dɛn we dɛn kin kɔt, ɔ di tin dɛn we dɛn nɔ kin gri fɔ it. Di rizultin fatigue krak, difכmeshכn, pitting, εn pכtεnshal katastrofik fεil kin lid to ridyus ikwipmεnt layfspan, inkrεsiv kכst, εn sef risk. Bay we dɛn alaynɛd di kɔt paramita dɛn wit bia kapabiliti, yuz shap tul dɛn, balans lod, ɛn impruv rɛgyula mentenɛns, ɔpreshɔn dɛn kin ridyus di risk fɔ ɔvalod bɔku bɔku wan. Dɛn proaktiv mɛsej ya de mek shɔ se dɛn ebul fɔ wok fayn, mek prɛsishɔn bɛtɛ, ɛn ɛkstɛnd di savis layf fɔ di bia dɛn ɛn di mashin dɛn we gɛt fɔ du wit am, ɛn dis kin mek dɛn ebul fɔ mek di opareshɔnal efyushɔn ɛn di kɔst sevings.

2. Inadequate ɔ kɔntaminɛt lɔbrik .

Lubrikeshɔn na impɔtant tin fɔ di bɛst pefɔmɛns ɛn lɔng layf fɔ bia dɛn na mashin dɛn we de rɔn, lɛk spindl, motoka, ɔ ɔda mɛkanikal sistem dɛn. I de ridyus frikshɔn bitwin di pat dɛn we de muv, i de mek di ɔt nɔ de, ɛn i de protɛkt di say dɛn we di wata de kɔmɔt frɔm wear. Bɔt, we dɛn nɔ gɛt di rayt ɔ kɔntaminɛt lɔbrik kin mek dɛn gɛt siriɔs opareshɔnal ishu dɛn, dɛn kin kɔmprɔmis di bia pefɔmɛns ɛn mek dɛn nɔ wok bifo tɛm.

Di tin dɛn we kin mek pɔsin nɔ gɛt bɛtɛ ɔ we dɛn kin yuz fɔ kɔt kɔt kɔt .

Lubrikeshɔn fayl kin apin bikɔs ɔf sɔm tin dɛn we kin ambɔg di lɔbrik in ebul fɔ du in impɔtant wok dɛn:

Di lɛvɛl dɛn we nɔ gɛt bɔku lɔbrik:

l Insufisεnt lכbrikεnt in di biεr sistεm de rεsult in dray kכntakt bitwin muv sεf dεm, lεk di rכlin εlimεnt dεm εn rεs dεm. Dis we aw dɛn nɔ gɛt lɔbrik de mek frikshɔn bɔku, we kin mek dɛn skɔ (skrat ɔ gouges) pan bia sɔfays.

l Di lכw lεvεl kin kכmכt frכm di mεntenans we nכ kin apin bכku bכku wan, di fכs filin we dεn bin de fil fכs, כ sכmtεm we dεn kin dכn sכmtεm ova tεm biכs fכ di εvapכreshכn כ lik.

Kɔntaminɛnt dɛn we de insay lɔbrik:

L dɔti, lɛk dɔst, dɔti, ɔ mɛtal patikyula, kin kam insay di lɔbrik, ɛn tɔn am to abraziv mɛdiɔm. Dɛn kɔntaminɛnt ya de grind agens bia sɔfays, aksɛleret wear.

l Wata ingress, bɔku tɛm bikɔs ɔf di po silin ɔ di humid envayrɔmɛnt, miks wit di lɔbrik, ridyus in viskɔsiti ɛn protɛkt kɔrɛshɔn ɔ emulsifikɛshɔn, we de ambɔg di lɔbrik pefɔmɛns.

Sil dɛn we de lik ɔ skip mentenɛns:

l we dɛn dɔn pwɛl, we dɔn pwɛl, ɔ we dɛn nɔ instɔl fayn fayn wan, de mek di lɔbrikɛn nɔ ebul fɔ rɔnawe, di rizɔv dɛn we de pwɛl ɛn mek di bia dɛn de na di say dɛn we gɛt dɔti.

l we yu de neglek di schedule fɔ mentenɛns ɔltɛm, lɛk fɔ nɔ chɛk ɔ riplenish lɔbrik lɛvɛl, kin mek yu nɔ gɛt bɛtɛ lɔbrik as tɛm de go.

Yuz di kɔrɛkt lɔbrikɛnt dɛn:

l We yu yuz lɔbrikɛnt dɛn we nɔ mit di bia in spɛsifikɛshɔn dɛn (ɛgz., kɔrɛkt viskɔsiti, tayp, ɔ aditiv) kin nɔ ebul fɔ gi yu di rayt protɛkshɔn, we kin mek yu gɛt mɔ frikshɔn ɛn wear.

l Fɔ miks di lɔbrikɛnt dɛn we nɔ kɔmpitabl, lɛk fɔ jɔyn gris ɛn ɔyl ɔ difrɛn kayn gris, kin mek di wok nɔ wok fayn ɛn mek di lɔbrik nɔ wok.

Ifɛkt dɛn we nɔ fayn ɔ we gɛt kɔntaminɛt lɔbrik .

We lɔbrik nɔ fayn ɔ kɔntamin, di bia dɛn kin gɛt bɔku bad bad tin dɛn we kin mek dɛn nɔ ebul fɔ du dɛn wok:

Surface erosion ɛn pitting:

l Insufisεnt lכbrikεshכn כ abraziv kכntaminεnt dεm de mek di sכfayz εroshכn, usay mεtirial de wear away frכm di bia in rכl εlimεnt כ rays. Dis kin mek dɛn gɛt pitting, we dɛn kin kɔl smɔl krata dɛn na di say we dɛn de, we kin ambɔg di we aw dɛn de wok fayn fayn wan.

l Pitting de mek di vaybreshɔn ɛn nɔys bɔku, i de ridyus prɛsishɔn ɛn aksɛleret mɔ damej.

Inkris ɔt frɔm frikshɔn:

l we nɔ gɛt di rayt lɔbrik, frikshɔn bitwin di pat dɛn we de muv de mek di ɔt pasmak. Dis elevated temperechur kin degrade di bearing material, wik in structure, en mek thermal expansion, we kin mek i misalignment or kliarens ishu dem.

l kontaminet lכbrikεnt dεm de mek di hεt jεnereshכn bכku bכku wan bay we dεn de introdכks abraziv patikyula dεm we de inkrεs frikshכn.

Seizure in ekstrim kes:

l Insay siriɔs kes, di absɛns ɔf ifɛktiv lɔbrikeshɔn kin mek di bia dɛn tek, usay di rɔlin ɛlimɛnt ɛn di rays dɛn kin lɔk bikɔs ɔf di frikshɔn we pasmak ɔ di matirial wɛldin. Seizure de stɔp mashin ɔpreshɔn, pɔtɛnɛshɛl fɔ mek katastrofik fayl ɛn damej to di kɔmpɔnɛnt dɛn we de rawnd.

L seizure na di rizulyt fɔ lɔng dray kɔntakt ɔ ekstrim kɔntaminɛshɔn.

Di tin dɛn we kin apin we pɔsin nɔ gɛt di rayt ɔ we gɛt kɔntaminɛt lɔbrik .

Di kɔnsikuns dɛm fɔ di lɔbrikɛshɔn fɔlt dɛn de go bifo pas di bia dɛm sɛf, we de impɛtɛkt ɔl di sistɛm pefɔmɛns ɛn ɔpreshɔnal kɔst dɛm:

l ridyus bia layfspan : inadekwat ɔ kɔntaminɛt lɔbrikeshɔn aksɛleret wear, signifyant shɔtin di savis layf fɔ biɛrin ɛn nid fɔ riplesmɛnt ɔltɛm.

l Inkris mentenɛns kɔst : Damej frɔm lɔbrikeshɔn fayl kin mek dɛn ripɛnt di kɔst, inklud di bia riplesmɛnt ɛn di dawt tɛm fɔ mentenɛns.

l Prodakshɔn dawt tɛm : Biɛrin fayl bikɔs ɔf po lɔbrikeshɔn kin stɔp prodakshɔn, we kin mek dɛn mis di dedlayn ɛn faynɛns lɔs.

l Kɔmprɔmis prɛsishɔn : sɔfayz damej ɛn inkris frikshɔn ridyus di akkuracy fɔ mashin, afɛkt prodak kwaliti na prɛsishɔn industri lɛk aerospace ɔ ilɛktroniks.

l Sefty risk : Wantɛm wantɛm we de bia ɔ we nɔ wok fayn kin mek di kɔndishɔn dɛn we de mek pɔsin sɔfa, lɛk di we aw mashin de biev we dɛn nɔ kɔntrol ɔ di we aw dɛn de mek dɔti, we de mek di wan dɛn we de wok de gɛt prɔblɛm.

Di bɛst we fɔ du tin fɔ mitigate .

Inadequate ɔ kontaminɛt lɔbrikeshɔn de mek wan impɔtant trɛt fɔ bia pefɔmɛns, we de mek di sɔfayz eroshɔn, pit, inkris ɔt, ɛn pɔtɛnɛshɛl sizi. Dɛn tin ya kɔmɔt frɔm di lɔbrik lɛvɛl dɛn we nɔ bɔku, di dɔti ɔ wata we de na di bɔdi, di sil dɛn we de lik, ɔ di we aw dɛn nɔ de mek dɛn fayn fayn wan. We dɛn yuz spɛsifikɛd lɔbrikɛnt, monitarin lɛvɛl dɛn, riples kɔntaminɛt lɔbrikɛnt dɛn kwik kwik wan, ɛn du rɛgyula sil chɛk, ɔpreshɔn dɛn kin mek dɛn nɔ gɛt lɔbrikɛshɔn-rilayt fɔlt dɛn. Dɛn proaktiv mɛzhɔ ya de ɛp fɔ mek di bia rilaybiliti, ɛkstɛnd di ikwipmɛnt layfspan, ɛn ridyus di opareshɔnal kɔst, mek shɔ se dɛn de du kɔnsistɛns pefɔmɛns ɛn sef na di impɔtant aplikeshɔn dɛn.

3. Misalaynmɛnt ɔ Impropa Instɔlɛshɔn .

Prɔpa alaynɛshɔn ɛn instɔleshɔn rili impɔtant fɔ di bɛst pefɔmɛns ɛn lɔng layf fɔ bia dɛn insay mashin dɛn we de rɔn, lɛk spindl, motoka, ɔ ɔda mɛkanikal sistem dɛn. Dɛn mek di bia dɛn fɔ wok wit prɛsis alaynɛshɔn fɔ mek shɔ se ivin lod distribyushɔn ɛn smol ɔpreshɔn. Misalaynmɛnt ɔ instɔlɛshɔn we nɔ fayn kin mek dɛn gɛt bɔku ɔpreshɔnal prɔblɛm dɛn, dɛn kin wɛr am kwik kwik wan, ɛn dɛn kin mek dɛn nɔ wok fayn bifo tɛm.

Di tin dɛn we kin mek pipul dɛn nɔ gɛt di rayt we ɔ dɛn nɔ kin yuz dɛn fayn ɔ dɛn nɔ kin instɔl dɛn di rayt we .

Misalaynmɛnt ɔ nɔ fayn instɔleshɔn kin apin we dɛn nɔ put di bia dɛn kɔrɛkt wan ɔ sikyuɔr, we kin mek dɛn nɔ ebul fɔ du di wok fayn fayn wan. Di tin dɛn we kin mek pɔsin gɛt dis sik na:

Asɛmbli mistek dɛn we de mek shaft tilt:

l mistek we dɛn de asembli, lɛk di kɔrɛkt mawntin fɔ di bia dɛn pan shaft ɔ haus, kin rili mek shaft tilt ɔ angul misalaynmɛnt. Dis misalaynmɛnt de ambɔg di bia in ebul fɔ rɔta fayn fayn wan.

l Di we aw dɛn nɔ de handle am di rayt we, lɛk fɔ yuz pawa we nɔ ivin we dɛn de instɔl am ɔ yuz tul dɛn we nɔ fayn, kin mek dɛn nɔ gi di bia dɛn di rɔŋ we frɔm di biginin.

Di pozishɔn dɛn we di tɛmal ɛkspɛnshɔn de shift:

l We dɛn de du di opareshɔn, di kɔmpɔnɛnt dɛn we dɛn kin yuz fɔ mek mashin kin wam, ɛn dis kin mek di ples wam we kin chenj di say we di bia, di shaft, ɔ di os dɛn de. If dɛn nɔ akɔntayn am na di dizayn ɔ instɔleshɔn prɔses, dis kin mek dɛn nɔ gi di pɔsin di rayt we.

l Inadequate kliarens ɔ improper preload setin kin mek di misalignment we kin kam bikɔs ɔf tɛmral ɛkspɛnshɔn, wɔs.

Maunt pan say dɛn we nɔ ivin:

l Inst ɔ l bi ɛ rin pan ɔniv ɔ ɔ nɔ ɔ r ɛ p r ɛ p r ɛ p r ɛ p ɛ rayp ɔ r s ɔ s, l ɛ ke warped h ɔ k h ɔ z ɔ mis alayned mashin b ɛ s, introd ɔ r f ɔ m a l i n m ɛ n fr ɔ m di stat.

l po mashin tolerans ɔ inadequate surface pripia (ɛgz., debris ɔ burrs on mounting surfaces) kin mek di bia nɔ sidɔm kɔrɛkt wan.

Di we aw dɛn nɔ go ebul fɔ instɔl di tin dɛn:

l Fɔ skip di impɔtant stɛp dɛn, lɛk fɔ chɛk fɔ no aw fɔ alaynɛd ɔ fɔ tɔk to di tɔk, we dɛn de instɔl am kin mek dɛn nɔ gɛt di sem alaynɛshɔn ɔ i kin mek di bia dɛn sidɔm fayn.

l Di nɔ gɛt trenin ɔ we dɛn nɔ fala di gaydlayn dɛn we di manifakta de gi kin mek dɛn mek mistek dɛn we kin mek dɛn nɔ ebul fɔ instɔl di tin dɛn we kin apin we kin mek dɛn nɔ ebul fɔ bia di we aw dɛn de du di wok.

Efεkt dεm we di misalignment כ di instכlεnt dεm we nɔ rayt fayn .

We dɛn nɔ alaynɛd di bia dɛn ɔ dɛn nɔ instɔl di rayt we, dɛn kin gɛt bɔku bad bad tin dɛn we kin mek dɛn nɔ ebul fɔ du wetin dɛn want ɛn dɛn kin liv lɔng:

Uneven Load Distribushɔn:

l Misalaynmɛnt de mek di fɔs dɛn we nɔ ivin de ɔlsay na di bia, wit sɔm eria dɛn we de ɛkspiriɛns pasmak lod. Dis kin mek di we aw dɛn kin wɛr pan di rɔlin ɛlimɛnt dɛn, di rays dɛn, ɔ di kech dɛn, we kin mek dɛn nɔ ebul fɔ wok bifo tɛm.

l Nɔ ivin lod kin mek bak lokaliz strɛs kɔnsɛntreshɔn, we kin mek di chans fɔ mek matirial taya go ɔp.

Vibration-induced fatigue:

l misaligned bearings de jenarate pasmak vaybreshɔn bikɔs ɔf nɔ ivin roteshɔn ɔ wobbling. dis vaybreshכn de indyuz saykli strεs, we de mek fכ fatigue krak in bia kכmכpכnt dεm.

l Fɔ lɔng tɛm vaybreshɔn kin prɔpagayt to ɔda mashin pat dɛn, we kin mek di sistem wear ɔ damej mɔ.

Hɛt frɔm ad frikshɔn:

l Misalaynmɛnt de inkrisayz frikshɔn bitwin bia kɔmpɔnɛnt dɛn, we de jenarayz ɛksɛs ɔt. Dis ɔt kin pwɛl di lɔbrikɛn, wikɛd di bia matirial, ɛn mek di tɛmral ɛkspɛnshɔn, mɔ ɛn mek di misalignmɛnt wɔs mɔ.

l εlevεt tεmprachכ dεm de ridyus di bia in prεsishכn εn efyushכn, we de mek di pכtεnshal כva hεt כ fεil.

Ridyus di bia layfspan:

l Di kɔmbayn ifɛkt dɛm we nɔ ivin lod, vaybrɛshɔn, ɛn inkris frikshɔn kin shɔt di bia in ɔpreshɔnal layf shɔt, we kin mek dɛn nid fɔ riples dɛn ɔltɛm ɛn fɔ mek dɛn gɛt mɔ mentenɛns kɔst.

Di tin dɛn we kin apin we pɔsin nɔ gɛt di rayt fɔ du wetin i want ɔ di we aw dɛn nɔ put am fayn fɔ instɔl .

Di tin dɛn we kin apin we dɛn nɔ gɛt ɛnitin fɔ du wit di we aw dɛn de du tin ɔ di we aw dɛn nɔ instɔl di tin dɛn we nɔ rayt, go bifo pas di bia dɛnsɛf, we go ambɔg di ɔl sistɛm pefɔmɛns ɛn di opareshɔn kɔst dɛn:

l Aksɛlɛrat Wear ɛn Failure : Nɔ ivin lod ɛn vaybreshɔn aksɛleret wear, we de lid to prɛmature bearing failure ɛn ridyus ikwipmɛnt layfspan.

l Inkris mentenɛns kɔst : Fɔ ripɛnt ɔltɛm ɔ fɔ riples am bikɔs ɔf di misalignmɛnt-rilayt damej de drɛb di mentenɛns ɛkspɛns.

l Production Downtime : Di bia we dɛn nɔ alaynɛd kin mek dɛn nɔ ebul fɔ du sɔntin we dɛn nɔ bin de ɛkspɛkt, dɛn kin mek dɛn nɔ gɛt bɔku mɔni ɛn dɛn kin mek dɛn gɛt mɔni we dɛn dɔn lɔs ɔ dɛn kin mis di dedlayn dɛn.

l Kɔmprɔmis prɛsishɔn : insay prɛsishɔn aplikeshɔn, lɛk CNC mashin ɔ rɔbɔtiks, misalignmɛnt de ridyus akkuracy, we de mek dɛn gɛt difɛkt prɔdak ɔ riwɔk.

l Sefty risk : If yu gɛt bɔku vaybreshɔn ɔ wantɛm wantɛm, i kin mek yu nɔ ebul fɔ bia wit di prɔblɛm dɛn we kin apin we kin mek yu gɛt prɔblɛm, lɛk di we aw di mashin kin de ɔ di mashin we yu nɔ kin kɔntrol, we kin mek di wan dɛn we de wok wit di mashin gɛt prɔblɛm dɛn.

Di bɛst we fɔ du tin fɔ mitigate .

Misalaynmɛnt ɔ improper instɔleshɔn fɔ bia, we dɛn kɔz bay asɛmbli mistek, tɛmral ɛkspɛnshɔn, ɔ nɔ ivin mawntin sɔfays, kin mek dɛn nɔ ebul fɔ sheb di lod, vaybreshɔn-indyuz fatigue, ɛn i kin mek frikshɔn bɔku. Dɛn tin ya kin mek dɛn wɛr kwik kwik wan, dɛn kin ridyus di prɛsishɔn, ɛn dɛn kin pwɛl di ikwipmɛnt dɛn we kin pwɛl, wit impɔtant ɔpreshɔnal ɛn faynɛns kɔnsikuns. Bay we dɛn de yuz alaynɛshɔn tul dɛn, we dɛn de chɛk fɔ no if dɛn gɛt alaynɛshɔn afta dɛn dɔn sɛt dɛn, we de akɔntayn fɔ mek dɛn go ebul fɔ du di tɛmal ɛkspɛnshɔn, ɛn fɔ du chɛk dɛn we dɛn kin du ɔltɛm, di wan dɛn we de wok kin mek dɛn nɔ gɛt prɔblɛm dɛn we gɛt fɔ du wit di misalignmɛnt. Dɛn proaktiv mɛzhɔ ya de mek shɔ se dɛn gɛt rilibul bia pefɔmɛns, ɛkstɛnd di ikwipmɛnt layfspan, ɛn ɛp fɔ mek di ɔpreshɔnal efyushɔn go bifo, fɔ mek di dawt tɛm ɛn di kɔst dɛn we de na di impɔtant aplikeshɔn dɛn nɔ bɔku.

4. Kɔntaminɛshɔn frɔm dɔst ɛn dɔti

Kɔntaminɛshɔn frɔm dɔst ɛn dɔti na impɔtant tin we de mɔna pipul dɛn na say dɛn usay prɛsishɔn mashin dɛn, lɛk spindl, bia, ɔ ɔda mɛkanikal kɔmpɔnɛnt dɛn, de wok. Dɛn tin ya we de dɔti, we gɛt fayn fayn tin dɛn lɛk dɔst, dɔti, mɛtal sheb, ɔ ɔda tin dɛn we de mek di maykroskɔpik, kin go insay mashin dɛn tru difrɛn we dɛn we dɛn kin yuz fɔ wok, ɛn dis kin mek dɛn nɔ ebul fɔ wok fayn ɛn dɛn kin pwɛl.

Di tin dɛn we kin mek pɔsin gɛt kɔntaminɛshɔn .

Dɔst ɛn dɔti infiltrɛshɔn kin apin bikɔs ɔf wan ɔ mɔ pan dɛn tin ya:

Di we dɛn we nɔ fayn fɔ silin:

Inadequate ɔ worn-out sil dɛn we de rawnd mashin kɔmpɔnɛnt dɛn de alaw ɛksternal patikyula dɛn fɔ go insay impɔtant eria dɛn. As tɛm de go, di sil dɛn kin pwɛl bikɔs dɛn dɔn wɛr, dɛn nɔ de instɔl dɛn fayn, ɔ dɛn nɔ de yuz di bad bad tin dɛn we de apin to dɛn na di envayrɔmɛnt, ɛn dis kin mek di tin dɛn we kin mek di wɔl nɔ klin kin go insay.

Sil dɛm we dɛn nɔ mek fɔ bia wit sɔm patikyula envayrɔmɛnt chalenj dɛm, lɛk ay dɔst lɛvɛl ɔ di tɛmpracha we rili bad, na dɛn kin rili ambɔg dɛn.

Dɔti ɔpreshɔn ɛnvayrɔmɛnt dɛn:

Mashin we de wok na say dɛn we gɛt ay levul pan patikyula tin dɛn we de na di ays, lɛk di plant dɛn we dɛn de mek, di say dɛn we dɛn de bil, ɔ di say dɛn we di briz nɔ kwaliti, de pan big big risk fɔ gɛt kɔntaminɛshɔn.

Di we aw dɛn nɔ de kia fɔ di os fayn, lɛk fɔ nɔ klin di say dɛn we dɛn de wok ɔ fɔ alaw di dɔti fɔ gɛda nia di ikwipmɛnt dɛn, mek di prɔblɛm wɔs.

Di we aw dɛn nɔ de du di mentenɛns di rayt we:

We dɛn de mentenɛns ɔ ripɛnt, tul dɛn, an dɛn, ɔ kɔmpɔnɛnt dɛn we dɛn nɔ klin fayn kin mek di tin dɛn we de insay di sistɛm, kam insay di sistem.

Lubrikɛnt dɛn we dɔn kɔntamin wit patikyula dɛn kin wok bak lɛk vektɔ fɔ introduks di dɔti dɛn insay mashin.

Di kɔntaminɛnt dɛn we de na di ays:

Fayn patikyula tin dɛn we dɛn kin stɔp na di ays, lɛk pɔlin, industrial dɔst, ɔ kemikal rɛsɛdyu, kin setul pan ɔ drɔ insay mashin dɛn tru ɛya intake sistem ɔ ventilashɔn.

Ifɛkt dɛn we di kɔntaminɛshɔn gɛt .

Wans dɔst ɛn dɔti infiltrate mashin dɛn, dɛn kin mek wan kaskad ɔf detrimental ifɛkt dɛn we kin kɔmprɔmis pefɔmɛns ɛn lɔng layf. Di men tin dɛn we go apin to wi na:

Abrasive grindin pan surfaces:

Dust ɛn dɔti, mɔ di had patikyula dɛn lɛk mɛtal shaving ɔ silika, de wok lɛk abraziv we dɛn trɔp bitwin pat dɛn we de muv. Dis kin mek yu gɛt maykro-abrashɔn ɔ grind pan sɔfays lɛk bia, spindl, ɔ gia.

As tɛm de go, dis abraziv akshɔn kin mek pɔsin wɛr, i kin mek di prɛsishɔn ɛn di efyushɔn we di kɔmpɔnɛnt dɛn gɛt ɛn mek dɛn nɔ alaynɛt ɔ mek frikshɔn bɔku.

Koroshɔn frɔm mɔstɔ-miks kɔntaminɛnt dɛn:

Bɔku tɛm, bɔku tɛm, di tin dɛn we kin dɔti kin miks wit mɔstɔ, ilɛksɛf na frɔm di envayrɔmɛnt ɔ frɔm lɔbrikɛn, we kin mek di say we dɛn de. Fɔ ɛgzampul, dɔst we gɛt sɔl ɔ kemikal kin mek di say dɛn we dɛn kin yuz fɔ mek rɔst kwik kwik wan na di say dɛn we dɛn mek wit mɛtal.

Kɔroshɔn kin wik kɔmpɔnɛnt dɛn, we kin mek dɛn gɛt pit, krak, ɔ strɔkchɔral fayl, we kin ridyus di layfspan fɔ di ikwipmɛnt dɛn bad bad wan.

Blɔk lɔbrik pat dɛn:

Dɔst ɛn dɔti kin mek dɛn nɔ gɛt lɔbrikeshɔn chanɛl dɛn, ɛn dis kin mek di lɔbrikɛn dɛn nɔ ebul fɔ rich di say dɛn we rili impɔtant. Dis kin mek dɛn nɔ gɛt bɛtɛ lɔbrik, i kin mek frikshɔn ɛn ɔt jenɛreshɔn de go ɔp.

Blɔk pat kin mek bak di lɔbrik distribyushɔn nɔ ivin, we kin mek di lokaliz ɔvahɛt ɔ di kɔmpɔnɛnt nɔ wok.

skrat, dent, ɛn di tɛm we dɛn go ebul fɔ brok:

Di kumulativ ifɛkt we abrashɔn, kɔrɛshɔn, ɛn inadekwat lɔbrikeshɔn de sho as damej we pɔsin kin si, lɛk skrat, dent, ɔ sɔfayz irɛgyulariti.

Dɛn tin ya de kɔmprɔmis di strɔkchɔral intɛgriti fɔ di kɔmpɔnɛnt dɛn, we de lid to aksɛleret wear ɛn, te go, katastrofik fayl fɔ di mashin.

Di tin dɛn we kin apin we pɔsin gɛt kɔntaminɛshɔn .

Di tin dɛn we kin apin we di dɔst ɛn dɔti dɔti tin dɛn kin apin kin go bifo pas di mɛkanikal damej we kin apin wantɛm wantɛm ɛn i kin gɛt bɔku ɔpreshɔnal ɛn faynɛns impak dɛn:

l Ridyus di ikwipmɛnt efyushɔn : Kɔntaminɛt kɔmpɔnɛnt dɛn de wok less efficiently, we nid mɔ ɛnaji fɔ du di sem wok ɛn inkris ɔpreshɔnal kɔst.

l Inkris mentenɛns kɔst : Fɔ ripɛnt ɔltɛm ɔ fɔ riples am bikɔs ɔf di damej we gɛt fɔ du wit kɔntaminɛshɔn de drɛb di mentenɛns ɛkspɛns.

l Dauntaym ɛn prodakshɔn lɔs : Brekdɔwn we dɛn nɔ bin de ɛkspɛkt we dɛn kɔz bay kɔntaminɛshɔn kin stɔp prodakshɔn, we kin mek dɛn mis di dedlayn ɛn lɔs revenyu.

l Kɔmprɔmis Prodak Kwaliti : Insay prɛsishɔn industri, lɛk aerospace ɔ ilɛktroniks manufakchurin, kɔntaminɛshɔn kin mek di prɔdak dɛn we nɔ fayn, we kin mek dɛn wok bak ɔ di kɔstɔma nɔ satisfay.

l Sefty hazards : Di ikwipmɛnt we dɔn pwɛl ɔ we nɔ de wok fayn kin mek di wan dɛn we de wok wit am gɛt prɔblɛm, we kin mek aksidɛnt ɔ injuri.

Di bɛst we fɔ du tin fɔ mitigate .

Kɔntaminɛshɔn frɔm dɔst ɛn dɔti de mek wan impɔtant trɛt fɔ di pefɔmɛns ɛn lɔng layf fɔ prɛsishɔn mashin. We dɛn ɔndastand di tin dɛn we kin mek dɛn mek dɛn—lɛk di say dɛn we nɔ fayn ɛn di say dɛn we dɔti kin de—ɛn di tin dɛn we kin apin we kin kɔmɔt frɔm dat, lɛk fɔ wɛr abraziv, fɔ kɔrɛshɔn, ɛn fɔ blok di lɔbrik, di wan dɛn we de wok kin tek proaktiv stɛp dɛn fɔ mek dɛn nɔ gɛt prɔblɛm dɛn. Impruv di bɛst we fɔ du tin, lɛk fɔ silin fayn fayn wan, fɔ filt fayn fayn wan, ɛn fɔ klin ɔltɛm, kin ridyus di kɔntaminɛshɔn bad bad wan, mek shɔ se dɛn ebul fɔ du di wok fayn fayn wan, dɛn kin mek di tɛm we dɛn nɔ de wok nɔ de, ɛn dɛn kin mek di savis layf we di impɔtant ikwipmɛnt dɛn de liv lɔng. Bay we dɛn de put di kɔntaminɛshɔn kɔntrol fɔs, di biznɛs dɛn kin mek di wok fayn, dɛn kin ridyus di kɔst, ɛn dɛn kin mek dɛn kɔntinyu fɔ gɛt ay standad fɔ di opareshɔn fayn fayn wan.

5. Di vaybreshɔn we pasmak ɔ di imbalans .

pasmak vaybreshכn כ imbalεns na rotating mashin, lεk spindl, mכta, כ כda sistεm wit biεn, de pos wan signifyant trεt fכ opεrayshכn pεrformεns εn kכmכpכnt lכng layf. Dɛn tin ya kin apin we tul, rɔta, ɔ ɔda tin dɛn we de rɔn nɔ balans ɔ we di sistɛm de wok na rezonant frikshɔn, we kin mek dɛn gɛt amplifyed mɛkanikal strɛs.

Di tin dɛn we kin mek pɔsin shek pasmak ɔ we i nɔ balans .

If yu gɛt bɔku bɔku vaybreshɔn ɔ i nɔ balans na mashin dɛn, dɛn kin kɔmɔt frɔm dɛn tin ya:

Tul dɛn ɔ rɔta dɛn we nɔ balans:

L Tul, lɛk fɔ kɔt tul dɛn na mashin ɔ rɔta dɛn na motoka, we nɔ balans fayn fayn wan de mek fɔs dɛn we nɔ ivin we dɛn de rɔtin. Dis imbalans de mek oscillations we strɛs bia ɛn ɔda kɔmpɔnɛnt dɛn.

l Imbalans kin kɔmɔt frɔm we dɛn nɔ de wɛr tul we nɔ ivin, we nɔ fayn asɛmbli, ɔ we nɔ de mek difɛkt pan di tin dɛn we de rɔn.

Resonant frikshɔn dɛn:

l We mashin de wok na ɔ nia in natura resonant frikshɔn, vaybreshɔn dɛn kin amplify, we kin mek dɛn ɔsishɔn pasmak. Dis rezonans kin apin bikɔs ɔf di impɔtant spid sɛtin ɔ dizayn flaw dɛn na di sistɛm.

l Ekstanshal tin dɛm, lɛk mashin we de nia yu ɔ envayrɔmɛnt vaybreshɔn, kin mek bak di rezonant frikshɔn dɛm gladi, ɛn mek di prɔblɛm wɔs.

I nɔ fayn fɔ sɛtup ɔ alaynɛshɔn:

l komponent dεm we nכ de alayf, lεk shaft כ kכplεn, kin introdכks vaybreshכn bay we dεn de mek fכs distribushכn we nכ ivin di tεm we dεn de rotashכn.

l loose ɔ improperly secured komponent dɛn, lɛk di wan dɛn we gɛt tul ɔ fiks, kin ɛp bak fɔ mek dɛn nɔ balans ɛn vaybrɛshɔn.

Wear ɔ damej insay kɔmpɔnɛnt dɛn:

l we dɛn dɔn wɛr, di gia dɛn we dɔn pwɛl, di tin dɛn we dɔn pwɛl, ɔ di tin dɛn we dɔn pwɛl kin mek dɛn nɔ muv we dɛn nɔ de muv ɔltɛm, ɛn dis kin mek di vaybrɛshɔn go ɔp mɔ ɛn mɔ.

l Di dɔti we dɔn gɛda ɔ di kɔntaminɛshɔn na di sistɛm kin ambɔg di balans mɔ, amplify oscillations.

Efεkt dεm we pasmak vaybreshכn כ imbalans .

We mashin dɛn kin gɛt pasmak vaybreshɔn ɔ imbalans, bia ɛn ɔda tin dɛn kin sɔfa wan rich detrimental ifɛkt:

Amplified oscillations damaging races:

l pasmak vaybreshכn de mek ripit impakt εn nכ ivin lod pan biεr rεs (di insay εn כta ring dεm we de haus di rolin εlimεnt dεm). Dis kin mek di sɔfayz damej, lɛk maykro-krak ɔ matirial difɔmeshɔn, kɔmprɔmis di bia in intɛgriti.

l oscillation kin propagεt bak to כda mashin kכmכpכnt dεm, we kin mek wi west bכku bכku wan.

Fatigue ova saykl:

l Kɔntinyu vaybreshɔn de indyuz saykli strɛs na bia, we de mek fatigue krak ova tɛm. Dɛn krak krak dɛn ya kin mek di bia strɔkchɔ wik, ɛn dis kin mek di prɔblɛm we kin apin we pɔsin nɔ ebul fɔ du natin bɔku.

l Fatigue damej de akumulet wit ɛni opareshɔnal saykl, signifyantli ridyus di bia in layfspan.

Hɛt frɔm kɔnstant muvmɛnt:

l Vaybreshɔn dɛn de inkrisayz frikshɔn bitwin bia kɔmpɔnɛnt dɛn, we de jenarayz ɛksɛs ɔt. Dis ɔt kin pwɛl di lɔbrikɛn, wikɛd di bia matirial, ɛn mek di tɛmral ɛkspɛnshɔn, mɔ ɛn mek di misalignmɛnt ɔ kliarens kwɛstyɔn dɛn wɔs.

l Fɔ lɔng tɛm fɔ mek di ɔt we dɛn de mek kin mek i wam pasmak, i kin mek di opareshɔnal efyushɔn ɛn prɛsishɔn go dɔŋ.

Sɛkɔndari damej to mashin dɛn:

l Fɔ vaybrɛshɔn pasmak kin mek di fastɛns dɛn, di misalign kɔmpɔnɛnt dɛn, ɔ pwɛl di pat dɛn we de nia de, nɔ wok, we kin mek di sistɛm nɔ wok fayn.

l We di bad bad tin apin, di vaybreshɔn we dɛn nɔ chɛk kin mek bad bad tin apin, lɛk fɔ bia wit di sik ɔ fɔ brok di shaft.

Di tin dɛn we kin apin we pɔsin de shek pasmak ɔ we nɔ balans pasmak .

Di kɔnsikuns dɛm fɔ pasmak vaybreshɔn ɔ imbalans de go bifo pas di bia dɛm, we de ambɔg di ɔl sistɛm pefɔmɛns ɛn di opareshɔnal kɔst dɛm:

l Ridyus di Ikwipmɛnt Layfspan : Vaybreshɔn dɛn kin aksɛlayt wear, we kin mek di bia dɛn nɔ pwɛl ɛn ɔda tin dɛn we kin apin bifo tɛm, we kin mek dɛn nid fɔ riples dɛn ɔltɛm.

l Inkris mentenɛns kɔst : Damej frɔm vaybreshɔn nid fɔ kɔst fɔ ripɛnt, inklud bia riplesmɛnt ɛn sistɛm rialaynmɛnt.

l Prodakshɔn dawt tɛm : Vaybreshɔn-indyuz fɔl kin stɔp prodakshɔn, we kin rilizɔt mis dedlayn ɛn faynɛns lɔs.

l Kɔmprɔmis prɛsishɔn : pasmak vaybrɛshɔn dɛn de ridyus mashin akkuracy, we de mek dɛn gɛt difɛkt prɔdak ɔ riwɔk na prɛsishɔn industri lɛk aerospace ɔ ilɛktroniks.

l Sefty risk : siriɔs vaybreshɔn kin mek kɔmpɔnɛnt detachmɛnt, mashin bihayvya we dɛn nɔ kɔntrol, ɔ debris jenɛreshɔn, we de mek di ɔpreshɔn dɛn de apin.

Di bɛst we fɔ du tin fɔ mitigate .

If yu gɛt bɔku bɔku vaybreshɔn ɔ i nɔ balans, dɛn kin mek tul dɛn we nɔ balans, di frikshɔn dɛn we de mek pɔsin fil fayn, ɔ di we aw dɛn nɔ de sɛtup am fayn, kin mek dɛn gɛt amplifyed oscillations, fatigue, ɛn di ɔt we dɛn kin mek, di bia dɛn we kin pwɛl ɛn ɔda tin dɛn we kin apin. Dɛn tin ya kin mek di ikwipmɛnt dɛn we dɛn kin yuz fɔ mek di ikwipmɛnt nɔ bɔku, dɛn kin mek dɛn kɔntinyu fɔ spɛn bɔku mɔni fɔ mek dɛn kɔntinyu fɔ de, ɛn dɛn kin mek di prɛsishɔn we dɛn kin mek nɔ bɔku, ɛn dɛn kin gɛt prɔblɛm dɛn we go mek dɛn nɔ gɛt prɔblɛm. Bay we dɛn de balans tul dɛn, ayd vaybreshɔn dɛn, monitar wit analaiza dɛn, ɛn mek shɔ se dɛn sɛtup di rayt we, di ɔpreshɔn dɛn kin mitigate dɛn risk dɛn ya. Dɛn proaktiv mɛzhɔ ya de ɛp fɔ mek mashin dɛn rilibiliti, ɛkstɛnd savis layf, ɛn mentɛn ɔpreshɔnal efyushɔn, minimiz dauntaym ɛn kɔst dɛn na impɔtant aplikeshɔn dɛn.

6. Di tɛmpracha we de ɔprɛt ay ay wan .

Di ay opareshɔn tɛmpracha de mek wan impɔtant chalenj to di pefɔmɛns ɛn lɔng layf we di bia dɛn ɛn ɔda mashin dɛn we de rɔn, lɛk spindl ɔ moto. If yu wam pasmak, dat kin mek di tin dɛn we dɛn de yuz nɔ pwɛl, i kin ambɔg di lɔbrik, ɛn mek di dimɛnshɔnal chenj, we kin mek di opareshɔn nɔ ebul fɔ wok fayn ɛn i nɔ kin wok bifo tɛm.

Di tin dɛn we kin mek di tɛmpracha go ɔp .

Elevated temperechur in mashin kin kɔmɔt frɔm wan kɔmbaynshɔn fɔ ɔpreshɔnal, envayrɔmɛnt, ɛn mentenɛns-rilayt tin dɛn:

frikshɔn we pasmak:

l ay frikshɔn bitwin bia kɔmpɔnɛnt dɛn, bɔku tɛm bikɔs ɔf inadekwat lɔbrikeshɔn, misalignmɛnt, ɔ ɔvalod, de jenarayz signifyant ɔt.

l Impɔtant balans tul ɔ pasmak vaybreshɔn kin mek frikshɔn go ɔp mɔ, we kin mek di tɛmpracha go ɔp.

Ovalod ɔ agresiv ɔpreshɔn:

l Opareshɔn mashin we pas di lod kapasiti we dɛn dɔn disayn, lɛk mashin taf matirial ɔ yuz agresiv kɔt paramita, de inkrisayz ɔt jenɛreshɔn bikɔs ɔf ayt mɛkanikal strɛs.

l ay spid ɔ fid ret kin amplify ɔt prodakshɔn, mɔ insay bia dɛn we nɔ rayt fɔ dɛn kayn kɔndishɔn dɛn de.

Inadequate Cooling Systems:

l Insufisɛnt ɔ malfunctioning cooling systems, lɛk fans, kulant pɔmp, ɔ ɔt ɛkschenja, nɔ kin dissipate ɔt fayn fayn wan, we kin mek di tɛmpracha go ɔp.

l po ventileshɔn ɔ ay ambiɛnt tɛmpracha na di ɔpreshɔn ɛnvayrɔmɛnt de mek di ɔt bildup wɔs.

Lubrikant dɛgradɛshɔn ɔ imprɔpa sɛlɛkshɔn:

l Lubrikant dɛm we nɔ fayn fɔ ay-tɛmpracha aplikeshɔn kin thin ɔ brok dɔŋ, we kin mek dɛn ebul fɔ dissipate ɔt ɛn protɛkt di bia sɔfays.

l Kɔntaminɛt ɔ degraded lɔbrikɛn kin ɛp bak fɔ mek frikshɔn ɛn ɔt jenɛreshɔn go ɔp.

Ekstanshal ɔt sɔs dɛn:

l mashin we de wok nia ɛksternal ɔt sɔs, lɛk ɔfna, ɔvin, ɔ dairekt san layt, kin gɛt ɛlevɛt tɛmpracha we kin afɛkt di bia pefɔmɛns.

l Inadequate insulation ɔ shielding frɔm ɛksternal ɔt sɔs kin kɔmpawnd di ishu.

Efεkt dεm we di ay opεrayt tεmpracha de gi .

We dɛn de sɔfa wit di bia ɛn mashin dɛn we gɛt ay tempɔret, dɛn kin gɛt difrɛn difrɛn bad bad tin dɛn we kin mek dɛn nɔ ebul fɔ du wetin dɛn want ɛn we go mek dɛn nɔ de wok fayn ɛn we go de fɔ lɔng tɛm:

Ridyus di lod kapasiti:

l ay tempɔret kin mek di tin dɛn we de bia kin sof, lɛk stɛl, we kin mek dɛn nɔ gɛt bɔku prɔblɛm ɛn dɛn kin ebul fɔ kɛr lod. Dis wikɛd wan de mek di bia dɛn gɛt mɔ susɛptibl fɔ difɔmeshɔn ɔnda nɔmal ɔpreshɔn lod dɛn.

L Softened matirial nɔ kin ebul fɔ bia wit mɛkanikal strɛs, aksɛleret wear ɛn fayl.

Lubrikant brekdaun:

l we di tεmprachכ de kכmכt de mek di lכbrikεnt dεm tin, כksidayz, כ brok dכn kεmikכl, dεn de ridyus dεn viskכsiti εn effektiv. Dis kin mek di lɔbrik nɔ fayn, i kin mek frikshɔn bɔku, ɛn i kin mek i wam mɔ.

l Digrɛd lɔbrikɛnt dɛn kin mek slɔd ɔ varnish, dɛn kin lɔk di lɔbrik pat dɛn ɛn mek di wear we de mek di lɔ wɔs.

Termal fatigue krak dɛn:

l we dεn rεpεt di εksposhכn to ay tεmprachכ de indyuz tεmral fatigue, usay saykli hεt εn kol de mek maykro-krak dεm na di bia sεf dεm. Dɛn krak krak ya de prɛd ova tɛm, wikɛd di bia ɛn inkrisayz di risk fɔ katastrofik fayl.

l uneven thermal expansion of komponent kin mek di strεs kכnsantreshכn bכku, we kin mek krak fכm.

Dimenshonal chenj en misalaynment:

l ay tempɔret kin mek di bia, shaft, ɔ os dɛn nɔ bɔku, we kin mek dɛn nɔ gi di rayt we, dɛn kin mek di vaybrɛshɔn bɔku, ɛn dɛn nɔ kin ebul fɔ sheb di lod.

l Dɛn dimɛnshɔnal chenj ya kin ridyus di bia kliarens, we kin mek dɛn tay ɔ mek frikshɔn go ɔp.

Di tin dɛn we kin apin we pɔsin gɛt ay ɔpreshɔn tɛmpracha .

Di tin dɛn we kin apin we pɔsin gɛt bɔku ɔt kin go bifo pas di bia dɛn, we kin ambɔg di ɔl di sistɛm pefɔmɛns ɛn di opareshɔn kɔst dɛn:

l Ridyus di ikwipmɛnt layfspan : Softened matirial ɛn lɔbrik brekdɔwn aksɛleret wear, signifyant shɔtin bia ɛn mashin layfspan.

l Inkris mentenɛns kɔst : Fɔ ripɛnt ɔltɛm ɔ fɔ riples am bikɔs ɔf di damej we gɛt fɔ du wit di ɔt de drɛb di mentenɛns ɛkspɛns.

l Prodakshɔn dawt tɛm : ay-tɛmpracha-indyuz fɔlt kin stɔp prodakshɔn, we kin mek dɛn mis di dedlayn ɛn faynɛns lɔs.

l Kɔmprɔmis prɛsishɔn : Tɛmral ɛkspɛnshɔn ɛn matirial dɛgradishɔn ridyus mashin akkuracy, afɛkt prodak kwaliti insay prɛsishɔn industri lɛk aerospace ɔ ilɛktroniks.

l Sefty risk : Di tin dɛn we dɛn kin ɔt pasmak kin fel wantɛm wantɛm, we kin mek bad bad tin dɛn apin lɛk fɔ bia wit di sik we dɛn kɔl seizure, component detachment, ɔ faya risk dɛn we kin apin bad bad wan.

Di bɛst we fɔ du tin fɔ mitigate .

Di ay opareshɔn tɛmpracha, we dɛn kin mek bikɔs ɔf di frikshɔn we pasmak, di ɔvalod, di kol we dɛn nɔ de kol fayn, ɔ di lɔbrikɛn we nɔ fayn, kin mek di lod nɔ ebul fɔ lod, i kin mek di lɔbrikɛn brok, ɛn i kin mek di tɛmral fatigue krak. Dɛn tin ya kin shɔt di ikwipmɛnt layfspan, inkrisayz di mentenɛns kɔst, ɛn kɔmprɔmis prɛsishɔn, wit pɔtɛnɛshɛl sef risk. Bay we dɛn de mek di kol sistɛm dɛn fayn fayn wan, dɛn de wach di tɛmpracha, dɛn de avɔyd fɔ lod pasmak, ɛn dɛn de pik di rayt lɔbrikɛnt dɛn, di wan dɛn we de wok de kin mek di prɔblɛm dɛn we gɛt fɔ du wit di ɔt nɔ bɔku. Dɛn proaktiv mɛsej ya de mek shɔ se mashin dɛn de wok fayn fayn wan, dɛn de ɛkstɛnd savis layf, ɛn dɛn de stɔp di dawt tɛm ɛn di kɔst dɛn na di impɔtant aplikeshɔn dɛn.

7. Ilektrikal Kɔrɛnt Pasej .

Ilɛktrik kɔrɛnt we de pas na di bia dɛn, bɔku tɛm dɛn kin mek am bikɔs ɔf di bad we aw dɛn de grɔn ɔ di kɔrɛnt we de rɔn, kin mek big big damej na mashin dɛn we de rɔn lɛk motoka, spindl, ɔ jenɛra. Dis fenomen, akin to ilektrikal dischaj mashin (EDM), erodes bearing surfaces en kompromis dem pefomans.

Di tin dɛn we kin mek di ilɛktrik kɔrɛnt pas .

Ilektrikal kɔrɛnt pasej kin apin we ilɛktrik kɔrɛnt we dɛn nɔ bin want fɔ pas de flɔ tru bia, tipikli bikɔs ɔf dɛn tin ya:

Di grɔn we nɔ fayn:

l Inadequate ɔ improper grounding of mashinri de alaw stray ilɛktrik kɔrɛnt fɔ flɔ tru biɛrin, we de luk fɔ di rod fɔ lɛst resistans to grɔn.

l Di grɔn we nɔ fayn kin kɔmɔt frɔm di waya dɛn we nɔ fayn, di kɔnɛkshɔn dɛn we dɔn kɔrɛkt, ɔ di grɔnd sistem dɛn we nɔ go du fɔ di mashin ɔ di fasiliti.

Stray kɔrɛnt frɔm ilɛktrik sistɛm dɛn:

l Stray kɔrɛnt kin kɔmɔt frɔm vɛriɔbul frikshɔn drayv (VFD), invɛrta, ɔ ɔda ilɛktrik kɔmpɔnɛnt dɛn we dɛn kin yuz na mɔdan mashin, mɔ na ay-pawa ɔ ay-spid aplikeshɔn dɛn.

l Ilɛktrɔmagnetik intafɛreshɔn (EMI) ɔ indyuz vɔltɛm frɔm ilɛktrik ikwipmɛnt we de nia kin mek bak kɔrɛnt pas tru di bia dɛn.

Statik ilɛktrishɔn we de bil:

l Statik chaj kin akumulet pan di komponent dɛn we de rɔn, mɔ na dray ɔ ay-spid ɛnvayrɔmɛnt, we kin mek dɛn dischaj dɛn tru di bia dɛn.

l Dis na kɔmɔn tin na aplikeshɔn dɛn we involv nɔ-kɔnduktiv matirial ɔ bɛlt we de mek statik ilɛktrishɔn.

Insuleshɔn ɔ shild nɔ fayn:

l Nɔ gɛt di rayt insuleshɔn pan di bia ɔ di kɔmpɔnɛnt dɛn we de rawnd de alaw ilɛktrik kɔrɛnt fɔ flɔ tru rod dɛn we dɛn nɔ bin want.

l Inadequate shielding against ilektromagnetik fild kin mek di pasej we de naw, wɔs insay sɛnsitiv ikwipmɛnt.

Efεkt dεm we ilektrikal kכrant pasεj de gi .

We ilɛktrik kɔrɛnt de pas tru di bia dɛn, dɛn kin mek wan rich detrimental ifɛkt, mɔ tru arsing ɛn ilɛktrik dischaj mashin (EDM) ifɛkt dɛn:

Surface erosion via arsing:

l Ilektrikal arcing bitwin bia komponent (eg, rolling elements en races) de kriet lokaliz spak we erode matiryal, we semwe laik EDM. Dis kin mek dɛn gɛt pit, flut, ɔ frɔst patɛn pan bia sɔfays.

l Dɛn sɔfayz dɛfɛkt ya de ambɔg di smol smol ɔpreshɔn, inkrisayz frikshɔn, ɛn aksɛleret wɛr.

Micro-craters ɛn matirial dɛgradishɔn:

l Arcing de prodyuz smɔl smɔl krata ɔ bɔn mak pan bia sɔfays, wikɛd di matirial ɛn ridyus in lod-kɛri kapasiti.

l ova tεm, dεn maykro-krat dεm ya de lid to spal (flaking fכ mεtirial), fכs dεgrad di biεn in integriti.

Di vaybreshɔn ɛn nɔys we de bɔku:

l Surface damage frɔm arcing de mek di roteshɔn we nɔ ivin de, we de mek di vaybreshɔn ɛn nɔys go ɔp we dɛn de wok.

l Vaybreshɔn kin prɔpagɛt to ɔda mashin kɔmpɔnɛnt dɛn, we kin mek dɛn west ɔda we dɛn ɔ we nɔ de alayf.

Di bad bad tin dɛn we kin apin to pɔsin:

l Arcing de mek ɔt na kɔntakt pɔynt dɛn, we kin pwɛl ɔ bɔn lɔbrikɛn, we kin ridyus dɛn ɛfɛktiv ɛn mek dɛn gɛt mɔ frikshɔn ɛn wear.

l Kɔntaminɛt ɔ kaboniz lɔbrikɛnt dɛn kin bi abrasive, exacerbating surface damage.

Premature Bearing Failure:

l di kumulativ ifekt dεm fכ di sכfayz εroshכn, di vaybreshכn, εn di lכbrik brεk dכn sכmtεm sכt di bεrεn layfspan, we de mek i fεil bifo tεm.

L Insay siriɔs kes, arcing kin mek dɛn tek tɛm wit dɛn bɔdi ɔ katastrofik fayl.

Di tin dɛn we kin apin we di ilɛktrik kɔrɛnt pas .

Di kɔnsikuns dɛm fɔ ilɛktrik kɔrɛnt pasej de go bifo pas di bia dɛm, we de ambɔg ɔl di sistɛm pefɔmɛns ɛn ɔpreshɔnal kɔst dɛm:

l Ridyus di Ikwipmɛnt Layfspan : Surface Erosion ɛn Material Degradation Accelerate bearing wear, we nid fɔ riples ɔltɛm.

l Inkris mentenɛns kɔst : Damej frɔm arsing nid fɔ kɔst fɔ ripɛnt, inklud bia riplesmɛnt ɛn sistɛm dawt tɛm.

l Production Downtime : Biɛrin fayl we dɛn kɔz bay ilɛktrik damej kin stɔp prodakshɔn, we kin mek dɛn mis di dedlayn ɛn faynɛns lɔs.

l Kɔmprɔmis prɛsishɔn : sɔfays difɛkt ɛn inkris vaybreshɔn ridyus mashin akkuracy, afɛkt prodak kwaliti insay prɛsishɔn industri lɛk ilɛktronik ɔ aerospace.

l Sefty risk : Wantɛm wantɛm we de bia fayl ɔ pasmak vaybreshɔn kin mek di kɔndishɔn dɛn we de mek pɔsin sik, lɛk di kɔmpɔnɛnt dɛtachmɛnt ɔ ilɛktrik hazad, we de mek di ɔpreshɔn pipul dɛn gɛt prɔblɛm.

Di bɛst we fɔ du tin fɔ mitigate .

Ilɛktrik kɔrɛnt pas, bɔku tɛm dɛn kin mek am bikɔs ɔf di grɔn we nɔ fayn, di kɔrɛnt we de rɔn, ɔ di statik ilɛktrishɔn, i kin pwɛl di say dɛn we dɛn kin put tin dɛn na di say dɛn we dɛn kin put tin dɛn we dɛn kɔl arsing, we kin mek dɛn gɛt pit, vaybreshɔn, ɛn lɔbrik we de pwɛl. Dɛn ifɛkt ya de ridyus di bia layfspan, inkrisayz di mentenɛns kɔst, ɛn kɔmprɔmis ɔpreshɔnal prɛsishɔn, wit pɔtɛnɛshɛl sef risk. We dɛn mek shɔ se dɛn grɔn fayn fayn wan, yuz di bearing dɛn we dɛn put insay, we dɛn de stɔp di kɔrɛnt we de rɔn, ɛn we dɛn de du inspekshɔn ɔltɛm, di wan dɛn we de wok de nɔ kin mek ilɛktrik nɔ pwɛl. Dɛn proaktiv mɛzhɔ ya de ɛp fɔ mek mashin dɛn rilibiliti, ɛkstɛnd savis layf, ɛn minimiz di dawt tɛm ɛn di kɔst dɛn na di impɔtant aplikeshɔn dɛn.

Sayn ɛn simptom dɛn fɔ CNC spindle ɔva ɔt .

Spindle moto na krichɔl komponent dɛn na prɛsishɔn mashin, lɛk CNC mashin, lath, ɛn mil ikwipmɛnt, usay bia dɛn de ple wan impɔtant pat fɔ mek shɔ se dɛn de wok fayn, kɔrɛkt, ɛn wok fayn. If yu gɛt damej, if yu nɔ no am, i kin mek yu nɔ gɛt bɔku mɔni, i kin ridyus di kwaliti fɔ di mashin, ɛn i kin ivin mek di spindle motoka nɔ wok fayn. Fɔ no kwik kwik wan na impɔtant tin fɔ mek dɛn nɔ gɛt dɛn prɔblɛm ya ɛn fɔ mek di tin dɛn we dɛn de yuz fɔ liv lɔng.

Nɔys dɛn we nɔ nɔmal .

Wan pan di fɔs sayn dɛm we dɛn kin notis ɛn we dɛn kin notis pas ɔl fɔ bia damej na di prɛzɛns fɔ ɔnusual sawnd dɛm we de kɔmɔt frɔm di spindle moto we dɛn de wok. Bɔku tɛm, dɛn nɔys dɛn ya kin sho di men tin dɛn we kin apin we, if dɛn nɔ pe atɛnshɔn to dɛn, dɛn kin go bifo pan siriɔs damej. Kɔmɔn abnɔmal nɔys dɛn na:

l we de whining ɔ ay-pitch sawnd : wan ay-pitch whine tipikli de sho se frikshɔn de go ɔp insay di bia, bɔku tɛm na bikɔs dɛn nɔ gɛt bɛtɛ lɔbrik, dɛn de wɛr di bia surface, ɔ di dɔti we de na di dɔti ɔ di mɛtal patikyula. Dis sawnd kin intensif as di bia de pwɛl mɔ.

l Fɔ grind ɔ skrap nɔys : Di sawnd dɛn we de grind de sho se dɛn dɔn west bɔku ɔ dɛn dɔn pwɛl di say we dɛn de, lɛk fɔ pit ɔ fɔ spal pan di bia rays ɔ di tin dɛn we de rɔl. Dis kin apin we di bia de ɔnda di lod dɛn we pasmak, di we aw dɛn nɔ de alayf, ɔ we dɛn de wok fɔ lɔng tɛm we dɛn nɔ de mek am fayn fayn wan.

l Klik ɔ tik : We yu klik ɔ tik nɔys dɛn wan bay wan, i kin pɔynt to di tin dɛn we nɔ tay, lɛk di kech we dɔn pwɛl ɔ di tin dɛn we de rɔl we nɔ de muv fayn fayn wan. Dis kin sho bak se dɛn dɔn taya kwik kwik wan ɔ dɛn nɔ ebul fɔ du bifo tɛm ɔ dɛn nɔ ebul fɔ lod di rayt we na di bia asɛmbli.

Wetin mek i impɔtant : Bɔku tɛm, dɛn nɔys ya na di fɔs tin we dɛn kin yɛri we pɔsin de fil bad. As frikshɔn ɛn wear de go ɔp, di sawnd dɛn kin lawd ɛn dɛn kin pronɔns mɔ, ɛn dis kin sho se di bia de kam nia fɔ mek i nɔ wok. Inspekshɔn kwik kwik wan impɔtant fɔ no di rut kɔz—ilɛksɛf na kɔntaminɛshɔn, misalignmɛnt, ɔ matirial fatigue—ɛn fɔ mek dɛn nɔ pwɛl di spindle moto mɔ.

Akshɔn Step dɛn : Yuz wan stɛtoskɔp ɔ vaybreshɔn analisis tul dɛn fɔ pinpoint di nɔys sɔs. Chek di lubrikeshɔn lɛvɛl ɛn kwaliti, inspɛkt fɔ kɔntaminɛshɔn, ɛn chɛk alaynɛshɔn. If di nɔys nɔ kɔntinyu fɔ de, tink bɔt fɔ disassembl di spindle fɔ mek dɛn inspɛkt am fayn fayn wan.

Di Vaybrɛshɔn we de bɔku bɔku wan .

Fɔ mek pipul dɛn shek pasmak na ɔda tin we de sho se dɛn dɔn pwɛl na spindle motoka dɛn. Pan ɔl we sɔm lɛvul fɔ vaybrɛshɔn na nɔmal tin na di mashin we de rɔn, we pɔsin notis inkris ɔ chenj na di vaybreshɔn patɛn kin sho siriɔs tin dɛn insay di bia asɛmbli. Di men tin dɛn we impɔtant na:

l Imbalans : We di bia we nɔ ivin de wear ɔ we dɔn pwɛl, dat kin mek di rɔta nɔ balans, we kin mek i shek pasmak. Bɔku tɛm dɛn kin fil dis as ritmik ɔ pulsatin vaybreshɔn we dɛn de wok.

l Pitting or surface damage : Microscopic pit ɔ spal dɛn na di bia sɔfays de ambɔg di smol smol roteshɔn, we de mek di vaybreshɔn dɛn we nɔ de ɔltɛm. Dɛn bad bad tin ya kin kɔmɔt frɔm we pɔsin taya, we i de lod pasmak, ɔ we i kin kɔntamin.

l Misalaynmɛnt ɔ lɔs kɔmpɔnɛnt dɛn : Misaligned bearings ɔ loose mounting hardware kin amplify vaybreshɔn, put adishɔnal strɛs pan di bearing ɛn aksɛleret wear.

Wetin mek i impɔtant : Inkris vaybreshɔn nɔ jɔs de sho se i dɔn pwɛl bɔt i de afɛkt di ɔl di pefɔmɛns fɔ di spindle moto. If yu shek pasmak, dat kin mek yu nɔ gɛt fayn mashin fɔ mek di mashin prɛsishɔn, i kin mek yu tɔk to ɔda tin dɛn, ɛn i kin pwɛl ɔda tin dɛn, lɛk sil ɔ os. As tɛm de go, we dɛn nɔ chɛk di vaybreshɔn, dat kin mek bad bad tin apin.

Akshɔn Step : Employ vaybreshɔn analaiza fɔ kwantifay vaybreshɔn lɛvɛl ɛn aydentify spɛshal frikshɔn dɛn we gɛt fɔ du wit bia fɔlt (ɛgz., bɔl pas frikyuɛnsi ɔ kech frikyuɛnsi). Fɔ wach ɔltɛm kin ɛp fɔ no di tin dɛn we de apin we di vaybreshɔn de go ɔp, we de sho se di damej dɔn go bifo. If dɛn no di vaybreshɔn dɛn we dɛn dɔn ɛlevɛt, chɛk di bia fɔ wɛr, chɛk alaynɛshɔn, ɛn chɛk fɔ si if di rɔta balans. If yu du am kwik kwik wan, dat kin mek yu nɔ gɛt mɔ pwɛl hat.

Pɔfɔmɛnshɔn Digrɛdishɔn .

Biɛrin damej kin sho bɔku tɛm as di spindle moto in opareshɔnal pefɔmɛns de dɔŋ, we kin afɛkt in ebul fɔ mentɛn prɛsishɔn, spid, ɛn pawa. Di kɔmɔn sayn dɛm na:

l We yu lɔs prɛsishɔn : di bia we dɔn pwɛl kin mek di spindle wobbul ɔ deviet frɔm di rod we i want, we kin mek yu nɔ kɔrɛkt pan mashin ɔ kɔt ɔpreshɔn. Dis na patikyula impɔtant tin na ay-prɛsishɔn aplikeshɔn dɛn lɛk CNC mashin, usay ivin smɔl smɔl dɛvyayshɔn dɛn kin pwɛl wokpies dɛn.

l Spid fluktueshɔn : We dɛn wɛr ɔ we dɔn pwɛl kin mek di rɛsistɛns nɔ gri, we kin mek di spindle motoka strɛch fɔ mek i kɔntinyu fɔ gɛt kɔnsistɛns rɔta spid. Dis kin mek dɛn kɔt ɔ grind di wok we dɛn de du we nɔ ivin.

l Pawa dip ɔ ɔvalod : As di bia dɛn de pwɛl, di frikshɔn we de go ɔp nid fɔ gɛt mɔ pawa fɔ mek dɛn kɔntinyu fɔ wok, we kin mek dɛn gɛt mɔ ɛnaji ɔ dɛn kin drɔp dɛn wan wan tɛm. If bad bad tin apin, di motoka kin stɔp ɔ i nɔ kin bigin fɔ stat ɔltogɛda.

Wetin mek i impɔtant : di pefɔmɛns dɛgradishɔn de ambɔg di kwaliti fɔ di autput ɛn di efyushɔn we di mashin de du dairekt wan. Fɔ industri dɛn we de abop pan prɛsishɔn ɛn kɔnsistɛns, lɛk aerospace ɔ ɔtomotiv manufakchurin, ivin smɔl pefɔmɛns ishu dɛn kin mek dɛn lɔs bɔku mɔni ɔ dɛn kin wɔri bɔt sef.

Akshɔn Step : Monitor spindle pefɔmans mɛtrik, lɛk spid stebiliti ɛn pawa kɔnsɔmshɔn, yuz diagnostik tul ɔ mashin kɔntrol sistem. If dɛn si se dɛn dɔn pwɛl, chɛk di bia dɛn fɔ wɛr, chɛk lɔbrik, ɛn chɛk fɔ si if dɛn dɔn kalibrayt di spindle fayn fayn wan. Fɔ adrɛs dɛn tin ya kwik kwik wan kin mek di wok go bifo bak ɛn mek dɛn nɔ pwɛl mɔ.

Diskoloreshɔn ɔ ɔda tin dɛn we de smɛl .

Di chenj dɛn we de apin na di bɔdi ɔ di tin dɛn we de rawnd am, lɛk we yu nɔ gɛt kɔlɔ ɔ we nɔ kɔmɔn ɔda tin dɛn we de smɛl, na impɔtant sayn dɛn we de sho se pɔsin gɛt prɔblɛm wit in bia, bɔku tɛm i kin gɛt sɔntin fɔ du wit di we aw i de ɔt pasmak ɔ i nɔ de wok fayn. Dɛn sayn ya na:

l Diskכlכrayshכn (blכ כ brawn) : di bεri dεm we dεn hεt kin sho blu כ brawn tint na dεn sεf biכs fכ di hכt we di hεt pasmak. Dis kin apin we frikshɔn de go ɔp bikɔs dɛn nɔ gɛt bɛtɛ lɔbrik, ay lod, ɔ fɔ lɔng tɛm we dɛn de wok wit ay spid. Diskoloreshɔn na klia sayn fɔ sho se di bia matirial de ɔnda tɛmral strɛs, we kin wik in strɔkchɔ.

l Akrid ɔ bɔn smel : Shap, akrid smel kin sho se di bia lɔbrik de bɔn ɔ brok bikɔs ɔf di wam we i wam pasmak. Sɔntɛnde, di ɔda tin we kin smɛl kin kɔmɔt frɔm di tin we de bia insɛf as i bigin fɔ pwɛl ɔ frɔm di tin dɛn we de nia de we di ɔt dɔn afɛkt.

Wetin mek i impɔtant : Diskɔlɔreshɔn ɛn ɔda tin dɛn we de smɛl de sho se di bia de wok ɔnda di kɔndishɔn dɛn we rili bad, we kin mek i west kwik kwik wan ɛn mek i nɔ wok fayn igen. If yu ɔt pasmak, dat kin pwɛl bak di tin dɛn we de nia de, lɛk sil, shaft, ɔ os, fɔ mek di kɔst fɔ mek di say dɛn we dɔn pwɛl bɔku ɛn fɔ mek dɛn nɔ wok fayn.

Akshɔn Step : If dɛn no di kɔlɔ ɔ di ɔda tin dɛn we de smɛl, stɔp di spindle motoka wantɛm wantɛm fɔ mek i nɔ pwɛl mɔ. Inspek di biɛrin dɛm fɔ si if dɛn gɛt sayn dɛm fɔ ɔva ɔt, chɛk lɔbrik kɔndishɔn (ɛgz., viskɔsiti, kɔntaminɛshɔn), ɛn asɛs di opareshɔn kɔndishɔn dɛm (ɛgz., spid, lod, kol sistɛm). Riples di bearing dɛn we dɔn pwɛl ɛn riplenish ɔ ɔpgrɛd lɔbrik fɔ mek dɛn nɔ kam bak.

Di tin dɛn we dɛn fɔ du fɔ mek dɛn nɔ gɛt di sik ɛn di bɛst we fɔ du tin ɛn di bɛst we fɔ du am .

Fɔ mek yu nɔ gɛt bɔku prɔblɛm dɛn we go mek yu gɛt prɔblɛm ɛn fɔ mek di spindle motoka dɛn liv lɔng, tink bɔt dɛn bɛst tin dɛn ya we yu de du:

l Rigyul mentenɛns : Impliment wan rutin mentenɛns schedule we inklud lɔbrikeshɔn chɛk, alaynɛshɔn verifyeshɔn, ɛn bia inspekshɔn. Yuz ay kwaliti lɔbrikɛnt dɛn we fit fɔ di spindle in opareshɔn kɔndishɔn dɛn.

l Vaybreshɔn monitarin : Instɔl vaybreshɔn sɛns ɔ yuz pɔtabl analaiz fɔ trak vaybreshɔn lɛvɛl ova tɛm. Sɛt trɛshɔld fɔ trig alɛt we vaybreshɔn pas akseptabl limit.

l Lubrikeshɔn manejmɛnt : Mek shɔ se yu gɛt di rayt lɔbrik bay we yu de wach di lɔbrik lɛvɛl ɛn kwaliti. Yuz di kayn lubrikant tayp we di wan we mek am kin kɔl ɛn ri-applikɛshɔn intaval fɔ ridyus frikshɔn ɛn wear.

l Envayrɔmɛnt kɔntrol : Minimayz kɔntaminɛshɔn bay we yu de kip klin opareshɔn ɛnvayrɔmɛnt ɛn yuz ifɛktiv sil fɔ protɛkt bia frɔm dɔst, dɔti, ɔ mɔstɔ.

l Trenin ɛn Aw fɔ no : Di wan dɛn we de wok na di tren ɛn di wan dɛn we de kia fɔ di wok fɔ no di fɔs sayn dɛn we de sho se dɛn dɔn pwɛl, lɛk di nɔys dɛn we nɔ nɔmal ɔ di chenj dɛn we de apin na di wok, ɛn fɔ ripɔt dɛn kwik kwik wan.

Biɛrin damej na spindle moto kin gɛt impɔtant kɔnsikuns, bɔt fɔ no kwik kwik wan kin sev ɔl tu di spindle ɛn di mashin we i de pawa. Bay we dɛn de wach fɔ sayn fɔ sayn dɛn lɛk abnɔmal nɔys, fɔ mek di vaybrɛshɔn bɔku, fɔ mek di wok nɔ pwɛl, ɛn fɔ mek di kɔlɔ nɔ gɛt kɔlɔ ɔ fɔ smɛl, di wan dɛn we de wok kin no di prɔblɛm dɛn bifo dɛn go ɔp. Fɔ wach ɔltɛm, fɔ mek dɛn mentenɛns fayn fayn wan, ɛn fɔ tek akshɔn kwik kwik wan na di men tin fɔ mek shɔ se di spindle motoka dɛn rili fayn ɛn fɔ mek dɛn liv lɔng. If dɛn si ɛni wan pan dɛn simptom ya, akt kwik kwik wan fɔ inspɛkt ɛn adrɛs di prɔblɛm, kɔnsul wit di bia spɛshal pipul dɛn ɔ di spindle manifakta as nid de fɔ mek dɛn gɛt di bɛst pefɔmɛns bak.

Dɔn

Fɔ bia damej na Spindle Motors na tif we go mek yu nɔ ebul fɔ du wetin yu want, we kin mek yu nɔ ebul fɔ du am, yu nɔ go wok fayn, ɛn yu kin pe bɔku mɔni if dɛn nɔ chɛk am. We dɛn ɔndastand di tin dɛn we kin mek dɛn du wetin kin mek dɛn apin—ɔvalɔd, kɔntaminɛshɔn, ɛn nɔ tek kia ɔf dɛn—ɛn yuz advans tul dɛn lɛk vaybreshɔn analaiza ɛn imej tɛnkɔlɔji, di wan dɛn we de wok kin no di prɔblɛm dɛn kwik kwik wan ɛn tek kɔrɛkt akshɔn. Fɔ fala di mentenɛns gaydlayn ɛn fɔ impruv di envayrɔmɛnt kɔntrol dɛn de protɛkt di bia dɛn mɔ frɔm di bad tin we de apin, fɔ mek shɔ se dɛn de du dɛn wok ɔltɛm ɛn dɛn de prɛsishɔn. Bearings pawa di spindle moto, ɛn nurture dɛm tru proactive care ɛn informed strategy na impɔtant tin fɔ bia wit rilaybiliti. Fɔ tayla sɔlvishɔn, kɔnsul wit bia manifakta ɔ spindle spɛshal pipul dɛn fɔ optimize bearing sɛlɛkshɔn ɛn mentenɛns fɔ yu spɛshal aplikeshɔn.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu