I CNC machine hian thawm mak tak tak a siam em, a nih loh leh precision a hloh em? Chu vibration fiah lo tak emaw, beisei loh downtime emaw chuan i spindle motor-a bearings chhia: a chhunga awm ngawi reng saboteur a kawk thei a ni. Bearing damage hi a lang chiang lo fo a, mahse thil pawimawh tak a ni a, a dikna tihtlem, component dang a inbel tam, repairs man to tak, emaw total spindle failure a awm chuan unaddeded a nih chuan.

He guide-ah hian spindle motor-a chhiatna thlen chungchanga hriat tur zawng zawng—a hmaa chhinchhiahna hmuh chhuah aṭanga a chhan hriat theihna leh invenna kawng ṭha tak tak kalpui thlengin kan chhui ang. CNC operator emaw, maintenance tech emaw, hobbyist emaw i setup humhimtu i nih pawhin, he resource hian i bearings te chu top shape-a dah turin a pui ang che a, a hnathawh dan tur a ti awlsam ang a, machine life pawh a ti rei thei ang.

Threat thup te chu i hmuchhuak ang a, i spindle chu flawless takin spinning takin i awm tir ang u!

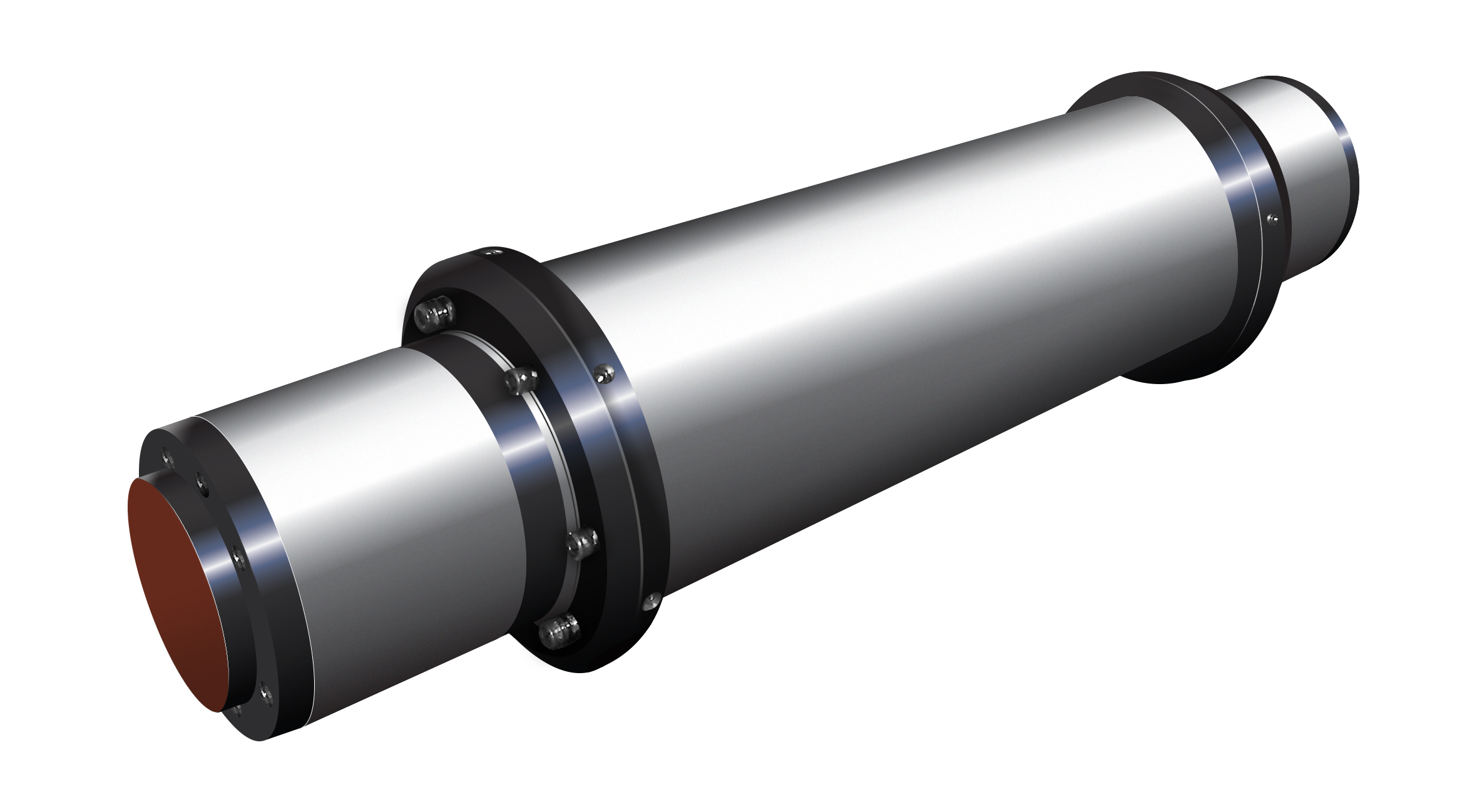

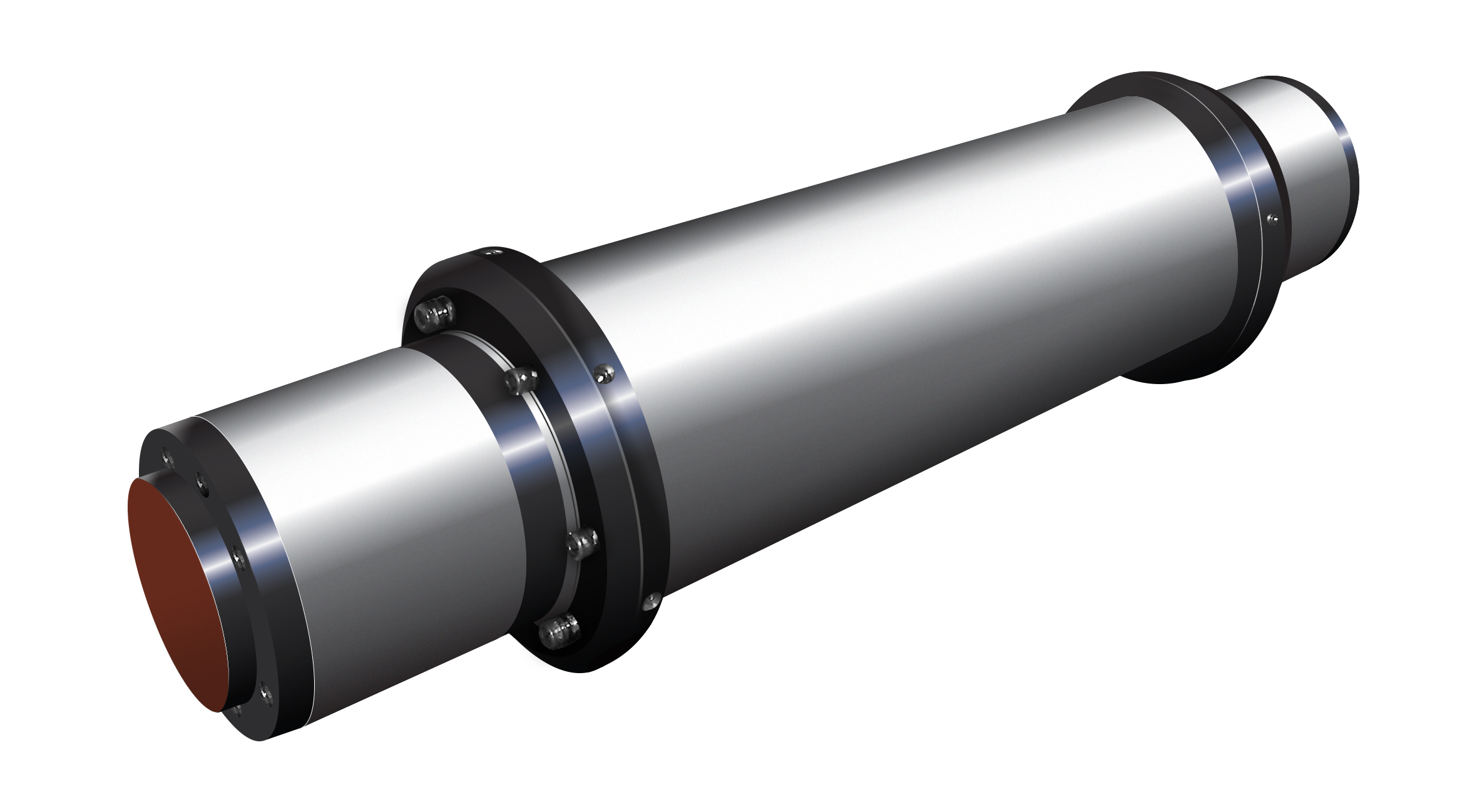

Spindle Motor Bearings chungchang inhriattirna .

Spindle motor bearings tih hi eng nge ni?

Spindle motor tin bulpui ber chu bearings set a ni a—precision-engineered components, rotating shaft thlawptu, high-speed, accurate motion ti thei a ni. Heng bearings te hian friction a ti tlem a, load a absorb a, alignment a vawng reng a, spindle chuan cutting tools te chu drilling, milling, leh shaping materials atana mamawh precision nen a khalh thei a ni.

Bearings hi chi hrang hrang a awm a, chu chu ball, roller, emaw angular contact, spindle-a speed, load, leh a hman dan tur ang chiah a ni—thing hnathawh emaw, metal fabrication emaw, composite machining emaw pawh ni se. Eng chi pawh ni se, bearings te hian vibration, heat buildup, leh wear te ven nan tight tolerances chhungah an thawk tur a ni.

High-performance vehicle-a wheel-te angin han mitthla teh—an wobble emaw, an man emaw chuan system pumpuiin an tuar a ni. Bearings chhia chuan friction nasa lutuk, misalignment, leh thermal issue a thlen thei a, spindle performance a tichhe thei bawk. Bearing types, lubrication mamawh, leh load capacities te hriatthiamna hian damage hriat hmasak leh venna kawngah edge a pe che a ni.

Spindle motor-a hriselna neih pawimawhna .

I spindle motor rintlakna chu a bearings-ah a innghat a ni. Bearings degrade lai chuan rotation chauh a hlauhawm lo; Shaft misalignment, vibration tihpun, workpiece chhe tawh, production tihkhawtlai, leh repair man sang zawk a thlen thei a ni.

Thil chhia chhinchhiahna hmasa ber, faint vibrations ang chi te chu ngaihthah a nih chuan a hlawhchham vek theih nan a escalate thei a ni. Monitoring Bearing Condition hian thil tenawm tak tak, lu natna lian tak a nih loh nan a veng a, spindle rebuilds man to tak tak atanga a chhanhim thei bawk.

Chu bâkah, bearing chhia chuan an harsatnate chu a isolate lo va—motor winding, cooling system, leh drive mechanism te chu a strain a ni. Operator tumahin trigger an duh loh domino effect a ni.

Bearing integrity hi mechanics aiin a tam zawk a ni—a himna, efficiency, leh bottom-line savings a ni. Mastering the causes and prevention of bearing damage hi peak performance atan chuan inrem theih loh a ni.

Spindle motor-a chhiatna thlen chhan tlangpui

| Cause |

description |

effects |

best practices . |

| Bearings te overloading . |

Machining tough materials, aggressive cutting depths, emaw feed rate rang tak tak atanga design limits kaltlanga forces te. |

Fatigue cracking, deformation, pitting/spalling hun hmaa awm, a nih loh leh a chhiat nghal (fracture/stall). |

cutting parameters te chu bearing ratings nen a inmil tur a ni; Sharp tools leh balanced load hmang rawh. |

| Lubrication tling lo emaw, bawlhhlawh lo emaw . |

Lubricant level hniam, contaminant (debris/water), emaw leak seal te chu dry contact emaw abrasive action emaw a ni thei. |

lei chung lama a tlakchhiatna, pitting, lumna tihpun, a nih loh leh seizure. |

Lubricant tarlan te hmang la, level monitor la, contaminated te thlak la, seals check bawk ang che. |

| Misalignment emaw install dik loh emaw . |

Assembly errors, thermal expansion emaw, mounting surface inang lo tak tak, shaft tilt emaw misalignment emaw a awm chuan. |

Load insem dan inang lo, a chak lohna (accelerated wear), vibration-induced fatigue, emaw heat emaw a ni. |

Install lai hian alignment tools hmang la, post-setup verify la, check fo ang che. |

| Dust leh debris atanga bawlhhlawh paih . |

Particle te chu seal tha lo emaw, boruak bawlhhlawh emaw hmanga infiltrate an ni a, chu chuan abrasion emaw, corrosion emaw a thlen thin. |

Scratch, dents, corrosion, emaw breakdown emaw. |

Seal tha tak tak hmang la, air filtration hmang la, tihfai fo bawk ang che. |

| Vibration emaw imbalance emaw nasa lutuk . |

Unbalanced tools emaw resonant frequency te chu oscillations amplifying a ni. |

Hnam hrang hrang, hahna, emaw, a kal zel avanga lumna emaw. |

Balance tools, isolate vibrations, leh monitor te chu analyzer hmangin. |

| Operation temperature sang tak a ni . |

Softening materials tihlum la, thinning lubricants, emaw, expansion inang lo tak siam thei bawk ang che. |

Load capacity tihtlem, lubricant breakdown, emaw thermal fatigue cracks te. |

Cooling optimize la, temperature monitor la, overloads awm loh nan. |

| Electrical current a kal theihna tur . |

Grounding tha lo atanga arcing awm chuan electrical discharge hmanga lei chunglam a erosion a thlen thin. |

Electrical discharge machining effect atanga lei chunglam chhiatna. |

Grounding dik tak enfiah la, a tulna hmunah insulated bearings hmang rawh. |

1. Bearings te overload .

Bearing Overloading hi mechanical components, spindle-a bearing emaw, rotating machinery emaw ang chi, an design theih zat aia tam chakna an neih chuan a thleng thin. He thu hi a bik takin machining leh industrial application-ah chuan a hluar hle a, chutah chuan operational parameter-te chuan hmanrua chu a huam chin aia nasain a nawr a ni. Overloading hian chhiatna nasa tak a thlen thei a, hmanrua a dam rei lo thei a, downtime pawh a ti tlem thei bawk.

Bearing overloading chhan .

Operational leh setup nena inzawm thil chi hrang hrang avang hian bearings hi overload theih a ni a, chungte chu:

Machining Tough Materials Setup mumal tak nei lo:

l Titanium, stainless steel emaw, hard alloy dang emaw ang chi, dense emaw high-strength materials processing chuan bearings-ah stress nasa tak a siam a, a bik takin chutiang load atana siam loh light-duty spindle hman a nih chuan.

l Machine setup tha tawk lo, tool thlan dik loh emaw, spindle rigidity tha tawk lo emaw chuan axial (along the axis of rotation) leh radial (axis nena inmil) loads te chu a tichak a, bearings te chu a hneh hle.

Aggressive cutting depths:

l Machining lai hian cutting depth tam lutuk chuan spindle leh bearings-ah chakna rang tak leh nasa tak a siam a. Heng shock load te hian bearing-a load-carrying capacity a pel thei a, chu chuan stress nghal vat leh hun rei tak chhunga chhiatna a thlen thei a ni.

l Deep cuts incremental step dik tak emaw toolpath optimization emaw awm lovin overloading neih theihna a tipung a ni.

Rapid feed rates spindle theihna nena inmil lo:

l Spindle design specification nena inmil lo feed rate sang tak chuan bearings-ah pressure inang lo tak a siam a. He inmil lohna hian vibration nasa lutuk leh dynamic loading a thlen a, chu chuan bearing system a tichhe thei a ni.

l Rapid feed rates leh improper tool emaw workpiece alignment te nena inzawm chuan force distribution inang lo tak a tizual zawk.

Machine design emaw hman dan dik lo emaw:

l Application atana load rating tling lo bearing emaw spindle emaw hman hian operating condition pangngai hnuaiah pawh overloading a thlen thei a ni.

l Operator tihsual, CNC machine programming dik lo emaw, material property account pek loh emaw te hian bearings-a force tam lutuk a thlen thei a ni.

Bearing overloading avanga nghawng a neih dan .

Bearing-te chu an design limit aia tam chakna hnuaia an awm chuan, performance leh durability tichhe thei tur thil ha lo chi hrang hrang an tawk hin:

Bearing race-a hahna (fatigue cracking):

l Overloading tih nawn leh chuan bearing race-ah cyclic stress a thlen thin (rolling elements awmna inner leh outer rings). Hun a kal zel a, hei hian fatigue cracking a thlen a, chutah chuan micro-cracks te chu an lo piang a, chu chu material kaltlangin an propagate a ni.

l Heng crack te hian bearing structure a tichak lo a, loads support theihna a ti tlem a, a hlawhchham theihna a ti sang bawk.

Load tam lutuk atanga deformation:

l Force tam lutuk hian bearing components plastic deformation a thlen thei a, chu chu rolling elements (balls emaw rollers emaw) emaw races te hi a ni. He deformation hian bearing geometry a tidanglam a, chu chuan misalignment a thlen a, friction a tipung a, precision a ti tlem bawk.

l Deformed bearings hian lum lutuk a siam thei bawk a, a ti chak zual thei bawk.

Premature pitting emaw spalling emaw:

l Overloading hian surface fatigue a ti chak a, chu chuan bearing surface-ah pitting (small craters) emaw spalling (material) emaw a thlen thin. Heng chhiatna te hian smooth operation a tibuai a, vibration a tipung a, bearing failure a tikhawlo bawk.

l Pitting leh spalling hian high-precision application-ah a tichhe nasa hle a, chutah chuan surface irregularities tenau tak tak pawhin performance a nghawng thei a ni.

Hlawhchham nghal tur: 1.1.

l A nasat chuan overloading hian chhiatna nasa tak a thlen thei a, chu chu bearing fracture emaw spindle stall emaw a ni thei. Bearing chhe tawh chuan a man vek thei a, machine hman a titawp thei a, component dangte pawh a tichhia thei bawk.

l Failure sudden hian operator-te tan himna atana hlauhawm a thlen thei bawk a, thil siamchhuahna hloh nasa tak a thlen thei bawk.

Bearing overloading avanga a rah chhuah .

Overloading bearings-in a rah chhuah chu bearing-a chhiatna thleng nghal mai aiin a zau zawk a, operational leh financial impact hla tak tak a nei thei bawk:

l Reduced Equipment Lifespan : Overloaded bearings hian a ti chhe rang zawk a, a thlak fo a ngai a, a enkawlna senso pawh a tisang a ni.

l Downtime tihpun : Bearing failure-ah chuan siamthatna nasa tak a ngai fo a, chu chuan ruahmanna awm lo downtime leh production schedule-a tihbuai a thlen thin.

l Compromised Precision : Bearings deformed emaw chhia emaw chuan machining process dikzia a ti tlem a, chu chuan parts chhia leh rework a thlen thei a ni.

l Energy consumption sang zawk : Overloaded bearings hian friction a tipung a, machinery hmanna tur leh cost driving up cost a mamawh zawk.

l Hriselna atana hlauhawm : Bearing a chhiat nghal emaw, spindle stall emaw chuan natna hlauhawm tak tak a siam thei a, chu chu thil chhe thei emaw, control loh machine behavior emaw a ni thei.

Mitigation atana tih dan tha ber berte .

Bearing overloading hi machining tih dan dik lo, thil ha lo hman, aggressive cutting depths emaw, feed rate inmil lo emaw aanga lo chhuak tur ven theih a ni. Chuta chhuak fatigue cracking, deformation, pitting, leh catastrophic failure awm thei chuan hmanrua a ti rei thei a, a senso a tisang thei a, himna a hlauhawm phah thei bawk. Cutting parameters te chu bearing capabilities nen a inmil a, sharp tools hmangin, loads balance a, regular maintenance implement hmang hian operator te chuan overloading risk chu nasa takin an ti tlem thei a ni. Heng proactive measures te hian rintlak taka hnathawh a tichiang a, precision a tichak a, bearings leh a kaihhnawih machinery te service life a ti rei a, a tawpah chuan operational efficiency leh cost savings ah a pui a ni.

2. Lubrication tling lo emaw, bawlhhlawh lo emaw .

Lubrication hi rotating machinery-a bearings te, spindle, motor, emaw mechanical system dang emaw-a bearings te performance tha ber leh dam rei theihna tur atan a pawimawh hle. A che vel inkar a inhnawh tawnna a tihziaawm a, lumna a ti bo a, lei chungte chu a chhe thei lo turin a veng bawk. Mahse, lubrication tling lo emaw, bawlhhlawh lo emaw chuan operational issue na tak a thlen thei a, bearing performance a tichhe thei a, a hun hmaa a hlawhchhamna a thlen thei bawk.

Lubrication tling lo emaw, bawlhhlawh lo emaw thlentu .

Lubrication failure hi lubricant-in a hna pawimawh tak a thawh theihna tibuaitu thil engemaw zat vang a ni:

Lubricant level hniam tak tak te:

l Bearing system-a lubricant tling lo chuan surface kal lai, rolling element leh race te inkarah dry contact a thlen thin. Hetianga lubrication awm lohna hian friction a tipung a, bearing surface-ah scoring (scratches emaw gouges) a thlen thei a ni.

l Level hniam tak takte chu enkawl loh vang emaw, initial filling dik lo, emaw, hun kal zelah a vawt emaw, leakage emaw avanga zawi zawiin a tlahniam thei a ni.

Lubricant-a bawlhhlawh awmte:

l Thil bawlhhlawh, leivut, bawlhhlawh, emaw, thir chi hrang hrang ang chi hian lubricant chu a chhungah a lut thei a, abrasive medium-ah a chantir thei a ni. Heng contaminants te hian bearing surface ah an grind a, wear a ti chak hle.

l Water ingress, sealing tha lo emaw, boruak lum lutuk vang emaw a ni fo thin, lubricant nen a inhmeh a, a viscosity a tihtlem bakah corrosion emaw emulsification emaw a tichak a, chu chuan lubrication performance a tichhe thin.

Seal leak emaw, enkawlna skipped emaw:

l seal chhe tawh, chhia, a nih loh leh dik lo taka dah chuan lubricant chu a tlanchhuak thei a, reserve a tichhia a, bearings chu contaminant-ah a pholang bawk.

l Maintenance schedule pangngai, lubricant level check loh emaw, replenish loh emaw ang chi chu ngaihthah chuan hun kal zelah lubrication tling lo a thlen thin.

Lubricant dik lo hman dan:

l Bearing-a specification zawm lo lubricant hman (eg, viscosity dik lo, type, emaw additives emaw) chuan venhimna tling a pe thei lo va, chu chuan friction leh wear a tipung thei a ni.

l Lubricant inmil lo, grease leh oil emaw grease chi hrang hrang inzawmkhawm ang chi mixing hian performance a tichhe thei a, lubrication failure a thlen thei bawk.

Lubrication tling lo emaw, bawlhhlawh lo emaw avanga nghawng .

Lubrication a tling tawk lo emaw, a bawlhhlawh emaw chuan bearings hian an hnathawh dan tichhe thei tur thil tha lo tak tak a tawk thin:

Surface erosion leh pitting:

l Lubrication tling lo emaw, abrasive contaminants emaw chuan surface erosion a thlen a, chutah chuan material chu bearing-a rolling elements emaw races emaw atanga hla takah a chhe thin. Hei hian pitting a thlen a, a chung lamah chuan crater te te a awm a, chu chuan smooth operation a tibuai a ni.

l Pitting hian vibration leh noise a tipung a, precision a ti tlem a, a ti chak zual bawk.

Friction atanga lumna tihpun:

l Lubrication dik tak nei lovin, a chhunga thil kalte inkara inhnawh tawnna (friction) chuan lumna nasa tak a siam thin. He temperature sang tak hian bearing material a tichhe thei a, a structure a tichak lo thei a, thermal expansion a thlen thei a, misalignment emaw clearance issues a thlen thei bawk.

l Lubricant bawlhhlawh chuan heat generation a tizual a, chu chuan abrasive particle a rawn luh tir a, chu chuan friction a tipung a ni.

Extreme case-a seizure tih hi:

l A nasat chuan lubrication ha tak awm lohna hian bearings a ti awlsam thei a, chutah chuan rolling element leh race te chu friction emaw material welding tam lutuk avangin an lock up thei a ni. Seizure hian machinery hnathawh a titawp a, hei hian chhiatna nasa tak a thlen thei a, a chhehvela component hrang hrangte a tichhia thei bawk.

L seizure hi hun rei tak chhunga dry contact emaw, contamination nasa tak emaw avanga lo awm a ni fo thin.

Lubrication tling lo emaw, bawlhhlawh lo emaw avanga a rah chhuah .

Lubrication hlawhchhamna avanga a rah chhuah chu bearings aiin a zau zawk a, overall system performance leh operational costs a nghawng a ni:

l Reduced Bearing Lifespan : Lubrication tling lo emaw, bawlhhlawh emaw chuan a chhe a ti chak a, bearing-te service nun chu nasa takin a ti tawi a, thlak fo a ngai bawk.

l Maintenance costs tihpun : Lubrication hlawhchhamna avanga chhiatna chuan siamthatna man to tak a thlen a, bearing replacement leh maintenance atana downtime te pawh a tel.

L Production Downtime : Lubrication tha lo avanga bearing failures hian production a titawp thei a, deadline leh sum lama hlohna a thlen loh phah thei.

l Compromised Precision : Lei chung lama chhiatna leh friction tihpun chuan machinery dikna a tihziaawm a, aerospace emaw electronics ang chi precision industry-a product quality a nghawng a ni.

l Safety Risks : Bearing emaw, a hlawhchhamna emaw chuan natna hlauhawm tak a siam thei a, chu chu uncontrolled machine behavior emaw debris generation emaw chuan operator-te tan risk a siam thei a ni.

Mitigation atana tih dan tha ber berte .

Lubrication tling lo emaw, bawlhhlawh lo emaw hian performance a neih theihna tur hlauhawm tak a siam a, chu chuan lei chung lama erosion, pitting, heat tihpun leh seizure awm thei a thlen a ni. Heng thilte hi lubricant level hniam, bawlhhlawh emaw tui emaw avanga bawlhhlawh, seal leak emaw, enkawlna dik lo emaw atanga lo chhuak a ni. Lubricant tarlan te, monitoring level te, lubricant bawlhhlawh te thlak nghal vat te, seal check mumal tak neih te hmang hian operator te chuan lubrication nena inzawm hlawhchhamna an veng thei a ni. Heng proactive measures te hian bearing reliability a tichak a, equipment lifespan a ti rei a, operational cost a ti tlem a, critical application-a performance leh safety mumal tak a awm theih nan a pui bawk.

3. Misalignment emaw install dik loh emaw .

Rotating machinery-a bearings, spindle, motor emaw, mechanical system dang emaw-a bearings-te performance leh dam rei theihna tur atan alignment leh installation dik tak neih a pawimawh hle. Bearings hi load distribution pawh leh smooth operation a nih theih nan alignment dik tak hmanga hnathawh theih tura siam a ni. Misalignment emaw install dik loh emaw chuan operational issue lian tak tak, accelerated wear, leh premature failure a thlen thei a ni.

Misalignment emaw install dik loh emaw chhan .

Misalignment emaw installation dik lo emaw a awm a, bearings chu a position dik lo emaw, a secure emaw a nih loh chuan, operational inefficiency a thlen thin. A chhan tlangpui te chu:

Assembly tihsual avanga shaft tilt lo awm thin:

l Assembly laiin tihsual, bearings chu shaft emaw housing emaw-a dah dik loh chuan shaft tilt emaw angular misalignment emaw a thlen thei. He misalignment hian bearing-in a rotate theihna a tibuaitu a ni.

l Hman dan dik lo, install lai emaw, hmanraw dik lo hman emaw ang chi, uneven force hman hian a tir atang khan bearings chu a inmil lo thei a ni.

Thermal expansion shifting position hrang hrang:

l Operation lai hian machinery components te chu a lum thei a, chu chuan thermal expansion a thlen thei a, chu chuan bearings, shafts, emaw housings te awmna hmun a tidanglam thei a ni. Design emaw installation process-a accounted a nih loh chuan hei hian misalignment a thlen thei a ni.

l Clearance tling lo emaw preload setting dik lo emaw chuan thermal expansion avanga misalignment awm chu a tizual thei a ni.

Uneven surface-a dah:

l Surface inang lo emaw, siam dik loh emaw, warped housings emaw, misaligned machine base emaw-a bearing dah chuan a tir atang khan misalignment a rawn luh tir thin.

l Machining tolerance ha lo emaw, lei chung siam ha lo (eg, mounting surface-a bawlhhlawh emaw, burr emaw) chuan bearing-te chu a thut dik loh nan a veng thei a ni.

Installation tih dan tur dik lo:

l Install lai hian alignment emaw torque specification emaw verify ang chi, step pawimawh tak tak skipping hian bearings te chu misalignment emaw, seating dik lo emaw a thlen thei a ni.

l Training neih loh emaw, siamtu kaihhruaina zawm loh emaw chuan installation error a thlen fo thin a, chu chuan bearing performance a tichhe thin.

Misalignment emaw install dik lo emaw avanga nghawng a neih dan .

Bearing-te chu misalign emaw, dik lo taka dah emaw an nih chuan, an hnathawh dan leh an dam rei theihna tichhe thei thil ha lo chi hrang hrang an tawk hin:

Load sem dan inang lo tak tak:

l Misalignment hian bearing pumpuiah force hrang hrang insem dan inang lo a siam a, hmun thenkhatah chuan phurrit tam lutuk a awm bawk. Hei hian rolling elements, races, or cages-ah te wear a ti chak a, chu chuan a hun hmaa hlawhchhamna a thlen thin.

l Uneven loading hian localized stress concentration a thlen thei bawk a, material fatigue awm theihna a tipung thei bawk.

Vibration avanga hahna (fatigue) te chu:

l Misaligned bearings hian rotation emaw wobbling emaw avanga vibration nasa lutuk a siam thin. He vibration hian cyclic stress a thlen a, bearing components-ah fatigue cracking a thlen thin.

l Prolonged vibration hian machine part dang a propagate thei a, chu chuan system a ti chhe emaw, a tichhia emaw thei bawk.

Heat chu friction dah belh a ni:

l Misalignment hian bearing components te inkarah friction a tipung a, heat tam lutuk a siam chhuak thin. He lumna hian lubricant a tichhe thei a, bearing materials a tichak lo thei a, thermal expansion a thlen thei a, chu chuan misalignment a tizual lehzual a ni.

l Temperature sang chuan bearing-a precision leh efficiency a ti tlem a, chu chuan overheating emaw failure emaw a thlen thei a ni.

Bearing dam rei zawng tihtlem:

l Uneven loading, vibration, leh increased friction te combined effects chuan bearing hnathawh hun a ti tawi hle a, thlak fo leh maintenance cost tihpun a ngai a ni.

Misalignment emaw install dik lo emaw avanga a rah chhuah .

Misalignment emaw, install dik lo emaw avanga thil thleng chu bearings aiin a zau zawk a, overall system performance leh operational costs a nghawng a ni:

L Accelerated Wear and Failure : Load leh vibration chak lohna a ti chak a, hei hian bearing hma lawk a tichhia a, hmanrua a ti tlem bawk.

l Maintenance costs tihpun : Misalignment nena inzawm chhiatna avanga siamthat emaw thlak emaw fo thin chuan enkawlna senso a tisang thin.

L Production Downtime : Misaligned bearings hian beisei loh taka hlawhchhamna a thlen thei a, production a titawp thei a, sum hloh emaw, hun bituk hloh emaw a thlen thei.

l Compromised Precision : Precision application-ah chuan CNC machining emaw robotics emaw ang chiah hian misalignment hian dikna a ti tlem a, chu chuan thil chhia emaw, hnathawh thar emaw a thlen thei a ni.

l Safety Risks : Vibration tam lutuk emaw, bearing failure rang lutuk emaw chuan natna hlauhawm tak a siam thei a, chu chu component detachment emaw, control loh machine behavior emaw hian operator-te tan risk a siam thei a ni.

Mitigation atana tih dan tha ber berte .

Misalignment emaw, bearings dah dik loh emaw, assembly errors, thermal expansion emaw, mounting surface inang lo emaw avanga lo awm chuan load distribution inang lo, vibration-induced fatigue, leh friction tihpunna a thlen thin. Heng thilte hian a chak zual zel a, a dik lo thei a, hmanrua a tichhia thei a, hnathawhna leh sum leh pai lama nghawng lian tak a nei bawk. Alignment tools hmanga, post-setup alignment verify, thermal expansion accounting, leh regular check neih te hian operator te chuan misalignment nena inzawm thil an veng thei a ni. Heng proactive measures te hian bearing performance rintlak tak a siam a, equipment lifespan a ti rei a, operational efficiency a ti sang a, critical application-a downtime leh cost a tih tlem phah bawk.

4. Leivut leh bawlhhlawh atanga bawlhhlawh paih .

Dust leh debris atanga contamination hi precision machinery, spindle, bearings emaw mechanical component dang emaw hnathawhna hmuna thil pawimawh tak a ni. Heng bawlhhlawh, leivut, bawlhhlawh, metal shavings, emaw microscopic debris dang ang chi te pawh a awm a, chu chuan machinery chu kawng hrang hrang hmangin a rawn luhchilh thei a, chu chuan operational inefficiency nasa tak leh chhiatna nasa tak a thlen thei a ni.

Contamination awm chhan .

Dust leh debris infiltration hi a tlangpuiin a hnuaia thil pakhat emaw a aia tam emaw vang a ni.

Sealing mechanism tha lo tak tak:

Machinery components vel a seal tha tawk lo emaw, a chhe tawh emaw chuan pawn lam thil te chu hmun pawimawh takah a lut thei a ni. Hun a kal zel a, seal te chu a chhe tawh a, a dah dik loh avangin a chhe thei a, a nih loh leh boruak chhe tak tak a tawh avangin a chhe thei a, chu chuan bawlhhlawh luh theihna tur gap a siam thei a ni.

Environment lama harsatna bik, leivut tamna emaw, boruak lum lutuk emaw tuar thei tura siam loh seal te chu a bik takin a hlauhawm hle.

Operation environment bawlhhlawh tak tak te:

Thlipui tleh tamna hmuna machinery hnathawk, thil siamna hmun, sakna hmun, emaw boruak quality tha lo awmna hmuna awm chu a bawlhhlawh theihna a sang zawk.

In enkawl dan dik lo, hnathawhna hmun tihfai loh emaw, hmanraw bula thil chhe tam tak a punkhawm phalsak emaw te hian buaina chu a tizual hle.

Enkawl dan dik lo:

Maintenance emaw repair lai hian hmanrua, kut, emaw components tihfai dik loh chuan system chhungah bawlhhlawh a rawn luh tir thei a ni.

Lubricants hian particle a tihbawlhhlawh avangin machinery-a bawlhhlawh luhtirna tur vector angin hna a thawk thei bawk.

Thli hmanga bawlhhlawh paihna (contaminants):

Thlipuiah hian thil chi hrang hrang, pollen, industrial dust, emaw chemical residue te chu a awm thei a, chu chu air intake system emaw ventilation hmangin machinery-ah a lut thei a ni.

Contamination avanga nghawng a neih dan .

Dust leh debris te hian machinery an rawn luhchilh chuan, an performance leh dam rei theihna tichhe thei tur cascade of detrimental effects an siam thei a ni. A rah chhuah ber chu:

Abrasive grinding chu lei chung lamah a awm a:

Dust leh debris, a bik takin metal shavings emaw silica emaw ang chi hard particle te hian thil che lai inkar a tang chuan abrasives angin hna an thawk thin. Hei hian micro-abrasion emaw, bearings, spindles, emaw gears ang chi surface-a grinding emaw a thlen thin.

Hun a kal zel a, he abrasive action hian wear a thlen a, components te precision leh efficiency a ti tlem a, misalignment emaw friction tihpun emaw a thlen thin.

Moisture-mixed contaminants atanga corrosion:

Contaminants te hi moisture nen an inhmeh fo thin a, chu chu environment atanga lo chhuak emaw, lubricants atanga lo chhuak emaw a ni a, chu chuan corrosive environment a siam thin. Entirnan, leivut awmna salt emaw chemical emaw chuan metal surface-ah rust a siam chak thei a ni.

Corrosion hian components a tichak lo a, pitting, cracking, emaw structural failure a thlen a, hei hian hmanrua te dam chhung a ti tlem thei hle.

Lubricant kawng block-a siam:

Dust leh debris hian lubrication channel a tikhawlo thei a, lubricant te chu hmun pawimawh tak tak a thlen loh nan a veng thei bawk. Hei hian lubrication tha tawk lo, friction a tipung a, heat generation a thlen bawk.

Blocked paths hian lubricant distribution inang lo a thlen thei bawk a, chu chuan localized overheating emaw component failure emaw a thlen thei bawk.

Scratch, dents, leh a tawpah breakdown te:

Abrasion, corrosion, leh inadequate lubrication-te cumulative effect chu hmuh theih chhiatna angin a lang a, chu chu scratch, dents, emaw surface irregularities te hi a ni.

Heng thilte hian component-te structural integrity a tichhe a, chu chuan a ti chak zual a, a tawpah chuan machinery-te chu a tichhia a ni.

Contamination avanga a rah chhuah .

Dust leh debris contamination avanga a rah chhuah chu mechanical damage nghal mai aiin a zau a, operational leh financial impact nasa tak a nei thei a ni:

l Reduced Equipment Efficiency : Contaminated components te hian an thawk tha lo hle a, hna inang thawk tur leh operational cost tihpun nan energy tam zawk an mamawh a ni.

l Maintenance cost tihpun : Contamination-a chhiatna avanga chhiatna avanga siamthat emaw thlak emaw fo thin chuan enkawlna senso a tisang thin.

L downtime leh production loss : Contamination avanga beisei loh taka a tlakchhiat chuan production a titawp thei a, deadline a awm loh bakah sum a hloh phah thei bawk.

l Compromised Product Quality : Precision industry-ah chuan aerospace emaw electronics siamna emaw ang chiah hian contamination hian thil chhia a thlen thei a, chu chuan rework emaw customer lungawi lohna a thlen thei a ni.

l Safety hazards : Thil chhia emaw, a thawk tha lo emaw chuan operator-te tan hlauhawmna a thlen a, accident emaw hliam emaw a thlen thei a ni.

Mitigation atana tih dan tha ber berte .

Dust leh debris atanga contamination hian precision machinery performance leh dam rei theihna tur hlauhawm tak a thlen a ni. A chhan—seal ṭha lo leh boruak bawlhhlawh ang chi—leh a rah chhuah, abrasive wear, corrosion, leh lubricant blockages te pawh hriatthiam a nih chuan, operator-te chuan risk tihziaawmna turin hma la theiin hma an la thei a ni. Thil tih dan tha ber, sealing tha tak, air filtration, leh regular cleaning te kalpui hian contamination nasa takin a tihziaawm thei a, rintlak taka hman a nih theih nan, downtime tih tlem a, hmanraw pawimawh tak tak service life a ti rei thei bawk. Contamination control chu dah pawimawh hmasak a nih chuan sumdawnna te chuan efficiency an tipung thei a, cost an tihtlem thei a, operational excellence standard sang tak an vawng thei bawk.

5. Vibration emaw imbalance emaw a tam lutuk .

Rotating machinery-a vibration emaw imbalance tam lutuk, spindle, motor emaw bearing nei system dang emaw hian operational performance leh component dam rei theihna tur hlauhawm tak a siam a ni. Heng thilte hi hmanrua, rotor emaw, rotating element dang emaw a inthlau emaw, system chu resonant frequency-a a thawh a, amplified mechanical stress a thlen emaw a nih chuan a lo chhuak thin.

Vibration tam lutuk emaw, imbalance emaw thlentu .

Machinery-a vibration tam lutuk emaw, imbalance emaw hi a tlangpuiin a hnuaia thilte atang hian a lo chhuak thin a ni.

Unbalanced tools emaw rotors emaw:

l hmanrua, machining-a cutting tools emaw motor-a rotors emaw ang chi, balance tha lo tak takte chuan rotation laiin uneven force an siam chhuak thin. He imbalance hian oscillations a thlen a, chu chuan bearings leh component dangte a stress a ni.

l Imbalance hi tool wear inang lo, assembly dik lo emaw, rotating elements-a thil siam that lohna emaw avanga lo awm thei a ni.

Resonant frequency te chu:

l Machinery hian a natural resonant frequency emaw a hnaih emawa a thawh chuan vibrations a amplified a, oscillations tam lutuk a thlen thin. He resonance hi speed setting dik lo emaw, system-a design flaws emaw avanga lo awm thei a ni.

l Pawn lam thil, a bul hnaia machinery emaw environment vibration emaw ang chi te hian resonant frequency a tizual thei a, chu chuan buaina chu a tizual thei a ni.

Setup emaw alignment emaw dik lo taka siam:

L Misaligned components, shaft emaw couplings emaw ang chi te hian rotation laiin uneven force distribution a siam a, vibrations a rawn luh tir thei a ni.

l Component, tool holder emaw fixture emaw ang chi, loose emaw dik taka secured emaw te hian imbalance leh vibration a thlen thei bawk.

Component-a inbel emaw, tihchhiat emaw:

l bearings chhe tawh, gear chhia, a nih loh leh components chhe tawh chuan irregular motion a siam thei a, chu chuan vibration a tisang thei a ni.

l System chhunga debris emaw contamination emaw accumulated chuan balance a tichhe zual a, oscillations a tichak thei bawk.

Vibration tam lutuk emaw imbalance emaw avanga nghawng a neih dan .

Machinery hian vibration emaw imbalance emaw nasa lutuk a tawn chuan bearings leh component dangte hian nghawng tha lo tak tak an nei thin:

Amplified oscillations race tichhe thei:

l Vibration tam lutuk hian bearing race (rolling elements awmna inner leh outer rings) ah nghawng a nei nawn fo a, uneven loading a thlen bawk. Hei hian lei chung lama chhiatna a thlen a, chu chu micro-crack emaw, material deformation emaw a ni a, bearing integrity a tichhe thei a ni.

l oscillations hian machine component dangte pawh a propagate thei a, chu chuan wear zau tak a thlen thei bawk.

Cycles aiin a chau hle:

l Vibration chhunzawm zel hian bearings-ah cyclic stress a thlen a, hun kal zelah fatigue cracking a thlen thin. Heng crack te hian bearing structure a tichak lo a, a hlawhchham theihna a tipung bawk.

L fatigue damage hi operational cycle tin hian a pung khawm a, hei hian bearing dam chhung a ti tlem hle.

Constant motion atanga lumna:

L vibrations hian bearing components inkarah friction a tipung a, excess heat a siam chhuak thin. He lumna hian lubricant a tichhe thei a, bearing materials a tichak lo thei a, thermal expansion a thlen thei a, misalignment emaw clearance issues emaw a tizual thei bawk.

l Hun rei tak chhung heat generation hian overheating a thlen thei a, operational efficiency leh precision a ti tlem thei bawk.

Machinery-a secondary damage:

l Vibration tam lutuk hian fastener a tizau thei a, components a misalign thei a, a kianga parts a tichhia thei bawk a, chu chuan system failure zau zawk a thlen thei a ni.

l A nasat chuan vibrations enkawl loh chuan chhiatna nasa tak a thlen thei a, chu chu bearing seizure emaw shaft fracture emaw a ni thei.

Vibration emaw imbalance nasa lutuk avanga a rah chhuah .

Vibration tam lutuk emaw, imbalance emaw avanga a rah chhuah chu bearings aiin a zau zawk a, system performance zawng zawng leh operational costs a nghawng a ni:

l Reduced Equipment Lifespan : Vibrations a chak zual a, bearings leh component dangte a tichhia a, a thlak fo a ngai a ni.

l Maintenance costs tihpun : Vibrations atanga chhiatna thleng tur chuan siamthatna man to tak tak a ngai a, bearing replacement leh system realignment te pawh a tel.

L Production Downtime : Vibration-induced failures hian production a titawp thei a, chu chuan deadline leh sum lama hlohna a thlen loh phah thei.

l Compromised Precision : Vibration tam lutuk hian machining accuracy a tihziaawm a, chu chuan product chhia emaw, aerospace emaw electronics ang chi precision industry-a rework emaw a thlen thin.

L Hriselna atana hlauhawm : Vibration na tak tak chuan component detachment, control loh machine behavior, emaw debris generation emaw a thlen thei a, operator te tan hlauhawmna a thlen thei.

Mitigation atana tih dan tha ber berte .

Vibration emaw imbalance emaw tam lutuk, hmanrua inthlau lo, resonant frequency, emaw setup dik lo avanga lo awm chuan amplified oscillations, fatigue, leh heat generation, chhiatna thlen thei bearings leh component dangte a thlen thin. Heng thilte hian hmanrua nunna a tihtlem a, enkawlna senso a tisang a, a dik lohna a tichhe bawk a, himna hlauhawmna a thlen thei a ni. Hmanrua inthlauhna siam te, vibrations isolating, analyzer te nena monitoring te, leh setup dik tak enkawl te hian operator te chuan heng risk te hi an tihziaawm thei a ni. Heng proactive measures te hian machinery rintlakna a tipung a, service life a ti rei a, operational efficiency a vawng reng a, application pawimawh tak takah downtime leh cost a ti tlem bawk.

6. Operating temperature sang .

Operating temperature sang tak hian bearings leh rotating machinery component dang, spindle emaw motor emaw te performance leh dam rei theihna kawngah harsatna lian tak a siam a ni. Khaw lum lutuk hian thil a tichhia thei a, lubrication a tichhe thei a, dimensional changes a thlen thei a, chu chuan operational inefficiency leh premature failure a thlen thei a ni.

Operating temperature sang chhan .

Machinery-a temperature sang tak takte hi a tlangpuiin operational, environmental, leh maintenance nena inzawm thil inzawmkhawm atanga lo chhuak a ni:

Friction tam lutuk:

l Bearing components inkara friction sang tak, a tam zawkah chuan lubrication tling lo, misalignment emaw overloading emaw avanga lumna nasa tak a awm thin.

l Hmanrua inthlau tak emaw, vibration tam lutuk emaw chuan friction a tipung lehzual thei a, temperature sang takah a pui thei bawk.

Overloading emaw aggressive taka hnathawh emaw:

l A designed load capacity piah lam, machining tough materials emaw, aggressive cutting parameters hman emaw ang chi operating machinery chuan heatened mechanical stress avanga heat generation a tipung a ni.

l High speed emaw feed rates emaw hian heat production a tichak thei a, a bik takin chutiang condition atana rated loh bearings-ah chuan.

Cooling system tling lo:

l Cooling system, fan, coolant pump emaw, heat exchanger emaw ang chi, cooling system tling lo emaw, a thawk tha lo emaw chuan lumna a ti bo thei lo va, chu chuan boruak lum a tisang thei a ni.

l Ventilation tha lo emaw, operating environment-a boruak lum lutuk emaw chuan heat buildup a tizual.

Lubricant tihchhiat emaw thlan dik loh emaw:

l Lubricant-te chu high-temperature hmanna atana ṭha lote chuan an ti tlem emaw, an chhe emaw thei a, chu chuan an lumna tihbo leh bearing surface humhim theihna a ti tlem thei a ni.

l Lubricant bawlhhlawh emaw, tihchhiat emaw hian friction leh heat generation a tipung thei bawk.

Pawn lam atanga lumna chhuahna: 1.1.

l Pawn lam khaw lumna hmun hnai ber, furnace, oven, emaw, ni êng direct-a thawkte chuan bearing performance tichhe thei temperature sang tak an tawk thei a ni.

l Insulation tling lo emaw, pawn lam lumna atanga shielding emaw chuan a tizual thei.

Operating temperature sang lutuk avanga nghawng a neih dan .

Bearings leh machinery te chu temperature sang tak an tawk a nih chuan, an functionality leh durability tichhe thei tur range of detrimental effects an tawk thin:

Load capacity tihtlem: 1.1.

l Temperature sang tak chuan bearing materials a ti nem a, chu chu steel ang chi te hian a hardness leh load-carrying capacity a ti tlem a ni. Hetianga a chak lohna hian bearings te chu normal operating load hnuaiah deformation a awlsam zawk a ni.

L Softened materials hian mechanical stress, wear leh failure chak zawk a tuar thei lo.

Lubricant tihchhiatna:

l Temperature sang chuan lubricant te chu a ti thin a, a oxidize a, a ti chhe a, chemical hmangin a ti chhe a, an viscosity leh effectiveness a ti tlem a ni. Hei hian lubrication tling lo, friction tihpun, leh heat generation dang a thlen bawk.

l Lubricant chhe tawh tak takte chuan sludge emaw varnish emaw a siam thei a, lubrication path a tikhawlo thei a, wear a tizual thei bawk.

Thermal fatigue crack te:

l Temperature sang tak tak a awm nawn fo hian thermal fatigue a thlen a, chutah chuan cyclic heating leh cooling hian bearing surface-ah micro-cracks a thlen thin. Heng crack te hi hun kal zelah a darh zel a, bearing a tichak lo va, catastrophic failure a thlen theihna a tipung bawk.

l Component-te thermal expansion inang lo chuan stress concentration a tizual thei a, chu chuan crack a siam thei a ni.

Dimensional inthlak danglamna leh a inmil lohna:

l Temperature sang chuan bearings, shafts, emaw housings te chu a tizau lo va, chu chuan misalignment, vibration a tisang a, load distribution pawh a inang lo.

l Heng dimensional inthlak danglamna te hian bearing clearance a ti tlem thei a, binding emaw friction a tisang thei bawk.

Operating temperature sang lutuk avanga a rah chhuah .

Heat nasa lutuk avanga thil thleng chu bearings aiin a sang zawk a, system performance zawng zawng leh operational costs a nghawng a ni:

l Reduced Equipment Lifespan : Thil nem tak leh lubricant breakdown a ti chak a, bearing leh machinery dam chhung dam rei lo tak a ni.

l Maintenance costs tihpun : Heat-related damage avanga siamthat emaw thlak emaw fo thin chuan maintenance expenses a tichak thin.

L Production Downtime : High-temperature-induced failures hian production a titawp thei a, chu chuan deadline leh sum lama hlohna a thlen loh phah thei a ni.

l Compromised Precision : Thermal expansion leh material degradation hian machining dikna a tihziaawm a, aerospace emaw electronics ang chi precision industry-a product quality a nghawng a ni.

l Safety risks : Overheated components chu a fail nghal thei a, chu chuan natna hlauhawm tak tak a siam thei a, chu chu seizure, component detachment, emaw kangmei chhuahna hlauhawm tak takah te a ni.

Mitigation atana tih dan tha ber berte .

Operating temperature sang tak, friction tam lutuk, overloading, cooling tha tawk lo, emaw lubricant dik lo avanga lo awm hian load capacity a tihhniam a, lubricant breakdown, leh thermal fatigue crack te a thlen thin. Heng thilte hian hmanrua dam chhung a ti tawi a, enkawlna senso a tipung a, precision a tichhe bawk a, himna atana hlauhawm awm thei te nen. Cooling system te optimize te, temperature monitoring te, overloads te pumpelh te, leh lubricant dik tak thlan te hian operator te chuan heat-related risk te chu an tihziaawm thei a ni. Heng proactive measures te hian machinery performance rintlak tak a siam a, service life a ti rei a, application pawimawh tak takah downtime leh cost a ti tlem bawk.

7. Electrical current kal dan .

Bearings kal tlanga electrical current kal, grounding tha lo emaw, current stray emaw avanga lo awm fo chuan motor, spindles, emaw generator ang chi rotating machinery-ah chhiatna nasa tak a thlen thei a ni. He thil thleng, electrical discharge machining (EDM) ang chi hian bearing surface a tichhia a, an performance a tichhe bawk.

Electrical current kal chhan .

Electrical current passage chu unintended electrical currents te chu bearings kaltlangin a luang chhuak a, a tlangpuiin a hnuaia thilte avang hian a thleng thin.

Grounding tha lo:

l Machinery grounding tha tawk lo emaw, dik lo emaw chuan stray electrical currents chu bearings kaltlangin a luang chhuak thei a, chu chuan lei laka invenna tlem ber kawng a zawng thei a ni.

l Grounding ha lo chu wiring dik lo, connection ha lo emaw, machine emaw facility-a grounding system ha lo emaw avanga lo awm thei a ni.

Electrical system atanga current lo chhuak (stray currents) te:

l Stray currents hi variable frequency drive (VFDs), inverter emaw, tunlai machinery-a hman tlanglawn electrical component dang emaw atanga lo chhuak a ni thei a, a bik takin high-power emaw high-speed application-ah emaw a lo chhuak thei a ni.

L Electromagnetic Interference (EMI) emaw, a bul hnaia electrical hmanrua atanga induced voltage emaw chuan bearings kaltlangin current a kal thei bawk.

Static electricity buildup:

L Static charges hi rotating components-ah a pung khawm thei a, a bik takin dry emaw high-speed environment-ah chuan bearings hmanga discharge a thlen thei a ni.

l Hei hi non-conductive material emaw belt emaw hmanga static electricity siamtu hmannaah a awm fo thin.

Insulation dik lo emaw, shielding emaw:

l Bearing emaw, a chhehvel component-a insulation dik tak awm lohna chuan electrical current chu tum loh taka kawng kal tlangin a luang chhuak thei a ni.

l Electromagnetic field laka shielding tling lo chuan sensitive equipment-a tuna kal mek chu a tizual thei a ni.

Electrical current passage a nghawng dan .

Electrical currents hian bearings a paltlang chuan a chhiatna tur a thlen thei a, a bik takin arcing leh electrical discharge machining (EDM) effects hmangin:

Arcing hmanga lei chunglam atanga erosion:

L Bearing components (eg, rolling elements leh races) inkara electrical arcing hian localized sparks a siam a, chu chuan material a tichhe a, EDM nen a inang a ni. Hei hian bearing surface-a pitting, fluting, emaw frosted pattern emaw a thlen thin.

l Heng lei chunglam chhiatna hian smooth operation a tibuai a, friction a tipung a, wear a ti chak bawk.

Micro-crater leh thil chhe (material degradation) te:

L arcing hian bearing surface-ah crater te tak te emaw, burn mark emaw a siam a, chu chuan material chu a tichak lo va, a load-carrying capacity a tihtlem bawk.

l Hun kal zelah heng micro-craters te hian spalling (flaking of material) a thlen a, bearing integrity chu a tichhe zual sauh sauh a ni.

Vibration leh noise tihpun:

l Arcing atanga surface damage hian rotation a ti danglam a, chu chuan operation laiin vibration leh noise a tisang a.

l vibration hian machine component dang a propagate thei a, additional wear emaw misalignment emaw a thlen thei bawk.

Lubricant tihchhiatna:

L arcing hian contact point-ah lumna a siam a, chu chuan lubricant a tichhe thei emaw, a hal thei a, a thatna a ti tlem a, friction leh wear a tipung thei bawk.

l Lubricant bawlhhlawh emaw, carbonized emaw chu abrasive a ni thei a, lei chung lama chhiatna a tizual thei bawk.

Premature bearing hlawhchhamna:

l Surface erosion, vibration, leh lubricant breakdown-a cumulative effects chuan bearing lifespan chu nasa takin a ti tawi a, chu chuan hun hmaa hlawhchhamna a thlen thei a ni.

l A nasat chuan arcing hian bearing seizure emaw catastrophic failure emaw a thlen nghal thei.

Electrical current kalkawng avanga a rah chhuah .

Electrical current passage avanga thil thleng chu bearings aiin a zau a, system performance zawng zawng leh operational costs a nghawng a ni:

l Reduced Equipment Lifespan : Lei chung lama a chhe leh thil tihchhiatna chu a tikhawlo chak a, a thlak fo a ngai a ni.

l Maintenance costs tihpun : Arcing atanga chhiatna thleng tur chuan siamthatna man to tak tak a ngai a, bearing replacement leh system downtime te pawh a tel.

L Production Downtime : Electrical damage avanga bearing failure awm chuan a siam chhuah a titawp thei a, deadline leh sum lama hlohna a thlen thei.

l Compromised Precision : Lei chung lama chhiatna leh vibration tihpun hian machining accuracy a tihziaawm a, electronics emaw aerospaces-a precision industry-a product quality a nghawng a ni.

l Safety Risks : Bearing a chhiat nghal emaw, a vibration tam lutuk emaw chuan natna hlauhawm tak a siam thei a, chu chu component detachment emaw electrical hazards emaw hian operator-te tan risk a siam thei a ni.

Mitigation atana tih dan tha ber berte .

Electrical current passage, grounding tha lo, current stray emaw, static electricity emaw avanga lo awm fo thin chuan arcing hmangin bearing surface a tichhia a, chu chuan pitting, vibration, leh lubricant degradation a thlen thin. Heng effects te hian bearing lifespan a ti tlem a, maintenance cost a tisang a, operational precision a tichhe bawk a, safety risk awm thei te nen. Grounding dik tak siam a, insulated bearings hmanga, stray currents tihziaawmna, leh inspection neih fo a nih chuan, operator-te chuan electrical chhiatna an veng thei a ni. Heng proactive measures te hian machinery rintlakna a tipung a, service life a ti rei a, critical application-a downtime leh cost a tihtlem bawk.

CNC spindle a lum lutuk chhinchhiahna leh a lan chhuah dan .

Spindle motor hi precision machinery-ah chuan thil pawimawh tak a ni a, chu chu CNC machine, lathe, leh milling hmanrua te a ni a, chutah chuan bearings te hian hnathawh awlsam, dik leh tha tak an neih theih nan hmun pawimawh tak an chang a ni. Bearing damage hi hriat loh a nih chuan downtime man to tak, machining quality tihtlem, leh spindle motor-a chhiatna nasa tak thleng thei pawh a thlen thei a ni. Heng hlauhawmna tihziaawmna tur leh hmanrua te dam rei theihna tur hian a hmaa hmuhchhuah hi a pawimawh hle.

thawm ri danglam tak tak .

Bearing chhiatna chhinchhiahna hmasa ber leh langsar ber pakhat chu operation laiin spindle motor atanga aw danglam tak tak lo chhuak a awm hi a ni. Heng thawmte hian ngaihthah a nih chuan chhiatna nasa tak thlen thei thil awmze nei lo (underlying issues) a tarlang fo thin. A ri pangngai lo tak takte chu:

l whining or high-pitched sounds : High-pitched whine chuan a tlangpuiin bearing chhunga friction tihpun a nih thu a sawi a, chu chu a tam zawkah chuan lubrication tlem vang emaw, bearing surfaces wear vang emaw, debris emaw, dust emaw metal particles ang chi emaw a ni. He aw hian bearing a chhiat belh zel avangin a tizual thei a ni.

l Grinding emaw scraping noises : Grinding sound hian wear emaw a chung lam chhiatna nasa tak a thlen tih a tilang a, chu chu bearing race emaw rolling elements-a pitting emaw spalling emaw a ni. Hei hi bearing chu load tam lutuk, misalignment emaw, enkawl dan mumal nei lova hun rei tak hman a nih chuan a thleng thei a ni.

l Clicking or Ticking : Intermittent clicking emaw ticking noises emaw hian components loose, cage chhia emaw rolling elements kal tluang tawh lo ang chi a kawk thei. Hei hian early-stage fatigue emaw bearing assembly-a preload dik lo emaw a lantir thei bawk.

Engvangin nge a pawimawh : Heng thawm te hi lungngaihna tuar theihna clues hriat theih hmasa ber a ni fo thin. Friction leh wear a pun zel chuan aw chu a ri nasa zual a, a langsar zual bawk a, chu chuan bearing chu a hlawhchham hnaih tawh tih a tilang a ni. A bulpui ber—a bawlhhlawh, misalignment emaw, material fatigue emaw pawh ni se—leh spindle motor tihchhiat belh loh nan enfiah nghal a pawimawh hle.

Action Steps : Stethoscope emaw vibration analysis hmanrua hmangin noise source chu a chiang hle. Lubrication level leh quality enfiah la, a bawlhhlawh awm leh awm loh enfiah la, alignment te chu verify rawh. A ri a awm reng chuan, bearing inspection uluk tak neih theih nan spindle chu thenfai tum ang che.

Vibration tihpun a ni .

Vibration tam lutuk hi spindle motor-a chhiatna thlen theihna chhinchhiahna dang a ni bawk. Machine rotating-ah chuan vibration level engemaw zat chu a pangngai a nih laiin, vibration pattern-a a punna emaw, a danglamna hriat theih chuan bearing assembly chhunga thil pawimawh tak tak a lantir thei a ni. Thil pawimawh tak takte chu:

L Imbalance : Bearing-a inbel emaw, a chhe lo emaw chuan rotor chu a inthlau thei a, chu chuan a tithinur lutuk thei a ni. Hei hi hnathawh laiin rhythmic emaw pulsating vibration emaw angin an hre fo thin.

L Pitting emaw Surface Damage : Bearing surface-a microscopic pits emaw spall emaw hian smooth rotation a tibuai a, vibration mumal lo a thlen thei. Heng chhiatna te hi hahna, overloading emaw, contamination emaw avanga lo awm thei a ni.

l Misalignment emaw Loose Components : Misaligned bearings emaw loose mounting hardware emaw hian vibrations a tichak thei a, bearing leh accelerating wear-ah stress dang a dah belh thei bawk.

Why it matters : vibration tihpun hian bearing damage a kawk mai bakah spindle motor performance pumpui a nghawng bawk. Shaking tam lutuk hian machining precision tha lo a thlen thei a, tool chatter, leh component dang, seal emaw housing emaw a tichhia thei bawk. Hun kal zelah vibration enkawl loh chuan chhiatna nasa tak a thlen thei a ni.

Action Steps : Vibration levels quantified turin vibration analyzer hmang la, bearing faults nena inzawm frequency bik (eg, ball pass frequency emaw cage frequency emaw) hriat theih a ni ang. Regular monitoring hian vibration trend sang zel hriat theihna a pui thei a, hei hian chhiatna zual zel a nih thu a tarlang. Elevated vibrations a hriat chuan bearing chu a wear em tih enfiah la, alignment enfiah la, rotor chu a balance em tih enfiah rawh. Intervention hmasa hian a chhe zual zel tur a veng thei a ni.

Performance tihchhiatna .

Bearing damage hi spindle motor operational performance tlahniam angin a lang fo thin a, chu chuan precision, speed leh power vawng reng thei a nih thu a nghawng thin. A lan chhuah dan tlangpui chu:

l Loss of precision : Bearings chhia chuan spindle chu a kalna tur kawng aangin a tikehsawm emaw, a kal bo emaw thei a, chu chuan machining emaw cutting operation-ah dik lo a thlen thei a ni. Hei hi CNC Machining ang chi high-precision application-ah chuan a pawimawh hle a, chutah chuan deviation tenau te pawhin workpiece a tichhe thei a ni.

l Speed Fluctuations : Bearing chhe tawh emaw, chhe tawh emaw chuan resistance inmil lo a siam thei a, chu chuan spindle motor chu consistent rotational speeds vawng reng turin a bei nasa thei hle. Hei hian uneven cutting emaw grinding performance emaw a thlen thei a ni.

l Power Dips emaw Overloading : Bearings a chhiat chhoh zel chuan friction tihpun hian operation a neih theih nan power tam zawk a mamawh a, chu chuan energy consumption sang zawk emaw power drop inkar emaw a thlen thei a ni. A nasat chuan motor chu a ding reng thei a, a nih loh leh a tan vek thei bawk.

A pawimawh chhan : Performance degradation hian direct takin output quality leh machinery efficiency a nghawng a ni. Industry-te chuan precision leh consistency-a innghat, aerospace emaw, automotive manufacturing emaw ang chite tan chuan, performance issue tlemte pawh hian sum lama hlohna nasa tak emaw, himna chungchangah ngaihtuahna lian tak a thlen thei a ni.

Action Steps : Spindle performance metrics, speed stability leh power consumption ang chi te, diagnostic tools emaw machine control system emaw hmanga enfiah thin ang che. Degradation hmuh a nih chuan bearings te chu a chhe tawh em tih enfiah la, lubrication enfiah la, spindle chu a dik taka calibrate a nih leh nih loh enfiah rawh. Heng thilte hi hma taka hmachhawn chuan hnathawh a tichak thei a, chhiatna dang a thlen loh nan a veng thei bawk.

A rawng a danglam emaw, a rim emaw a danglam thei .

Bearing emaw, a chhehvela component-a taksa inthlak danglamna emaw, a rawng danglam emaw, rim danglam tak emaw ang chite hi lungngaihna thlenna chhinchhiahna pawimawh tak, lum lutuk emaw, thil tih loh emaw nena inzawm fo a ni. Heng symptoms te hi:

L Discoloration (bluing emaw browning) : Bearing lum lutuk hian an surface-ah blue emaw brownish tint emaw a lantir thei a, hei hi a lum lutuk vang a ni. Hei hi lubrication tling lo, load sang, emaw speed sang taka hun rei tak hnathawh avanga friction a san chuan a thleng thei a ni. Discoloration hian bearing material chu thermal stress a neih thu a tilang chiang hle a, chu chuan a structure a tichak lo thei a ni.

l acrid or burnt odors : A rimtui, a rim na tak chuan bearing lubricant chu a lum lutuk avangin a kang emaw a chhe emaw tih a tilang thei. Thil engemaw takah chuan, rim chu bearing material aang ngeia lo chhuak a ni thei a, a chhe an tan emaw, a lumnain a nghawng hnai ber component aanga lo chhuak emaw pawh a ni thei bawk.

Why it matters : Discoloration leh odors te hian bearing chu extreme condition hnuaiah a thawk tih a hriattir a, chu chuan wear a ti chak thei a, failure a thlen thei bawk. Overheating hian a kianga awm, seal, shaft, emaw housing te pawh a tichhia thei a, repair man leh downtime a tisang thei bawk.

Action Steps : Discoloration emaw odors emaw a awm tih hmuhchhuah a nih chuan spindle motor chu a chhiat belh loh nan khar nghal tur a ni. Bearing-te chu a lum lutuk tih hriat a nih leh nih loh enfiah la, lubricant dinhmun (eg, viscosity, contamination) enfiah la, operating conditions (eg, speed, load, cooling systems) endik rawh. Bearing chhia te thlak la, a lo awm leh loh nan lubrication replenish emaw upgrade emaw.

Invenna leh tih dan tha ber berte .

Thil chhiatna thlen theihna tur leh spindle motor-te dam rei theihna tur tihtlem nan a hnuaia thil tih dan tha ber berte hi han ngaihtuah teh:

l Regular Maintenance : Lubrication check, alignment verification, leh bearing inspection te telna tur routine maintenance schedule kalpui. Spindle hnathawh dan nena inmil lubricant tha tak tak hmang rawh.

l vibration monitoring : Vibration sensor dah emaw, portable analyzer hmang emaw chuan hun kal zelah vibration level track theih a ni. Vibrations chuan acceptable limits a pelh hunah alerts trigger turin thresholds set rawh.

l Lubrication Management : Lubricant level leh quality enfiahin lubrication dik tak neih theih a ni. Manufacturer recommended lubricant type leh reapplication interval hmangin friction leh wear tihziaawmna tur a ni.

l Environmental Control : Operation environment thianghlim tak vawng reng a, bearings leivut, bawlhhlawh emaw, tuihna emaw venna atana seal tha tak tak hmanga contamination tih tlem.

l Training and Awareness : Train operator leh maintenance personnel te chuan bearing chhiatna chhinchhiahna hmasa te, thawm pangngai lo emaw, performance inthlak danglamna emaw te chu an hriat theih nan leh an report nghal vat thin.

Spindle motor-a chhiatna thleng hian nghawng lian tak a nei thei a, mahse a hmaa hmuhchhuah chuan a chakna leh a chakna machinery te pawh a humhim thei a ni. Noise danglam tak tak, vibration tihpun, performance degradation, leh discoloration emaw odors emaw ang chi sign-te tana fimkhur reng chuan operator-te chuan an escalate hmain harsatna an hmu thei a ni. Spindle motor rintlak leh dam rei theihna tur atana thil pawimawh tak a ni. Heng symptoms zinga pakhat tal hmuh a nih chuan, chu harsatna chu enfiah leh hmachhawn turin rang takin hma la la, bearing specialist emaw, spindle siamtu emaw nen a tul angin optimal performance siam that leh turin inrawn rawh.

Tawpna

Spindle motor-a chhiatna thleng thei hi stealthy threat a ni a, a hlawhchham chuan a hlawhchham a, a downtime a, a man pawh a tlawm thei a, chu chu enkawl loh a nih chuan a ni. A chhante hriatthiamna hmangin—overload, contamination, leh neglect—leh vibration analyzer leh imaging technology ang chi hmanraw changkang tak tak hmangin, operator-te chuan thil awmte chu a hmain an hmu thei a, siamhatna action an la thei bawk. Maintenance guidelines zawm leh environmental controls kalpui hian bearings te chu harsatna atanga a humhim belh a, performance leh precision mumal tak a nei thei a ni. Bearings hian spindle motor a tichak a, proactive care leh informed strategies hmanga enkawl a pawimawh a, rintlakna nghet tak a awm theih nan a pawimawh hle. Tailored solutions atan chuan bearing manufacturer emaw spindle specialist emaw te nen inrawn la, i application bik atan bearing selection leh maintenance tha zawk siam rawh.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu