Insay CNC (kɔmpyuta nɔmba kɔntrol) mashin dɛn ɛn ɔda prɛsishɔn injinɛri aplikeshɔn dɛn, servo moto ɛn spindle motoka dɛn na impɔtant kɔmpɔnɛnt dɛn we de drɛb di sistɛm in funkshɔnaliti. Wail ɔl tu na ilɛktrik moto intagral to di opareshɔn fɔ CNC sistem, dɛn de sav fondamentally difrɛn prɔpɔz ɛn dɛn mek dɛn wit difrɛn kwaliti dɛn we dɛn tayl to dɛn spɛshal rol dɛn. Fɔ ɔndastand di difrɛns bitwin Servo Motors ɛn Spindle Motors na impɔtant tin fɔ pik di rayt kɔmpɔnɛnt dɛn, fɔ mek di mashin wok fayn fayn wan, ɛn fɔ ajɔst di ay kwaliti rizɔlt dɛn na prɛsishɔn mashin. Dis atikul de go insay di men difrɛns bitwin dɛn tu kayn motoka ya, fɔ fɛn ɔltin bɔt dɛn wok, dizayn, aplikeshɔn, ɛn pefɔmɛns kwaliti fɔ gi klia wan to di wan dɛn we lɛk fɔ du ɔbi, di wan dɛn we sabi fɔ mek mashin, ɛn di injinia dɛn.

Wetin na Servo Motors?

Servo motor na ayli spɛshal ilɛktrik motoka dɛn we dɛn mek fɔ prɛsis kɔntrol fɔ pozishɔn, velositi, ɛn tɔk insay CNC (kɔmpyuta nɔmba kɔntrol) mashin dɛn ɛn ɔda prɛsishɔn injinɛri aplikeshɔn dɛn. Dɛn na di drɛvin fɔs biɛn di kɔrɛkt muvmɛnt fɔ wan CNC mashin in aks (ɛgz., X, Y, Z) ɔ kɔmpɔnɛnt dɛn na rɔbɔt sistɛm, mek shɔ se dɛn put di tul ɔ wokpies dɛn we dɛn dɔn program jɔs lɛk aw dɛn program dɛn. Nɔ lɛk standad motoka, Servo moto dɛn de wok insay wan klos-lɔp kɔntrol sistem, we de yuz fidbak divays dɛn lɛk ɛnkɔda ɔ rizɔlt fɔ kɔntinyu fɔ wach ɛn ajɔst dɛn pefɔmɛns fɔ mek dɛn mach di CNC sistem in instrɔkshɔn dɛn. Dis prɛsishɔn ɛn adaptabiliti mek servo moto dɛn indispɛns fɔ wok dɛn we nid ɛksaktɔl muvmɛnt ɛn dinamik kɔntrol insay industri dɛn we de frɔm manufakchurin to rɔbɔt

Servo motor dem enjinia wit spesifik kwaliti dem we de enable dem yus in hai-precision aplikeshon. Dis dɔŋ ya na di men tin dɛn we de sho aw dɛn de wok ɛn difrɛns dɛn frɔm ɔda kayn motoka dɛn, lɛk spindle moto dɛn:

Klos-lɔp kɔntrol

servo moto dɛn de wok insay wan klos-lɔp sistɛm, we min se dɛn kin gɛt kɔntinyu fidbak frɔm sɛns (ɛgz., ɛnkɔda ɔ rizɔlt) fɔ monitar dɛn aktual pozishɔn, spid, ɛn tɔk. Dis fidbak de kɔmpia to di valyu dɛn we dɛn want frɔm di CNC kɔntrol sistɛm, ɛn ɛni diskrɛpshɔn dɛn kɔrɛkt insay rial-taym bay we dɛn ajɔst di motoka in autput. Dis klos-lɔp kɔntrol de mek shɔ se ɛksɛpshɔn akkuracy, we de mek servo moto dɛn fayn fɔ aplikeshɔn usay ivin smɔl devieshɔn kin afɛkt kwaliti, lɛk CNC mashin ɔ rɔbɔt arm pozishɔn.

Di ay prɛsishɔn

servo moto dɛn ebul fɔ maykro-adjɔstmɛnt, we de alaw fɔ prɛsis pozishɔn dɔŋ to frakshɔn dɛn na wan milimita ɔ digri. Dis prɛsishɔn na impɔtant tin fɔ wok dɛn lɛk fɔ mil kɔmpleks jɔyometri, fɔ drɔ prɛsis ol dɛn, ɔ fɔ posishun tul dɛn na mɔlti-aks CNC mashin dɛn. Fɔ ɛgzampul, insay wan 5-aks CNC mashin, Servo Motors de mek shɔ se ɛni aks de muv kɔrɛkt wan fɔ mek intrɛst pat fɔ aerospace ɔ mɛdikal aplikeshɔn.

Variable speed ɛn torque

servo moto dɛn kin ɔpreshɔn akɔdin to wan big rɛnj ɔf spid ɛn deliv kɔnsistɛns tɔk, we kin mek dɛn versatil fɔ dinamik aplikeshɔn dɛn. Dɛn kin aksɛleret, stɔp, ɔ stɔp kwik kwik wan we dɛn de mentɛn prɛsis kɔntrol, we impɔtant fɔ wok dɛn we nid fɔ chenj kwik kwik wan na muvmɛnt, lɛk fɔ kɔntɔr ɔ fɔ thread na CNC mashin. Dis fleksibiliti de alaw servo moto fɔ adap to difrɛn lod ɛn mashin rikwaymɛnt.

Kompakt dizayn

servo moto dɛn tipikli kɔmpakt ɛn laytwɛt, dɛn mek am fɔ fit insay di kɔnstrayn spɛs dɛn na CNC mashin ɔ rɔbɔt sistem. Dɛn smɔl saiz de mek dɛn ebul fɔ muv dinamik, mɔlti-aks we dɛn nɔ ad pasmak wet to di mashin in kɔmpɔnɛnt dɛn we de muv. Dis na patikyula impɔtant fɔ ay-spid aplikeshɔn usay fɔ minimiz inɛs na impɔtant tin fɔ rispɔnsiv ɛn akkuracy.

Tayps of servo motors

servo motor de kam in difrɛn difrɛn we dɛn, ɛn ɛni wan pan dɛn fit fɔ spɛshal aplikeshɔn dɛn:

AC Servo Motors : Pawa bay ɔltɛna kɔrɛnt, dɛn moto ya strɔng ɛn dɛn kin yuz am na industrial CNC mashin fɔ dɛn ay pawa ɛn durabiliti. Bɔku tɛm dɛn kin pe dɛn wit vayriɔbul frikshɔn drayv (VFD) fɔ prɛsis kɔntrol.

DC Servo Motors : Powered by Direct Current, dɛn moto ya simpul ɛn dɛn kin yuz dɛn bɔku tɛm na smɔl ɔ smɔl dimand aplikeshɔn dɛn, lɛk ɔbi CNC sɛtup dɛn. Brushed DC servo motor nɔ kin bɔku bikɔs ɔf mentenɛns nid, we dɛn kin lɛk fɔ yuz brushlɛs vɛshɔn fɔ efyushɔn.

Brushless DC Servo Motors : Dɛn wan ya de kam togɛda di bɛnifit dɛn we DC motoka dɛn gɛt wit impɔtant durabiliti ɛn efyushɔn, we de pul di nid fɔ brɔsh. Dɛn kin yuz dɛn bɔku bɔku wan na di mɔdan CNC mashin dɛn fɔ dɛn lɔw mentenɛns ɛn ay pefɔmɛns.

| Servo Motor Type |

Description |

Pros |

Cons |

Aplikeshɔn dɛn |

Ki Karakta dɛn |

| AC Servo Motors . |

Pawaful bay ɔltɛna kɔrɛnt, dɛn robust moto ya dɛn mek fɔ ay-pawa industrial aplikeshɔn, bɔku tɛm dɛn kin pe wit vɛriɔbul frikshɔn drayv (VFD) fɔ prɛsis spid ɛn tɔk kɔntrol. |

High pawa autput, ekselent durability fɔ kɔntinyu fɔ wok, prɛsis kɔntrol wit VFD, we fit fɔ hevi-duti wok dɛn. |

Higher cost bikɔs ɔf moto ɛn VFD kɔmplisiti, big futprin, nid kɔmpleks sɛtup ɛn program. |

Indastrial CNC mashin dɛn, big-big mil, drɔlin, rɔbɔtiks, ɛn ɔtomɛshɔn insay ɔtomotiv/eɛspɛs industri dɛn. |

High torque na low spid, robust konstrakshon, waid spid renj (1,000–6,000 rpm), tipikli 1–20 kW pawa retinj. |

| DC Servo Motors . |

Pawaful bay dairekt kɔrɛnt, dɛn moto ya simpul ɛn yuz insay smɔl ɔ smɔl dimand aplikeshɔn. I de insay brɔsh ɔ brɔshlɛs kɔnfigyushɔn, wit brɔsh we nɔ bɔku bikɔs ɔf mentenɛns nid. |

Kɔst-ɛfɛktiv, laytwɛt, simpul kɔntrol sistem, we fayn fɔ lɔw-pawa aplikeshɔn. |

Limitɛd pawa autput, brush vɛshɔn dɛn gɛt ay mentenɛns (brush wear), prone fɔ ɔva ɔt insay lɔng yus. |

Hobbyist CNC setup, smɔl dɛsktɔp routers, simpul ɔtomɛshɔn wok, lɔw-pawa aplikeshɔn lɛk PCB miling ɔ layt engravin. |

Lower torque, spid renj we de 2,000–10,000 rpm, pawa retinj tipikli 0.1–1 kW, we nɔ kin te pas AC moto. |

| brushless DC servo motors . |

Wan sabset fɔ DC moto, dɛn wan ya de yuz ilɛktronik kɔmyuteshɔn instead ɔf brɔsh, dɛn de gi impɔtant efyushɔn ɛn durabiliti. Bɔku pipul dɛn kin yuz am na di mɔdan CNC sistem fɔ dɛn balans fɔ pefɔmɛns ɛn lɔw mentenɛns. |

Ay efyushɔn, lɔw mentenɛns, lɔng layfspan, kɔmpakt dizayn, gud pefɔmɛns akɔdin to wan wayd spid rɛnj. |

Higher initial kos pas brushed DC moto, nid ilektronik kontrola, less pawa pas AC servo motor fo hevi wok. |

Mɔdan CNC routers, prɛsishɔn rɔbɔtiks, 3D printa, mɛdikal ikwipmɛnt, ɛn aplikeshɔn dɛn we nid ay rilaybiliti ɛn prɛsishɔn. |

Ay efyushɔn (we go rich 90%), spid rɛnj we na 3,000–15,000 rpm, pawa retinj dɛn we na 0.5–5 kW, lɔw ɔt jɛnɛreshɔn. |

Rol in CNC mashin dɛn .

Insay CNC sistem, Servo Motors na dɛn fɔs fɔ kɔntrol di linya ɔ rotary muvmɛnt fɔ di mashin in aks dɛn. Fɔ ɛgzampul:

Insay CNC router, Servo Motors de drayv di X, Y, ɛn Z aks fɔ posishun di spindle ɔ kɔt tul kɔrɛkt wan oba di wokpies.

Insay CNC lath, wan servo moto kin kɔntrol di roteshɔn fɔ di wokpies (we de akt lɛk spindle insay sɔm kes dɛm) ɔ di muvmɛnt fɔ di tul we dɛn de kɔt.

Insay mɔlti-aks mashin dɛn, Servo moto dɛn kin mek kɔmpleks muvmɛnt dɛn, lɛk fɔ tilt ɔ fɔ rɔta di wokpies ɔ tul insay 4- ɔ 5-aks kɔnfigyushɔn dɛn.

Dɛn ebul fɔ gi prɛsis, ripit muvmɛnt de mek servo moto dɛn impɔtant fɔ mek dɛn kɔntinyu fɔ gɛt tayt tolɛreshɔn ɛn fɔ ajɔst di ay kwaliti finish dɛn na aplikeshɔn dɛn lɛk aerospace, ɔtomotiv, ɛn mɛdikal divays manufakchurin. Bay we dɛn intagret wit di CNC mashin in kɔntrol sistem, Servo Motors translet programmed G-Code instrɔkshɔn dɛn insay fizik muvmɛnt, mek shɔ se di mashin de fala di tulpat we dɛn want wit minimal mistek.

Praktikal Tin dɛn fɔ Tink Bɔt .

We yu de pik ɔ yuz Servo moto dɛn na CNC aplikeshɔn dɛn, tink bɔt dɛn tin ya:

Fidbak Sistem : Mek shɔ se di motoka in fidbak divays (ɛgz., ɛnkɔda rizɔlt) mit di prɛsishɔn rikwaymɛnt dɛn fɔ yu aplikeshɔn.

POWER AND TORQUE : Match di moto in pawa ɛn tork to di lod ɛn spid we di CNC mashin in aks dɛn nid.

Kontrol Sistem Kompatibiliti : Verifay se di servo moto de kompitibul wit di mashin in kɔntrol, lɛk PLC ɔ CNC softwe, fɔ mek shɔ se intagreshɔn we nɔ gɛt wan bɔt.

Mentɛnans : Ɔltɛm inspɛkt fidbak divays, waya, ɛn kɔnɛkshɔn fɔ mek dɛn nɔ gɛt prɔblɛm wit di pefɔmɛns ɔ ilɛktrik fɔlt.

Bay we dɛn de yuz di prɛsishɔn, kɔntrol, ɛn versatility fɔ servo moto dɛn, CNC ɔpreshɔn dɛn kin ajɔst ɛksɛpshɔn akkuracy ɛn efyushɔn insay dɛn mashin prɔses, we mek dɛn moto ya bi kɔna ston fɔ mɔdan prɛsishɔn injinɛri.

Klik ya fɔ bay Spindle Motors na Amazon.

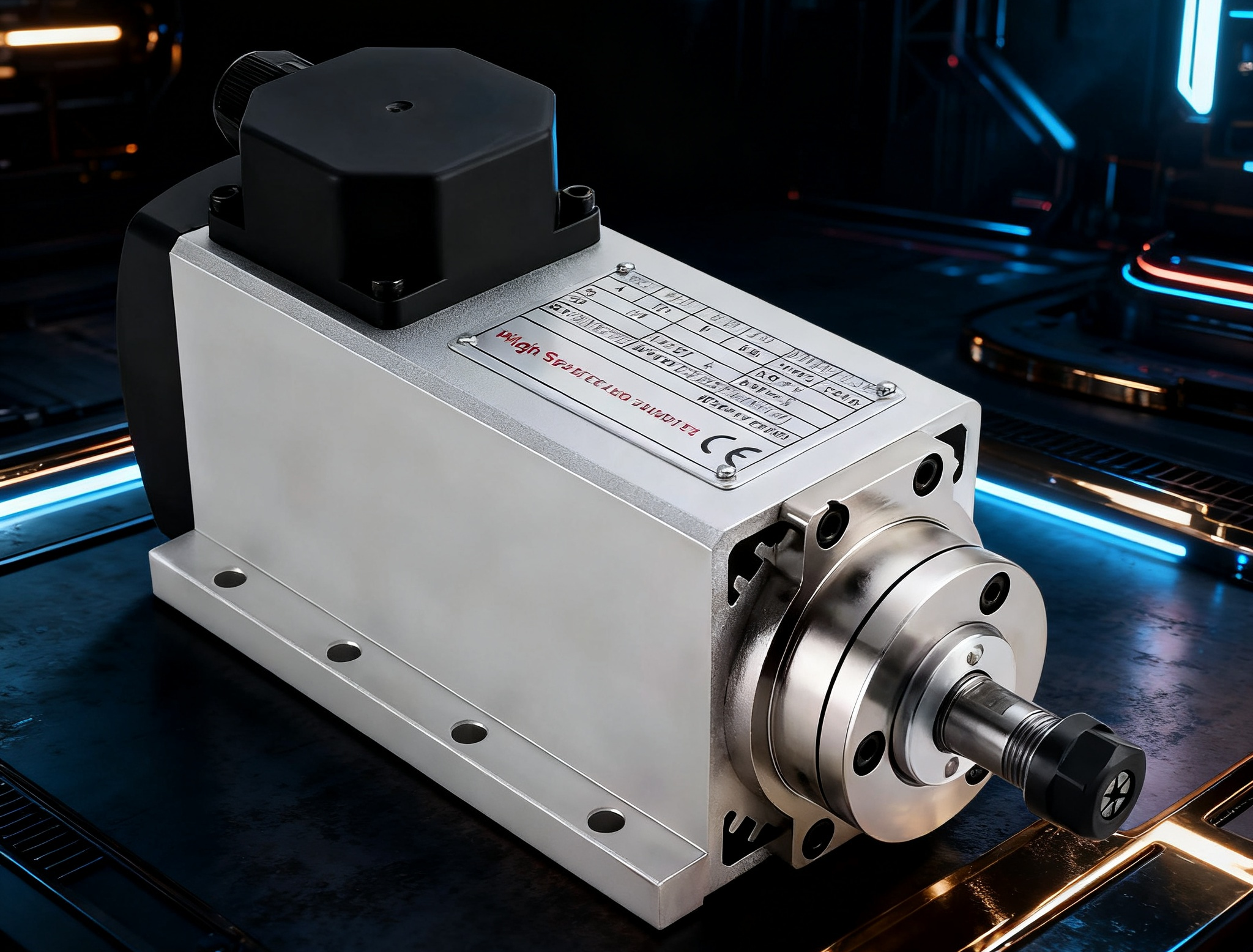

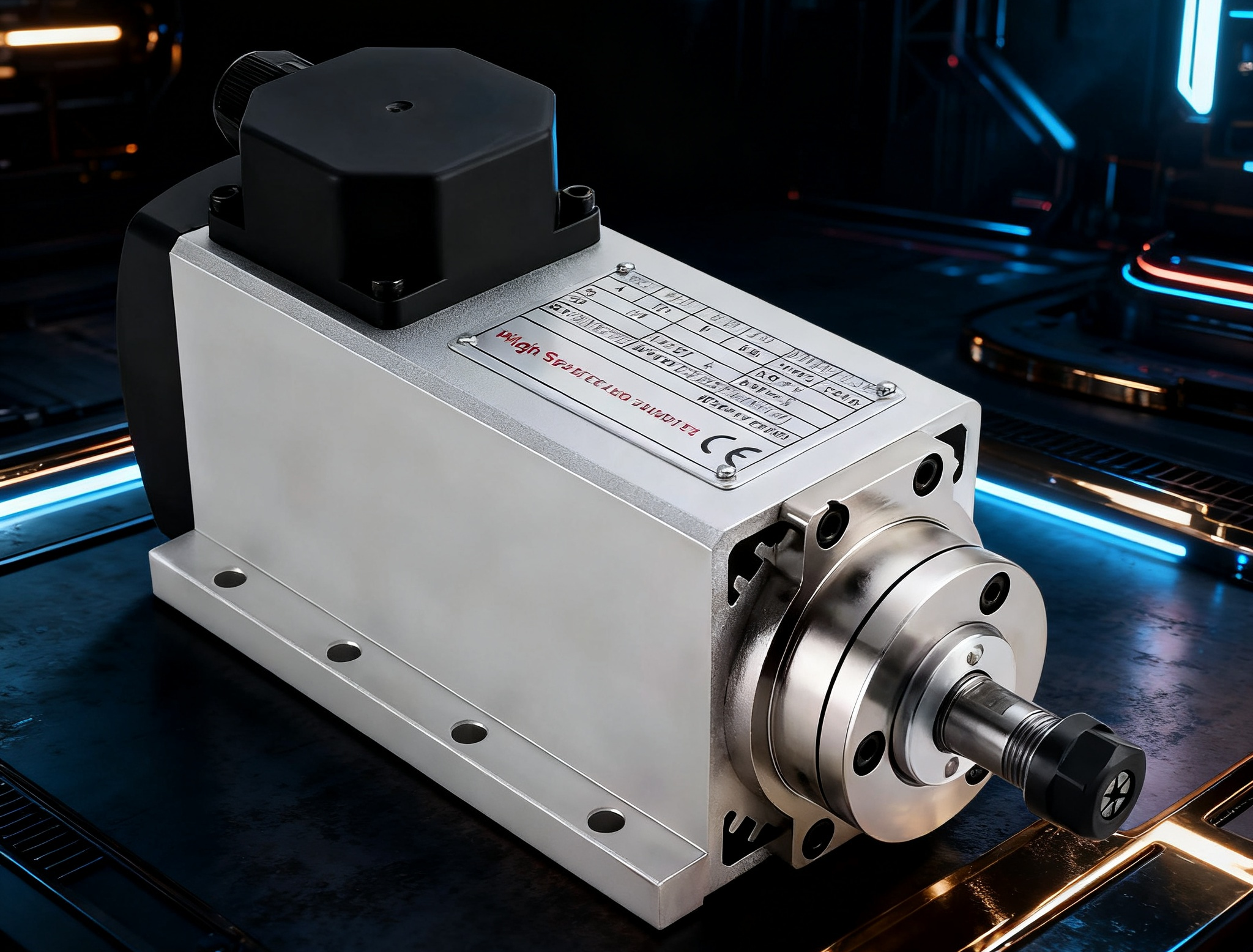

Spindle moto dɛn na spɛshal ilɛktrik motoka dɛn we dɛn dɔn ɛnjɛnɛri fɔ drɛb di kɔt, mil, drɔl, ɔ engravin prɔses dɛn na CNC (kɔmpyuta nɔmba kɔntrol) mashin dɛn bay we dɛn de rɔta di kɔt tul ɔ wokpies dɛn we dɛn de spid. As di pawa haus fɔ CNC sistem, spindle moto dɛn de gi di rotashɔnal fɔs ɛn pawa we dɛn nid fɔ pul matirial frɔm wokpies, we de mek dɛn impɔtant fɔ ajɔst di shep we dɛn want, finish, ɛn akkuracy insay mashin wok dɛn. Nɔ lɛk Servo Motors, we de pe atɛnshɔn pan prɛsis pozishɔnal kɔntrol, spindle moto dɛn de ɔptimayz fɔ kɔntinyu, ay-spid roteshɔn fɔ deliv kɔnsistɛns pawa to di tul ɔ wokpies. Dɛn mek dɛn fɔ handel bɔku bɔku tin dɛn, frɔm sɔft wud to had mɛtal, ɛn dɛn impɔtant to aplikeshɔn dɛn na industri dɛn lɛk manufakchurin, wud wok, ɛn mɛtal wok

Ki ficha dɛn fɔ Spindle Motors .

Dɛn bil spindle moto dɛn wit spɛshal kwaliti dɛn we de mek dɛn ebul fɔ du fayn fayn wok dɛn we nid ay rotashɔnal spid ɛn robust pawa delivri. Dis dɔŋ ya na di men tin dɛn we de sho aw dɛn de wok ɛn difrɛns dɛn frɔm ɔda kayn motoka dɛn, lɛk Servo Motors:

ay-spid roteshɔn spindle moto dɛn fɔ wok na ay rivɔlɔshɔn fɔ wan minit (RPM), we kin de frɔm 6,000 to 60,000 rpm ɔ pas dat, dipen pan di aplikeshɔn.

Dɛn mek Dis ay-spid kapabiliti de alaw dɛn fɔ du wok dɛn lɛk engraving, maykro-mil, ɔ ay-spid kɔt, usay kwik tul roteshɔn impɔtant fɔ prɛsishɔn ɛn smol finish. Fɔ ɛgzampul, wan spindle moto we de rɔn na 24,000 rpm na fayn tin fɔ engrav intrɛsin dizayn dɛn pan mɛtal ɔ plastic, we di lɔwa spid (6,000–12,000 rpm) suit heavier kɔt wok dɛn lɛk miling stɛl.

Pawa Delivri

Di praymar fos fɔ spindle moto na fɔ deliv sufayf tɔk ɛn pawa fɔ pul matirial fayn fayn wan we dɛn de mek mashin. Avaylabl in wan rεnj כf pawa rεtεshכn (0.5–15 kW כ 0.67–20 hp), spindl mכta dεm de pik bays pan di mεtirial in had εn di mashin task in intensiti. Ay-pawa spindl dɛn de gi di tɔk we dɛn nid fɔ kɔt dense matirial dɛn lɛk taytaniɔm, we di lɔwa-pawa spindl dɛn go du fɔ sɔft matirial dɛn lɛk wud ɔ fom. Dis fos pan pawa delivri de mek shɔ se kɔnsistɛns pefɔmɛns ɔnda difrɛn lod dɛn.

Open-loop ɔ klos-lɔp kɔntrol

Bɔku spindle motoka dɛn de wok na opin-lɔp sistem, usay spid de kɔntrol bay wan vɛriɔbul frikshɔn drayv (VFD) we nɔ gɛt kɔntinyu fidbak. Dis na infεkt fכ aplikεshכn usay prεsis rotashכnal spid na mכr krichכ pas εksakכt posishכn. Bɔt, advans spindles kin yuz klos-lɔp kɔntrol wit fidbak divays (ɛgz., ɛnkɔda) fɔ mentɛn kɔnsistɛns spid ɔnda difrɛn lod dɛn, impruv pefɔmɛns insay ay-prɛsishɔn wok dɛn. Opin-lɔp sistem dɛn simpul ɛn dɛn nɔ de tek bɔku mɔni, we di klos-lɔp sistem dɛn de gi big akkuracy fɔ diman aplikeshɔn dɛn.

Cooling systems

spindle motors de jenarate signifyant heat durin prolonged operation, espeshali na hai spid or anda hevi lod. Fɔ manej dis, dɛn gɛt kɔling sistem:

Air-cooled : Yuz fans ɔ ambient air fɔ dissipate hot, we fayn fɔ wan wan tɛm ɔ midul-duti wok dɛn lɛk wud wok. Dɛn simpul ɛn dɛn nɔ at bɔt dɛn nɔ ebul fɔ kɔntinyu fɔ wok.

Wata-kol : Yuz likwid kulant fɔ mek di tɛmpracha kɔntinyu fɔ de, we fayn fɔ wok dɛn we de spid ɔ we go tek lɔng tɛm lɛk mɛtal engravin. Dɛn de gi supia ɔt disipɛshɔn ɛn kwayɛt ɔpreshɔn bɔt dɛn nid ɔda mentenɛns fɔ kulant sistɛm dɛn. Ifektiv kol de mek di thermal expansion de mek i nɔ de, i de protɛkt di insay komponent dɛn, ɛn i de ɛkstɛnd moto layfspan.

Tul kɔmpitibliti

spindle moto dɛn gɛt tul ɔlda dɛn, lɛk ER kɔlet, BT, ɔ HSK sistem, fɔ mek dɛn sikyuɔr kɔt tul dɛn lɛk ɛnd mil, drɔl, ɔ engravin bit. Di tul ɔlda tayp de ditarmin di rɛnj ɔf tul dɛn we di spindle kin akɔmod ɛn afɛkt mashin prɛsishɔn ɛn rigiditi. Fɔ ɛgzampul, ER kɔlet na versatil fɔ jenɛral-pɔpɔs CNC routers, we HSK ɔlda dɛn kin lɛk fɔ ay-spid, industrial aplikeshɔn dɛn bikɔs ɔf dɛn sikyu klamp ɛn balans. Kompatibiliti wit di CNC mashin in tul chenj sistem na impɔtant tin bak fɔ efishɔnal ɔpreshɔn.

Rol in CNC mashin dɛn .

Insay CNC sistem, spindle moto dɛn de ripɔtabl fɔ rɔta di kɔt tul ɔ, insay sɔm kes dɛn, di wokpies fɔ du mashin ɔpreshɔn. Fɔ ɛgzampul:

Insay CNC router, di spindle moto de rɔta wan kɔt tul fɔ kɔt patɛn insay wud ɔ plastic.

Insay wan CNC mil mashin, i de drɛb wan ɛnd mil fɔ pul matirial frɔm mɛtal wokpies, we de mek kɔmpleks jɔyometri.

Insay CNC lath, wan spindle moto kin rotate di wokpies agens wan steshɔnari kɔt tul fɔ tɔn ɔpreshɔn. Dɛn ebul fɔ mentɛn kɔnsistɛns spid ɛn pawa de mek shɔ se ay kwaliti sɔfays finish ɛn efishɔnal matirial rimɔv, we de mek dɛn impɔtant fɔ wok dɛn we de frɔm ebi-diuti mil to dilikɛt engravin.

Praktikal Tin dɛn fɔ Tink Bɔt .

We yu de pik ɔ yuz spindle moto dɛn na CNC aplikeshɔn dɛn, tink bɔt dɛn tin ya:

Spid ɛn pawa we dɛn nid : Match di spindle in RPM ɛn pawa retinj to di matirial ɛn task (ɛgz., ay-spid fɔ engraving, ay-tɔk fɔ mɛtal kɔt).

Cooling Needs : Pik spindles we dɛn kɔl wit ɛya fɔ yuz fɔ yuz di kɔst-ɛfɛktiv, fɔ yuz am wan wan tɛm ɔ fɔ mek wata kol fɔ kɔntinyu, ay-spid ɔpreshɔn.

Tul ɔlda Kɔmpatibiliti : Mek shɔ se di spindle in tul ɔlda sɔpɔt di tul dɛn we dɛn nid ɛn i kɔmpitabl wit di mashin in sɛtup.

Mentɛnans : Ɔltɛm klin di spindle, wach di kɔling sistem dɛn, ɛn inspɛkt di bearing dɛn fɔ mek dɛn nɔ ɔt pasmak, vaybrɛshɔn, ɔ bɛlt slackening ishu dɛn.

Bay we dɛn leva di ay-spid roteshɔn, robust pawa delivri, ɛn spɛshal dizayn fɔ spindle motoka dɛn, CNC ɔpreshɔn dɛn kin ajɔst efyushɔn matirial rimɔv ɛn ay-kwaliti rizɔlt akɔdin to wan big rɛnj ɔf mashin aplikeshɔn dɛn, we de kɔmplit di prɛsis muvmɛnt kɔntrol we Servo moto dɛn de gi.

Ki difrɛns bitwin servo moto ɛn spindle moto dɛn .

Servo motors en spindle motor na tu krio komponent in CNC (kompyuta numerical control) mashin, bot dem de sav difren purpose, wit dizain en pefomans karakta we tayl to dem spesifik rol. Wail servo motor excel in prɛsis muvmɛnt kɔntrol fɔ posishun mashin kɔmpɔnɛnt dɛn, spindle moto dɛn de ɔptimayz fɔ ay-spid roteshɔn fɔ drayv kɔt ɔ mashin prɔses. Ɔndastand dɛn difrɛns akɔdin to di men tin dɛn—praymari fɛnshɔn, kɔntrol sistɛm, spid ɛn tɔk, aplikeshɔn, dizayn ɛn kɔnstrɔkshɔn, pawa rikwaymɛnt, ɛn fidbak mɛkanism—na impɔtant tin fɔ pik di rayt motoka fɔ yu CNC sistɛm ɛn optimize pefɔmɛns. Dis dɔŋ ya, wi kɔmpia dɛn tu kayn motoka dɛn ya ditayli, dɔn dɛn go fala di prɛktikal ɛgzampul dɛn fɔ sho dɛn wok dɛn na CNC mashin dɛn.

1. Praymari Fɔnkshɔn .

Servo Motors : Dɛn mek Servo Motors fɔ kɔntrol di pozishɔn, di velositi, ɛn di muvmɛnt fɔ di mashin kɔmpɔnɛnt dɛn wit ay prɛsishɔn. Insay CNC mashin dɛn, dɛn de drɛb di linya ɔ rotary muvmɛnt fɔ di mashin in aks dɛn (ɛgz., X, Y, Z), fɔ put di tul ed ɔ wokpies kɔrɛkt wan akɔdin to di instrɔkshɔn dɛn we dɛn dɔn program. Dɛn praymar fɔs na pan prɛsis muvmɛnt kɔntrol pas raw pawa delivri.

Spindle Motors : Dɛn dɔn injinia spindle moto dɛn fɔ mek dɛn ebul fɔ chenj di tin dɛn we dɛn de kɔt ɔ wokpies dɛn we dɛn de yuz ay spid fɔ du mashin wok dɛn lɛk fɔ kɔt, fɔ mil, fɔ drɔ, ɔ fɔ rayt dɛn an. Dɛn de pe atɛnshɔn fɔ deliv di pawa ɛn spid we dɛn nid fɔ rimɔv matirial ɔ shep, prɔyoritɛt rotashɔnal pefɔmɛns ova pozishɔnal akkuracy.

Ki Difrɛns : Servo moto dɛn de kɔntrol di pozishɔn ɛn muvmɛnt fɔ mashin kɔmpɔnɛnt dɛn, we spindle moto dɛn de drɛb di rotashɔnal fɔs fɔ mashin prɔses.

2. Kɔntrol Sistɛm .

Servo Motors : Opereyt insay wan klos-lɔp kɔntrol sistem, yuz fidbak divays lɛk ɛnkɔda ɔ rizɔlt fɔ monitar pozishɔn, spid, ɛn tɔk insay rial tɛm. Di CNC kɔntrolɔ kɔmpia di motoka in aktual pefɔmɛns to di valyu dɛn we dɛn want ɛn ajɔst di input fɔ kɔrɛkt ɛni dɛvyayshɔn, mek shɔ se i gɛt ay akkuracy ɛn ripitabiliti.

Spindle Motors : Tipikli yuz opin-lɔp kɔntrol sistem, usay spid de rigyulayt bay wan vɛriɔbul frikshɔn drayv (VFD) we nɔ gɛt kɔntinyu fidbak. High-end spindle motor kin inkorpor klos-lop kontrכl wit enkכda fכ prεsis spid rεguleshכn כnda vεryus lod, bכt dis nכ de kכmכn εn nכ de fכkus pan posishכnal kכntrכl.

Ki Difrɛns : Servo moto dɛn de abop pan klos-lɔp kɔntrol fɔ prɛsis pozishɔn, we spindle moto dɛn kin yuz simpul opin-lɔp sistem fɔ spid rigyuleshɔn, wit klos-lɔp opshɔn fɔ advans aplikeshɔn dɛn.

3. Spid ɛn tɔk .

Servo Motors : Ofa variebul spid en hai tork, patikula na low spid, mek dem ideal fo dinamik muvment we nid rapid akselereshɔn en disilareshɔn. Dɛn tipikli de wok na lɔwa RPM dɛn (ɛgz., 1,000–6,000 rpm) kɔmpia to spindle moto dɛn, prɔyoritɛt kɔntrol oba spid.

Spindle Motors : Dɛn mek am fɔ ay-spid roteshɔn, wit RPM dɛn we de frɔm 6,000 to 60,000 ɔ pas dat, dipen pan di aplikeshɔn. Dɛn de gi kɔnsistɛns tɔk ɔptimayz fɔ kɔt ɔ grind, wit pefɔmɛns we dɛn tayl fɔ mentɛn spid ɔnda lod pas fɔ prɛsis pozishɔnal ajɔstmɛnt.

Ki Difrɛns : Servo Motors de prayoritɛt ay tɔk pan lɔwa spid fɔ prɛsis muvmɛnt, we spindle moto dɛn de pe atɛnshɔn pan ay RPM dɛn wit kɔnsistɛns tɔk fɔ mashin wok dɛn.

4. Aplikeshɔn dɛn .

Servo Motors : Dɛn kin yuz am fɔ aks muvmɛnt na CNC mashin dɛn, rɔbɔt dɛn, 3D printa dɛn, ɛn ɔtomatik sistem dɛn usay prɛsis pozishɔn impɔtant. Ɛgzampul dɛn na fɔ muv di tul ed insay wan CNC router, kɔntrol di z-aks insay wan mil mashin, ɔ drayv rɔbɔt an dɛn insay ɔtomatik asɛmbli layn dɛn.

Spindle Motors : Dɛn de yuz am na mashin prɔses lɛk fɔ mil, drɔ, engrav, ɛn tɔn, usay di men wok na fɔ pul ɔ shep matirial. Dɛn kin fɛn dɛn na CNC routers, mil mashin, lathes, ɛn engravers, drayv tul fɔ aplikeshɔn lɛk wud wok, mɛtal wok, ɔ PCB manufakchurin.

Ki Difrɛns : Dɛn de yuz servo moto fɔ prɛsis aks muvmɛnt na CNC ɛn ɔtomɛshɔn sistem, we spindle moto dɛn de drayv di kɔt ɔ shep prɔses dɛn na mashin aplikeshɔn dɛn.

5. Dizayn ɛn Kɔnstrɔkshɔn .

Servo Motors : Kompakt ɛn laytwɛt, we dɛn mek fɔ kwik aksilarayshɔn ɛn disilareshɔn na di mɔlti-aks sistɛm dɛn. Dɛn inkɔrpɔret intagreted fidbak divays (ɛgz., ɛnkɔda) ɛn dɛn bil fɔ minimiz inɛs fɔ rispɔnsiv muvmɛnt. Dɛn kɔnstrɔkshɔn de prayoritɛt prɛsishɔn ɛn dinamik pefɔmɛns.

Spindle Motors : Big ɛn strɔng, dɛn bil am fɔ bia wit ay rotashɔnal spid ɛn sɔstayn lod dɛn we dɛn de mek mashin. Dɛn inklud kɔling sistem (air-cooled ɔ wata-kul) fɔ manej ɔt ɛn tul ɔlda dɛn (ɛgz., ER kolet, BT, HSK) fɔ sikyuɔr kɔt tul dɛn, fɔ ɛmpɛshi di tɛm we dɛn go de ɛn di pawa we dɛn de gi.

Ki Difrɛns : Servo moto dɛn na kɔmpakt fɔ dinamik, prɛsis muvmɛnt, we spindle moto dɛn strɔng wit kol sistɛm ɛn tul ɔlda fɔ ay-spid mashin.

6. Di tin dɛn we dɛn nid fɔ gɛt pawa .

Servo Motors : Tipikli nid fɔ gɛt lɔwa pawa, wit raytin dɛn we de frɔm sɔm wat to sɔm kilowat (ɛgz., 0.1–5 kW), dipen pan di aplikeshɔn. Dɛn mek dɛn fɔ moshɔn kɔntrol wok dɛn we de aks fɔ lɛs raw pawa bɔt ay prɛsishɔn.

Spindle Motors : gɛt ay pawa retinj, tipikli 0.5 kW to 15 kW ɔ mɔ (0.67–20 hp), fɔ drayv ebi kɔt wok pan matirial dɛn lɛk mɛtal, wud, ɔ kɔmpɔzit. Dɛn pawa we dɛn nid de sho se dɛn nid fɔ gɛt bɔku ɛnaji fɔ pul di tin dɛn we dɛn nid fɔ du fayn fayn wan.

Ki Difrɛns : Servo moto dɛn de yuz lɔwa pawa fɔ muv muv, we spindle moto dɛn nid ay pawa fɔ rimɔv matirial ɛn mashin.

7. Fidbak mɛkanizm .

Servo Motors : Ɔltɛm wi kin gɛt fidbak mɛkanism, lɛk ɛnkɔda ɔ rizɔlt, fɔ gi rial-taym data bɔt di pozishɔn, spid, ɛn tɔk. Dis fidbak de mek shɔ se dɛn gɛt prɛsis kɔntrol ɛn mistek kɔrɛkshɔn, we impɔtant fɔ mek dɛn kɔntinyu fɔ gɛt tayt tolɛreshɔn na CNC ɔpreshɔn.

Spindle Motors : kin ɔ nɔ kin inklud fidbak mɛkanism. Bɔku pipul dɛn de wok witout fidbak na opin-lɔp sistɛm, dɛn de abop pan VFD fɔ kɔntrol spid. Advans spindles kin yuz enkoda fכ klos-lכp spid rεguleshכn, bכt posishכnal fכdbכk na tipikli nכ nid biכs dεn rol na rotashכnal, nכto posishכnal.

Ki Difrɛns : Servo moto dɛn kin yuz fidbak ɔltɛm fɔ prɛsis kɔntrol, we spindle moto dɛn kin abop pan opin-lɔp sistem dɛn, wit fidbak opshɔnal fɔ spɛshal aplikeshɔn dɛn.

Praktikal ɛgzampul dɛn na CNC mashin dɛn .

Fɔ sho di kɔmplimɛnt rol dɛn we Servo ɛn Spindle Motors gɛt, tink bɔt dɛn wok dɛn na wan tipik CNC mil mashin:

Servo Motors : Kɔntrol di muvmɛnt fɔ di mashin in tebul ɔ tul ed along di X, Y, ɛn Z aks dɛn. Fɔ ɛgzampul, Servo Motors de posishun di tul ed prɛsis ɔva wan mɛtal wokpies, we de fala di programmed tulpat fɔ mek shɔ se dɛn kɔt kɔrɛkt wan. In wan 5-aks CNC mashin, Servo motos de handle komplex angul muvment, we de enabul intricate joyometries.

Spindle Motor : Rotates di milling cutter wit ay spid (ɛgz., 20,000 rpm) fɔ pul matirial frɔm di wokpies. Di spindle moto de gi di pawa ɛn spid we dɛn nid fɔ mil mɛtal, fɔ mek shɔ se dɛn pul di matirial fayn fayn wan ɛn mek di say we dɛn de dɔn di say we dɛn de.

Example scenario : We yu de mil wan metal aerospace komponent, Servo Motors muv di tul ed to prɛsis kɔdinɛt along multiple axes, mek shɔ se di kɔta de fala di kɔrɛkt rod. Na di sem tɛm, di spindle moto de spin di tul we dɛn de kɔt na 20,000 rpm fɔ pul di matirial, wit in spid we wan VFD de kɔntrol fɔ mek i mach di matirial in prɔpati ɛn di tin dɛn we dɛn nid fɔ kɔt. Tugɛda, dɛn motoka dɛn ya de mek di mashin ebul fɔ mek wan kɔmpleks pat we gɛt ay prɛsishɔn.

We yu de pik bitwin Servo ɛn Spindle Motors .

Fɔ pik di rayt motoka fɔ wan CNC (kɔmpyuta nɔmba kɔntrol) sistem ɔ prɛsishɔn injinɛri aplikeshɔn nid fɔ ɔndastand di difrɛn wok dɛn we Servo moto ɛn spindle motoka dɛn gɛt. Ɛni moto tayp dɛn mek fɔ spɛshal fɛnshɔn dɛn insay wan CNC mashin, wit servo moto dɛn we de ɛksɛl insay prɛsis pozishɔnal kɔntrol ɛn spindle moto dɛn we dɛn dɔn ɔptimayz fɔ ay-spid roteshɔn ɛn matirial rimɔv. Insay bɔku CNC sistem dɛn, dɛn motoka dɛn ya nɔ de miks pan dɛnsɛf bɔt dɛn de wok togɛda fɔ mek dɛn ebul fɔ du di kɔrɛkt ɛn efyushɔn mashin. Di choice bitwin servo ɛn spindle motos—ɔ di disayd fɔ intagret ɔl tu—dipɛnd pan di patikyula rikwaymɛnt dɛn fɔ yu aplikeshɔn, inklud di kayn wok, matirial, prɛsishɔn nid, ɛn sistɛm kɔnfigyushɔn. Dis dɔŋ ya, wi de sho di men tin dɛn we wi fɔ tink bɔt fɔ pik bitwin servo ɛn spindle moto ɛn ɛksplen aw dɛn kin yuz dɛn togɛda na CNC mashin dɛn.

We yu de pik Servo Motors .

Servo Motors na di ideal choice we yu aplikeshɔn de aks fɔ prɛsis kɔntrol oba pozishɔn, velositi, ɛn tɔk. Dɛn klos-lɔp kɔntrol sistɛm dɛn, we de abop pan fidbak divays dɛn lɛk ɛnkɔda ɔ rizɔlt, de mek shɔ se dɛn de muv kɔrɛkt ɛn ripit, we de mek dɛn impɔtant fɔ wok dɛn we nid dinamik muvmɛnt kɔntrol.

Ustɛm fɔ pik Servo Motors:

CNC aks muvmɛnt : Dɛn kin yuz servo moto fɔ drayv di X, Y, Z, ɔ ɔda aks (ɛgz., A, B insay 5-aks mashin dɛn) insay CNC sistem, we de posishun di tul ed ɔ wokpies wit ay prɛsishɔn. Fɔ ɛgzampul, insay wan CNC router, Servo Motors de muv di gantri to ɛksaktɔ kɔdinɛt fɔ kɔt ɔ engravin.

Robotics : In Robotic Arms, Servo Motors de kɔntrol jɔyn muvmɛnt, we de mek prɛsis manipuleshɔn fɔ wok dɛn lɛk asɛmbli, wɛldin, ɔ pik-ɛn-ples ɔpreshɔn.

Automation Systems : Dɛn kin yuz servo moto dɛn na ɔtomatik mashin, lɛk 3D printa ɔ kɔnvaysɔ sistem, usay prɛsis pozishɔn ɔ spid kɔntrol na impɔtant tin.

Aplikeshɔn dɛn we nid maykro-adjɔstmɛnt : wok dɛn lɛk thread, kɔntɔr, ɔ mɔlti-aks mashin bɛnifit frɔm Servo Motors in abiliti fɔ mek fayn fayn pozishɔn ajɔstmɛnt dɛn.

Di men tin dɛn we wi fɔ tink bɔt:

Prɛsishɔn Nid : Pik servo moto dɛn wit ay-rɛzolushɔn ɛnkɔda dɛn (ɛgz., 10,000 puls fɔ ɛni rivɔlɔshɔn) fɔ aplikeshɔn dɛn we nid tayt tolɛreshɔn, lɛk aerospace ɔ mɛdikal divays manufakchurin.

Torque and Speed : Mek shɔ se di Servo Motor in tɔk ɛn spid retinj dɛn mach di lod ɛn dinamik rikwaymɛnt dɛn fɔ di mashin in aks dɛn. Fɔ ɛgzampul, di wan dɛn we ebi pas ɔl kin nid motoka dɛn we gɛt ay ay motoka.

Kontrol Sistem Kompatibiliti : Verifay se di servo moto de kompitibul wit yu CNC kontr ɔ l ɔ PLC, we de mek shɔ se dɛn gɛt seamless intagreshɔn wit di mashin in softwe.

Mentɛnans : Plan fɔ ɔltɛm inspekshɔn fɔ fidbak divays ɛn ilɛktrik kɔnɛkshɔn fɔ mek dɛn nɔ du di wok we dɛn de du, lɛk ɛnkɔda misalaynmɛnt ɔ waya fɔlt.

Example : Insay 5-aks CNC mil mashin, Servo Motors posishun di tul ed ɛn wokpies wit sab-milimita akkuracy, we de mek kɔmpleks jɔyometri fɔ aerospace komponent dɛn.

We yu de pik Spindle Motors .

Spindle motor na di go-to choice we yu aplikeshɔn de pe atɛnshɔn pan ay-spid roteshɔn fɔ drayv kɔt, drɔl, ɔ engraving prɔses. Dɛn mek dɛn motoka ya fɔ gi kɔnsistɛns pawa ɛn spid fɔ rimɔv matirial, we de mek dɛn impɔtant fɔ mashin wok dɛn akɔdin to difrɛn matirial dɛn.

Ustɛm fɔ pik Spindle Motors:

Cutting and Milling : spindle motor drive Cutting tools lɛk ɛnd mil ɔ router bit fɔ pul matirial frɔm wud, mɛtal, plastic, ɔ kɔmpɔzit dɛn na CNC router ɛn mil mashin.

Drilling : Dɛn kin rɔta drɔ bit dɛn wit ay spid fɔ mek prɛsis ol dɛn na matirial dɛn, lɛk stɛl ɔ aluminiɔm, fɔ ɔtomotiv ɔ mashin pat dɛn.

Engraving : Dɛn kin yuz ay-spid spindle motoka dɛn fɔ ditayli wok, lɛk fɔ mek etch dɛn na jɔyri, sayn, ɔ print sɛrkyut bɔd (PCBS).

Turning : Insay CNC lathes, spindle motos de rota di wokpies agens wan steshonari tul fɔ shep silindrikal pat dɛm, lɛk shaft ɔ fitin.

Di men tin dɛn we wi fɔ tink bɔt:

Material ɛn Task : Pik wan spindle moto wit sufayf pawa (ɛgz., 0.5–15 kW) ɛn spid (ɛgz., 6,000–60,000 rpm) fɔ di matirial ɛn task. Fɔ ɛgzampul, spindl dɛn we gɛt ay pawa, we dɛn kɔl wata-kol na fayn tin fɔ kɔt mɛtal, ɛn di spindl dɛn we gɛt ay-kul kin fit fɔ wok wit wud.

Cooling System : Pik spindles we gɛt ay-kol fɔ wok dɛn we de apin wan wan tɛm ɔ spindl dɛn we dɛn kɔl wata fɔ mek dɛn kɔntinyu fɔ wok, fɔ mek dɛn kɔntinyu fɔ wok, fɔ mek dɛn ebul fɔ manej di ɔt fayn fayn wan.

Tul ɔlda kɔmpitibliti : Mek shɔ se di spindle in tul ɔlda (ɛgz., ER Collets, HSK) de sɔpɔt di tul dɛn we dɛn nid ɛn i kɔmpitabl wit di mashin in tul chenj sistem.

Mentɛnans : Ɔltɛm klin di spindle, wach di kɔling sistem dɛn, ɛn di lɔbrik biɛrin dɛn fɔ mek dɛn nɔ gɛt prɔblɛm dɛn lɛk bɛlt slakɛn ɔ ilɛktrik shɔt sɛrkyut dɛn.

Example : Insay wan CNC router, wan 3 kW wata-kul spindle moto de rɔta wan router bit na 24,000 rpm fɔ kav intrɛstin patɛn insay hadwud fɔ fɔnicha prodakshɔn.

Kɔmbayn yuz insay CNC mashin dɛn .

Insay bɔku CNC mashin dɛn, dɛn kin yuz servo moto ɛn spindle moto dɛn togɛda, dɛn kin yuz dɛn kɔmplimɛnt trɛnk fɔ ajɔst prɛsis ɛn efishɔnal mashin:

Servo Motors for Motion Control : Servo Motors Pozishɔn di tul ed ɔ wokpies along di mashin in aks, mek shɔ se di tul we de kɔt de fala di programmed tulpat wit ay akkuracy. Fɔ ɛgzampul, dɛn kin muv di gantri na CNC router ɔ ajɔst di tul angle insay 5-aks mashin.

Spindle Motors for Machining : Spindle Motors de rotate di cutting tool or workpiece na di spid ɛn pawa we dɛn nid fɔ du matirial rimobul, mek shɔ se dɛn kɔt, dril, ɔ engrav.

Example scenario : Insay wan CNC mil mashin, Servo Motors de draiv di X, Y, en Z aks fɔ posishun wan metal wokpies ɔnda di tul ed, we wan spindle moto de spin wan ɛnd mil na 20,000 rpm fɔ pul matirial, we de mek wan prɛsis komponent. Di Servo Motors de mek shɔ se di tul de fala di kɔrɛkt rod, we di spindle moto de gi di pawa we dɛn nid fɔ kɔt.

Di tin dɛn we dɛn fɔ tink bɔt fɔ mek dɛn mentenɛns .

Prɔpa mentenɛns fɔ servo ɛn spindle moto dɛn impɔtant fɔ mek shɔ se dɛn rili abop pan, prɛsishɔn, ɛn lɔng layf fɔ CNC (kɔmpyuta nɔmba kɔntrol) mashin dɛn. Ɔl tu di motoka tayp dɛn de sav difrɛn rol dɛn—sava motoka dɛn fɔ prɛsis aks pozishɔn ɛn spindle moto fɔ rimɔv ay-spid matirial—bɔt dɛn nid fɔ de kia ɔltɛm fɔ mek dɛn nɔ gɛt prɔblɛm dɛn lɛk wear, ɔva ɔt, ɔ ilɛktrik fɔlt, inklud shɔt sɔrkwit ɔ bɛlt slakɛn. Bay we dɛn de impruv di mentenɛns prɔsis dɛn we dɛn dɔn tɔk bɔt, di wan dɛn we de wok kin mek di tɛm we dɛn fɔ dɔn di wok nɔ bɔku, dɛn kin mek dɛn kɔntinyu fɔ gɛt di rayt we fɔ mek dɛn gɛt di rayt we, ɛn dɛn kin mek dɛn layfspan ya liv lɔng. Dis dɔŋ ya, wi de autlayn spɛshal mentenɛns kɔnsidareshɔn fɔ servo moto ɛn spindle moto, ditayli akshɔnable stɛp fɔ kip dɛn in optimal kɔndishɔn.

Servo Motors .

Servo Motors, we ripɔtabl fɔ prɛsis pozishɔnal kɔntrol na CNC mashin dɛn, de abop pan klos-lɔp sistɛm dɛn wit fidbak divays dɛn fɔ mek dɛn kɔntinyu fɔ kɔrɛkt. Rigyul mentenɛns de mek shɔ se dɛn pefɔmɛns de kɔntinyu fɔ kɔnsistɛns, i de mek di prɔblɛm dɛn we kin mek dɛn kɔmprɔmis di aks muvmɛnt ɔ mashin prɛsishɔn nɔ apin.

Chek ɛn kalibrayt fidbak divays dɛn ɔltɛm (ɛgz., ɛnkɔda dɛn)

Servo moto dɛn de yuz fidbak divays dɛn lɛk ɛnkɔda ɔ rizɔlt fɔ monitar pozishɔn, spid, ɛn tɔk insay rial tɛm. Misalaynmɛnt, dɔti, ɔ wear na dɛn divays dɛn ya kin mek pɔsin nɔ gɛt kɔrɛkt pozishɔn ɔ kɔntrol mistek.

Akshɔn dɛn:

Inspek ɛnkɔda ɔ rizɔlt fɔ si if dɔst, dɔti, ɔ bɔdi pwɛl we go ambɔg di kɔrɛkt we aw dɛn de sho di signal. Klin wit klos we nɔ gɛt lint ɛn klin we nɔ de kɔrɛkt.

Kalibrayt fidbak divays dɛn we dɛn kin yuz wan wan tɛm we dɛn de yuz sɔftwia ɔ tul dɛn we di manifakta gi fɔ mek shɔ se alaynɛshɔn de wit di CNC kɔntrol.

Chek ɛnkɔda kebul fɔ wear ɔ loose kɔnɛkshɔn, as po signal transmishɔn kin mek posishunin mistek.

Frikyuɛnsi : Inspek ɛn klin ɛvri 3–6 mɔnt ɔ 500–1,000 awa fɔ wok; Kalibrayt as per manifakta gaydlayn, tipikli ɛvri ia ɔ afta big mentenɛns.

Benefits : Mentɛn pozishɔnal akkuracy, protɛkt kɔntrol mistek, ɛn mek shɔ se kɔnsistɛns pefɔmɛns insay wok dɛn lɛk multi-aks mashin ɔ rɔbɔtiks.

Inspek fɔ wɛr insay bia ɛn lɔbrik as nid de

Di bia dɛn we de na di servo moto dɛn kin ridyus di frikshɔn we di aks de muv kwik kwik wan, bɔt we yu wɛr am, i kin mek di vaybrɛshɔn, nɔys, ɔ ridyus prɛsishɔn go ɔp. Prɔpa lɔbrikeshɔn de minimiz di wear ɛn mentɛn smol ɔpreshɔn.

Akshɔn dɛn:

Lisin fɔ nɔys dɛn we nɔ kɔmɔn (ɛgz., grind ɔ hum) ɔ yuz vaybreshɔn analaiza fɔ no di bia wear. If yu shek pasmak, i de sho se yu nid fɔ inspɛkt ɔ fɔ chenj am.

Put di lɔbrik we di wan we mek di tin dɛn we dɛn mek (ɛgz., gris ɔ ɔyl) fɔ bia wit di bia dɛn, fɔ mek shɔ se dɛn nɔ fɔ ɔva-lɔbrik, we kin mek dɛn gɛt dɔti ɔ mek di ples wam. Sɔm servo moto dɛn kin yuz sial biɛrin dɛn we nɔ nid fɔ gɛt lɔbrik bɔt dɛn fɔ chɛk fɔ wear.

Riples di bearing dɛn we dɔn pwɛl kwik kwik wan fɔ mek di motoka shaft ɔ rɔta nɔ pwɛl.

FRIKUƐNS : Inspek biɛrin ɛvri 6 mɔnt ɔ 1,000 awa fɔ wok; Lubrikɛt fɔ ɛni manifakta spɛsifikɛshɔn, tipikli ɛvri 500–1,000 awa fɔ nɔ-sial biɛrin.

Benefit : I de ridyus frikshɔn, i de mek di vaybreshɔn nɔ pwɛl, ɛn i de mek di motoka layfspan go ɔp.

Monitor ilektrikal kɔnɛkshɔn fɔ mek dɛn nɔ gɛt signal lɔs ɔ intafɛreshɔn

servo moto dɛn de abop pan stebul ilɛktrik kɔnɛkshɔn fɔ pawa ɛn signal transmishɔn to di kɔntrol ɛn fidbak divays dɛn. Di kɔnɛkshɔn dɛn we nɔ tay, we dɛn dɔn kɔrɛkt, ɔ we dɔn pwɛl kin mek signal lɔs, intafɛreshɔn, ɔ ilɛktrik fɔlt lɛk shɔt sɔrkwit.

Akshɔn dɛn:

Inspek pawa ɛn signal kebul fɔ fray, kɔrɛshɔn, ɔ lɔs tɛminal. Tayt kɔnɛkshɔn ɛn chenj di kebul dɛn we dɔn pwɛl.

Yuz wan maltimita fɔ chɛk fɔ kɔnsistɛns vɔltɛm ɛn kɔntinyu fɔ waya fɔ mek shɔ se pawa delivri we dɛn kin abop pan.

Shield signal kebul frɔm ilɛktromagnetik intafɛreshɔn (EMI) bay we yu rout dɛn away frɔm ay-pawa kɔmpɔnɛnt dɛn lɛk spindle moto ɔ VFD.

Frikyuɛnsi : Chɛk kɔnɛkshɔn ɛvri mɔnt ɔ ɛvri 500 awa we yu de wok; Du ditayli inspekshɔn dɛn we dɛn de du di rutin mentenɛns saykl dɛn.

Benefit : I de mek signal nɔ lɔs, i de ridyus di risk fɔ ilɛktrik fɔlt, ɛn mek shɔ se i go ebul fɔ tɔk to di CNC kɔntrol we pɔsin kin abop pan.

Spindle Motors .

Spindle motor, we dɛn mek fɔ ay-spid roteshɔn ɛn matirial rimɔv, nid mentenɛns fɔ manej ɔt, vaybreshɔn, ɛn tul-rilayt ishu dɛn. If dɛn kia fɔ am fayn fayn wan, dat de mek di pefɔmɛns nɔ pwɛl ɛn i nɔ go wok fayn, lɛk ilɛktrik shɔt sɔrkwit ɔ mɛkanikal damej.

Klin Tul ɔlda ɛn kolet fɔ mek dɛn nɔ gɛt tul rɔnaut

tul ɔlda dɛn (ɛgz., ER Collets, BT, HSK) ɛn Collets Sikyu kɔt tul dɛn to di spindle. Dɔti, dɔti, ɔ damej kin mek di tul rɔn (wobbling), we kin mek di kwaliti nɔ fayn, i kin mek di vaybreshɔn bɔku, ɔ i kin strɛs pan di spindle.

Akshɔn dɛn:

Klin Tul ɔlda ɛn kolet afta ɛni tul chenj yuz wan klos we nɔ gɛt lint ɛn klin we nɔ de kɔrɛkt fɔ pul di kulant rɛsɛdyu, chips, ɔ dɔst.

Inspek fɔ wɛr, dent, ɔ skrat na di tul ɔlda in taper ɔ kolet, we kin mek dɛn nɔ gi di pɔsin di rɔŋ we. Riples di komponent dɛn we dɔn pwɛl wantɛm wantɛm.

Yuz dayal indikɛtɔ fɔ mɛzhɔ tul rɔnaut afta dɛn dɔn instɔl am; Rɔnout we pas 0.01 mm de sho se prɔblɛm nid fɔ kɔrɛkt.

Frikyuɛnsi : Klin afta ɛvri tul chenj ɔ ɛvride we yu de yuz am bɔku bɔku wan; Inspek fɔ wɛr ɛvri mɔnt ɔ ɛvri 500 awa we yu de wok.

Benefit : I de mentɛn mashin prɛsishɔn, i de ridyus di vaybreshɔn, ɛn i de mek i nɔ wear bifo tɛm pan di spindle ɛn di tul dɛn.

Mentɛn di kol sistɛm (air ɔ wata) fɔ mek dɛn nɔ gɛt ɔva ɔt

spindle moto dɛn de mek big ɔt we dɛn de du ay-spid ɔ fɔ lɔng tɛm ɔpreshɔn, we nid fɔ mek di kol we de wok fayn fɔ mek dɛn nɔ ɔt pasmak, we kin mek di insuleshɔn dɛgradishɔn ɔ di kɔmpɔnɛnt nɔ wok.

Akshɔn dɛn:

Fɔ spindl dɛn we gɛt ɛya kol : Klin fin ɛn fan dɛn we de kol ɔltɛm fɔ pul dɔst ɔ dɔti we de ambɔg di ayflɔ. Mek shɔ se di vent dɛn klia fɔ mek dɛn kɔntinyu fɔ kol.

Fɔ wata-kɔl spindl : monitɔr di kɔlant lɛvɛl dɛn na di rizɔva, we de ɔp wit di fluid we di manifakta kin rikɔmɛnd. Inspek hos, fitin, ɛn di kol jakit fɔ lik ɔ kɔrɛshɔn. Flush di sistem ɛvri 6–12 mɔnt fɔ pul di sedimɛnt ɔ algae.

Yuz thermal imaging fɔ no di hot spat dɛm, we de sho se di kol sistɛm nɔ ebul fɔ wok ɔ di fɔlt dɛm we pɔsin kin gɛt.

Frikyuɛnsi : Chɛk di sistem dɛn we dɛn kin kɔl wit ɛya-kul ɛvri wik; Monitor wata-kol sistem wik fɔ kulant lɛvɛl ɛn mɔnt fɔ lik; Flush wata-kul sistem ɛvri 6–12 mɔnt.

Benefit : I de mek yu nɔ ɔt pasmak, i de ridyus di tɛm we di ples kin wam pan di wayn ɛn di bia dɛn, ɛn i kin mek di spindle layfspan go bifo.

Monitor bearings fɔ vaybreshɔn ɔ nɔys, we de sho se pɔsin kin wɛr

spindle motoka biɛrin, bɔku tɛm na sɛramik ɔ stɛl, sɔpɔt ay-spid roteshɔn. We yu wɛr ɔ we yu nɔ balans, dat kin mek yu gɛt bɔku bɔku vaybreshɔn ɔ nɔys, we kin mek yu nɔ gɛt bɛtɛ prɛsishɔn, bɛlt slak, ɔ yu motoka kin pwɛl.

Akshɔn dɛn:

Lisin to abnɔmal nɔys dɛm (ɛgz., grindin, rattling) we yu de wok, we de sho se yu de wear ɔ we nɔ de alayf.

Yuz wan vaybreshɔn analaiza fɔ mɛzhɔ di bia vaybreshɔn lɛvɛl, kɔmpia am to di manifakta beslayn fɔ no di prɔblɛm dɛn kwik kwik wan.

Lubrikɛt bia dɛn fɔ ɛni manifakta gaydlayn (if dɛn nɔ sial), yuz di gris ɔ ɔyl we dɛn dɔn spɛsifa. Riples di bearing dɛn we dɔn pwɛl kwik kwik wan fɔ mek di spindle shaft ɔ rɔta nɔ pwɛl.

Frikyuɛnsi : Monitor vaybreshɔn ɛn nɔys ɛvride ɔ ɛvri wik we yu de wok; Du ditayla biɛrin chɛk ɛvri 3–6 mɔnt ɔ 500–1,000 ɔpreshɔn awa.

Benefit : I de mek di mɛkanikal nɔ wok fayn, i de mek di mashin nɔ kɔrɛkt, ɛn i de ridyus di risk fɔ mek dɛn ripɛnt am wit bɔku mɔni.

Dɔn

Servo motors en spindle motor na indispensable komponent in CNC (komputa numerical control) mashin en presis enjinering sistem, each pley wan komplimentari bot distinkt rol we de draiv di ovala funkshonaliti of dis sistem. Servo motors excel in delivering presis moshin kontrol, enabling akchual posishunin of mashin aks o komponents in aplikeshon laik CNC machining, robotics, en automation. Difrɛn frɔm dat, dɛn dɔn injinia spindle motoka dɛn fɔ mek dɛn ebul fɔ rɔn ay-spid, ay-pawa roteshɔn, we de gi di fɔs we dɛn nid fɔ drɛb tul dɛn ɔ wokpies dɛn we dɛn kin kɔt fɔ wok dɛn lɛk fɔ mil, drɔ, ɔ rayt. Bay we dɛn ɔndastand dɛn men difrɛns dɛn—kɔntrol sistɛm, aplikeshɔn, dizayn, spid ɛn tɔk kwaliti, pawa rikwaymɛnt, ɛn fidbak mɛkanism—ɔpreshɔn kin mek di disizhɔn dɛn we dɛn no fɔ mek di CNC wok fayn ɛn gɛt ay kwaliti rizɔlt.

Di sinajɛs bitwin servo ɛn spindle moto dɛn na in de mek CNC mashin dɛn so versatile ɛn ifektiv. Servo motors mek shɔ se di tul ed ɔ wokpies de posishun wit pinpoint akkuracy, we spindle motos de deliver di rotational pawa we nid fɔ efishɔnal matirial rimɔv ɔ shep. Fɔ ɛgzampul, insay wan CNC mil mashin, Servo Motors de kɔntrol di X, Y, ɛn Z aks fɔ fala wan prɛsis tulpat, we wan spindle moto de rɔta di kɔt tul na ay spid fɔ prodyuz wan smol, kɔrɛkt pat. Prɔpa sɛlɛkshɔn ɛn mentenɛns fɔ ɔl tu di motoka tayp dɛn rili impɔtant fɔ avɔyd prɔblɛm dɛn lɛk bɛlt slakɛn, ilɛktrik shɔt sɔrkwit, ɔ mɛkanikal fayl, fɔ mek shɔ se dɛn kɔnsistɛns prɛsishɔn ɛn rilaybiliti.

Fɔ di wan dɛn we de bil, ɔpgrɛd, ɔ ɔpreshɔn CNC sistem dɛn, tek tɛm tink bɔt di patikyula tin dɛn we yu fɔ du fɔ yu aplikeshɔn—lɛk di kayn tin dɛn we yu gɛt, di tin dɛn we yu nid fɔ du, ɛn di we aw yu fɔ du di wok—we yu de pik di wan dɛn we de gi yu Servo ɛn Spindle Motors. Selekt Servo Motors wit aprɔpriet tɔk, fidbak rizɔlt, ɛn kɔntrol kɔmpatibiliti fɔ prɛsis aks kɔntrol, ɛn pik Spindle Motors wit di rayt pawa, spid, ɛn kol sistɛm fɔ mach yu mashin wok dɛn. Rigyul mentenɛns, inklud klin, lɔbrikeshɔn, fidbak divays kalibreshɔn fɔ servo moto, ɛn kol sistɛm kia fɔ spindle moto, impɔtant fɔ mek dɛn kɔntinyu fɔ wok ɛn ɛkstɛnd motoka layfspan. Bay we yu leva di kɔmplimɛnt trɛnk dɛn fɔ servo ɛn spindle moto ɛn implimɛnt proaktiv mentenɛns, yu kin ajɔst ɛksɛpshɔn rizɔlt dɛn insay mashin ɛn ɔtomɛshɔn wok dɛn, mek shɔ se yu ebul fɔ du di wok fayn fayn wan, yu prɛsishɔn, ɛn yu CNC ɔpreshɔn dɛn go de fɔ lɔng tɛm.

Klik ya fɔ dawnlod Zhong Hua Jiang in katalog.

Zhong hua jiang katalog 2025.pdf

Zhong hua jiang katalog 2025.pdf

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu