Inhmelhriattirna

CNC Machining-a chatter—all-too-familiar nuisance—chuan i part finish a tichhe thei a, i tooling a tichhia a, i productivity chu a bulpui berah a tisang thei bawk. Cutting laiin unwanted vibration a thleng thin a, chu screeching, rattling noise chu machine a kal laiin i hre tawh a nih chuan a takin i tawng tawh a ni. Mahse hetah hian thu lawmawm chu a awm: Chatter hi pumpelh theih loh monster engemaw zat a ni lo. Hriatna dik tak, hmanrua leh strategy hmang hian curb-ah i kick thei a ni.

Hetiang hian han ngaihtuah teh: Chatter hi CNC machining a ni a, radio broadcast-a static chu eng nge a nih. Thuchah chu a tichhe a, hnathawh that lohna a siam a, tihsual a thlen bawk. Machining-ah chuan chutiang tihsualte chu scrap parts, tool life tawi zawk, leh cost sang zawk a ni. Chuvangin, chatter tihbo hi quality tihsan mai mai a ni lo—i operation pumpui performance leh bottom line tihsan a ni.

He guide hian chatter chhan te, a hmuh theih dan tur te, a pawimawh ber chu a tihbo dan tur te a luhchilh ang. Machinist tawnhriat ngah tak i nih pawhin CNC khawvelah i ke a hnim mai mai emaw, he step-by-step blueprint hian actionable tactics a pe ang che, chatter silence leh precision thlenga i kalna tur kawng ti awlsam turin.

CNC Chatter hriatthiamna .

Definition leh chi hrang hrang chatter .

CNC Chatter tih hian self-excited vibrations a tih hian cutting process laiin a thleng tihna a ni. Workpiece surface-a repetitive wave angin a lang a, high-pitched noise a siam fo bawk. A chi lian pahnih a awm a, chungte chu:

1. Regenerative Chatter – A hmaa cutting pass tawh atanga tool leh workpiece inkar feedback loop avanga lo awm.

2. Mode Coupling Chatter – Vibration mode hrang hrang pahnih (lateral leh torsional ang chi) te chu an inzawm khawm chuan a lo chhuak thin.

3. Forced vibration chatter – pawn lam thil, motor imbalance emaw, bearings worn-out emaw ang chi atanga lo chhuak.

Heng chi hrang hrangte hian harsatna danglam tak an rawn thlen a, mahse an vai hian result inang an nei vek a ni: machining quality tihtlem leh hmanruaa wear and tear tihpun. I part-a squeal emaw noticing ridges i hriat chuan heng misual zinga pakhat hi i buaipui a nih a rinawm.

CNC Machining-a Chatter awm chhan

Chuti a nih chuan engvangin nge chatter hi a lo awm? Thil pakhat chauh a ni lo—a tlangpuiin thil chi hrang hrang inzawmkhawm a ni:

· Improper Cutting Parameters : Spindle speed sang lutuk emaw feed rate emaw hian vibration a tichak thei.

· Tooling chak lo emaw holders : rigidity awm loh emaw tool dik lo emaw geometry hian vibration a tichhuak thei.

· Poor fixturing : I chanvo chu him taka vawn a nih loh chuan eng movement pawh hi chatter episode-ah a spiral thei.

· Machine condition : Guideways loose, ball screw chhe tawh, leh misalignment zawng zawng hian a pui vek.

· Material Properties : Material thenkhat chu an hardness emaw elasticity emaw avang hian a dang aiin vibration an nei tam zawk.

A bulpui ber hriat chhuah hi thawm ri bengchheng tak tak tihreh nâna hmalâkna hmasa ber a ni—a ṭawngkam leh a lan dân chuan. I hriatthiam loh chu i siam tha thei lo.

Chatter hian CNC machining a nghawng dan .

A nghawngna hmun . |

Hrilhfiahna |

Nghawng |

Surface finish . |

Wavy patterns, workpiece-a hmanrua chhinchhiahna mumal lo tak takte |

Aesthetics tha lo, part rejection, dimensional dik lohna |

Dimensional a dikna . |

Vibrations hian hmanrua chu kawng atanga a kal bo tir thin . |

Out-of-tolerance parts, a hnathawh dan tihtlem . |

Hmanrua inbel . |

Vibration chhunzawm zel chuan edge chipping leh fracture a thlen thin. |

Hmanraw thlak fo, hmanrua man sang zawk . |

Machine a chhe tawh . |

Chatter hian stress a transfer a, machine components te chu a . |

Bearing damage, machine life tihtlem, enkawlna tihpun . |

cycle hun hman dan . |

Chatter awm loh nan feed rates slow zawk a ngai a ni . |

A siam chhuah hun rei zawk, efficiency tihtlem . |

A siam chhuah man . |

Scrap, rework, leh hmanrua chhiatna tihpun . |

Operational expenses sang zawk, profit margin tlahniam . |

Surface finish leh part quality a nghawng dan .

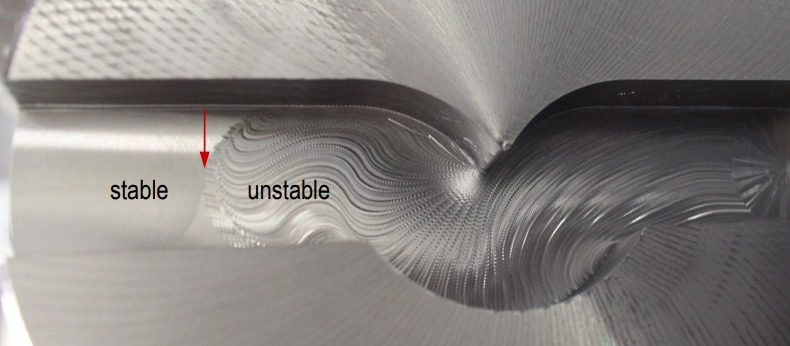

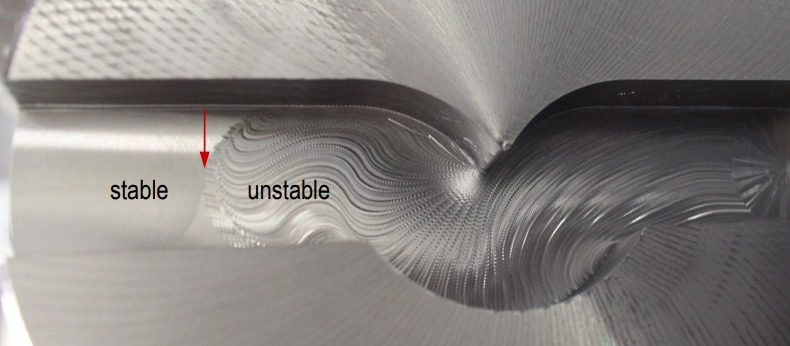

Chatter avanga thil thleng langsar ber pakhat chu surface finish tha lo tak a ni. I kut a khur lai hian pen hmanga ziak tum tum ang che—chu chu a bul berah chuan Chatter-a’n i cutting tool-a a tih ang kha a ni. Vibrations hian tool path mumal lo tak tak a siam a, chu chuan i lam atang chuan wave ang chi pattern a hnutchhiah a ni.

Heng imperfections te hi cosmetic mai mai an ni lo. Tight tolerances an compromise thei a, structural weakness an rawn luh tir thei a, part rejection an thlen thei bawk. Aerospace emaw medical ang chi industry-ah chuan, precision chu engkim a nihna hmunah chuan, chu chu deal-breaker a ni.

Chatter hian dimensional accuracy a nghawng bawk. I part chu a chung lamah a okay hmel a nih pawhin, thil dik lo thup hian performance failure a thlen thei a, a bik takin stress emaw load emaw hnuaiah a thlen thei a ni.

Tool wear leh machine life .

Chatter hi a part tan chuan a chhe mai mai lo—i tooling-ah chuan brutal tak a ni. Vibration chhunzawm zel hian cutting edge-ah micro-fracture a siam a, chu chuan tool wear a ti chak hle. End mill emaw insert emaw i thlak tam zawk ang a, chu chuan a adds up rang zawk ang.

Tin, i machine chungchang hi theihnghilh lo ila. Hun rei tak chhunga vibration-a i awm chuan bolt a tizau thei a, bearings a tichhia thei a, i CNC hmanrua te dam chhung a ti tawi thei bawk. Maintenance cost a sang a, ruahmanna awm lo downtime chu lu natna pangngai a lo ni ta a ni.

Production efficiency leh cost implications .

A tawpah chuan Chatter chuan a na ber na hmunah a rawn deng che a—i wallet. Surface finish tha lo tak tak te chu rework emaw, parts scrap emaw pawh a ngai a ni. Hmanrua thlak tam zawk a ngai. Machine te chu beisei loh takin an chhe vek a. Heng zawng zawng hian:

· Cycle hun rei zawk .

· Throughput hniam zawk .

· Hnathawh man a san .

· Deadline a awm loh chuan .

High-volume dawr i kalpui a nih chuan heng loss te hi a compound nghal vat thin. Mahse operation tenau te tan pawh a nghawng chu a pawimawh hle. Chatter ngaihthah man hi invenna atana investment aiin a tam zawk fo thin.

CNC hnathawh chhunga chatter hriatchhuah .

Hriatthiamna hman dan . |

Indicator te . |

Hmanrua/Techniques . |

Auditory chhinchhiahna 1.1. |

Cutting laiin squealing, rattling, emaw screeching noise sang tak nei squealing, rattling, emaw screeching thawm nei . |

Operator-in a ngaihtuah, acoustic emission sensor te |

Visual inspection . |

wavy surface finish, streak eng tak tak, cut lines inmil lo tak tak te. |

Post-process part enfiahna . |

Tool wear patterns . |

Unusual wear ang chi chipping emaw burning emaw to tool edges . |

Microscope, lens lian tham tak tak . |

Heat siam chhuah dan . |

Cutting laiin khaw lum lutuk emaw meikhu emaw . |

Thermal camera te, infrared sensor te pawh a awm bawk. |

Vibration tehna . |

Threshold pawm theih aia sang vibrations tehna . |

Accelerometers, vibration sensor te pawh a awm bawk. |

Cutting force feedback . |

Machining laiin cutting force-a spike awmte chu . |

Cutting Force Dynamometers, Torque Sensor te pawh a awm bawk. |

Hmuh theih leh hriat theihna chhinchhiahna .

Chatter hi a ri nasa tlangpui a—chu pawh chu rinhlelh rual a ni lo. Chu high-pitched squeal, grinding, or rattling noise chu i machine-in tanpuina a dil dan a ni. Ngaihsak lo mai mai suh. Red flag a ni a, thil pakhat off a ni.

Mahse, thawm mai mai a ni lo. I hre bawk ang:

· A chung lam thil ( wavy surface patterns) ('chatter marks' tia sawi fo thin')

· Streak eng mawi tak tak emaw, burnished area emaw .

· Hmanhmawh taka hmanrua hman tur .

· Cutting laiin khaw lum lutuk emaw meikhu emaw .

Heng symptoms te hi i ngaihven a nih chuan hmuh a awlsam hle. Run apianga parts enfiah thin chu tih dan tur siam la, a bik takin roughing emaw high-speed operation emaw neih laiin.

Diagnostic hmanrua leh hman dan .

I mit leh beng aia sang zawka kal i duh chuan diagnostic tools hi i thian tha ber a ni. Hmang:

· dial indicators . Machine looseness awm leh awm loh enfiah nan

· Accelerometer hmanga vibration tehna atan hman a ni.

· thermal imaging . Overheating zone te hriat theihna tur

· force sensor te cut . Tool engagement hriatthiam theihna turin

Heng hmanrua te hian surgical precision hmanga chatter awmna hmun chu a hriat theih nan a pui che a ni. I lo rin lawk a ngai lo—fixing ngai tih chiang takin i hre mai ang.

Chatter detection atan vibration analysis hmangin .

Vibration analysis hi i CNC machine atana MRI ang a ni. Frequency leh amplitude thlirletna hmang hian chu chatter chu a thleng tih chauh ni lovin—whert why.

Setup hmasawn tak takte chuan spindle-a sensor, tool holder, leh workpiece thlengin sensor nena inzawm software an hmang a. Heng system te hian vibration frequency te chu an map chhuak a, machine parameters nen an inzawm tir thin. He data hmang hian:

· Resonant frequency awm loh nan speed siamrem theih a ni .

· I spindle emaw tool holder emaw kha balance rawh .

· Chatter a awm theih hun tur hrilhlawk rawh .

He proactive approach hian kangmei vengtu atanga strategist-ah a chantir che a—a tan hmain chatter chu venhim rawh.

Chatter tihbo theihna tur technique finfiah tawh .

Cutting parameters te optimize .

I cutting parameters dik tak hmuh hi chatter silence na kawng tha ber pakhat a ni. Musical instrument tuning ang maiin han ngaihtuah teh: adjustment tenau te hian engkim a perform danah khawvel danglamna a siam thei a ni.

Spindle speed leh feed rate siamrem dan .

Vawi tam tak chu chatter tihbo theihna tura hmalakna hmasa ber chu i spindle speed tweak hi a ni. Hetah hian trick chu a awm—10%-a inthlak danglamna tenawm tak tak, 10%-a inthlak pawhin, i operation chu resonant frequency range aṭangin a sawn chhuak thei a ni. Feedback loop-a brake kah ang mai a ni.

tia hriat chu hmang la 'spindle speed variation' (SSV) —chu chu CNC feature a ni a, a cut laiin spindle speed a danglam thei. Hei hian regenerative chatter rhythm chu a ti chhe a, a siam hmain a titawp a ni.

Chutiang bawkin feed rate tihpun emaw tihhniam emaw hian vibration a ti tlem thei bawk. I cut chak lutuk a nih chuan, hmanrua chu a tam zawk thei a, chu chuan instability a thlen thei a ni. A slow lutuk a nih chuan, hmanrua chu cut ai chuan a rub mai thei—chuan chatter recipe pawh a ni thei.

Tips pawimawh tak tak:

· Manufacturer-te suggested speed leh feed te chu reference fo thin ang che.

· Engagement dik tak neih theih nan chip load calculator hmang ang che.

· Test cuts run pawh hlau suh, variation tlem te te.

Depth of cut leh tool engagement .

Chatter hnung lama thil tisualtu lian dang chu depth of cut (doc) emaw width of cut (WOC) emaw a ni . I hmanrua hian a ei theih aia tam a bih a nih chuan a au chhuak dawn a ni—literally.

Heng hmanrua te hi han en ve teh:

· Vibrations a stabilize hma loh chuan doc chu a pung zel ang.

· hmang rawh . Radial engagement strategy —trochoidal milling ang chi—chu hmanrua pressure mumal tak neih theih nan

· Deep cuts chu pass tam takah then rawh.

Workpiece chhunga tool chhunga a luh dan balance hi stable machining atan a pawimawh hle. A châng chuan, slow, rit tak tak aiin pass pass light mahse rang tak tak a thawk ṭha ṭhin.

Tooling thlan leh tool geometry .

I cutting tool chu operation a MVP a ni. Mahse a type dik lo, a pianzia, a material dik lo a nih chuan chatter chu tihtawp ai chuan a amplify thei a ni.

hmanrua hmanrua leh coating .

Tool material hrang hrang hian stiffness leh vibration-dampening property hrang hrang a pe a:

· Carbide hmanrua hi high-speed steel (HSS) aiin a rigid zawk a, chu chuan chatter dona kawngah a ti tha zawk.

· Coated tools (tin emaw altin ang chi) hian friction a tihziaawm a, chu chuan lumna leh vibration a tihniam a ni.

I material hmanga combination dik tak hman (aluminum vs. titanium, entirnan) hian danglamna zawng zawng a siam thei a ni.

Geometry adjustment te chu stability a awm theih nan .

He hmanrua geometry hi machinist tam zawkin an hriat aiin a pawimawh zawk. Bei:

· helix angle danglam thei . Harmonic vibrations tihchhiat nan

· flute spacing inang lo . Vibration synchronization awm lohna turin

· overhang tawi zawk . Rigidity tam zawk neih theih nan

· Core diameter lian tak tak, chakna belhchhah tur.

Variable pitch nei 3-flute end mill chuan chatter control chungchangah chuan standard geometry hmanga 4-flute chu a phak lo thei. Trial and error a ni fo thin a, mahse sweet spot i hmuh chuan finish smoother leh quiet zawk runs i hmu ang.

Machine setup leh enkawl dan .

Fixturing leh workpiece clamping te pawh a awm bawk.

I chanvo chu nghet taka chelh a nih loh chuan a vibrate ang. Hunbi. Hnathawh dik tak tur chu chatter-free machining dinna lungphum a ni.

FixTuring tihchangtlun dan tur tips:

· hmang rawh Rigid, vibration-dampening vise emaw clamp emaw .

· dah tur . overhang awm thei ang bera Workpiece- a

· hmang ang che . step block emaw custom jig emaw Stability tihpun nan

· ngaihtuah rawh —mahse, an rigidity chu a tichak zawk ang. vacuum table Flat part-te tan

Parts nalh tak tak tan chuan soft jaws emaw custom fixtures emaw a ngai thei a, chu chuan deformation awm lovin security a awm theih nan a pui thei a ni.

Machine rigidity leh alignment .

I CNC machine ngei pawh hi hnathawh tur a nih loh chuan hmanraw leh setting tha ber ber pawh a pui dawn lo.

Check rawh:

· Slide emaw kawng emaw a lo chhuak .

· Ball screw chhe tawh tak tak te .

· Spindle misalignment 1.1.

· Table Vibration . Operation neih chhunga

Heng hmunte hi tihkhauh hian vibration transmission nasa takin a ti tlem thei a, cut apiang quality a ti tha thei bawk.

Routine maintenance leh calibration .

Thil an tihchhiat hunah thil siam that mai mai suh. an tihchhiat loh nan ven rawh.

Maintenance checklist pangngai siam rawh:

· Kaihhruaina leh screw te chu a hmin theih reng e.

· Bolt leh connection te kha tikhauh rawh .

· Spindle balance leh bearing health enfiah .

· Thla engemaw zat chhungin axes te chu re-calibrate leh rawh .

Machine enkawl tha tak chu chatter-resistant machine a ni. Preventive care hian harsatna chu hmanrua a thlen hmain a ti bo thei fo thin.

Chatter mitigation atana hmasawnna tur advanced solutions .

Damped tool holder hman dan .

Damped tool holder te hi i cutting tools te tan shock absorber ang mai an ni. Vibrations atanga energy chu critical level a thlen hmain an absorb thin.

Heng neitute hian polymer emaw, holder body chhunga tuned mass dampers ang chi thil an nei fo thin. A result chu? Vibration nasa takin a ti tlem a, hmanrua a rei zawk a, finish pawh a ti tha zawk.

A bik takin ah te an tangkai hle a, deep-pocket milling leh long-reach application- chutah chuan standard tools te chu an resonate duh hle.

Variable pitch leh helix hmanrua te .

nei tools te Variable pitch emaw variable helix hian flute geometries an nei a, chu chu tumruh taka inthlau tak a ni. Hei hian cutting forces symmetry a tichhia a, vibration buildup a tibuai bawk.

Flute zawng zawng hian frequency inangah material an engage ai chuan variable spacing hian force load a thehdarh vek a ni. Hei hian harmonic buildup neih theihna a ti tlem a, regenerative chatter chu practically-in a ti bo bawk.

Hengte hi:

· Hnathawh chak tak tak neih a ni .

· Thin-walled parts .

· Aerospace-grade hmanrua te .

Vibration Dampening Systems 1000 a awm bawk.

High-end CNC system thenkhatah chuan built-in vibration dampener a awm a, a nih loh leh external add-ons a awm thei bawk:

· active dampening system hmanga siam a ni. Sensor leh actuators hmanga

· magnetic dampers a awm bawk. Spindle assembly atan

· dampers tam tak awm chu . Spindle housing chhunga

A man to viau nachungin, heng system te hi ultra-precision work-ah chuan a hlu hle a, chutah chuan surface finish leh dimensional integrity chu a pawimawh ber a ni.

CAM software leh simulation .

Software hmanga chatter prediction .

Modern Cam (Computer-Aided Manufacturing) software hian toolpath siam chhuah mai aia tam a ti a—tunah chuan thil pakhat i khawih hmain chatter a hrilhfiah thei tawh a ni. Chu chu i machining process atan crystal ball neih ang mai a ni.

Advanced Software Tools hian mathematical model leh machining dynamics hmangin chatter a awm theih hun tur a sawi lawk a, chu chu:

· Thil neih theihna (Material Properties) .

· Hmanrua geometry .

· Parameter hrang hrang a cut .

· Machine hmanga thil awm dan .

Heng prediction te hmang hian digital phase ah i setup i siamrem thei a, hun, material leh tool life te pawh i save thei bawk. ang programme te Machiningcloud , Vericut , emaw NC Simul hi chatter analysis leh prevention chungchangah chuan industry duh ber an ni.

Toolpath optimization hman dan tur .

Toolpath design hian direct takin chatter a nghawng a ni. Pattern thenkhat chuan vibrations a thlen a, thenkhat chuan natural takin an dampen thung.

Hetah hian i tih tur chu:

· hmang ang che . high-speed machining strategy Tool engagement tihtlem nan leh force te tihngheh nan adaptive clearing ang chi

· I toolpaths-a directional change rang tak emaw, corner nalh tak tak emaw chu pumpelh rawh.

· awm reng thin. Tool deflection tihtlem thei tur tool engagement technique

Smarter toolpaths tih awmzia chu balanced cutting forces tam zawk tihna a ni a, chu chu smoother, chatter-free finish-ah a chantir a ni.

Real-time simulation leh feedback .

CAM solution thenkhat chuan machine-a sensor dah hmangin real-time feedback loop an inzawm khawm a. Heng system te hian spindle vibration, cutting force, leh acoustic emission te chu real-time-in an enfiah thin. Chatter a lo thang tan a nih chuan hetiang hian an ti thei ang:

· Operator hnenah alerts thawn rawh .

· Feed/speed on-the-fly ah automatic in adjust theih a ni .

· Post-process analysis atana log data .

He proactive layer of chatter control hi a bik takin automated emaw lights-out machining environment- ah chuan manual monitoring tih theih lohnaah a tangkai hle.

Operator training leh thil tih dan tha ber berte .

Operator thiam tak takte pawimawhna .

Hmanraw tha ber ber, software fing ber ber, leh rock-solid machine i nei thei a—mahse, i operator-in experience a neih loh chuan chatter chuan kawng a zawng ang.

Machinist thiam tak chuan:

· Cut tha leh tha lo inthlauhna hriat .

· Vibrations fiah lo tak tak a awm .

· Tool marks chauh hmanga chatter hmuhchhuah .

Operator thiam tak takte pawhin engtikah nge an inrawlh ang a, hmanrua an thlak ang a, settings chu real-time-in an siamrem ang. An instinct, dawr chunga darkar sang tam tak chhunga lo thanglian chu thlak theih loh a ni.

Zirna chhunzawm zel tura fuih. I team hmasawnna tur ah invest rawh. Smart operator hi Chatter laka i defense line hmasa ber a ni.

Zirna leh workshop neih chhunzawm zel .

Machining khawvel hi a lo thang chak hle a, hma la zel tur chuan training kalpui zel a ngai a ni. Host emaw attend emaw:

· In-house workshop-ah chuan chatter diagnostics lam hawi a ni.

· Vendor kaihhruai seminar te chu tooling leh cutting technique thar hmanga siam a ni.

· online course leh certification te Coursera, Tooling U, emaw LinkedIn Learning ang chi platform atanga

Hriatna chu thiltihtheihna a ni—chuan CNC machining-ah chuan scrap tihtlem theihna, quality tihsan theihna, leh machine life tihzauh theihna thiltihtheihna a ni.

Industry entirnan leh case study te .

Khawvel tak tak hlawhtlinna chanchin .

Company thenkhatin chatter an tihbo dan leh production an tihchangtlun dan hi han en ila:

Ohio-a Aerospace siamtute chuan an siam chhuak a.

Buaina: Deep-pocket aluminum parts-a chatter .

Solution: Variable helix end mills ah a inthlak a, damped holders a dah belh bawk.

Result: Cycle time 30% a tihtlem, finish grade RA 6.3 μM atanga RA 1.2 μm a tihsan

Germany rama Automotive Supplier te chuan an rawn ti a.

Buaina: Hmanraw inbel tam lutuk leh a chung lam chhiatna .

Solution: CAM feedback hmanga real-time vibration monitoring kalpui a ni.

Result: Tool life 40% a sang a, a part hnawl a tlem zawk

California-a damdawi hmanrua dawr .

Buaina: Titanium implant te tak tea chatter .

Hrehawmna chinfel dan: Toolpath strategy tha ber, high-rigidity fixtures tih belh

Result: ±0.005 mm tolerance a thleng thei reng a ni.

Heng entîrnate hian industry emaw, thil emaw eng pawh ni se, ruahmanna dik tak hman chuan hmasawnna tak tak, teh theiha siam ṭhatna a thlen tih a târ lang a ni.

CNC professionals te hnen atanga zir tur zir tur

Machinist seasoned tu pawh biak la, an hrilh ang che—chatter hi thil buaithlak tak mai a ni lo; Dawr thattu a ni. Harsa taka an zir chhuah chu hetiang hi a ni:

· Sign hmasa te chu ngaihthah ngai suh—chatter chu a na zual fo thin.

· Fast setup aiin rigid setup a pawimawh zawk.

· Test cut leh documentation te hi i thian tha ber a ni.

· Tooling man tlawm tak chu hun rei tak chhung atan a man a to zawk.

Dawr floor finna ngaihthlak chu manual chhiar ang bawkin a pawimawh hle. Real-world experience hi gold a ni a, chatter diagnose leh solve chungchangah hian.

Thil tihsual tlanglawn tak takte chu pumpelh theih a ni.

Machine calibration thlir theihna .

Machine calibrated tha lo tak chu car ang mai a ni a, a wheel misaligned a ni. Sure, a che ang—mahse a awlsam lo. Regular calibration hian axes zawng zawng align vek a, backlash tih tlem a, components te chu harmony-a hnathawh a nih theih nan a enkawl bawk.

A dik lo tlangpui:

· Alignment chungchanga harsatna tenau te ngaihthah .

· Scilled maintenance skipping .

· Part crash hnua recalibrate theih loh .

Brand-new machine pawhin calibration check hmasa ber aṭangin hlawkna a hmu thei a ni—factory settings chu a ṭha famkim ang tih ring suh.

Tooling dik lo hman dan .

Hmanraw dik lo hman chu screwdriver i mamawh hunah hammer hman ang a ni—a hlawhtling lo mai ni lovin, a tichhe thei hle.

Tooling lama tihsual tlangpui:

· Long-reach hmanrua te chu shallow cuts atan .

· Gummy materials atana flute tam lutuk .

· Tool coatings pawimawhzia ngaihthah .

· Material hardness nena inmil lo geometry .

Hna thar i thawh hmain i tooling supplier emaw rep emaw zawt hmasa phawt ang che. Minute nga chhunga call chuan darkar tam tak rework a ti tlem thei.

Chatter venna atana technology hman dan .

IoT leh smart machining system hmanga siam a ni.

Industrial Internet of Things (IIOT) chuan CNC machining a thlak danglam mek a ni. Smart sensor, machine, spindle, leh hmanruaa embedded te chuan vibrations, temperature, leh cutting force te chu real-time data an khawlkhawm thei a ni.

He data hi dashboard emaw cloud platform emaw-ah an dah a, hei hian predictive adjustment a siam thei a ni:

· Vibration hian limit a pelh hunah speed a tihhniam .

· Chatter hian tooling a tichhia hmaa operator te hriattir .

· Extreme conditions a awm chuan machine chu khar .

Heng smart system te hian chatter an detect mai mai lo—a ven theih nan active takin an thawk a ni.

Predictive maintenance hmanrua te .

Predictive maintenance chuan machine component a chhiat hunah data leh analytics hmangin a lo thlir lawk thin. Chatter control na tur game-changer a ni.

A hlawkna te chu:

· Bearing wear hriat chhuah hmaa spindle vibration a thlen hmaa .

· . Linear rail-a looseness venna

· Production tihbuai lohvin downtime schedule .

Thubuai siamin chatter a thlen hmaa a chinfel chuan, predictive maintenance chuan i dawr chu a kal tluang a, ngawi rengin a awm reng a ni.

CNC boruak chatter-free siam theihna tur siam .

Lean siam chhuah dan inzawmkhawm .

Chatter control hi a pianphungah chuan lean manufacturing principle ah a inmil a ni . Bawlhhlawh tihtlem te, flow tihchangtlun te, leh quality mumal tak neih te nen a inmil a ni.

Chatter puitu lean tools:

· Kaizen thilthlengte chu a zung (root causes) tihbo nan .

· hman tur Standard Work dan tur . Machine setup atana

· 5S programme . Environment thianghlim leh nghet tak neih theihna tur

A lean, organized workspace chuan chatter a hring fo thin buaina chu a ti tlem a ni.

Standard Operating Procedures (SOPS) 1.1.

A tawp berah chuan engkim document vek rawh. SOP siam la, chutah chuan:

· Material tin atan ideal cutting parameters .

· Machine warm-up leh calibration routine te .

· Tooling thlan chhuah checklist te .

· Nitin machine enfiah dan tur kaihhruaina .

SOP chiang tak, awlsam taka hman theihte chuan operator tinte chu—a thar emaw, a hun lai emaw—a ṭanpui a, chu chuan thil tih dân ṭha ber berte chu a zawm a, chu chuan thusawi chu a ti buai reng a ni.

Tawpna

Chatter hi CNC machining-ah chuan harsatna tlangpui a ni thei a, mahse pumpelh theih loh a ni lo. A chhan hriatthiamna chiang tak leh hmanrua dahna hmanrua (toolbox) chu strategic fixes tam tak awmna nen—cutting parameters atanga software leh hardware upgrading thlengin—shop environment quiet, efficient leh productive tak i siam thei a ni.

Chatter hian i precision chu a tichhe lo va, i thil neihte pawh a tichhe lo va, i hlawkna pawh a tichhe lo. Proactive takin awm la, zirna sang nei la, chatter control chu i CNC strategy bulpui ber atan en rawh.

FAQS 1000 a ni.

1. Engtin nge ka CNC machine hian chatter a tawk em tih ka hriat theih ang?

Cutting laiin high-pitched noises zawng la, i workpiece-a visible wave patterns, leh rapid tool wear emaw surface damage emaw chhinchhiahna zawng rawh. Real-time vibration sensor hian a hmain a lo hmu thei bawk.

2. Chatter hi tihbo vek theih a ni em?

Thil awmdan zawng zawngah 100% pumpelh theih a nih loh laiin, technique leh hmanrua dik tak hman chuan zero hnaih takah a tihtlem thei a ni. Experience leh setup dik tak nen chuan parts te chu a hun apiangah awlsam takin i run thei.

3. Chatter tihtlem nan hian eng nge a man tlawm ber?

Feed rates siamrem emaw, hmanraw tawi zawk hman emaw ang chi fix awlsam tak tak hmangin tan la rawh. I CAM software-a toolpath optimization leh fixturing tha zawk pawh a man tlawm a, mahse a hlawk hle bawk.

4. CNC machining-ah hian engtin nge temperature hian chatter a nghawng?

Temperature sang zawk chuan thermal expansion a thlen thei a, chu chuan misalignment a thlen thei a, vibration susceptibility a tipung thei bawk. I cutting environment-ah thermal stability vawng reng turin a pawimawh hle.

5. Chatter siam that nan ka CAM software hi ka thlak tur em ni?

Tuna i software hian simulation emaw chatter prediction features emaw a neih loh chuan upgrading hi a hlu thei hle. Tunlai cam solutions hian programming stage atanga chatter awm lohna tura puitu analysis tools chak tak a pe a.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu