Sho

Chatter in CNC mashin—wan ɔl-tu-familiar nuisance—kin pwɛl yu pat finish, damej yu tul, ɛn shek yu prodaktiviti to in kɔr. Na di vaybreshɔn we yu nɔ want we kin apin we yu de kɔt, ɛn if yu dɔn ɛva yɛri da skreech, rattling nɔys we di mashin de rɔn, yu dɔn mit am fɔshand. Bɔt na di gud nyus: Chata nɔto sɔm monsta we nɔ go ebul fɔ avɔyd. Wit di rayt no, tul, ɛn strateji, yu kin kik am to di kɔba.

Tink bɔt am dis we: Chata na fɔ CNC mashin wetin statik bi to redio brodkas. I de mek di mɛsej chenj, i de mek pɔsin nɔ ebul fɔ wok fayn, ɛn i de mek mistek. Insay mashin, dɛn mistek dɛn de translet to skrap pat dɛn, shɔt tul layf, ɛn ay kɔst. So, fɔ pul chata nɔto jɔs fɔ impɔtant kwaliti—na bɔt fɔ bɔst yu ɔl di opareshɔn in pefɔmɛns ɛn bottom layn.

Dis gayd go tek yu dip dip wan insay di tin dɛm we de mek pɔsin chata, aw fɔ si am, ɛn, di impɔtant tin, aw fɔ pul am. If yu na ɛkspiriɛns mashinist ɔ jɔs de wet yu fut wet na di CNC wɔl, dis stɛp-by-stɛp blueprint go gi yu akshɔnable taktik fɔ silɛns chata ɛn smol yu rod fɔ prɛsishɔn.

Ɔndastand CNC Chatter .

Difinishɔn ɛn di kayn chata dɛn .

CNC Chatter de rifer to self-excited vibrations we de apin di tɛm we dɛn de kɔt di prɔses. I de sho as wev dɛn we de ripit na di say we dɛn de wok ɛn bɔku tɛm i kin mek wan nɔys we gɛt ay ay nɔys. Tu men kayn dɛn de:

1. Rijeneretiv Chata – we dɛn kɔz bay fidbak lɔp bitwin di tul ɛn wokpies frɔm di prɛviɔs kɔt pas.

2. MODE Coupling Chatter – de apin we tu difrɛn vaybreshɔn mod (lɛk lateral ɛn torsional) kɔpl togɛda.

3. Fɔs vaybreshɔn chata – trig bay ɛksternal tin dɛn lɛk moto imbalans ɔ worn-out bearings.

Ɛni wan pan dɛn kayn ya kin prɛzɛnt wan spɛshal chalenj, bɔt ɔl gɛt wan kɔmɔn rizɔlt: ridyus mashin kwaliti ɛn inkris wear pan ikwipmɛnt. If yu de yɛri wan swɛt ɔ notis rij na yu pat, i go mɔs bi se yu de dil wit wan pan dɛn kulprit ya.

Di tin dɛn we kin mek pɔsin ebul fɔ tɔk to pɔsin we de tɔk to pɔsin we de tɔk to pipul dɛn we de tɔk to pipul dɛn na CNC.

So wetin mek chata kin apin? Nɔto jɔs wan tin—i kin bi wan kɔmbaynshɔn fɔ tin dɛn:

· improper cutting parameters : Tu ay spindle spid ɔ fid ret kin amplify vaybreshɔn.

· Wik tul ɔ ɔlda : Nɔ gɛt rigiditi ɔ nɔ aprɔpriet tul jɔyometri kin initiate vaybreshɔn.

· Poor Fixturing : If yu pat nɔ de ol sikrit wan, ɛni muvmɛnt kin spiral insay wan chata episɔd.

· Mashin kondishɔn : Lus gaydway, bɔl skru we dɔn pwɛl, ɛn misalignmɛnt ɔl kin kɔntribyut.

· Material Properties : Sɔm matirial dɛn kin prona fɔ vaybrɛshɔn pas ɔda wan dɛn bikɔs ɔf dɛn had ɔ elastisiti.

Fɔ no di rut kɔz na di fɔs tin we yu fɔ du fɔ mek di nɔys nɔ de silɛns—literally ɛn figuratively. Yu nɔ go ebul fɔ fiks wetin yu nɔ ɔndastand.

Aw Chata de afɛkt CNC mashin .

Impekt Eria . |

Tɔk bɔt |

Rizɔlt dɛn |

Surface Finish . |

Wavy patterns, irregular tool maks pan di wokpies |

Poor aesthetics, pat rijekshɔn, dimɛnshɔnal inakyurasi |

Dimenshonal akkuracy . |

Vaybreshɔn de mek di tul kɔmɔt na di rod . |

Aut-of-tolerance parts, ridyus funkshɔnaliti . |

Tul Wear . |

Kɔntinyu vaybreshɔn de lid to edj chip ɛn fraktrɔs |

Frɛkuɛnt tul riplesmɛnt, ay tul kɔst . |

Mashin Wear . |

Chata transfa strɛs to mashin kɔmpɔnɛnt dɛn . |

Bearing damage, ridyus mashin layf, inkris mentenɛns |

Saykl tɛm . |

Slower feed rates we dɛn nid fɔ avɔyd chata . |

Di tɛm we dɛn de mek di prodakshɔn fɔ lɔng tɛm, di tɛm we dɛn dɔn ridyus di efyushɔn . |

Prodakshɔn kɔst dɛn . |

Inkris skrap, riwok, ɛn tul damej |

Di ay opareshɔnal ɛkspɛns, di ridyus prɔfit margin . |

Impekt pan di sɔfays finish ɛn pat kwaliti .

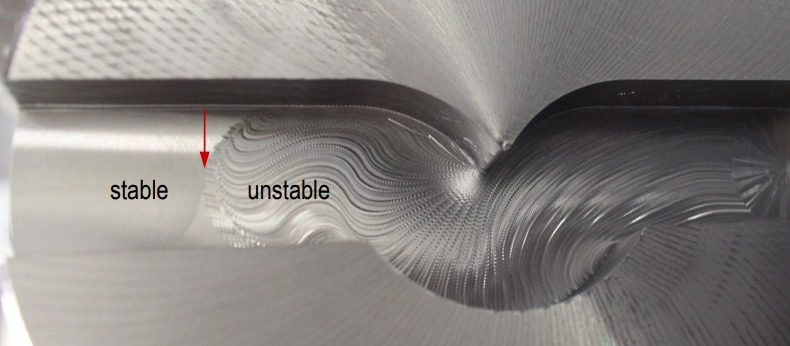

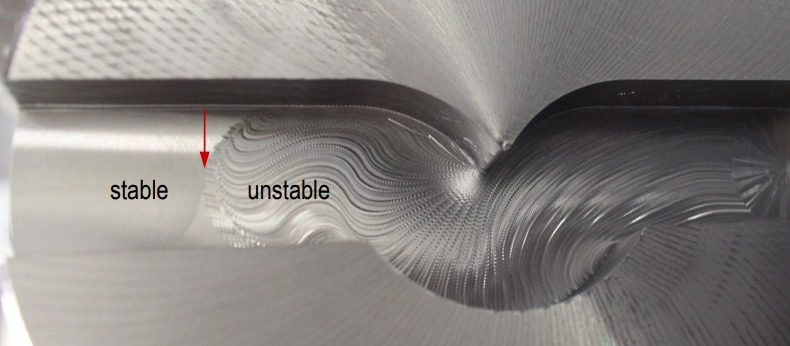

Wan pan di tin dɛn we pɔsin kin si we kin apin we pɔsin de tɔk to pɔsin na fɔ dɔn di say we i de, na we pɔsin nɔ de du bad bad tin dɛn. Imajin se yu de tray fɔ rayt wit pen we yu an de shek shek—dat na essentially wetin Chatter de du to yu cutting tool. Di vaybreshɔn dɛn kin mek yu gɛt irɛgyula tul pat, we kin lɛf wev-layk patɛns na yu pat.

Dis imperfekshon dem no bi jos kosmetik. Dɛn kin kɔmprɔmis tayt tolɛreshɔn, introduks strɔkchɔral wikɛdnɛs, ɛn lid to pat rijɛkt. Insai industri laik aerospace o medikal, wia presishon na evritin, dat na deal-breaker.

Chata de afɛkt bak dimɛnshɔnal akkuracy. Ivin if yu pat luk okay pan di surface, di hidden irregularities kin lid to pefomans failures, espeshali anda stres or lod.

Tul wear ɛn mashin layf .

Chatter nɔto jɔs bad fɔ di pat—na brutal pan yu tul. Kɔntinyu vaybreshɔn de mek maykro-frakt na di kɔt ed, we de mek di tul wear we dɛn de wɛr aksɛleret. Yu go si yusɛf de riples ɛnd mil ɔ insay mɔ ɛn mɔ, we de ad ɔp fast.

Ɛn lɛ wi nɔ fɔgɛt bɔt yu mashin. If yu tek lɔng tɛm fɔ mek yu vaybrɛshɔn, i kin mek yu gɛt mɔ bolt, i kin pwɛl di bia dɛn, ɛn i kin mek di layf we yu CNC ikwipmɛnt gɛt shɔt. Di kɔst fɔ mentenɛns kin bɔku, ɛn di tɛm we dɛn nɔ plan fɔ du di wok kin bi wan ɔltɛm ed we de at.

Prodakshɔn efyushɔn ɛn kɔst implikashɔn dɛn .

We di de dɔn, Chata hit yu usay i de at pas ɔl—yu walet. Poor surface finish dem nid riwok o ivin scrapping parts. Tul dɛn nid fɔ chenj bɔku tɛm. Mashin dɛn kin brok dɔŋ we dɛn nɔ bin de ɛkspɛkt. Ɔl dɛn tin ya kin ɛp fɔ:

· Di tɛm we di sayklɔs tɛm go tek lɔng tɛm .

· di ɔda truput dɛn we de dɔŋ

· Inkris opareshɔnal kɔst dɛm .

· Di tɛm dɛn we dɛn mis di de we dɛn fɔ dɔn

If yu de rɔn wan ay-volyum shɔp, dɛn lɔs dɛn ya kin kɔmpawnd kwik kwik wan. Bɔt ivin fɔ smɔl opareshɔn dɛn, di impak impɔtant. Di kɔst fɔ ignore Chatter ɔltɛm ay pas fɔ invɛst insay prɛvɛnshɔn.

Fɔ no di chata we dɛn de du CNC ɔpreshɔn .

Di we aw fɔ no di pɔsin . |

Indikɛtɔ dɛn . |

Tul dɛn/Tɛknik dɛn . |

Oditɔri sayn dɛn . |

Squealing, rattling, ɔ skreech nɔys we dɛn de kɔt we dɛn de kɔt |

Di ɔpreshɔn we di ɔpreshɔn de yɛri, di akostik ɛmishin sɛnsa dɛn . |

Visual Inspekshɔn . |

Wavy surface finish, shayn streaks, inkonsistent kot layn dɛn |

Pɔst-prɔses pat inspekshɔn . |

Tul Wear Patterns . |

Unusual wear lɛk chip ɔ bɔn pan tul edj dɛn . |

Maykroskɔp, magnifying lens dɛn . |

Hɛt Jɛnɛreshɔn . |

If yu wam pasmak ɔ smok we yu de kɔt . |

Tɛmral kamɛra dɛn, infrarɛd sɛns dɛn . |

Vaybreshɔn Mɛzhɔmɛnt . |

Di vaybreshɔn dɛn we dɛn mɛzhɔ ɔp di akseptabl trɛshɔld dɛn . |

aksilaromita, vaybreshɔn sɛnsɔn dɛn . |

Fɔ kɔt fɔs fidbak . |

Spikes in cutting forces durin machining . |

Fכs fכs dinamכmita, tork sεnsכr dεm . |

Visual ɛn ɔditɔri indikɛtɔ dɛn .

Bɔku tɛm, pɔsin kin tɔk lawd wan—ɛn i nɔ kin mistek. Dat ay-pitch swɛt, grindin, ɔ rattling nɔys na yu mashin in we fɔ ala fɔ ɛp. Nɔ ignore am. Na red flag we sɔntin dɔn ɔf.

Bɔt nɔto jɔs bɔt nɔys. Yu go notis bak se:

· Wavy sɔfayz patɛn (bɔku tɛm dɛn kin kɔl am 'chatter marks')

· Shiny streaks ɔ burnished eria dɛn .

· Premature tool wear .

· Ɔt pasmak ɔr smok we yu de kɔt .

Dɛn simptom ya kin izi fɔ si if yu de pe atɛnshɔn. Mek i bi abit fɔ inspɛkt pat dɛn afta ɛvri rɔn, mɔ we dɛn de du roughing ɔ ay-spid opareshɔn.

Diagnostik tul ɛn di we aw dɛn de du tin .

If yu want fɔ go bifo yu yay ɛn yes, diagnostik tul dɛn na yu bɛst padi. Yuz:

· Dayal indikɛtɔ fɔ chɛk fɔ mashin lɔsnɛs .

· Aksɛlɛrɔmita fɔ mɛzhɔ vaybreshɔn .

· Tɛmral imej fɔ no di say dɛn we dɛn kin ɔt pasmak .

· Kɔt fɔs sɛns fɔ ɔndastand tul ɛnjɔymɛnt .

Dɛn tul ya de ɛp yu fɔ pinpoint di sɔs fɔ chata wit ɔspitul prɛsishɔn. Yu nɔ nid fɔ gɛs—yu go no gud gud wan wetin nid fɔ fiks.

Yuz vaybreshɔn analisis fɔ chata ditekshɔn .

Vaybreshɔn analisis tan lɛk MRI fɔ yu CNC mashin. Bay we yu analayz frikshɔn ɛn amplityudɔ, yu kin no nɔto jɔs da chata de de apin—bɔt wetin mek.

Advanced Setups Yuz softwe we de kɔnɛkt to sɛns dɛn na di spindle, tul ɔlda, ɛn ivin di wokpies. Dɛn sistɛm ya de map ɔut vaybreshɔn frikshɔn ɛn kɔrɛlat dɛn wit mashin paramita dɛn. Wit dis data, yu kin:

· Adjɔst spid fɔ avɔyd rezonant frikshɔn dɛn .

· Balans yu spindle ɔ tul ɔlda .

· Prɛdikt we chata go mɔs apin .

Dis proaktiv we fɔ du tin de tɔn yu frɔm fayaman to strateji man—we de mek pipul dɛn nɔ de tɔk bifo i ivin bigin.

Provened Techniques fɔ pul Chatter .

Optimizing Cutting Parameters .

Fɔ gɛt yu kɔt paramita dɛn rayt na di singl mɔs ifɛktiv we fɔ silɛns chata. Tink bɔt am lɛk fɔ tyu myuzik inschrumɛnt: Smɔl ajɔstmɛnt kin mek wan wɔl difrɛns pan aw ɔltin de du.

Spindle spid ɛn fid ret ajɔstmɛnt dɛn .

Bɔku tɛm, di fɔs muv fɔ pul chata na fɔ tweak yu spindle spid. Na di trik—smɔl chenj dɛn, ivin bay 10%, kin shift yu ɔpreshɔn aut pan wan rezonant frikshɔn rɛnj. I tan lɛk se yu de hit di brek dɛn pan fidbak lɔp we dɔn go wayl.

Yuz wetin dɛn kɔl 'Spindle Speed Variation' (SSV) —wan CNC ficha we de chenj spindle spid we yu de kɔt. Dis de brok di ritm fɔ rijeneretiv chata, stɔp am bifo i bil.

Semweso, fɔ mek di fid rit go ɔp ɔ fɔ mek i nɔ bɔku kin mek bak di vaybreshɔn nɔ bɔku. If yu de kɔt tu fast, di tul kin bi ɔva-ɛnjɔy wit di matirial, we kin mek yu nɔ stebul. If i tu slo, di tul kin rɔb pas fɔ kɔt—also wan risɛp fɔ chata.

Di men tin dɛn we yu fɔ no:

· Ɔltɛm rɛfrɛns di manifakta-sɔj spid ɛn fid.

· Yuz chip lod kalkyulatɔ fɔ mek dɛn kɔntinyu fɔ gɛt di rayt ɛnjɔymɛnt.

· Nɔ fred fɔ rɔn tɛst kɔt wit smɔl chenj.

Dip fɔ kɔt ɛn tul ɛnjɔymɛnt .

Wan ɔda big kulprit biɛn Chata na wan pasmak dip we dɛn kɔt (DOC) ɔ di wit we dɛn kɔt (WOC) . If yu tul de bit ɔf mɔ pas aw i kin chew, i go ala—literally.

Tray fɔ yuz dɛn we ya:

· Ridyus di dok inkrimental wan te di vaybreshɔn dɛn stebul.

· Yuz raydial engagement strateji —layk trochoidal milling —fo kip konsistent tul preshos.

· Split op dip kot insay plɛnti pas.

Fɔ balans aw di tul de go insay di wok na impɔtant tin fɔ mek yu nɔ gɛt stebul mashin. Sɔntɛnde, layt bɔt fast pas kin wok bɛtɛ pas slo, ebi wan dɛn.

Tooling selekshɔn ɛn tul jɔyometri .

Yu kot tul na di MVP fɔ di ɔpreshɔn. Bɔt if na di rɔng tayp, shep, ɔ matirial, i kin amplify chata instead fɔ suprɛs am.

Tul matirial ɛn kɔtin .

Difrɛn tul matirial dɛn de gi difrɛn stiffnɛs ɛn vaybreshɔn-dampening prɔpati dɛn:

· Di tin dɛn we dɛn kin yuz fɔ mek kabayd kin strɔng pas di ay-spid stɛl (HSS), we kin mek dɛn bɛtɛ fɔ mek dɛn nɔ chata.

· di tul dɛm we dɛn kɔt (lɛk tin ɔ altin) de ridyus frikshɔn, we de mek di ɔt ɛn vaybrɛshɔn go dɔŋ.

If yu yuz di rayt kɔmbaynshɔn bays pan yu matirial (aluminum vs. titanium, fɔ ɛgzampul) kin mek ɔl di difrɛns.

Jɔyometri ajɔstmɛnt fɔ stebiliti .

Di tul in jɔyometri impɔtant pas aw bɔku mashinist dɛn kin no. Tray:

· Variable helix angles fɔ brok ɔp hamonik vaybreshɔn.

· Nɔ ikwal flut spays fɔ mek dɛn nɔ mek di vaybrɛshɔn sinkronizashɔn.

· Short ovahang fɔ mɔ rigiditi.

· Big kor dayamita fɔ ad trɛnk.

Wan 3-flut ɛnd mil wit wan vɛriɔbul pitch kin pas 4-flut wit standad jɔyometri we i kam pan chata kɔntrol. Bɔku tɛm na trial ɛn mistek, bɔt we yu dɔn fɛn di swit ples, yu go si smol smol finish ɛn kwayɛt rɔn.

Mashin Sɛtup ɛn Mentɛnans .

Fiksturing ɛn wokpies klamp .

If yu pat nɔ de ol tayt, i go vibrate. Tɛm. Prɔpa wokholdin na di fawndeshɔn fɔ chata-fri mashin.

Tips fɔ mek dɛn ebul fɔ fiks di tin dɛn we dɛn dɔn fɛn:

· Yuz rigid, vaybreshɔn-dampening vises ɔ klem.

· Kip di lest posibul ovahang of di wokpies.

· Yuz stɛp blɔk ɔ kɔstɔm jig fɔ ɛp fɔ mek yu stebul.

· Tink bɔt vaykum tebul fɔ flat pat dɛm—bɔt riinfɔs dɛn rigiditi.

Fɔ dilik pat dɛn, sɔft jaw ɔ kɔstɔm fiks fɔ mek shɔ se sikyɔriti nɔ gɛt difɔmeshɔn. dɛn kin nid fɔ gɛt

mashin rigiditi ɛn alaynɛshɔn .

Ivin di bɛst tul ɛn sɛtin dɛn nɔ go ɛp if yu CNC mashin sɛf nɔ de ɔp to di wok.

Chek fɔ:

· Lus slayd ɔ we dɛn de slayd .

· Skru dɛn we dɔn pwɛl ɛn we dɔn pwɛl .

· Spindle misalaynmɛnt .

· Tebul vaybreshɔn we dɛn de du ɔpreshɔn .

If yu tayt dɛn eria ya, i kin ridyus di vaybreshɔn transmishɔn bad bad wan ɛn i kin mek di kwaliti fɔ ɛvri kɔt bɛtɛ.

Rutin Mentɛnans ɛn Kalibreshɔn .

No jos fix tins wen dem brok. mek dɛn nɔ brok.

Bil wan rutin mentenɛns chɛklist:

· Lubrik gaydway ɛn skru dɛn ɔltɛm

· Tayt bolt ɛn kɔnɛkshɔn .

· Chɛk spindle balans ɛn bia wɛlbɔdi .

· Ri-kalibrayt aks ɛvri sɔm mɔnt

Mashin we dɛn dɔn mek fayn fayn wan na mashin we nɔ de chata. Bɔku tɛm, dɛn kin kia fɔ pikin dɛn we dɛn nɔ de tek kia ɔf bɔku tɛm bifo dɛn rich to di tul.

Advans Sɔlwɛshɔn fɔ Chata Mitigashɔn .

Yuz di damped tul holda dɛn .

Damped tool holders na lɛk shɔk absɔba fɔ yu kɔt tul dɛn. Dɛn kin absɔb di ɛnaji frɔm vaybreshɔn bifo i rich di impɔtant lɛvɛl dɛn.

Bɔku tɛm dɛn ɔlda dɛn ya kin gɛt tin dɛn lɛk polimɛr ɔ mas dampa dɛn we dɛn dɔn tyu insay di ɔlda bɔdi. Di rizulyt? dramatik ridyus vaybreshɔn, lɔng tul layf, ɛn bɛtɛ finish.

Dɛn kin wok fayn mɔ pan dip-pɔkit mil ɛn lɔng-rich aplikeshɔn usay standad tul dɛn kin gɛt rɛsɔn.

Variable Pitch ɛn Ɛliks Tul dɛn .

Tul dɛn wit wan vɛriɔbul pitch ɔ vɛriɔbul ɛliks gɛt flut jɔyometri dɛn we nɔ ivin bay wilful. Dis de brok di simetri fɔ kɔt fɔs ɛn disrɔb di vaybreshɔn bildup.

Insted of ol flutes engaging di matiryal na di sem frikshɔn, di variebul spays de spred aut di fos lod. Dis de ridyus di chans fɔ mek hamonik bildup ɛn praktis fɔ pul di rijeneretiv chata.

Yuz dɛn wan ya fɔ:

· Di opareshɔn dɛn we dɛn de du fɔ mek dɛn wok fayn fayn wan .

· Pat dɛn we gɛt tin-wɔl .

· Erospes-grɛd matirial dɛn .

Vaybreshɔn Dampening Sistem dɛn .

Sɔm ay-ɛnd CNC sistem dɛn kin kam wit bilt-in vaybreshɔn dampeners ɔ alaw fɔ ɛksternal ad-ɔn dɛn:

· Aktiv Dampening Sistem dɛn we de yuz sɛns ɛn aktyuator dɛn .

· Magnɛtik dampa fɔ spindle asɛmbli dɛn .

· Mass-tuned dampers insay di spindle haus

Pan ɔl we dɛn sistɛm ya dia, dɛn sistɛm ya nɔ gɛt valyu na ɔlta-prɛsishɔn wok usay sɔfays finish ɛn dimɛnshɔnal intɛgriti na di men tin.

CAM Softwe ɛn Simyuleshɔn .

Chata prɛdikshɔn tru sɔftwɛl .

Modan CAM (Computer-Aided Manufacturing) softwea nɔ de du mɔ pas fɔ mek tulpat dɛn—i kin naw prɛdikt chata bifo yu ivin tɔch wan pat pan di matirial. Dat na laik se yu get kristal bol fo yu mashin proses.

Advanced Software Tools Yuz matematikal mɔdel ɛn mashin dinamik fɔ fɔkɔs we chata go mɔs apin bay:

· Matirial prɔpati dɛn .

· Tul jɔyometri .

· Di paramita dɛn we dɛn de kɔt .

· Mashin dinamiks .

Wit dis prɛdikshɔn dɛm, yu kin ajɔst yu sɛtup na di dijital faz, sev tɛm, matirial, ɛn tul layf. Program dɛm lɛk Machiningcloud , Vericut , ɔ NC Simul na industri favrit we i kam pan chata analisis ɛn prɛvɛnshɔn.

Toolpath optimizashɔn tɛknik dɛn .

Toolpath dizayn de inflɔws di chata dairekt wan. Sɔm patɛns kin mek di vaybrɛshɔn dɛn, ɔda wan dɛn kin mek dɛn nɔ gɛt bɛtɛ trɛnk.

Na dis yu fɔ du:

· Yuz ay-spid mashin strateji lɛk adaptiv klia fɔ ridyus tul ɛnjɔymɛnt ɛn stebul fɔs.

· Avɔyd chenj dɛn we de chenj wantɛm wantɛm ɔ shap kɔna dɛn na yu tulpat dɛn.

· Employ kɔnstant tul ɛnjɔymɛnt tɛknik dɛm we de ridyus tul diflɛshɔn.

Smarter toolpaths min mɔ balans kɔt fɔs, we translet to smol, chata-fri finish.

Rial-taym simulshɔn ɛn fidbak .

Sɔm CAM sɔlvishɔn dɛn de intagret rial-taym fidbak lɔp dɛn we de yuz sɛnsɔn dɛn we dɛn dɔn instɔl na di mashin. Dɛn sistɛm ya de monitar spindle vaybreshɔn, kɔt fɔs, ɛn akostik ɛmishin insay rial-taym. If chata bigin fɔ divɛlɔp, dɛn kin:

· Sɛnd alɛt to di ɔpreshɔn .

· Ajɔst di fid/spid ɔtomɛtik wan na di Flay .

· Log data fɔ post-prɔses analisis .

Dis proaktiv layt fɔ chata kɔntrol na spɛshal yusful insay ɔtomatik ɔ layt-ɔut mashin ɛnvayrɔmɛnt usay manual monitarin nɔ fisabili.

Di trenin we dɛn de gi ɛn di bɛst we fɔ du di wok ɛn di bɛst we fɔ du am .

Impɔtant tin dɛn bɔt di wan dɛn we sabi du di wok .

Yu kin gɛt di bɛst tul dɛn, di softwe we smat pas ɔl, ɛn wan rɔk-solid mashin—bɔt if di pɔsin we de wok wit yu nɔ gɛt ɛkspiriɛns, Chatter go fɛn we fɔ du am.

Wan mashin we dɛn dɔn tren fayn fayn wan kin:

· Yɛri di difrɛns bitwin gud ɛn bad kɔt

· Fil di subtil vaybreshɔn dɛn .

· Diagnose Chatter bays pan tul mak dɛn nɔmɔ

Di wan dɛn we sabi du di wok kin no bak ustɛm fɔ intavyu, chenj tul dɛn, ɔ ajɔst di sɛtin dɛn insay rial-taym. Dɛn instinkt dɛn, we dɛn bin de divɛlɔp fɔ bɔku bɔku tawzin awa na di shɔp flo, nɔ go ebul fɔ tek dɛn ples.

Ɛnkɔrej fɔ kɔntinyu fɔ lan buk. Invest in yu tim in growth. Wan smat ɔpreshɔn na yu fɔs layn fɔ difens agens Chata.

Kɔntinyu fɔ lan ɛn wokshɔp .

Di wɔl wɔl de evolv kwik kwik wan, ɛn fɔ de bifo nid fɔ gɛt trenin we go kɔntinyu. Ɔs ɔ atɛnd:

· In-haus wokshɔp dɛn we de pe atɛnshɔn pan chata diagnostik .

· Seminari we di vendor de lid bɔt nyu tul ɛn kɔt tɛknik

· Onlayn kɔs ɛn sɛtifiket dɛn frɔm pletfɔm dɛn lɛk Coursera, Tooling U, ɔ LinkedIn Lanin

No na pawa—ɛn insay CNC mashin, na di pawa fɔ ridyus skrap, impruv kwaliti, ɛn ɛkstɛnd mashin layf.

Indastri Ɛgzampul dɛn ɛn Kes Stɔdi dɛn .

Rial-Wɔl Sakses Stori dɛn .

Lɛ wi luk aw sɔm kɔmni dɛn dɔn pul chata ɛn impɔtant prodakshɔn:

Aerospace manifakta na Ohio .

Prɔblɛm: Chata insay dip-pɔkit aluminiɔm pat dɛn

Sɔlv: Switched to variable Helix End Mills, ad damped holda dɛn

Rizult: Ridyus saykl tɛm bay 30%, impɔtant finish gred frɔm RA 6.3 μm to RA 1.2 μm

Otomotiv supplier in Jamani .

Prɔblɛm: Di we aw dɛn de wɛr di tul pasmak ɛn di difrɛn difrɛn tin dɛn we de ɔp di wɔl .

Sɔlv: Implimented rial-taym vaybreshɔn monitɔrin wit CAM fidbak

Rizult: 40% inkris na tul layf ɛn smɔl pat dɛn we dɛn nɔ gri fɔ tek pat pan

Medikal Divays Shop na Kalifɔnia .

Prɔblɛm: Chata insay smɔl titanium implant dɛn .

Sɔlv: Optimayz tulpat strateji, ad ay-rigiditi fiks dɛn

Rizult: Achieve ±0.005 mm tolerans konsistentli

Dɛn ɛgzampul ya sho se ilɛk aw di industri ɔ di tin we dɛn yuz, yuz di rayt strateji, de mek pɔsin gɛt rial tin dɛn we pɔsin kin mɛzhɔ.

Lɛsin dɛn we dɛn lan frɔm CNC pɔshɔnal dɛn .

Tɔk to ɛni sizin mashinist ɛn dɛn go tɛl yu—chata nɔto jɔs wan nuisance; Na shop killer. Na dis na wetin dɛn dɔn lan di had we:

· Nɔ ɛva ignore di fɔs sayn dɛm—chatter ɔltɛm kin wɔs.

· Wan rigid setup impɔtant pas wan fast setup.

· Test kot ɛn dɔkyumentri na yu bɛst padi dɛm.

· Cheap tooling de kos yu mo in di long run.

Fɔ lisin to di sɛns we de na di shɔp flo na impɔtant tin jɔs lɛk fɔ rid wan manual. Rial-wɔl ɛkspiriɛns na gold we i kam pan fɔ no ɛn sɔlv chata.

kɔmɔn mistek dɛn fɔ avɔyd .

We yu de luk oba mashin kalibreshɔn .

Mashin we dɛn nɔ kalibrayt fayn tan lɛk motoka we gɛt wil dɛn we nɔ gɛt alayn. Fɔ tru, i go muf—bɔt nɔto fayn fayn wan. Rigyul kalibreshɔn de mek shɔ se ɔl di aks dɛn alaynɛd, baklash de minimiz, ɛn kɔmpɔnɛnt dɛn de wok insay wanwɔd.

Di mistek dɛn we dɛn kin si:

· Fɔ ignore smɔl alaynɛshɔn kwɛstyɔn dɛn .

· Skip Scheduled Mentɛnans .

· Fail fɔ rikalibrayt afta pat krash .

Ivin brand-nyu mashin dɛn kin bɛnifit frɔm wan fɔs kalibreshɔn chɛk—nɔ tek am se faktri sɛtin dɛn pafɛkt.

Yuz Impɔtant Tul .

Yuz di rɔng tul tan lɛk fɔ yuz hama we yu nid skru drayva—nɔto jɔs nɔ ebul fɔ du am, i de pwɛl.

Kɔmɔn tul mistek dɛn:

· Long-rich tul fɔ shalo kɔt .

· Tumɔs flut fɔ gɔmi matirial dɛn .

· Fɔ ignore di impɔtants fɔ tul kɔtin dɛn .

· nɔt maching tul jɔyometri to matirial hadnɛs

Ɔltɛm, luk yu tul spɔlayt ɔ rep bifo yu rɔn nyu wok. Fayv minit kɔl kin sev awa fɔ wok bak.

Di wok we teknɔlɔji de du fɔ mek pɔsin nɔ tɔk to pɔsin .

IoT ɛn smat mashin sistem dɛn .

Di Indastrial Intanɛt fɔ Tin dɛn (IIOT) de transfɔm CNC mashin. Smat sɛnsa dɛn we dɛn put insay mashin, spindl, ɛn tul dɛn kin gɛda rial-taym data bɔt vaybreshɔn, tɛmpracha, ɛn kɔt fɔs.

Dis data de fid insay dashbɔd ɔ klawd pletfɔm, we de ɛnabul prɛdiktiv ajɔstmɛnt dɛn lɛk:

· spid ridɔkshɔn we di vaybrɛshɔn pas di limit dɛn .

· Alerting operators bifo Chatter damages tooling

· Shut dɔŋ di mashin in kes fɔ di ekstrim kɔndishɔn dɛn .

Dɛn smat sistɛm ya nɔ jɔs de no chata—dɛn de wok tranga wan fɔ mek i nɔ apin.

Prediktiv Mentɛnans Tul dɛn .

Prediktiv Mentɛnans de yuz data ɛn analitiks fɔ si bifo tɛm we wan mashin kɔmpɔnɛnt go fel. Na gem-chenja fɔ chata kɔntrol.

Di bɛnifit dɛn na:

· Fɔ no di bia wear bifo i de lid to spindle vaybreshɔn .

· Fɔ mek dɛn nɔ lɔs di lɔs we de na di linya rel dɛn .

· scheduling downtimes witout disrupting prodakshɔn

Bay we yu adrɛs di prɔblɛm dɛn bifo dɛn mek chata, prɛdiktiv mentenɛns de mek yu shɔp de rɔn fayn fayn wan ɛn kwayɛt wan.

Fɔ bil wan chata-fri CNC ɛnvayrɔmɛnt .

Integretin Lian Manufakchurin .

Chata kɔntrol fit dɛn naturally insay smɔl smɔl tin dɛn we dɛn kin yuz fɔ mek tin dɛn . I alayns wit ridyusin west, optimizing flow, ɛn mentɛn kɔnsistɛns kwaliti.

Lian tul dɛm we de ɛp wit Chatter:

· Kaizen ivent fɔ pul di rut kɔz dɛm .

· Standart wok instrɔkshɔn fɔ mashin sɛtup .

· 5S program fɔ mek yu kɔntinyu fɔ gɛt klin, stebul ɛnvayrɔmɛnt .

Wan slim, ɔganayz wokples de ridyus di chaos we kin brid bɔku tɛm chata.

Standard operetin prosidur (SOPS) .

Fɔ dɔn, rayt ɔltin. Krio Sops we inklud:

· Ideal kɔt paramita fɔ ɛni matirial .

· Mashin wam-ap ɛn kalibreshɔn rutin dɛn .

· Tul Sɛleshɔn Chɛklist dɛn .

· Di mashin inspekshɔn gaydlayn dɛn ɛvride .

Klir, aksesbul SOPs de ɛp ɛvri ɔpreshɔn—nyu ɔ sizin—adhere to bɛst prɔsis, kip chata at bay kɔnsistɛntli.

Dɔn

Chatter kin bi wan kɔmɔn prɔblɛm fɔ CNC mashin, bɔt i fa frɔm inevitable. Wit klia ɔndastandin fɔ in kɔz dɛm ɛn wan tulbɔks we ful-ɔp wit stratejik fiks dɛm—frɔm tuning kɔt paramita to ɔpgrɛd sɔftwɛl ɛn hadwɔd—yu kin mek wan kwayɛt, efishɔnal, ɛn prodaktiv shɔp ɛnvayrɔmɛnt.

Nɔ mek Chatter kɔmprɔmis yu prɛsishɔn, west yu matirial dɛn, ɔ pwɛl yu prɔfit. Bi proaktiv, de lan buk, ɛn trit chata kɔntrol as fawndeshɔn pat pan yu CNC strateji.

FAQ dɛn .

1. Aw a go no if mi CNC mashin de experiens chata?

Luk fɔ ay-pitch nɔys dɛn we yu de kɔt, wev patɛn we yu kin si na yu wokpies, ɛn sayn dɛn we de sho se yu de wɛr di tul kwik kwik wan ɔ di say we yu de pwɛl di wata. Rial-taym vaybreshɔn sɛns kin ɛp bak fɔ no am kwik kwik wan.

2. Yu tink se dɛn go dɔnawe wit chata kpatakpata?

Pan ɔl we i nɔ kin bi 100% we dɛn kin avɔyd pan ɔl di sityueshɔn dɛn, if dɛn yuz di rayt tɛknik ɛn tul dɛn, i kin ridyus am to nia ziro. Wit expiriens en di rait setup, yu kin run pats smol smol evri taim.

3. Wetin na di mɔs kɔst-ɛfɛktiv we fɔ ridyus chata?

Start wit simpul fiks lɛk fɔ ajɔst di fid ret ɔ yuz wan shɔt tul. Toolpath optimization in yu kam softwea ɛn bɛtɛ fixturing na afɔdabul bak bɔt i rili ebul fɔ wok.

4. Aw di tɛmpracha kin afɛkt chata na CNC mashin?

If yu gɛt ay tempɔret kin mek di tɛmral ɛkspɛnshɔn, we kin mek yu nɔ gɛt wan prɔblɛm ɛn we kin mek di vaybreshɔn susɛptibiliti go ɔp. I rili impɔtant fɔ mek yu kɔntinyu fɔ gɛt thermal stebiliti na yu say we yu de kɔt.

5. A fɔ chenj mi kam softwe fɔ fiks chata?

If yu softwea we yu gɛt naw nɔ gɛt simulshɔn ɔ chata prɛdikshɔn ficha dɛn, fɔ ɔpgrɛd kin fayn fɔ am. Modan CAM Solutions de gi pawaful analisis tul dɛm we de ɛp fɔ mek Chatter nɔ kɔmɔt na di program stej.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu