CNC (computer numerical control) machine leh precision engineering application dang ah chuan servo motor leh spindle motor te hi system hnathawh tichaktu thil pawimawh tak an ni. An pahnih hian CNC system kalpui dan atana electric motor integral an nih laiin, an hnathawh dan bik nena inmil characteristic hrang hranga siam an ni. Servo motor leh spindle motor inthlauhna hriatthiam hi a pawimawh ber a, a component dik tak thlan nan te, machine performance tihchangtlun nan te, precision machining-a result quality sang tak neih theihna tur te a ni. He thuziak hian heng motor chi hnih inkara danglamna pawimawh tak takte chu a chhui chhuak a, hobbyist, professional machinist leh engineer-te tan chiang zawka hriat theihna turin an hnathawh, an design, an hman dan leh an hnathawh dan an zir chiang a ni.

Servo motor te hi eng nge ni?

Servo Motors hi CNC (Computer Numerical Control) machine leh precision engineering application dang danga position, velocity leh torque control dik taka hman theih tura siam, specialized electric motor sang tak a ni. Anni hi CNC machine-a axes (eg, X, Y, Z) emaw components emaw, robotic system-a components emaw, hmanrua emaw, workpiece emaw chu programmed ang chiaha dah a nih theih nan a kal dan dik tak thlentu an ni. Standard motor ang lo takin Servo Motors hian closed-loop control system chhungah hna an thawk a, encoder emaw resolver ang chi feedback device hmangin CNC system-a instruction nena inmil turin an performance an enfiah chhunzawm zel a, an siamrem zel bawk. He precision leh adaptability hian servo motors chu a pawimawh hle a, hna thawh tur dik tak leh dynamic control a ngai a, chu chu industry atanga robotic thlengin a ni.

Servo Motors hi engineer-te chu a nihna bik neia engineer an ni a, chu chuan high-precision application-a hman theihna a siam a ni. A hnuaia tarlan te hi an hnathawh dan tur sawifiahtu leh motor chi dang, spindle motor ang chi atanga thliar hrangtu thil pawimawh tak takte an ni:

Closed-Loop Control

Servo Motors hian closed-loop system-ah an thawk a, chu chu an awmna tak tak, an tlan chakna leh torque te enfiah turin sensor (eg, encoder emaw resolver emaw) atanga feedback an dawng chhunzawm zel tihna a ni. He feedback hi CNC control system atanga value duh zawng nen khaikhin a ni a, a inmil lohna apiang chu motor output siamrem hmangin real-time-in siamthat a ni. He closed-loop control hian exceptional accuracy a siam a, servo motors te chu application atan a tha hle a, chutah chuan deviation tenau te pawhin quality a nghawng thei a, chu chu CNC machining emaw robotic arm positioning emaw a ni.

High precision

servo motor hian micro-adjustment a nei thei a, chu chuan millimeter emaw degree emaw fractions-ah a ti tlem thei a ni. He precision hi complex geometries milling, drilling precise holes, emaw multi-axis CNC machine-a positioning tools ang chi hna thawhna atan a pawimawh hle. Entirnan, 5-axis CNC machine-ah chuan Servo Motors chuan axis tinte chu aerospace emaw, medical application emaw atana part intricate siam turin dik takin an kalpui tih an enfiah thin.

Variable speed leh torque

servo motor te hian speed hrang hrangah an thawk thei a, consistent torque an pe thei a, hei hian dynamic application atan a versatile hle. Control dik tak an vawn laiin an tlan chak thei a, an tlahniam thei a, an tawp thei bawk a, hei hi CNC machining-a contouring emaw threading emaw ang chi, motion-a inthlak danglamna rang tak mamawh hna thawhna atana pawimawh tak a ni. Hetiang flexibility hian Servo motor te chu load hrang hrang leh machining mamawhna hrang hrangah a insiamrem thei a ni.

Compact Design

Servo Motors hi a tlangpuiin compact leh lightweight a ni a, CNC machine emaw robotic system emaw space constrained chhunga dah theih tura siam a ni. An size te tak te hian dynamic, multi-axis motion a siam thei a, machine-a thil che thei te chu rit lutuk belh lovin a siam thei bawk. Hei hi high-speed application-ah chuan a pawimawh hle a, chutah chuan inertia tih tlem hi responsiveness leh accuracy atan a pawimawh hle.

Servo Motor chi hrang hrang

Servo Motors hi variant engemaw zat a awm a, application bik atan a tha vek a ni:

AC Servo Motors : Powered by alternating current, heng motor te hi an robust a, industrial CNC machine-ah pawh an power sang leh an durability atan an hmang tlangpui. Control dik tak atan variable frequency drive (VFDs) nen an paih fo thin.

DC Servo Motors : Direct current hmanga power pek a nih avangin heng motor te hi a awlsam zawk a, a te zawk emaw, a mamawh lo zawk emaw hman thin, hobbyist CNC setup ang chi te pawh an hmang fo thin. Brushed DC Servo motor hi maintenance mamawh avangin a tam lo hle a, brushless version erawh chu efficiency atan a tha zawk thung.

Brushless DC Servo Motors : Hengte hian DC motor-te hlawkna leh a chhe thei lo leh an thawhrimna a tha zawk a, brush mamawhna a ti bo a ni. Tunlai CNC machine-ah chuan an enkawlna hniam leh an performance sang avangin an hmang nasa hle.

| Servo Motor Type |

Thuziak |

Pros |

Cons |

hman dan |

Key characteristics . |

| AC Servo Motors 1000 a ni. |

Powered by alternating current, heng motor chak tak tak te hi high-power industrial application atana siam an ni a, a tam zawkah chuan variable frequency drive (VFDs) nen an paih a, speed dik tak leh torque control nan an hmang thin. |

High power output, continuous operation atana durability tha tak, VFDs hmanga control dik tak, heavy-duty task atana tha. |

Motor leh VFD complexity vangin cost sang zawk, footprint lian zawk neih a ngai a, complex setup leh programming a ngai a ni. |

Industrial CNC machine, milling lian tak tak, drilling, robotics, leh automotive/aerospace industry-a automation te. |

Speed hniam takah torque sang, construction nghet tak, speed range zau tak (1,000–6,000 rpm), a tlangpuiin 1–20 kW power rating. |

| DC SERVO MOTORS 1000 a ni. |

Direct current hmanga power pek a nih avangin heng motor te hi a awlsam zawk a, application tenau zawk emaw, mamawh tlem zawk emaw-ah an hmang thin. Brushed emaw brushless configuration-ah te a awm a, brushed chu maintenance mamawhna avangin a tam lo hle. |

A man tlawm, a rit lo, control system awlsam tak, power tlem zawk hmanna atana tha. |

Power output tlemte, brushed version te hian maintenance sang (brush wear) an nei a, hun rei tak hman a nih chuan a lum lutuk thin. |

Hobbyist CNC setups, desktop router te te, automation task awlsam tak tak, PCB milling emaw light engraving emaw ang chi, power hniam tak application te pawh a awm thei. |

Torque hniam zawk, speed range 2,000–10,000 rpm, power ratings a tlangpuiin 0.1–1 kW, AC motor aiin a chhe thei lo zawk. |

| Brushless DC Servo Motors te pawh a awm bawk. |

DC motor subset, hengte hian brush aiah electronic commutation an hmang a, efficiency leh durability tihchangtlunna an pe a ni. Tunlai CNC system-a an balance of performance leh low maintenance atan hman lar tak a ni. |

Efficiency sang, enkawl tlem, dam rei zawk, compact design, speed range zau tak huam chhunga performance tha tak. |

Brushed DC motor aiin initial cost sang zawk, electronic controller a mamawh a, hna rit tak tak thawh nan AC servo motor aiin power a tlem zawk. |

Tunlai CNC router, precision robotics, 3D printer, damdawi hmanrua, leh rintlakna sang tak leh chiang taka mamawh application te. |

Efficiency sang (90% thleng), speed range 3,000–15,000 rpm, power ratings 0.5–5 kW, heat generation hniam tak a ni. |

CNC machine-a chanvo .

CNC system-ah chuan servo motor-te hian machine-a axes linear emaw rotary motion control-na hna an thawk ber a ni. Entir nan:

CNC router-ah chuan servo motor-te chuan X, Y, leh Z axes-te chu an khalh a, chu chuan spindle emaw, cutting tool emaw chu workpiece chungah dik takin a dah a ni.

CNC lathe-ah chuan servo motor chuan workpiece rotation (a ṭhenah chuan spindle anga thawk) emaw, cutting tool movement emaw a control thei a ni.

Multi-axis machine-ah chuan servo motor hian complex movement a siam thei a, chu chu 4- emaw 5-axis configuration-a workpiece emaw tool emaw tilt emaw rotate emaw ang chi a ni.

An theihna dik tak, repeatable motion an pek theihna hian servo motors te chu tight tolerances vawng reng tur leh aerospace, automotive, leh medical device siamna atana hman tur finish quality sang tak neih theihna atan a pawimawh hle. CNC machine-a control system nena inzawm chuan Servo Motors chuan programmed G-Code instructions chu physical movement-ah an letling a, machine chuan toolpath duh chu error tlemte nen a zawm tih a tichiang a ni.

Practical ngaihtuah tur .

CNC application-a Servo Motor thlan emaw, hman emaw hunah chuan a hnuaia mi hi ngaihtuah rawh:

Feedback System : Motor-a feedback device (eg, encoder resolution) chuan i application-a precision mamawh a tlin ngei ngei tur a ni.

Power and Torque : Motor power leh torque te chu CNC machine axes load leh speed mamawh nen a inmil tur a ni.

Control System Compatibility : Servo motor chu machine controller nen a inmil em tih finfiah la, PLC emaw CNC software ang chi te chu seamless integration a awm theih nan.

Maintenance : Feedback device, wiring, leh connection te chu performance issue emaw electrical fault emaw ven nan enfiah fo thin ang che.

Servo motor-te precision, control, leh versatility hmang tangkaiin, CNC operator-te chuan an machining process-ah accuracy leh efficiency danglam tak an nei thei a, heng motor-te hi tunlai precision engineering lungphum a ni.

Amazon-a Spindle Motors lei duh tan hetah hian click la.

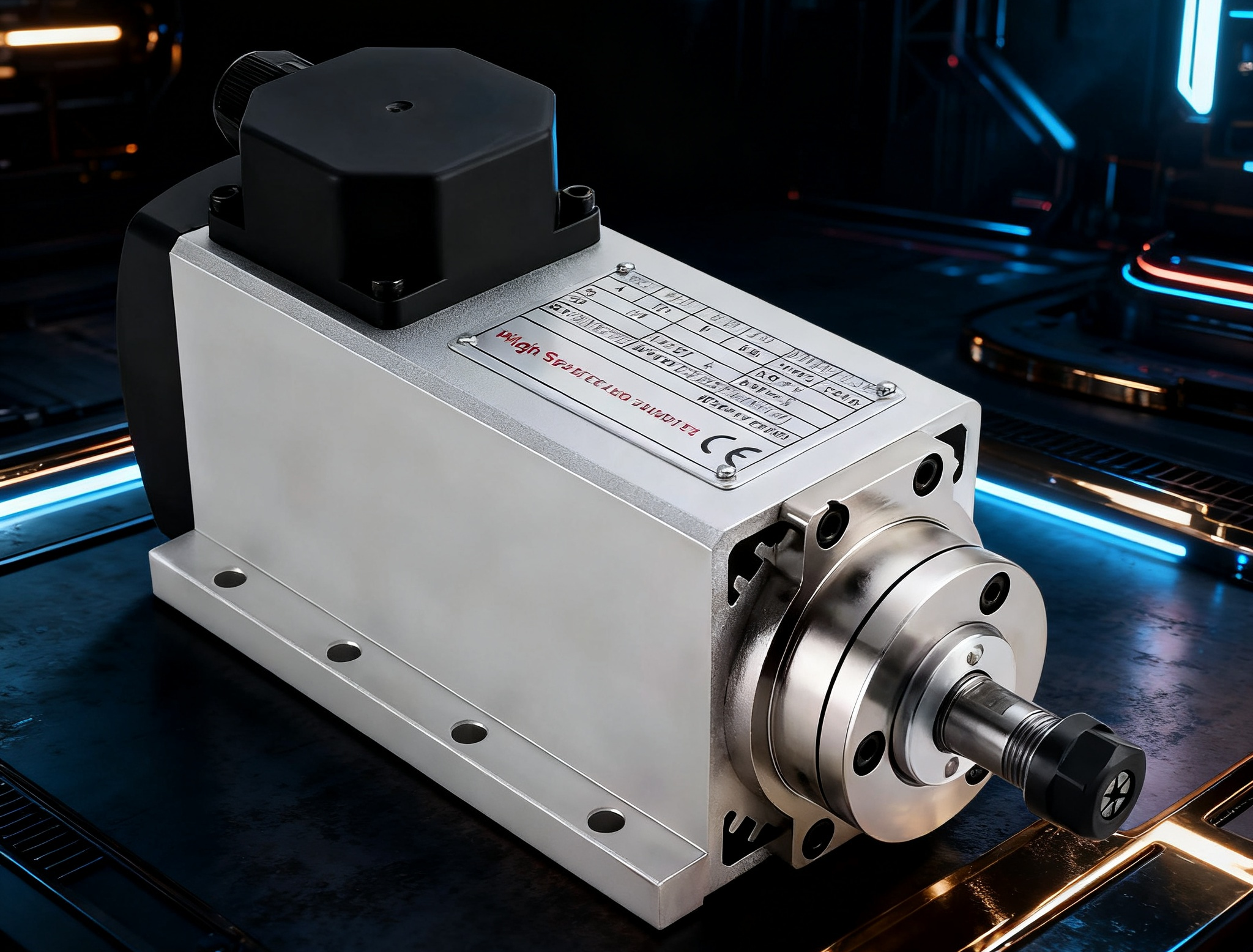

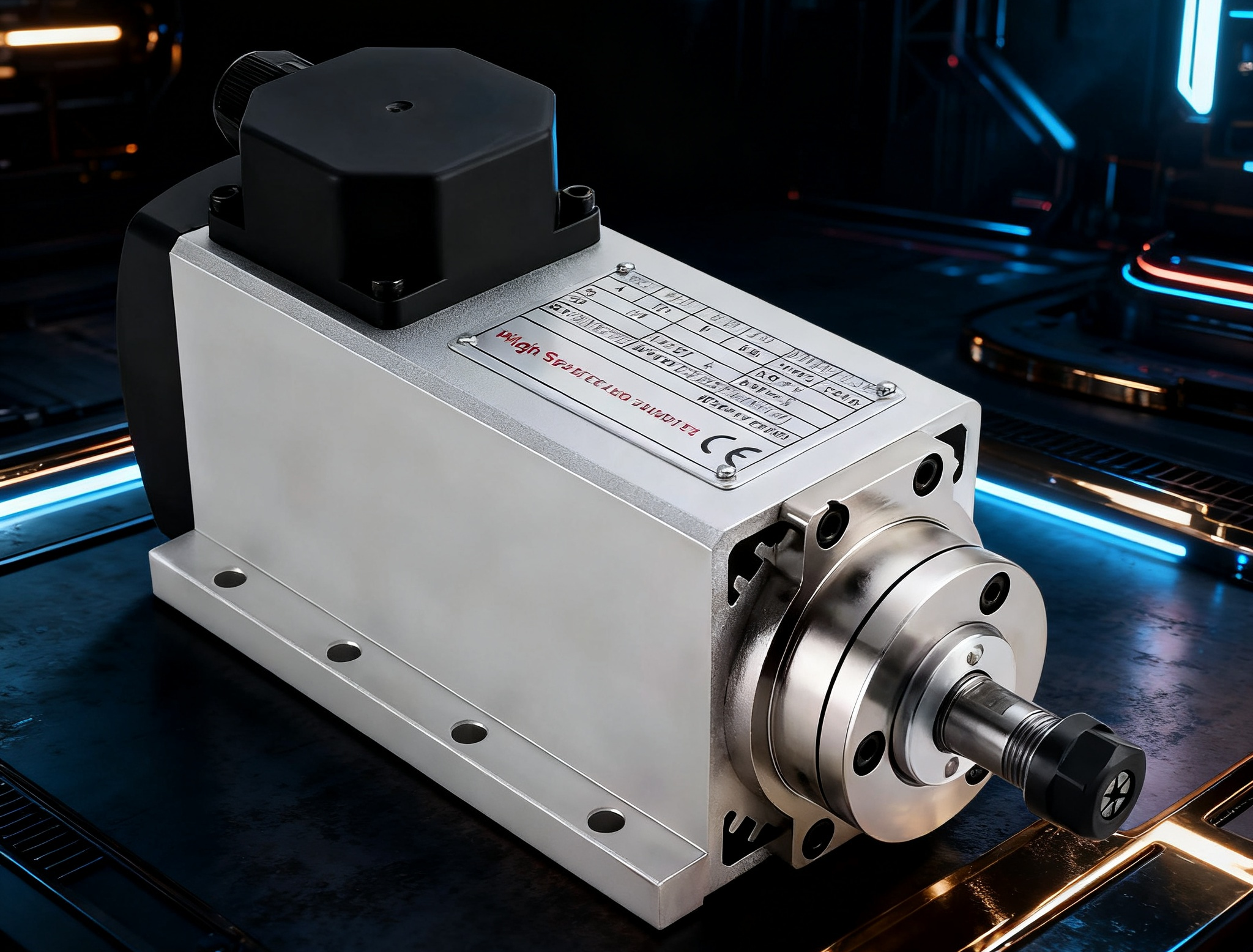

Spindle motor hi specialized electric motors a ni a, CNC (Computer Numerical Control) machine-a cutting, milling, drilling, emaw engraving process te chu speed sang taka cutting tools emaw workpiece emaw rotate-in a khalh thei a ni. CNC system-te powerhouse a nih angin, spindle motor-te chuan workpiece-a thil awmte paih chhuahna atana mamawh rotational force leh power an pe a, chu chuan machining task-a duhthusam ang chiah, a tawp leh dik taka an tih theih nan a pawimawh hle a ni. Servo motor ang lo takin, positional control dik tak ngaihtuah a ni a, spindle motor te chu continuous, high-speed rotation atan optimized an ni a, chu chuan tool emaw workpiece emaw ah consistent power a pe thei a ni. Thil chi hrang hrang, thing nem tak tak atanga hard metal thlenga hman theih tura siam an ni a, thil siamchhuah, thinga siam, leh metalworking ang chi industry-a hmanna atan an pawimawh hle bawk.

Spindle Motors-a thil pawimawh ber berte

Spindle motor hi characteristic bik neia siam a ni a, chu chuan machining task-ah rotational speed sang tak leh power delivery robust a ngai a ni. A hnuaia tarlan te hi an hnathawh dan tur sawifiahtu leh motor chi dang, Servo Motors ang chi atanga thliar hrangtu key features te an ni:

High-speed rotation

spindle motor hi high revolutions per minute (RPM)-a thawk thei tura siam a ni a, a tlangpuiin a hman dan azirin 6,000 atanga 60,000 rpm emaw a aia sang emaw a ni. Hetiang high-speed capability hian engraving, micro-milling, emaw high-speed cutting ang chi hna an thawk thei a, chutah chuan rapid tool rotation hi precision leh smooth finish atan a pawimawh hle. Entirnan, spindle motor 24,000 rpm-a tlan chu metal emaw plastic emaw-a design inthup tak tak engraving atan a tha hle a, speed hniam zawk (6,000–12,000 rpm) chu steel milling ang chi cutting task rit zawk a ni.

Power delivery

Spindle motor-te ngaih pawimawh ber chu machining laiin material tha taka paih chhuah theihna tur torque leh power tling tak pek chhuah a ni. Power ratings hrang hrang (0.5–15 kW emaw 0.67–20 hp emaw a awm thei, spindle motor te hi material hardness leh machining task intensity atanga thlan a ni. High-power spindles hian titanium ang chi dense materials tanna atana mamawh torque a pe a, lower-power spindles te chu thing emaw foam emaw ang chi thil nem zawk atan chuan a tawk bawk. He power delivery-a kan ngaihtuahna hian load hrang hrang hnuaiah performance mumal tak a siam thei a ni.

Open-loop emaw closed-loop control

Spindle motor tam tak chu open-loop system-ah an thawk a, chutah chuan speed chu variable frequency drive (VFD) hmanga control a ni a, feedback chhunzawm zel a ni lo. Hei hi a positioning dik tak aiin precise rotational speed a pawimawh zawkna hmunah a tawk a ni. Mahse, advanced spindles chuan load hrang hrang hnuaia speed mumal tak vawng reng turin feedback device (eg, encoders) hmangin closed-loop control a hmang thei a, hei hian high-precision task-a performance a ti tha thei a ni. Open-loop system hi a awlsam zawk a, a man pawh a tlawm zawk a, closed-loop system erawh chuan application mamawh tak takte tan dikna nasa zawk a pe thung.

Cooling Systems

Spindle motor hian hun rei tak hnathawh chhungin lumna nasa tak a siam a, a bik takin speed sang takah emaw, phurrit rit tak hnuaiah emaw a ni. Hei hi enkawl tur chuan cooling system hmanga thuam an ni:

Air-cooled : Fans emaw ambient air emaw hmangin lumna tihbo nan, thing hnathawh ang chi intermittent emaw medium-duty task emaw atan a tha. An awlsam zawk a, an man pawh a tlawm zawk a, mahse hnathawh chhunzawm zelna atan chuan a tangkai lo zawk.

Water-cooled : Liquid coolant hmang la, temperature tha ber a awm theih nan, high-speed emaw long-duration hna thawk tur chuan metal engraving ang chi atan a tha hle. Heat dissipation tha zawk leh quieter operation an pe a, mahse coolant system tan chuan maintenance dang an mamawh bawk. Cooling tha tak hian thermal expansion a veng a, internal components a venghim a, motor lifespan a ti rei bawk.

Tool compatibility

Spindle motor-ah hian tool holder, ER collets, BT, emaw HSK system te dah a ni a, chu chuan cutting tools end mill, drills, emaw engraving bits ang chi te a secure thei a ni. Tool holder type hian spindle-in a hman theih tur range a ruat a, machining precision leh rigidity a nghawng bawk. Entirnan, ER collets hi general-purpose CNC router tan chuan versatile a ni a, HSK holder te erawh chu high-speed, industrial application atan an secure clamping leh balance avangin an duh zawk thung. CNC machine-a tool change system nena inmilna pawh a pawimawh hle.

CNC machine-a chanvo .

CNC system-ah chuan spindle motor-te hian cutting tool emaw, a then phei chuan machining operation tihna tur workpiece emaw an rotate emaw a ni. Entir nan:

CNC router-ah chuan spindle motor chuan thing emaw plastic emaw-a pattern siam turin cutting tool a rotate a.

CNC milling machine-ah chuan metal workpiece atanga material lakchhuahna tur end mill a khalh a, geometries complex tak tak a siam a ni.

CNC lathe-ah chuan spindle motor chuan workpiece chu turning operation atan stationary cutting tool-ah a rotate thei a ni. An speed leh power mumal tak an neih theihna hian surface finish quality sang tak leh material removal tha tak a siam a, hei hian heavy-duty milling atanga delicate engraving thlenga hna thawh tur atan a pawimawh hle.

Practical ngaihtuah tur .

CNC application-a spindle motor thlan emaw hman emaw hian a hnuaia mi hi ngaihtuah la:

Speed leh Power mamawh : Spindle-a RPM leh power rating chu material leh task nen a inmil tur a ni (eg, engraving atana high-speed, metal cutting atana high-torque).

Cooling Needs : Air-cooled spindles chu a man tlawm, a hman hun inkar a hman tur emaw, tui-cooled spindles emaw, a chhunzawm zel tur, high-speed operation atan thlan tur a ni.

Tool Holder Compatibility : Spindle-a tool neituin a mamawh hmanrua a support a, machine setup nen a inmil em tih enfiah tur a ni.

Maintenance : Spindle te chu tifai fo la, cooling system te chu enfiah la, bearing te enfiah la, a lum lutuk loh nan, a vibration, emaw belt slackening issues te chu enfiah thin ang che.

High-speed rotation, robust power delivery, leh specialized design of spindle motors te hmang tangkaiin, CNC operator te chuan machining application hrang hrangah material removal tha tak leh high-quality result an hmu thei a, servo motors ten motion control dik tak an pek chu an tihlawhtling thei a ni.

Servo motor leh spindle motor te inthlauhna pawimawh tak tak te

Servo motor leh spindle motor te hi CNC (Computer Numerical Control) machine-ah chuan thil pawimawh tak an ni a, mahse thil tum hrang hrang an nei a, design leh performance characteristics te chu an role bik ang zela siam an ni. Servo motors te chu positioning machine components te tan motion control dik takah an hlawhtling laiin, spindle motor te hi high-speed rotation atan optimized an ni a, chu chuan cutting emaw machining process emaw a khalh thei a ni. Thil pawimawh tak tak—primary function, control system, speed leh torque, application, design leh construction, power mamawhna, leh feedback mechanism te—a danglamna hriatthiamna chu i CNC system atana motor dik thlan leh performance tihchangtlunna atan a pawimawh hle. A hnuaiah hian heng motor chi hnih te hi chipchiar takin kan khaikhin a, chutah chuan CNC machine-a an chanvo tarlanna tur practical example kan siam a ni.

1. A hnathawh dan bulpui ber .

Servo Motors : Servo Motors hi machine components te chu precision sang tak neia an awmna hmun, velocity leh an kal dan tur control turin an siam a ni. CNC machine-ah chuan machine-a axes (eg, x, y, z) linear emaw rotary motion an khalh a, programmed instruction angin tool head emaw workpiece emaw chu dik takin an dah a ni. An ngaih pawimawh ber chu raw power delivery aiin motion control dik tak a ni.

Spindle Motors : Spindle motor te hi engineer-in cutting tools emaw workpiece emaw speed sang taka rotate turin engineer a ni a, machining task, cutting, milling, drilling, emaw engraving te tih theih a ni. Material removal emaw shaping emaw atana mamawh power leh speed pek chhuah te, positional accuracy aia rotational performance dah pawimawh ber te an ngaihtuah a ni.

Key difference : Servo motor hian machine components awmna leh a kal dan a control a, spindle motor erawh chuan machining process atan rotational force a khalh thung.

2. Control system 1.1.

Servo Motors : Closed-loop control system-ah thawk la, encoder emaw resolver ang chi feedback device hmangin position, speed, leh torque te chu real time-in enfiah rawh. CNC controller chuan motor performance tak tak chu a duh ang value nen a khaikhin a, deviation awm apiang siamthat nan input chu a siamrem a, accuracy sang tak leh repeatability a awm theih nan a pui bawk.

Spindle Motors : A tlangpuiin open-loop control system hmang la, chutah chuan speed chu variable frequency drive (VFD) hmanga regulated a ni a, feedback chhunzawm zel lovin. High-end spindle motor-ah chuan load hrang hrang hnuaia speed regulation dik tak neih theihna turin encoder hmanga closed-loop control an dah tel thei a, mahse hei hi a awm tlem zawk a, positional control-ah a innghat lo.

Key difference : Servo motor-te chuan positioning dik tak neih theihna turin closed-loop control-ah an innghat a, spindle motor-te erawh chuan speed regulation atan open-loop system awlsam zawk an hmang fo a, advanced application atan closed-loop option an hmang fo bawk.

3. Speed leh Torque .

Servo Motors : Variable speed leh torque sang tak a pe a, a bik takin speed hniam takah chuan dynamic movement tan a tha ber a, dynamic movement leh rapid acceleration leh deceleration a ngai a ni. Anni hian spindle motor nena khaikhin chuan rpm hniam zawkah (eg, 1,000–6,000 rpm) an thawk tlangpui a, speed aiin control an dah pawimawh ber.

Spindle Motors : High-speed rotation atana siam a ni a, RPM hi a hman dan azirin 6,000 atanga 60,000 emaw a aia sang emaw a ni. Anni hian consistent torque optimized for cutting or grinding an pe a, performance siamremna dik tak aiin load hnuaia speed vawng reng turin performance siam a ni.

Key difference : Servo Motors hian motion dik tak atan speed hniam zawkah high torque an dah pawimawh ber a, spindle motor erawh chuan machining task atan consistent torque nei RPM sang tak tak an ngaihtuah thung.

4. A hman dan tur .

Servo Motors : CNC machine, robotics, 3D printer, leh automated system-a axis motion atan hman a ni a, chutah chuan positioning dik tak a pawimawh hle. Entirnan, tool head chu CNC router-a sawn emaw, z-axis chu milling machine-a control emaw, robotic arm-te automated assembly line-a khalh emaw a ni.

Spindle Motors : Machining process-a hman thin, milling, drilling, engraving, leh turning te, hna pawimawh ber chu material removal emaw shaping emaw a ni. CNC router, milling machine, lathe, leh engraver-ah te hmuh tur an awm a, thingpui siamna atana hman tur, metalworking, emaw PCB siamna atana hman tur driving tools te an ni.

Key difference : Servo motor hi CNC leh automation system-a axis movement dik tak atan hman a ni a, spindle motor erawh chuan machining application-a cutting emaw shaping process emaw a khalh thung.

5. Design leh sak dan .

Servo Motors : Compact leh lightweight, multi-axis system-a acceleration leh deceleration chak taka hman theih tura siam a ni. Integrated feedback device (eg, encoder) te an dah tel a, responsive motion atan inertia tih tlem nan an siam a ni. An sak dan hian precision leh dynamic performance a dah pawimawh ber a ni.

Spindle Motors : A lian zawk leh a nghet zawk, machining laiin rotational speed sang leh sustained loads tuar thei tura siam. Anni hian cooling system (air-cooled emaw water-cooled emaw) hmangin heat leh tool holder (eg, ER collets, BT, HSK) te chu cutting tools secure turin an dah a, durability leh power delivery an ngai pawimawh hle.

Key difference : Servo motor hi dynamic, precise motion atan a compact a, spindle motor erawh chu high-speed machining atan cooling system leh tool holder te nen a robust thung.

6. Power mamawh .

Servo Motors : A tlangpuiin power hniam zawk a mamawh a, ratings chu watt tlemte atanga kilowatt engemaw zat (eg, 0.1–5 kW) thlengin a awm a, a hman dan azirin a awm thei bawk. Motion control task-a raw power mamawh tlem zawk mahse precision sang tak nei tura siam an ni.

Spindle Motors : Power rating sang zawk, a tlangpuiin 0.5 kW atanga 15 kW emaw a aia tam (0.67–20 hp) nei, metal, thing, emaw composite ang chi thila cutting task rit tak tak kalpui thin. An power mamawhna chuan material chu a tha zawnga paih chhuah theihna tur energy pawimawh tak a mamawhzia a tilang a ni.

Key difference : Servo motor hian motion control atan power hniam zawk a hmang a, spindle motor erawh chuan material removal leh machining atan power sang zawk a mamawh thung.

7. Feedback mechanism 1.1.

Servo Motors : Feedback mechanism, encoder emaw resolver emaw ang chi te chu position, speed, leh torque chungchanga real-time data pek theih nan dah fo thin ang che. He feedback hian control leh error siamthatna dik tak a siam a, CNC operation-a tight tolerances vawn rengna atana pawimawh tak a ni.

Spindle Motors : Feedback mechanism a huam thei a, a huam lo thei bawk. Mi tam tak chuan open-loop system-ah feedback awm lovin an thawk a, speed control nan VFD an rinchhan a ni. Advanced spindles hian closed-loop speed regulation atan encoder an hmang thei a, mahse positional feedback hi a tlangpuiin an role rotational a nih avangin a tul lo a, positional a ni lo.

Key difference : Servo motor te hian control dik tak atan feedback an hmang fo thin a, spindle motor te erawh chuan open-loop system an rinchhan fo thin a, application bik atan feedback optional an nei thin.

CNC machine-a entirnan hmantlak tak takte

Servo leh spindle motor-te nena inzawmna (complementary role) tarlan tur chuan an hnathawh dan chu CNC milling machine pangngaia ngaihtuah tur a ni:

Servo Motors : Machine table emaw tool head emaw chu X, Y, leh Z axes-ah te a kal dan tur control rawh. Entirnan, servo motor-te chuan tool head chu metal workpiece chungah chiang takin an dah a, chu chu programmed toolpath zuiin, cut dik tak a awm theih nan. 5-axis CNC machine-ah chuan servo motor-te chuan complex angular movement an handle a, chu chuan geometries intricate tak a siam thei a ni.

Spindle Motor : Workpiece atanga material lakchhuah nan milling cutter chu speed sang (eg, 20,000 rpm) ah a rotate thin. Spindle motor hian metal mill theihna tur power leh speed a pe chhuak a, chu chuan material removal tha tak leh surface finish tha tak a siam thei a ni.

Entirna Scenario : Metal aerospace component mill-naah Servo Motors chuan tool head chu axes tam takah coordinate dik takah a kal tir a, chu chuan cutter-in kawng dik a zawh theih nan a enkawl a ni. Chutih rual chuan, spindle motor chuan cutting tool chu 20,000 rpm-in a spin a, chu chuan material chu a paih chhuak a, a speed chu VFD-in a control a, chu chuan material property leh cutting requirements nen a inmil a ni. Heng motor te hian an thawhhona chuan machine hian a part complex, high-precision a siam thei a ni.

Servo leh Spindle Motors zingah duhthlan tur .

CNC (Computer Numerical Control) system emaw precision engineering application atana motor dik tak thlan tur chuan servo motor leh spindle motor-te chanvo hrang hrang hriatthiam a ngai a ni. Motor chi hrang hrang hi CNC machine chhunga hnathawh bik atan siam a ni a, servo motor te chu positional control dik takah an tha hle a, spindle motor te chu high-speed rotation leh material removal atan an optimized bawk. CNC system tam zawkah chuan heng motor te hi an inzawm tlat lo va, machining dik leh tha tak tak an neih theih nan an thawk ho a ni. Servo leh spindle motor-te duhthlanna—a nih loh leh an pahnih inzawmkhawm tura thutlukna siam—chu i application-a thil mamawh bikteah a innghat a, chutah chuan hna chi hrang hrang, thil mamawh, thil mamawh dik tak, leh system configuration te pawh a tel a ni. A hnuaiah hian servo leh spindle motor thlan dan tur ngaihtuah tur pawimawh tak tak kan tarlang a, CNC machine-a an hman dun dan tlangpui kan sawifiah bawk.

Servo Motors thlan dan .

Servo motor hi i application-in position, velocity, leh torque-a control dik tak a phut hunah chuan duhthlanna ṭha ber a ni. An closed-loop control system, encoder emaw resolver ang chi feedback device-a innghatte chuan an chet dan dik leh tih leh theih an enkawl a, chu chuan dynamic motion control ngai hna thawhna atan a pawimawh hle.

Servo Motors thlan hun tur:

CNC axis movement : Servo motor hmang hian CNC system-ah X, Y, Z, emaw axes dang (eg, A, A, B-a 5-axis machine-ah) te chu an khalh a, tool head emaw workpiece emaw chu precision sang tak neiin an dah a ni. Entirnan, CNC router-ah chuan servo motor-te chuan gantry chu an cut emaw, engraving emaw atan exact coordinate-ah an sawn a.

Robotics : Robotic arm-ah chuan servo motor-te chuan joint movement an control a, chu chuan hna hrang hrang, assembly, welding, emaw pick-and-place operation ang chi hnate chu a manipulation dik tak a siam thei a ni.

Automation Systems : Servo motor hi automated machinery-ah hman a ni a, chu chu 3D printer emaw conveyor system emaw a ni a, chutah chuan positioning dik tak emaw speed control emaw a pawimawh hle.

Micro-adjustment mamawhna application : threading, contouring, emaw multi-axis machining ang chi hnate hian servo motor-te’n positional adjustment tha tak tak an siam theihna aṭangin hlawkna an hmu a ni.

Ngaihtuah tur pawimawh tak tak:

Precision Needs : Servo motor, high-resolution encoder nei (eg, revolution khata pulse 10,000) te chu aerospace emaw medical device siamna emaw ang chi, tight tolerance mamawhna atana hman tur thlang rawh.

Torque leh Speed : Servo motor-a torque leh speed ratings te chu machine-a axes load leh dynamic requirement nena inmil turin enfiah rawh. Entirnan, workpiece rit zawk chuan motor sang zawk motor a mamawh thei.

Control System Compatibility : Servo motor chu i CNC controller emaw PLC emaw nen a inmil em tih enfiah la, machine software nena inzawmna mumal tak siam a ni ang.

Maintenance : Feedback device leh electrical connection te enfiah fo tur ruahmanna siamin performance issues, encoder misalignment emaw wiring faults te ang chi te.

Entirna : 5-axis CNC milling machine-ah chuan Servo Motor-te chuan tool head leh workpiece chu sub-millimeter dikna hmangin an dah a, aerospace component-te tan complex geometries a siam thei a ni.

Spindle Motors thlan dan .

Spindle motor hi i application-in high-speed rotation-a cutting, drilling, emaw engraving process-a kalpui tur a ngaihtuah chuan go-to choice a ni. Heng motor te hi material lakchhuahna atana power leh speed mumal tak pe thei tura siam a ni a, chu chuan material hrang hranga machining task atan a pawimawh hle.

Engtikah nge Spindle Motors thlan tur:

Cutting leh milling : Spindle Motors hian CNC router leh milling machine-a thing, thir, plastic, emaw composite-a thil awmte paih chhuah nan end mill emaw router bits ang chi cutting tools an khalh thin.

Drilling : Drill bits te chu speed sang takin an rotate a, chu chuan materials, steel emaw aluminum ang chi, automotive emaw machinery parts atan te hole dik tak a siam thin.

Engraving : High-speed spindle motor hi hnathawh chipchiar tak atan hman a ni a, chu chu jewelry, signage, emaw printed circuit board (PCB) chungchanga etching design te hi a ni.

Turning : CNC lathes-ah chuan spindle motor-te chuan workpiece chu cylindrical parts, shaft emaw fittings emaw ang chi siam turin stationary tool-ah an rotate a.

Ngaihtuah tur pawimawh tak tak:

Material and task : Material leh task atan spindle motor power tling (eg, 0.5–15 kW) leh speed (eg, 6,000–60,000 rpm) thlang rawh. Entirnan, high-power, water-cooled spindles te hi metal cutting atan a tha hle a, air-cooled spindles te erawh chuan wood working atan a tha hle thung.

Cooling System : Hnehna tha taka enkawl theih nan hnathawh chhunzawm zel tur, chak taka hnathawh chhunzawm zelna tur tui-cooled spindle emaw atan air-cooled spindles thlang rawh.

Tool Holder Compatibility : Spindle-a tool holder (eg, ER collets, HSK) hian tools mamawh a support tih enfiah la, machine-a tool change system nen a inmil thei ang.

Maintenance : Belt slackening emaw electrical short circuit emaw ang chi thil awm loh nan spindle, cooling system, leh bearings te chu tifai fo thin ang che.

Entirnan : CNC router-ah chuan 3 kW water-cooled spindle motor chuan router bit chu 24,000 rpm-in a rotate a, furniture siamna atana thing harsa tak takah intricate pattern a carve thei a ni.

CNC machine-a hman dun .

CNC machine tam zawkah chuan servo motor leh spindle motor te chu hman dun a ni a, an complementary strength te chu hmang tangkaiin machining dik leh tha tak tak an siam thei a ni:

Servo Motors for Motion Control : Servo Motors Tool head emaw workpiece emaw chu machine-a axes-ah dah la, cutting tool chuan programmed toolpath chu a dik taka a zui tih a tichiang ang. Entirnan, gantry chu CNC router-ah an sawn emaw, tool angle chu 5-axis machine-ah an siam a.

Spindle Motors for Machining : Spindle Motors hian cutting tool emaw workpiece emaw chu a mamawh ang speed leh power-in a rotate a, chu chuan material removal a ti a, a cut a, a drilling, emaw engraving tha tak a siam thei a ni.

Entirna Scenario : CNC milling machine-ah chuan Servo Motors chuan X, Y, leh Z axes te chu tool head hnuaiah metal workpiece dah turin an khalh a, chutih laiin spindle motor chuan end mill chu 20,000 rpm-in a spin a, material chu a paih chhuak a, component dik tak a siam a ni. Servo Motors chuan hmanrua chuan kawng dik a zawh theih nan a enkawl a, chutih laiin spindle motor chuan cutting atana mamawh power a pe chhuak thung.

Maintenance ngaihtuah tur .

Servo leh spindle motor enkawl dan dik hi CNC (Computer Numerical Control) machine rintlak, dik leh dam rei theihna tur atan a pawimawh hle. Motor chi hnih hian hna hrang hrang an thawk a—sservo motors for precise axis positioning leh spindle motors for high-speed material removal—mahse, an incheina, a lum lutuk, emaw, electrical fault te, short circuit emaw belt slackening emaw te pawh tel lo turin enkawlna mumal tak an mamawh a ni. Targeted maintenance practices kalpui a nih chuan operator-te chuan downtime an tihtlem thei a, machining accuracy an vawng reng thei a, heng critical components te dam chhung pawh an ti rei thei bawk. A hnuaiah hian servo motor leh spindle motor-te enkawlna ngaihtuah chiang tak takte kan tarlang a, a tha ber tur atana actionable step te chipchiar takin kan tarlang a ni.

Servo Motors 1000 a ni.

CNC machine-a positional control dik tak nei tura mawhphurtu Servo Motor-te chuan feedback device hmanga closed-loop system an rinchhan a, a dik leh dik loh an vawng reng a ni. Regular maintenance chuan an performance chu a inmil reng tih a tichiang a, axis movement emaw machining precision emaw tichhe thei tur thil a veng thei a ni.

Feedback device (eg, encoder) te check leh calibrate fo thin

Servo Motors Encoder emaw resolver ang chi feedback device hmangin position, speed, leh torque te chu real time in enfiah thin ang che. Heng device-a misalignment, bawlhhlawh, emaw wear emaw hian positioning dik lo emaw control error emaw a thlen thei a ni.

Thiltih tur: 1.1.

Encoder emaw, resolver emaw chu leivut, bawlhhlawh, emaw, signal dikna tibuai thei taksa chhiatna emaw, taksa chhiatna emaw enfiah rawh. Lint-free puan leh non-corrosive cleaner hmangin silfai tur a ni.

CNC controller nena alignment awm theihna turin siamtuin software emaw hmanrua emaw a pek hmangin feedback devices chu a hun hunah calibrate thin ang che.

Encoder cables te chu wear emaw loose connection emaw a awm leh awm loh enfiah la, signal transmission tha lo chuan positioning error a thlen thei a ni.

Frequency : Thla 3–6 chhunga enfiah leh tihfai emaw, darkar 500–1,000 chhunga hman tur; Manufacturer guidelines angin calibrate la, a tlangpuiin kum tin emaw, major maintenance hnuah emaw.

Benefits : Positional accuracy a vawng reng a, control error a veng a, multi-axis machining emaw robotics ang chi task-a performance mumal tak a siamsak bawk.

Bearings-a wear awm leh awm loh enfiah la, a tul angin lubricate rawh .

Servo motor-a bearings hian rapid axis movement-a friction a tihziaawm a, mahse wear hian vibration a tisang thei a, noise a tisang thei a, a nih loh leh precision a ti tlem thei bawk. Lubrication dik tak chuan wear a ti tlem a, smooth operation a vawng reng bawk.

Thiltih tur: 1.1.

Aw danglam tak tak (eg, grinding emaw huming emaw) ngaithla la, bearing wear hriat theih nan vibration analyzer hmang bawk ang che. Vibration tam lutuk hian enfiah emaw thlak emaw a ngai tih a tilang.

Manufacturer-in a rawt lubricant (eg, grease or oil) chu bearings-ah hnawih la, over-lubricate lo turin a enkawl a, chu chuan debris a hip thei a, heat buildup a thlen thei bawk. Servo motor thenkhat chuan sealed bearings an hmang a, chu chu lubrication ngai lo mahse a chhe leh chhe loh enfiah tur a ni.

Motor shaft emaw rotor emaw a chhiat loh nan bearing chhe tawh chu thlak nghal tur a ni.

Frequency : thla 6 emaw, darkar 1,000 emaw chhunga bearings enfiah; Lubricate per manufacturer specifications, a tlangpuiin non-sealed bearings atan darkar 500–1,000 danah hman thin ang che.

Benefits : Friction a tihziaawm a, vibration-induced damage a veng a, motor lifespan a ti rei bawk.

Signal hloh emaw, interference emaw ven nan electrical connection enkawl dan

Servo motor te hian controller leh feedback device-a power leh signal thawn chhuahna atan stable electrical connection an ring a. Connection lo awm, a chhe tawh emaw, a chhe tawh emaw, a chhe tawh emaw chuan signal hloh, interference, emaw electrical faults short circuit ang chi a thlen thei a ni.

Thiltih tur: 1.1.

Power leh signal cable te chu a chhe tawh em tih te, a chhe tawh te, a loose terminal te enfiah thin ang che. Connection te kha tikhauh la, cable chhia te chu thlak leh rawh.

Power delivery rintlak tak neih theih nan wiring-a voltage leh continuity mumal tak awm leh awm loh enfiah nan multimeter hmang la.

Shield signal cable te chu electromagnetic interference (EMI) atanga lo chhuakin spindle motor emaw VFD emaw ang chi high-power component atanga hlaah an tlan tir thin.

Frequency : Thla tin emaw, operating hour 500 danah emaw connection neih thin tur; Routine maintenance cycle neih laiin chipchiar taka enfiah thin ang che.

Benefits : Signal hloh tur a veng a, electrical faults awm theihna a ti tlem a, CNC controller nena inbiakpawhna rintlak tak a siam bawk.

Spindle Motors .

Spindle motor, high-speed rotation leh material removal atana siam te hian heat, vibration, leh tool nena inzawm thil enkawl nan enkawlna an mamawh a ni. Enkawlna dik chuan hnathawh chhiatna leh chhiatna man to tak tak, electrical short circuit emaw mechanical damage emaw a veng thei a ni.

Tool runout turin tool holder leh collet te chu tifai rawh .

tool holder (eg, ER collets, BT, HSK) leh collets te chu spindle thlenga secure Thil bawlhhlawh, bawlhhlawh, a nih loh leh chhiatna hian tool runout (wobbling) a thlen thei a, chu chuan machining quality tha lo, vibration a tisang a, spindle-a stress a thlen thei bawk.

Thiltih tur: 1.1.

Tool holder leh collet te chu tool thlak apiangin lint-free cloth leh non-corrosive cleaner hmangin silfai la, coolant residue, chips, emaw dust te chu paih chhuak rawh.

Tool holder-a taper emaw collet emaw-a wear, dents, emaw scratch awm leh awm loh enfiah la, chu chuan misalignment a thlen thei. Component chhia chu thlak nghal rawh.

Install zawh hnua tool runout tehna atan dial indicator hmang la; Runout 0.01 mm aia tam chuan siamthat ngai harsatna a awm tih a tarlang.

FREQUENCY : Hmanrua thlak apiangin emaw, hman rit laiin nitin emaw tifai tur a ni; Thla tin emaw, darkar 500 chhunga hman tur emaw a awm leh awm loh enfiah thin ang che.

Benefits : Machining precision a vawng reng a, vibration a ti tlem a, spindle leh tools-a premature wear a veng thei bawk.

Overheating spindle motors ven nan cooling system (air or water) enkawl la,

high-speed emaw hun rei tak emaw hman laiin lumna nasa tak a chhuak a, chu chuan lum lutuk lo turin cooling tha tak a mamawh a, chu chuan insulation tihchhiat emaw component failure emaw a thlen thei a ni.

Thiltih tur: 1.1.

Air-cooled spindles tan : cooling fins leh fans te chu tihfai fo thin a ni a, chu chuan airflow tikhawlo thei dust emaw debris emaw a paih chhuak thin. Cooling efficiency vawng reng turin vents a chiang em tih enfiah rawh.

Water-cooled spindles atan : Reservoir chhunga coolant level enkawl, a siamtuin a rawn rawt fluid nen topping up. Hose, fittings leh cooling jacket te chu leak emaw corrosion emaw a awm leh awm loh enfiah thin ang che. Thla 6–12 danah system chu flush la, sediment emaw algae emaw chu paih chhuah thin ang che.

Thermal imaging hmangin hot spots te chu detect la, cooling system inefficiency emaw potential fault emaw a awm tih a tarlang.

Frequency : kar tin air-cooled system te enfiah thin ang che; Kar tin coolant level leh thla tin leak a awm chuan water-cooled systems enfiah thin; Thla 6–12 danah water-cooled system te chu flush thin ang che.

A hlawkna : A lum lutuk tur a veng a, winding leh bearing-a thermal stress a tihziaawm bakah spindle lifespan a ti rei bawk.

Vibration emaw noise emaw a awm leh awm loh enfiah, wear

spindle motor bearings awm thei, a tam zawkah chuan ceramic emaw steel emaw chuan high-speed rotation a support. Wear emaw imbalance emaw hian vibration emaw thawm emaw a thlen tam thei a, chu chuan precision a ti tlem a, belt slackening a ti tlem a, motor a tichhia thei bawk.

Thiltih tur: 1.1.

Operation laiin thawm pangngai lo (eg, grinding, rattling) ngaithla la, bearing wear emaw misalignment emaw a awm tih a tilang.

Bearing vibration level tehna atan vibration analyzer hmang la, thil awmdan hriat hmasak nan manufacturer baseline nen khaikhin rawh.

Lubricate bearings per manufacturer guidelines (a seal loh chuan), grease emaw oil emaw tarlan hmangin. Spindle shaft emaw rotor emaw a chhiat loh nan bearing chhe tawh chu thlak nghal tur a ni.

Frequency : hnathawh laiin nitin emaw, kar tin emaw vibration leh noise enfiah; Thla 3–6 danah emaw, darkar 500–1,000 chhung emawa bearing check kimchang tak tih thin ang che.

Benefits : Mechanical failures a veng a, machining accuracy a vawng reng a, repairs man to tak tak a awm theihna a ti tlem bawk.

Tawpna

Servo motor leh spindle motor te hi CNC (Computer Numerical Control) machine leh precision engineering system-ah te chuan component pawimawh tak tak an ni a, heng system-te hnathawh dan tlangpui tichaktu tur, complementary but distinct role an nei vek a ni. Servo Motors hian motion control dik tak an pe chhuak thei a, CNC machining, robotics, leh automation ang chi application-a machine axes emaw components emaw position dik tak an pe thei a ni. Chumi nêna inkalh takin, spindle motor-te chu high-speed, high-power rotation atan engineer-in an siam a, chu chuan cutting tools emaw workpiece emaw, milling, drilling, emaw engraving ang chi hna thawhna atana mamawh chakna a pe a ni. An danglamna pawimawh tak takte hriatthiamna hmangin—control system, application, design, speed leh torque characteristics, power mamawh, leh feedback mechanism te—operator-te chuan CNC performance tihchangtlunna tur leh result tha tak tak an hmuh theih nan thutlukna dik tak an siam thei a ni.

Servo leh spindle motor te inkara thawhhona (synergy) hi CNC machine te hi a versatile em em a, a tangkai em em bawk. Servo Motors chuan tool head emaw workpiece emaw chu pinpoint accuracy-a dah a nih theih nan a enkawl a, spindle motor erawh chuan material lakchhuah emaw shaping tha taka hman theihna tura rotational power mamawh chu a pe chhuak thung. Entirnan, CNC milling machine-ah chuan servo motor-te chuan x, y, leh z axes te chu an control a, chu chuan toolpath dik tak a zui a, spindle motor chuan cutting tool chu speed sang takin a rotate a, a hmunhma chu a awlsamin a dik a ni. Motor chi hnih thlan leh enkawl dan dik tak chu belt slackening, electrical short circuit, emaw mechanical failures ang chi thil pumpelh nan a pawimawh hle a, precision leh reliability mumal tak neih theihna tur a ni.

CNC system siam, tihchangtlun, emaw, enkawltute tan chuan i application-a thil phut bikte chu ngun takin ngaihtuah la—material type, precision requirement, leh duty cycle ang chi—servo leh spindle motor thlan hunah. Axis control dik tak neih theihna tur torque, feedback resolution, leh controller nena inmil tur Servo Motors thlang la, i machining task-te nena inmil turin spindle motors power, speed, leh cooling system dik tak thlang rawh. Maintenance mumal tak, tihfai, lubrication, servo motor-a feedback device calibration, leh spindle motor-a cooling system care te chu performance vawng reng tur leh motor lifespan tihzauh nan a pawimawh hle. Servo leh spindle motor-a complementary strengths te hmang tangkaiin, proactive maintenance implement-in, machining leh automation task-ah result danglam tak i hmu thei a, i CNC hnathawhnaah efficiency, precision, leh durability i enkawl thei a ni.

Zhong Hua Jiang-a catalogue download tur chuan hetah hian click la.

Zhong Hua Jiang Catalogue 2025.pdf

Zhong Hua Jiang Catalogue 2025.pdf

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu