Ðe wò CNC-mɔ̃a le toɣliɖeɖe wɔnukuwo wɔm loo alo ɖe nèle nu wɔm pɛpɛpɛa? Ʋuʋu ma si menya kpɔna dzea sii bɔbɔe o alo ɣeyiɣi si me womele mɔ kpɔm na o ate ŋu afia nu gbegblẽ aɖe si me ɖoɖoezizi le si le bebem le eme: bearing siwo gblẽ le wò spindle motor me. Bearing damage medzena ƒã ɣesiaɣi o, gake enye nya vevi aɖe si ate ŋu ana be woaɖe nusiwo le eme dzi akpɔtɔ, woƒe akpa bubuwo ƒe vuvu nadzi ɖe edzi, woaɖɔ wo ɖo xɔasiwo, alo woƒe spindle ƒe gbagbã katã ne womekpɔ wo gbɔ o.

Le mɔfiame sia me la, míadzro nusianu si wòle be nànya tso bearing damage le spindle motors me ŋu—tso dzesi gbãtɔwo kpɔkpɔ dzi va ɖo nusiwo gbɔ wòtso ƒe dzesidede kple mɔxexeɖedɔléle nu ƒe mɔnu nyuiwo zazã dzi. Eɖanye CNC dɔwɔla, beléle na mɔ̃ɖaŋununya, alo modzakaɖela le wò ɖoɖoa ta kpɔm o, dɔwɔnu sia akpe ɖe ŋuwò be wò bearings nanɔ nɔnɔme nyuitɔ me, akpɔ egbɔ be dɔwɔwɔ nyuie kple mɔ̃a ƒe agbenɔƒe didi.

Mina míake ɖe ŋɔdzinu ɣaɣlawo ŋu eye míana wò spindle nanɔ tsatsam vodadamanɔŋui!

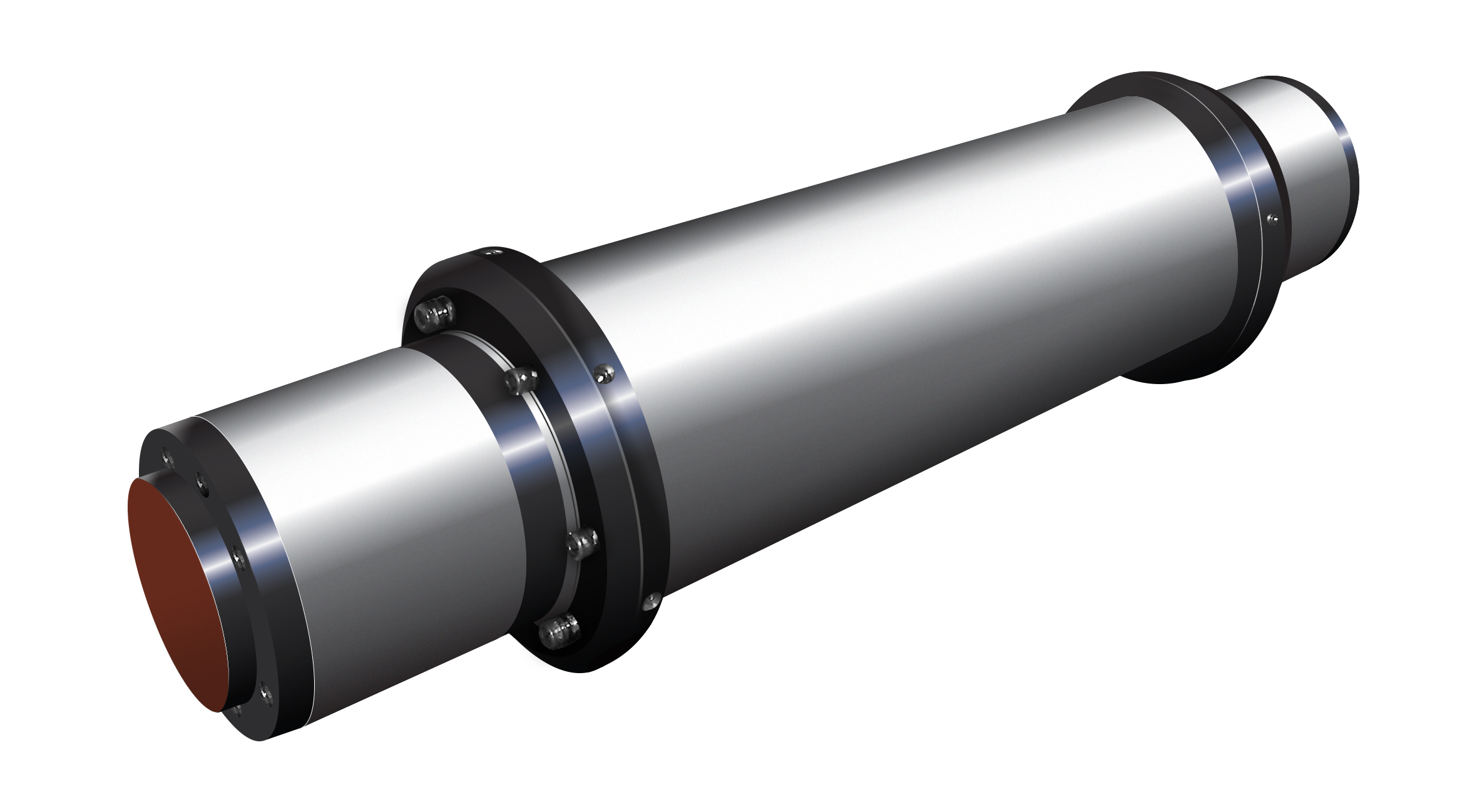

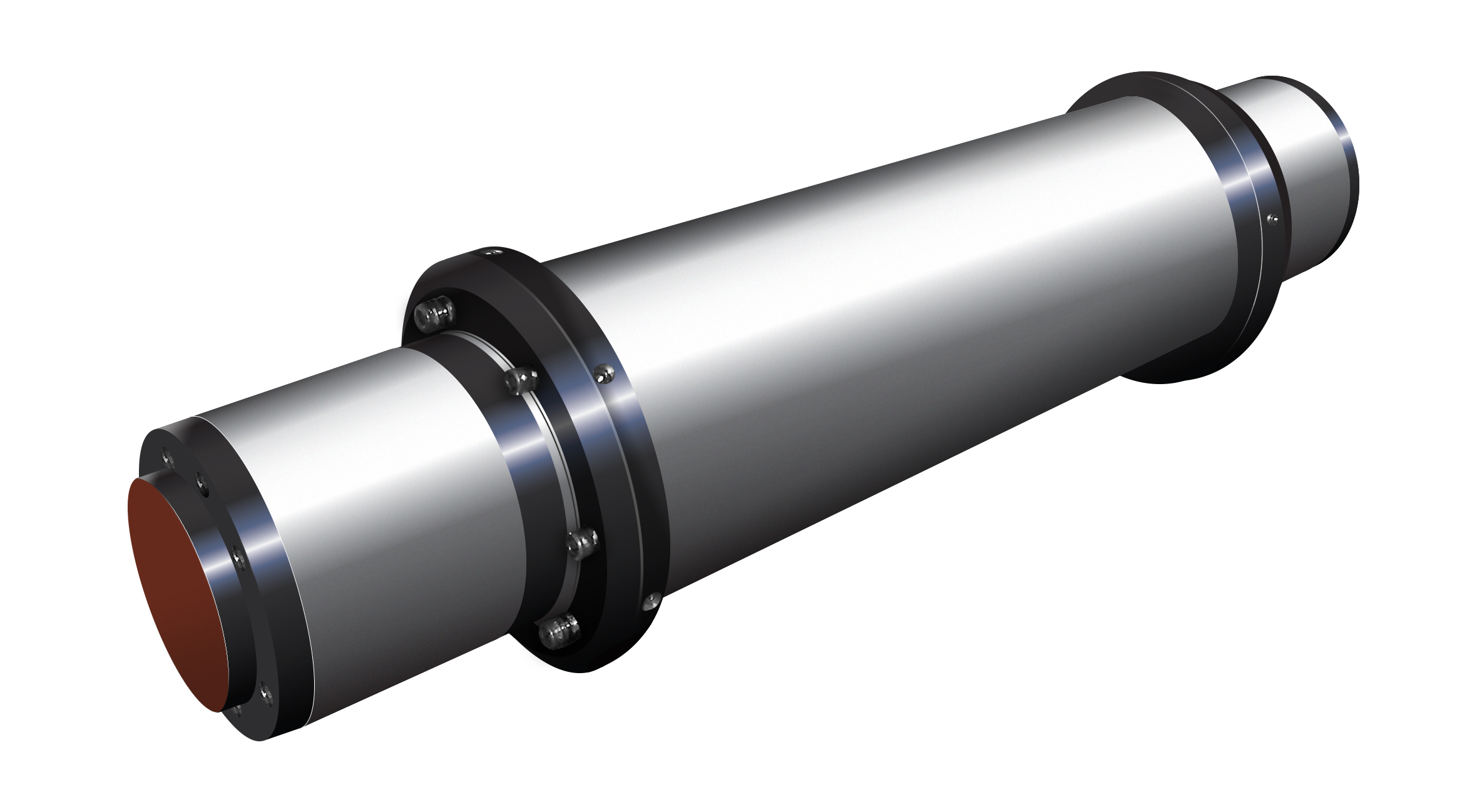

Sprindle motor bearings ƒe ŋgɔdonya .

Nukae nye spindle motor bearings?

Bearings ƒe hatsotso aɖe le spindle motor ɖesiaɖe ƒe titina—nu siwo ƒe wɔwɔme le abe alesi wowɔa nu pɛpɛpɛ ene siwo léa ʋuƒo si le tɔtrɔm la ɖe te, si wɔnɛ be woate ŋu awɔ dɔ sesĩe, si sɔ pɛpɛpɛ. Bearing siawo ɖea ʋuʋudedi dzi kpɔtɔna, xɔa agbawo, eye woléa wo ɖe ɖoɖo nu, si wɔnɛ be lãgbalẽgoloa te ŋu ʋua dɔwɔnu siwo wotsɔ lãa nu la kple nusiwo sɔ pɛpɛpɛ si hiã hena tomekuku, nutunu, kple nuwo ƒe nɔnɔme wɔwɔ.

Bearingwo le ƒomevi vovovowo me, abe ball, roller, alo angular contact ene, si wowɔ ɖe spindle ƒe duƒuƒu, agba, kple eŋudɔwɔwɔ nu—eɖanye atikpakpa, ga wɔwɔ, alo mɔ̃ si wotsɔ ƒo ƒui o. Eɖanye ƒomevi ka kee o, ele be bearings nawɔ dɔ le mɔɖeɖe ɖe nu ŋu sesĩe me be wòaxe mɔ na ʋuʋudedi, dzoxɔxɔ ƒe ƒoƒo ɖe ame dzi, kple eƒe vuvu.

Kpɔe ɖa le susu me be wonye ʋu si wɔa dɔ nyuie ŋutɔ ƒe tasiaɖamfɔwo—ne woʋuʋu alo xɔe la, ɖoɖo bliboa kpea fu. Bearing siwo gblẽ ate ŋu ana ʋuʋudedi si gbɔ eme, si mesɔ ɖe ɖoɖo nu o, kple dzoxɔxɔ ƒe nyawo nado, si ana spindle la nawɔ dɔ. Bearing ƒomeviwo, amisisi ƒe hiahiãwo, kple agba ƒe ŋutetewo gɔmesese naa wò nugbɔ le nusiwo gblẽ la didi kple mɔxexe ɖe enu me kaba.

Vevienyenye si le bearing lãmesẽ ŋu le spindle motors me .

Wò spindle motor ƒe kakaɖedzi nɔ te ɖe eƒe bearings dzi. Ne bearings gblẽ la, menye tɔtrɔ si le afɔku me koe o; Ate ŋu ana shaft nasɔ ɖe ɖoɖo nu, eƒe ʋuʋu dzina ɖe edzi, eƒe dɔwɔwɔ ƒe akpa siwo gblẽ, ewɔwɔ ƒe megbetsitsi, kple ga si woatsɔ adzrae ɖo si le dzidzim ɖe edzi.

Dzesi siwo dzena kaba be nu gblẽ le ame ŋu, abe ʋuʋudedi siwo me mekɔ o ene, ate ŋu adzi ɖe edzi be yeawu enu ne woŋe aɖaba ƒu edzi. Bearing ƒe nɔnɔme dzi kpɔkpɔ xea mɔ na nya suesuesuewo be woagazu taɖuame gãwo o, si wɔnɛ be nègaxɔa spindle gbugbɔgatu xɔasiwo o.

Gawu la, bearing siwo gblẽ meɖea woƒe kuxiwo ɖe vovo o—woɖea mɔ̃a ƒe ʋuƒo, fafamɔ̃wo, kple mɔ̃ siwo wotsɔna ʋua mɔ̃woe la ɖe aga. Enye domino ƒe ŋusẽkpɔɖeamedzi si dɔwɔla aɖeke medi be yeaʋã o.

Bearing integrity ku ɖe nu geɖe ŋu wu mɔ̃ɖaŋununya ko—enye dedienɔnɔ, dɔwɔwɔ nyuie, kple ga si wodzra ɖo ɖe anyigba dzi. Nusiwo gbɔ wòtso kple mɔxexe ɖe bearing ƒe nugbegblẽ nu nye nusi ŋu womate ŋu awɔ ɖoɖo ɖo na dɔwɔwɔ ƒe kɔkɔƒe o.

Nusiwo zi geɖe hea bearing ƒe gbegblẽ le spindle motors

| vɛ hea |

Numeɖeɖe |

Effects |

Best Practices |

| Bearings-awo ƒe agba tsɔtsɔ fũ akpa . |

Ŋusẽ siwo gbɔ aɖaŋuwɔwɔ ŋu tso mɔ̃ɖaŋunu sesẽwo wɔwɔ, lãɖeɖe ƒe goglome sesẽwo, alo nuɖuɖu ƒe agbɔsɔsɔ kabakaba gbɔ. |

Ðeɖiteameŋu ƒe gbagbã, eƒe nɔnɔme ƒe tɔtrɔ, pitting/spalling kaba, alo kpododonu enumake (fracture/stall). |

Woaɖo lãɖeɖe ƒe nɔnɔmewo ɖe ɖoɖo nu kple bearing ƒe dzidzedzekpɔkpɔwo; Zã dɔwɔnu ɖaɖɛwo kple agba siwo da sɔ. |

| Amisisi si mesɔ o alo esi me ɖiƒoƒo mele o . |

Ami ƒe agbɔsɔsɔ si bɔbɔ, ɖiƒoƒo (nuɖuɖɔ/tsi), alo nutrenu siwo le dodom si wɔnɛ be wotsia anyi ƒuƒlu alo wowɔa nu ɖe wo ŋu. |

Anyigba ƒe ʋuʋu, dowo, dzoxɔxɔ si dzina ɖe edzi, alo alɔ̃madɔmadɔ. |

Zã ami siwo woɖo ɖi, ŋkuléleɖenuŋu ƒe agbɔsɔsɔ, ɖɔli esiwo me dɔlékuiwo le, eye nàlé ŋku ɖe nutrenuwo ŋu. |

| Misalignment alo installation si mesɔ o . |

Nuƒoƒoƒu ƒe vodadawo, dzoxɔxɔ ƒe keke ɖe enu, alo nusiwo wotsɔna ɖoa wo nɔewo dzi si mesɔ o si wɔnɛ be shaft ƒe ʋuʋu alo eƒe tsɔtsɔ ɖe ɖoɖo nu mesɔna o. |

Agbamama si mesɔ o, vuvu kabakaba, ɖeɖiteameŋu si ʋuʋuna, alo dzoxɔxɔ. |

Zã dɔwɔnu siwo woɖo ɖe ɖoɖo nu le eɖoɖo me, kpɔ post-setup la ɖa, eye nàlé ŋku ɖe eŋu edziedzi. |

| Ðiƒoƒo tso ke kple gbeɖuɖɔ me . |

Nusuekpɔmɔ̃wo toa nutrenu gbegblẽwo alo nuto ƒoɖiwo me, si wɔnɛ be ʋuʋudedi alo xɔdzo. |

ŋlɔmi, ʋuʋudedi, ʋuʋudedi, alo gbagbã. |

Zã nutrenu nyuiwo, ya ƒe ʋuʋu, kple dzadzɛnyenye edziedzi. |

| Ʋuʋu alo dadasɔmakpɔmakpɔ si gbɔ eme . |

Dɔwɔnu siwo meda sɔ o alo resonant frequencies amplifying oscillations. |

Ameƒomevinyenye, ɖeɖiteameŋu, alo dzoxɔxɔ ƒe nugbegblẽ le ame ŋu le ʋuʋu atraɖii ta. |

Dɔwɔnu siwo da sɔ, ɖea ʋuʋudediwo ɖe aga, eye wotsɔa numekukumɔ̃wo léa ŋku ɖe wo ŋu. |

| Dzoxɔxɔ si le dɔ wɔm le dɔwɔwɔ me kɔkɔ . |

Do dzo ɖe nusiwo fa miamiamia, ami siwo le ƒuƒuie, alo esiwo ana wòakeke ɖe enu madzemadzee la nu. |

Agba ƒe ŋutete dzi ɖe kpɔtɔ, ami ƒe gbagbã, alo dzoxɔxɔ ƒe ɖeɖiteameŋu ƒe gbagbãƒewo. |

Na fafa nanyo ɖe edzi, lé ŋku ɖe dzoxɔxɔ ŋu, eye nàƒo asa na agba siwo wu tsɔtsɔ. |

| Elektrikŋusẽ ƒe Nyagbɔkpɔmɔ̃ . |

arcing tso anyigba manyomanyo si hea anyigba ƒe ʋuʋu to elektrikŋusẽ ƒe dodo me. |

Anyigba ƒe gbegblẽ tso elektrikŋusẽ ƒe dzodzo ƒe mɔ̃wo ƒe ŋusẽkpɔɖeamedziwo gbɔ. |

Kpɔ egbɔ be woɖo anyigba nyuie eye nàzã bearings siwo me wodea tsii le afisi wòhiã le. |

1. Bearings-awo ƒe agba tsɔtsɔ fũ akpa .

Bearing overloading dzɔna ne mɔ̃ɖaŋununya ƒe akpa aɖewo, abe bearings le spindle alo mɔ̃ siwo le tɔtrɔm me, le ŋusẽ siwo sɔ gbɔ wu woƒe ŋutete si woɖo la te. Nya sia bɔ ŋutɔ le mɔ̃ɖaŋudɔwɔwɔ kple dɔwɔƒewo ƒe dɔwɔwɔwo me afisi dɔwɔwɔ ƒe nɔnɔmewo tutua dɔwɔnuwo ɖe ŋgɔ wu eƒe seɖoƒewo. Agbatsɔtsɔ fũ ate ŋu agblẽ nu le ame ŋu ŋutɔ, woaɖe dɔwɔnuwo ƒe agbenɔƒe dzi akpɔtɔ, eye woadzudzɔ dɔwɔwɔ le ame ŋu si xɔa ga geɖe.

Nusiwo gbɔ wòtsona be agbatsɔtsɔ wu .

Bearings ate ŋu axɔ agba fũ le nu vovovo siwo ku ɖe dɔwɔwɔ kple ɖoɖowɔɖi ŋu ta, siwo dometɔ aɖewoe nye:

Machining nu sesẽ siwo me ɖoɖo nyui mele o:

l Nusiwo wotsɔ wɔa dɔe siwo le ʋeʋẽm alo esiwo ŋu ŋusẽ le ŋutɔ, abe titanium, gakpo si mexɔ dzo o, alo kpe sesẽ bubuwo ene, tsɔa nuteɖeamedzi ɖedzesi aɖe dea bearings dzi, vevietɔ ne wozã kekeli-dɔwɔnu siwo womewɔ na agba mawo o.

l Mɔ̃a ƒe ɖoɖo si mesɔ o, abe dɔwɔnu tiatia si mesɔ o alo spindle ƒe sesẽ si mesɔ gbɔ o ene, doa ŋusẽ axial (kple axis of rotation) kple radial (le eɖokui si ɖe axis la ŋu), overwhelming the bearings.

Nutsotso ƒe goglome si me wowɔa adã le:

l Nutsotso ƒe goglome si gbɔ eme le mɔ̃ɖaŋudɔwɔwɔ me zi ŋusẽ ɖe spindle kple bearings dzi kpata eye wòsẽna ɖe edzi. Agba siawo siwo wotsɔna ƒoa agbae ate ŋu agbɔ bearing la ƒe agbatsɔtsɔ ƒe ŋutete ŋu, si ana nuteɖeamedzi enumake eye wòagblẽ nu le eŋu ɣeyiɣi didi.

l Deep cuts si me afɔɖeɖe nyui siwo dzi ɖe edzi alo dɔwɔnu ƒe mɔ̃ɖaŋununya ƒe nyonyome dzina ɖe edzi o dzia agbatsɔtsɔ fũ ƒe mɔnukpɔkpɔ ɖe edzi.

Nuɖuɖu ƒe agbɔsɔsɔ kabakaba si mesɔ ɖe spindle ƒe ŋutetewo nu o:

l Nuɖuɖu ƒe agbɔsɔsɔ kɔkɔ siwo mewɔ ɖeka kple spindle ƒe aɖaŋuwɔwɔ ƒe nɔnɔmewo o la hea nyaƒoɖeamenu si mesɔ o ɖe bearings dzi vɛ. Masɔmasɔ sia hea ʋuʋudedi kple agba si trɔna fũu akpa vɛ, si ate ŋu ana bearing ƒe ɖoɖoa natɔ te.

l Nuɖuɖu ƒe agbɔsɔsɔ kabakaba tsɔ kpe ɖe dɔwɔnu alo dɔwɔwɔ ƒe ɖoɖo si mesɔ o ŋu la gagblẽa ŋusẽ ƒe mama si mesɔ o me ɖe edzi.

Mɔ̃a ƒe nɔnɔme alo dɔwɔwɔ si mesɔ o:

l Bearings alo spindles zazã kple agba ƒe dzidzedzekpɔkpɔ si mesɔ gbɔ na dɔwɔwɔ o ate ŋu ana agbatsɔtsɔ na ame geɖe gɔ̃ hã le dɔwɔwɔ ƒe nɔnɔme siwo sɔ me.

l Dɔwɔƒe ƒe vodadawo, abe CNC mɔ̃wo ƒe ɖoɖowɔwɔ si mesɔ o alo aɖabaŋeŋe ƒu nusiwo le eme ƒe nɔnɔmewo dzi ene, kpena ɖe ŋusẽ siwo gbɔ eme le bearings ŋu.

Dɔwɔwɔ ɖe bearing overloading dzi .

Ne wotsɔ ŋusẽ siwo gbɔ woƒe aɖaŋuwɔwɔ ŋu la ɖo bearings dzi la, wokpɔa nu vovovo siwo gblẽa nu le ame ŋu si gblẽa nu le dɔwɔwɔ kple nusiwo nɔa anyi didina ŋu:

Ðeɖiteameŋu ƒe gbagbã le bearing duɖimekekewo me:

l Agbatsɔtsɔ fũ enuenu hea cyclic stress vɛ le bearing races (ememe kple egodo ƒe asigɛ siwo me nusiwo le ʋuʋum la le). Le ɣeyiɣi aɖe megbe la, esia nana ɖeɖiteameŋu ƒe gbagbã, afisi micro-cracks ƒoa ƒu ɖo eye wòkakana to nusi wotsɔ wɔe me.

l Akpa si me gbagbãƒe siawo le la nana bearing ƒe wɔwɔme gbɔdzɔna, si ɖea ŋutete si le esi be wòado alɔ agbawo dzi kpɔtɔna eye wòdzia afɔku si le kpododonu me ɖe edzi.

Deformation tso agba siwo gbɔ eme gbɔ:

l Ŋusẽ siwo gbɔ eme ate ŋu ana bearing ƒe akpa aɖewo natrɔ, abe nusiwo le ʋuʋum (ball alo rollers) alo duɖimekeke ene. Deformation sia trɔa bearing ƒe geometry, si wɔnɛ be wometrɔna ɖe ɖoɖo nu o, eƒe ʋuʋudedi dzina ɖe edzi, eye wòɖea pɛpɛpɛ dzi kpɔtɔna.

l deformed bearings hã ate ŋu ahe dzoxɔxɔ si gbɔ eme vɛ, si ana be wòagado kabakaba wu.

Do alo spalling kaba:

l Agbatsɔtsɔ fũu akpa naa ɖeɖiteameŋu si le anyigba dzi kabakaba, si wɔnɛ be dowo (do suewo) alo spalling (nuawo ƒe fliwo) nɔa bearing la dzi. Gblẽƒe siawo gblẽa nu le dɔwɔwɔ nyuie ŋu, wodzia ʋuʋu ɖe edzi, eye bearing ƒe dɔmawɔmawɔ kabakaba.

l pitting kple spalling gblẽa nu le dɔ siwo wowɔna pɛpɛpɛ ŋutɔ ŋu vevietɔ, afisi anyigba ƒe nɔnɔme madzɔmadzɔ suesuesuewo gɔ̃ hã ate ŋu akpɔ ŋusẽ ɖe dɔwɔwɔ dzi le.

Dodokpɔ enumake:

l Le nɔnɔme sesẽwo me la, agbatsɔtsɔ fũ ate ŋu ana ame nado kpo nu vevie, abe bearing fracture alo spindle stall ene. Bearing si me gbagbã ate ŋu axɔ keŋkeŋ, atɔ te mɔ̃a ƒe dɔwɔwɔ eye wòate ŋu agblẽ nu le akpa bubuwo ŋu.

L ƒe kpododonu kpata hã ate ŋu ahe dedienɔnɔ ƒe afɔkuwo vɛ na dɔwɔlawo eye wòahe nuwɔwɔ ƒe nugblẽfe gã aɖe vɛ.

Nusiwo dona tso agbatsɔtsɔ fũu me .

Nusiwo dona tso agbatsɔtsɔ fũ me la keke ta wu nusiwo gblẽna enumake le bearing la ŋutɔ ŋu eye ate ŋu akpɔ ŋusẽ ɖe dɔwɔwɔ kple ganyawo dzi kura:

l Dɔwɔnu siwo dzi woɖe kpɔtɔ ƒe agbenɔƒe : Bearings siwo me agba le fũu la gblẽna kabakaba, si wɔnɛ be woɖɔlia wo enuenu eye wodzia beléle na wo ƒe gazazãwo ɖe edzi.

l Ɣeyiɣi si woatsɔ awɔ dɔe dzi ɖe edzi : Zi geɖe la, bearing ƒe kpododonuwo bia be woadzra wo ɖo vevie, si wɔnɛ be womewɔa ɖoɖo ɖe dɔwɔwɔ ŋu o eye wowɔa tɔtɔ le ewɔwɔ ƒe ɖoɖowɔɖiwo me.

l Nusiwo gblẽ le eŋu : Bearing siwo gblẽ alo esiwo gblẽ la ɖea mɔ̃ɖaŋununya ƒe dɔwɔwɔ ƒe nyateƒenyenye dzi kpɔtɔna, si ate ŋu ahe akpa siwo gblẽ kple dɔwɔwɔ ake vɛ.

l Ŋusẽzazã si lolo wu : Bearings siwo me agba le fũ akpa dzina ɖe edzi, si bia ŋusẽ geɖe wu be woatsɔ awɔ mɔ̃wo ŋudɔ eye woahe gazazãwo ɖe dzi.

l Dedienɔnɔ ƒe afɔkuwo : Bearing ƒe gbagbã kpata alo spindle stall ate ŋu ahe nɔnɔme siwo me afɔku le vɛ, abe gbeɖuɖɔ siwo dzona alo mɔ̃ ƒe nuwɔna si dzi womeɖu o ene.

Nu nyuitɔ kekeake siwo woawɔ atsɔ aɖe edzi akpɔtɔ .

Agbatsɔtsɔ fũ nye nya si woate ŋu axe mɔ na si dona tso mɔ̃ɖaŋununya ƒe nuwɔna siwo mesɔ o me, abe nusiwo mesɔ o zazã, lãɖeɖe ƒe goglome sesẽwo, alo nuɖuɖu ƒe agbɔsɔsɔ si mesɔ o zazã ene. Ðeɖiteameŋu si dona tso eme, eƒe nɔnɔme ƒe tɔtrɔ, eƒe dowo, kple kpododonu si ate ŋu adzɔ si ate ŋu adzɔ ate ŋu ana dɔwɔnuwo ƒe agbenɔƒe naɖiɖi, gazazãwo dzi ɖe edzi, kple afɔku siwo le dedienɔnɔ me. To lãɖeɖe ƒe nɔnɔmewo ƒe sɔsɔ kple bearing ŋutetewo, dɔwɔnu ɖaɖɛwo zazã, agbawo dadasɔ, kple beléle na wo edziedzi zazã me la, dɔwɔlawo ate ŋu aɖe afɔku si le agbatsɔtsɔ fũ me dzi akpɔtɔ ŋutɔ. Afɔɖeɖe siawo siwo wowɔna do ŋgɔ la kpɔa egbɔ be wowɔa dɔ si ŋu kakaɖedzi le, wodoa ŋusẽ bearings kple mɔ̃ siwo do ƒome kplii ƒe agbenɔƒe ɖe edzi, eye mlɔeba la, wowɔa akpa aɖe le dɔwɔwɔ nyuie kple gazazã dzi ɖeɖe kpɔtɔ me.

2. Amisisi si mesɔ o alo esi me ɖiƒoƒo mele o .

Amisisi le vevie ŋutɔ na bearings ƒe dɔwɔwɔ nyuie wu kple agbenɔƒe didi le mɔ̃ siwo trɔna me, abe spindles, motors, alo mɔ̃ bubuwo ene. Eɖea ʋuʋudedi si le akpa siwo le ʋuʋum dome dzi kpɔtɔna, eɖea dzoxɔxɔ ɖa, eye wòkpɔa anyigba ƒe akpa aɖewo ta be woagavuvu o. Gake amisisi si mesɔ o alo esi me ɖi le ate ŋu ahe dɔwɔwɔ ƒe nya sesẽwo vɛ, si ana bearing ƒe dɔwɔwɔ nagblẽ eye wòana kpododonu kaba.

Nusiwo hea amisisi si mesɔ o alo esi me ɖiƒoƒo mele o vɛ .

Amisisi ƒe kpododonuwo dzɔna le nu geɖe siwo gblẽa nu le amia ƒe ŋutete be wòawɔ eƒe dɔ veviwo ŋu ta:

Ami ƒe agbɔsɔsɔ si bɔbɔ:

l Ami si mesɔ gbɔ o si le bearing-mɔ̃a me nana be anyigba siwo le ʋuʋum, abe nusiwo le ʋuʋum kple ameƒomeviwo ene, kana ɖe wo nɔewo dzi ƒuƒlu. Ami ƒe anyimanɔmanɔ sia nana ʋuʋudedi dzina ɖe edzi, si wɔnɛ be dzesi (scratches alo gouges) nɔa bearing surfaces dzi.

l Agbɔsɔsɔme si bɔbɔ ate ŋu atso beléle na wo edziedzi, gbãtɔ si me mekɔna le gɔmedzedzea me o, alo woƒe vɔvɔ vivivi le ɣeyiɣi aɖe megbe le yaƒoƒo alo tsi si le dodom ta.

Ðiƒoƒo siwo le ami me:

l Gbeɖuɖɔ, abe ke, ɖiƒoƒo, alo ga ƒe akpa aɖewo ene, ate ŋu age ɖe amia me, atrɔe wòazu nusi wotsɔna ƒoa nui. Ðiƒoƒo siawo ƒoa nu ɖe anyigba siwo dzi wotsɔa nu ƒoa nui ŋu, si wɔnɛ be woƒe lãme gbãna kabakaba.

l Tsi ƒe gege ɖe eme, zi geɖe le nutrenu alo teƒe siwo tsi dzana le o ta la, etsaka kple amia, si ɖea eƒe ʋeʋẽ dzi kpɔtɔna eye wòdoa xɔxlɔ̃ alo emulsification ɖe ŋgɔ, si gblẽa amisisi ƒe dɔwɔwɔ me.

Nutrenu siwo le tsia dzi alo beléle na wo si wodzo le wo dzi:

l Nutrenu siwo wodo, gblẽ, alo esiwo womede nyuie o la ɖea mɔ na ami si sina, si wɔnɛ be nusiwo wodzra ɖo ɖi la nu yina eye wònaa bearingwo ɖina na ɖinuwo.

l Ne womeŋe aɖaba ƒu beléle na wo edziedzi ƒe ɖoɖowɔɖiwo dzi o, abe ami ƒe agbɔsɔsɔ me dzodzro alo eɖoɖo ɖe teƒe bubu o ene la, ehea amisisi si mesɔ o vɛ le ɣeyiɣi aɖe megbe.

Ami siwo mesɔ o zazã:

l Ami siwo mewɔ ɖeka kple bearing la ƒe nɔnɔmewo o (le kpɔɖeŋu me, viscosity, type, alo additives siwo mesɔ o) ate ŋu ado kpo ametakpɔkpɔ si sɔ nana, si ana ʋuʋudedi kple vuvu nadzi ɖe edzi.

l Ami siwo mewɔ ɖeka kple wo nɔewo o tsakatsaka, abe ami kple ami alo ami ƒomevi vovovowo tsɔtsɔ ƒo ƒui ene, ate ŋu agblẽ dɔwɔwɔ me eye wòana amisisi nado kpo nu.

Amisisi si mesɔ o alo esi me dɔlékuiwo le ƒe ŋusẽkpɔɖeamedziwo .

Ne amisisi mesɔ gbɔ alo ƒo ɖii o la, bearings kpɔa nu vovovo siwo gblẽa nu le woƒe dɔwɔwɔ ŋu:

Anyigba ƒe ʋuʋu kple dowo:

l Ami si mesɔ gbɔ o alo ɖiƒoƒo siwo me wodea amii la nana anyigbaa ƒuna, afisi wodoa nu le bearing la ƒe rolling elements alo ameƒomeviwo. Esia hea dowo vɛ, si ƒe dzesi enye be do suewo le edzi, si gblẽa nu le dɔwɔwɔ nyuie ŋu.

l Dodo dzia ʋuʋudedi kple toɣliɖeɖe ɖe edzi, si ɖea pɛpɛpɛ dzi kpɔtɔna eye wògagblẽa nu geɖe wu.

Dzoxɔxɔ si dzi ɖe edzi tso ʋuʋudedi me:

l Ami nyui aɖeke manɔmee la, ʋuʋudedi si le akpa siwo le ʋuʋum dome la nana dzoxɔxɔ si gbɔ eme la nana ame. Dzoxɔxɔ sia si kɔ la ate ŋu agblẽ nu le nusi wotsɔ ƒoa nui ŋu, ana eƒe wɔwɔme nagbɔdzɔ, eye wòana dzoxɔxɔ nakeke ɖe enu, si ana be nyawo nasɔ ɖe wo nɔewo nu alo woaɖe wo ɖa.

l Ami siwo me dɔlékuiwo le la nana dzoxɔxɔ dzinana ɖe edzi to nu suesuesue siwo nana ʋuʋudedi dzina ɖe edzi la dodo ɖe ŋgɔ me.

Alɔ̃dɔdɔ le nɔnɔme siwo gbɔ eme me:

l Le nɔnɔme sesẽwo me la, amisisi nyuie ƒe anyimanɔmanɔ ate ŋu ana bearings naxɔ, afisi ʋuʋudedi ƒe akpawo kple ameƒomeviwo tsia le le ʋuʋudedi si gbɔ eme alo nusiwo wotsɔ wɔa nu ƒe ƒoƒo ta. Seizure tɔa mɔ̃wo ƒe dɔwɔwɔ, si ate ŋu ahe afɔku gã aɖe vɛ eye wòagblẽ nu le akpa siwo ƒo xlãe ŋu.

l Zi geɖe la, alɔ̃dɔdɔ nyea nusi dona tso eme ɣeyiɣi didi alo ɖiƒoƒo si gbɔ eme.

Amisisi si mesɔ o alo esi me ɖiƒoƒo mele o me tsonu .

Amisisi ƒe kpododonuwo me tsonuwo keke ta wu bearings ŋutɔ, si kpɔa ŋusẽ ɖe ɖoɖoa ƒe dɔwɔwɔ bliboa kple dɔwɔwɔ ƒe gazazãwo dzi:

l Reduced Bearing Lifespan : Amisisi si mesɔ o alo esi me ɖiƒoƒo mele o naa vuvu kabakaba, si wɔnɛ be bearings ƒe agbenɔƒe nɔa kpuie ŋutɔ eye wòhiã be woaɖɔli wo enuenu.

l Beléle na wo ƒe gazazãwo dzi ɖe edzi : Nuwo ƒe gbegblẽ tso amisisi ƒe kpododonuwo gbɔ nana wodzraa nuwo ɖo le ga geɖe me, siwo dometɔ aɖewoe nye bearing replacement kple downtime hena beléle na wo.

l Nuwɔwɔ ƒe dɔwɔwɔ ƒe ɖiɖi : Bearing ƒe kpododonuwo le amisisi manyomanyo ta ate ŋu atɔ te ewɔwɔ, si ana be ɣeyiɣi mamlɛawo nato ŋuwò eye wòagblẽ ga.

l Nusiwo gblẽ le eŋu : Nusiwo gblẽ le anyigba ŋu kple Friction ƒe dzidziɖedzi ɖea mɔ̃wo ƒe nyateƒetoto dzi kpɔtɔna, si gblẽa nu le adzɔnuwo ƒe nyonyome ŋu le nusiwo wowɔna pɛpɛpɛ abe yamenutomeyimɔ̃ alo elektrɔnikmɔ̃wo ene me.

l Dedienɔnɔ ƒe afɔkuwo : Bearing seizure alo kpododonu kpata ate ŋu ahe nɔnɔme siwo me afɔku le vɛ, abe mɔ̃ ƒe nuwɔna si dzi womeɖu o alo gbeɖuɖɔ wɔwɔ ene, si ahe afɔkuwo vɛ na dɔwɔlawo.

Nu nyuitɔ kekeake siwo woawɔ atsɔ aɖe edzi akpɔtɔ .

Amisisi si mesɔ gbɔ o alo esi me aɖi le la nye afɔku gã aɖe na bearing ƒe dɔwɔwɔ, si wɔnɛ be anyigba ƒe ʋuʋu, dowo, dzoxɔxɔ si dzina ɖe edzi, kple alɔ̃madɔmadɔ si ate ŋu adzɔ la vaa ame dzi. Nya siawo tsoa amisisi ƒe agbɔsɔsɔ si bɔbɔ, ɖiƒoƒo to gbeɖuɖɔ alo tsi, nutrenu siwo le dodom, alo beléle na wo ƒe nuwɔna siwo mesɔ o gbɔ. Ne wozã ami siwo woɖo ɖi, ŋkuléle ɖe ami ƒe agbɔsɔsɔ ŋu, ami siwo me dɔlékuiwo le ɖɔliɖɔli enumake, kple nutrenu siwo wotsɔna léa ami ɖe te edziedzi la, dɔwɔlawo ate ŋu axe mɔ ɖe amisisi siwo do ƒome kple wo nɔewo ƒe kpododonuwo nu. Afɔɖeɖe siawo siwo wowɔna do ŋgɔ la doa ŋusẽ bearing kakaɖedzi, kekea dɔwɔnuwo ƒe agbenɔƒe ɖe enu, eye woɖea dɔwɔwɔ ƒe gazazãwo dzi kpɔtɔna, si wɔnɛ be dɔwɔwɔ kple dedienɔnɔ nɔa anyi ɖaa le dɔ veviwo wɔwɔ me.

3. Misalignment alo installation si mesɔ o .

Ðoɖo nyuie kple wo ɖoɖo ɖe ɖoɖo nyui nu le vevie ŋutɔ na bearings ƒe dɔwɔwɔ nyuie wu kple agbenɔƒe didi le mɔ̃ siwo trɔna me, abe spindles, motors, alo mɔ̃ɖaŋunu bubuwo ene. Wotrɔ asi le bearings ŋu be woawɔ dɔ kple wo nɔewo pɛpɛpɛ be woakpɔ egbɔ be agbawo mama gɔ̃ hã kple dɔwɔwɔ nyuie. Ne mesɔ ɖe ɖoɖo nu o alo eɖoɖo ɖe teƒe si mesɔ o ate ŋu ahe dɔwɔwɔ ƒe nya veviwo vɛ, eƒe dodo kabakaba, kple kpododonu kaba.

Nusiwo gbɔ wòtsona be womewɔa nu ɖe ɖoɖo nu o alo eɖoɖo ɖe teƒe si mesɔ o .

Misalignment alo imroper installation dzɔna ne bearings mele teƒe si sɔ alo dedienɔnɔ, si hea dɔwɔwɔ ƒe dɔmawɔmawɔ nyuie vɛ o. Nusiwo gbɔ wòtsona zi geɖe dometɔ aɖewoe nye:

Assembly vodadawo si hea shaft tilt vɛ:

l Vodadawo le kpekpea me, abe bearings ƒe tsɔtsɔ ɖe shafts alo xɔwo dzi nyuie o, ate ŋu ana shaft naʋuʋu alo dzogoe ƒe masɔmasɔ. Misignment sia gblẽa nu le bearing la ƒe ŋutete be wòatrɔ nyuie ŋu.

l Nuwɔwɔ ɖe ame ŋu le mɔ gbegblẽ nu, abe ŋusẽ si mesɔ o zazã le eɖoɖo me alo dɔwɔnu siwo mesɔ o zazã ene, ate ŋu ana bearings nato vovo tso gɔmedzedzea me ke.

Dzoxɔxɔ ƒe kekeɖenudɔwɔwɔ ƒe tɔtrɔ ƒe nɔƒewo:

l Le dɔwɔwɔ me la, mɔ̃wo ƒe akpa aɖewo ate ŋu ado dzo, si ana dzoxɔxɔ nakeke si atrɔ afisi bearing, shafts, alo xɔwo le. Ne womebu akɔnta le aɖaŋuwɔwɔ alo eɖoɖo ƒe ɖoɖoa me o la, esia ate ŋu ana woawɔ nu ɖe ɖoɖo nu.

l clearance si mesɔ o alo preload settings si mesɔ o ate ŋu ana dzoxɔxɔ ƒe kekeɖenudɔwɔwɔ si mesɔ o nagado gã ɖe edzi.

Dodo ɖe anyigba siwo mesɔ o dzi:

l Bearings dede anyigba siwo mesɔ o alo esiwo womedzra ɖo nyuie o, abe xɔ siwo wotsɔ ƒo ƒu alo mɔ̃ siwo ƒe gɔmeɖoanyi mesɔ o ene, hea nusiwo mesɔ o vɛ tso gɔmedzedzea me.

l Mɔ̃ɖaŋununya ƒe mɔɖeɖe ɖe nu ŋu nyuie alo anyigba dzi dzadzraɖo si mesɔ o (le kpɔɖeŋu me, gbeɖuɖɔ alo burrs siwo le anyigba dzi) ate ŋu axe mɔ na bearings be woaganɔ anyi nyuie o.

Ðoɖo siwo mewɔ ɖeka kple wo ɖoɖo o:

l Afɔɖeɖe veviwo dzi ɖeɖe kpɔtɔ, abe alesi woaɖo kpe edzi alo torque ƒe nɔnɔmewo ene, le eɖoɖo me ate ŋu ana bearings ƒe zikpuiwo mesɔ o alo woanɔ anyi ɖe mɔ gbegblẽ nu.

l Hehenana ƒe anyimanɔmanɔ alo mɔ̃a wɔlawo ƒe mɔfiamewo dzi mawɔmawɔ zi geɖe hea vodada siwo le eɖoɖo me si gblẽa bearing ƒe dɔwɔwɔ me la vɛ.

Nusiwo dona tso ɖoɖo si mesɔ o alo eɖoɖo ɖe teƒe si mesɔ o me .

Ne wotsɔ bearingwo ɖo wo nɔewo gbɔ le mɔ si mesɔ o nu alo woda wo ɖe mɔ̃ dzi o la, wokpɔa nu vovovo siwo gblẽa nu le woƒe dɔwɔwɔ kple agbenɔƒe didi ŋu le mɔ gbegblẽ nu:

Agbamama si mesɔ o:

l Misalignment hea ŋusẽwo mama ɖe mɔ si mesɔ o nu ɖe bearing la dzi, eye teƒe aɖewo toa agba siwo gbɔ eme me. Esia nana be nu siwo le ʋuʋum, duɖimekeke, alo atɔ siwo le ʋuʋum la nu sẽna kabakaba, si hea kpododonu kaba vɛ.

l Agbatsɔtsɔ le mɔ si mesɔ o hã ate ŋu ana nuteɖeamedzi ƒe ƒuƒoƒo si le teƒe ɖeka hã, si ana ŋutilãmenuwo ƒe ɖeɖiteameŋu nadzi ɖe edzi.

Ðeɖiteameŋu si vibration hena vɛ:

l Bearings siwo mesɔ o la hea ʋuʋudedi si gbɔ eme vɛ le esi wometrɔna le mɔ si mesɔ o nu alo woʋuʋuna ta. Ʋuʋu sia hea nuteɖeamedzi si nɔa tsatsam vɛ, si hea ɖeɖiteameŋu ƒe gbagbã vɛ le bearing ƒe akpawo me.

l Ʋuʋudedi ƒe ʋuʋu didi ate ŋu akaka ɖe mɔ̃a ƒe akpa bubuwo, si ana be ɖoɖoa nagavuvu alo agblẽ nu le eŋu.

Dzoxɔxɔ si tso ʋuʋudedi si wotsɔ kpe ɖe eŋu me:

l Malignment dzia ʋuʋudedi ɖe edzi le bearing components dome, si wɔnɛ be dzoxɔxɔ si gbɔ eme dona. Dzoxɔxɔ sia ate ŋu agblẽ amiwo me, ana bearing-nuawo nagbɔdzɔ, eye wòana dzoxɔxɔ nakeke ta, si ana be woagaɖo wo ɖe ɖoɖo nu o.

l Dzoxɔxɔ si kɔ ɖe dzi ɖea bearing la ƒe nuwɔwɔ pɛpɛpɛ kple eƒe dɔwɔwɔ nyuie dzi kpɔtɔna, si wɔnɛ be dzoxɔxɔ si ate ŋu anɔ eme alo doa kpo nu.

Bearing ƒe agbenɔƒe dzi ɖe kpɔtɔ:

l Agbatsɔtsɔ, ʋuʋu, kple ʋuʋudedi ƒe dzidziɖedzi ƒe ŋusẽkpɔɖeamedzi siwo katã wotsɔ ƒo ƒui la nana bearing la ƒe dɔwɔwɔ dzi ɖena kpɔtɔna ŋutɔ, si wɔnɛ be wòhiãna be woaɖɔli wo enuenu eye woadzi beléle na wo ƒe gazazãwo ɖe edzi.

Nusiwo dona tso eme ne womeɖoe ɖe ɖoɖo si mesɔ o alo eɖoɖo ɖe ɖoɖo si mesɔ o nu .

Nusiwo dona tso eme ne woɖo wo ɖe ɖoɖo si mesɔ o alo wo ɖoɖo ɖe mɔ gbegblẽ nu la keke ta wu bearings la ŋutɔ, si kpɔa ŋusẽ ɖe ɖoɖoa ƒe dɔwɔwɔ bliboa kple dɔwɔwɔ ƒe gazazãwo dzi:

l Accelerated Wear and Failure : Agba siwo mesɔ o kple ʋuʋudedi kabakaba, si hea bearing ƒe kpododonu kaba kple dɔwɔnuwo ƒe agbenɔƒe dzi ɖeɖe kpɔtɔ vɛ.

l Dzadzraɖo ƒe ga si dzi ɖe edzi : Wodzraa wo ɖo enuenu alo woɖɔlia wo le nusiwo gblẽ le wo ŋu le mɔ gbegblẽ nu ta la ʋua beléle na wo ƒe gazazãwo.

l Nuwɔwɔ ƒe dɔwɔwɔ ƒe ɖiɖi : Bearings siwo mesɔ o ate ŋu ahe kpododonu siwo womele mɔ kpɔm na o vɛ, woatɔ te nuwɔwɔ eye wòahe gakpɔkpɔ si bu alo ɣeyiɣi mamlɛ siwo woda ɖi la vɛ.

l Nusiwo gblẽ le eŋu : Le dɔwɔwɔ pɛpɛpɛ, abe CNC mɔ̃ alo robot ene me la, vovomanɔmanɔ ɖea nyateƒetoto dzi kpɔtɔna, si wɔnɛ be wowɔa nusiwo gblẽ alo gbugbɔgawɔ.

l Dedienɔnɔ ƒe afɔkuwo : Ʋuʋu fũ akpa alo bearing ƒe gbegblẽ kpata ate ŋu ahe nɔnɔme siwo me afɔku le vɛ, abe akpa aɖewo ɖeɖeɖa alo mɔ̃ ƒe nuwɔna si dzi womeɖu o ene, si ahe afɔkuwo vɛ na dɔwɔlawo.

Nu nyuitɔ kekeake siwo woawɔ atsɔ aɖe edzi akpɔtɔ .

Bearings ƒe ɖoɖo si mesɔ o alo esi mesɔ o, si tso vodada siwo wowɔ le kpekpewo me, dzoxɔxɔ ƒe kekeɖenudɔwɔwɔ, alo anyigba siwo dzi womeɖoa wo ɖo o gbɔ la, hea agbawo mama si mesɔ o, ɖeɖiteameŋu si ʋuʋuna vɛ, kple ʋuʋudedi si dzina ɖe edzi vɛ. Nya siawo nana be woƒe lãme gbãna kabakaba, woɖea wo pɛpɛpɛ dzi kpɔtɔna, eye dɔwɔnu siwo ate ŋu ado mo ɖa la me gblẽna le wo ŋu, eye woƒe dɔwɔwɔ kple ganyawo me tsonu gãwo. Ne wozã dɔwɔnu siwo sɔ ɖe wo nɔewo nu, wowɔ ɖe ɖoɖo ɖe wo nɔewo ŋu vɔ megbe, akɔntabubu le dzoxɔxɔ ƒe kekeɖenudɔwɔwɔ ŋu, kple ŋkuléle ɖe wo ŋu edziedzi me la, dɔwɔlawo ate ŋu axe mɔ ɖe nya siwo ku ɖe ɖoɖo si mesɔ o ŋu nu. Afɔɖeɖe siawo siwo wowɔna do ŋgɔ la kpɔa egbɔ be bearing ƒe dɔwɔwɔ si ŋu kakaɖedzi le, na dɔwɔnuwo ƒe agbenɔƒe nadidi ɖe edzi, eye woana dɔwɔwɔ nyuie nanyo ɖe edzi, si ɖea ɣeyiɣi si woatsɔ awɔ dɔe kple gazazãwo dzi kpɔtɔna le dɔ veviwo wɔwɔ me.

4. ɖiƒoƒo tso ke kple gbeɖuɖɔ me .

Ðiƒoƒo tso ke kple gbeɖuɖɔ me nye nusi ŋu wotsi dzi ɖo vevie le nuto siwo me mɔ̃ siwo wɔa dɔ pɛpɛpɛ, abe spindles, bearings, alo mɔ̃ɖaŋunu bubuwo ene, wɔa dɔ le la me. Ðiƒoƒo siawo, siwo dometɔ aɖewoe nye nu suesuesuewo abe ke, ɖiƒoƒo, ga lũlũ, alo nusuekpɔmɔ̃ bubuwo ene, ate ŋu age ɖe mɔ̃wo me to mɔ vovovowo dzi, si ana be dɔwɔwɔ ƒe dɔmawɔmawɔ nyuie kple nusiwo gblẽ le eŋu ŋutɔ.

Nusiwo hea ɖiƒoƒo vɛ .

Zi geɖe la, ke kple gbeɖuɖɔwo ƒe gege ɖe eme dzɔna le nu siwo gbɔna la dometɔ ɖeka alo esi wu nenema ta:

Nutrenu ƒe mɔnu gbegblẽwo:

Nutrenu siwo mesɔ gbɔ o alo esiwo vuvu siwo ƒo xlã mɔ̃wo ƒe akpa aɖewo la ɖea mɔ gotagomenu suesuesuewo gena ɖe teƒe veviwo. Le ɣeyiɣi aɖe megbe la, nutrenuwo ate ŋu aɖiɖi le esi wovuvu, wo dede wo me nyuie o, alo woƒe nɔnɔme sesẽ ta, si wɔnɛ be dometsotsowo nɔa anyi na ɖiƒoƒo be wòage ɖe eme.

Nutrenu siwo womewɔ be woanɔ te ɖe nutome ƒe kuxi aɖewo koŋ nu o, abe ke ƒe agbɔsɔsɔ si sɔ alo dzoxɔxɔ si gbɔ eme ene, koŋue nye esiwo ŋu woate ŋu adze agɔ le.

Dɔwɔƒe ƒoɖiwo:

Mɔ̃ siwo le dɔ wɔm le nuto siwo me ya me nu suesuesuewo sɔ gbɔ ɖo me, abe dɔwɔƒewo, xɔtuƒewo, alo teƒe siwo ya ƒe nyonyome mede o ene la le afɔku me wu be woaƒo ɖi.

Aƒemedzadzraɖo ƒe nuwɔna siwo mesɔ o, abe dɔwɔƒe siwo me mekɔ o ƒe kpododonu alo mɔɖeɖe na gbeɖuɖɔwo be woaƒo ƒu ɖe dɔwɔnu siwo te ɖe wo ŋu ene, si ana nyaa nagado gã ɖe edzi.

Beléle na amewo ƒe nuwɔna siwo mesɔ o:

Le beléle na wo alo wo dzadzraɖo me la, dɔwɔnuwo, asiwo, alo akpa siwo ŋu womekɔ nyuie o ate ŋu ana ɖiƒoƒonuwo naɖo ɖoɖoa me.

Ami siwo ŋu nu suesuesuewo le hã ate ŋu awɔ dɔ abe vektor ene hena mɔ̃wo ƒe gbagbãƒewo dede.

ɖiƒoƒo siwo le yame:

Nu suesuesue siwo wotsɔ ƒo ɖe yame, abe aŋɔ, dɔwɔƒewo ƒe ke, alo atike ƒe nugbagbevi siwo susɔ ene, ate ŋu anɔ mɔ̃wo dzi alo ahe wo ɖe mɔ̃wo me to yaxɔƒe alo yaƒoƒo me.

Nusiwo ɖiƒoƒo gblẽna le ame ŋu .

Ne ke kple gbeɖuɖɔwo nya ge ɖe mɔ̃wo me ko la, woate ŋu ana nu gbegblẽwo nado tso eme si gblẽa nu le dɔwɔwɔ kple agbenɔƒe didi ŋu. Nu vevi siwo ado tso eme dometɔ aɖewoe nye:

Abrasive grinding le anyigba dzi:

Ke kple gbeɖuɖɔwo, vevietɔ nu sesẽwo abe ga lũhɛwo alo silica ene, wɔa dɔ abe nusiwo wotsɔna ƒoa nu ene ne woxaxa ɖe akpa siwo le ʋuʋum dome. Esia hea micro-abrasions alo grinding ɖe edzi abe bearings, spindles, alo gears ene.

Le ɣeyiɣi aɖe megbe la, afɔɖeɖe sia si me woɖea nu le la nana be nuawo ƒe akpa aɖewo vuvuna, si ɖea akpa vovovoawo ƒe pɛpɛpɛ kple woƒe dɔwɔwɔ nyuie dzi kpɔtɔna eye wòhea masɔmasɔ alo ʋuʋudedi si dzina ɖe edzi vɛ.

Gbegblẽ tso ɖiƒoƒo siwo me tsi le me:

Zi geɖe la, ɖinuwo tsakana kple tsidzadza, tso nutoa me alo tso ami me, si wɔnɛ be nuto si gblẽa nu le ame ŋu la nɔa anyi. Le kpɔɖeŋu me, ke si me dze alo atikewo le ate ŋu ana gbeɖuɖɔ nadzɔ kabakaba ɖe ga dzi.

Gbegblẽ nana akpa aɖewo gbɔdzɔna, si hea dowo, gbagbã, alo xɔtunuwo ƒe gbagbã vɛ, si ate ŋu aɖe dɔwɔnuwo ƒe agbenɔƒe dzi akpɔtɔ ŋutɔ.

Mɔ siwo dzi woxe mɔ ɖo siwo woxe mɔ na:

Ke kple gbeɖuɖɔ ate ŋu axe ami ƒe mɔ̃wo, si ana be amiwo nagaɖo teƒe veviwo o. Esia wɔnɛ be womegadea ami me nyuie o, si wɔnɛ be ʋuʋudedi kple dzoxɔxɔ dzina ɖe edzi.

Mɔ siwo woxe mɔ na hã ate ŋu ahe ami ƒe mama si mesɔ o vɛ, si ana dzoxɔxɔ si gbɔ eme alo eƒe akpa aɖewo nado kpo nu.

ŋlɔmiwɔwɔ, ʋuʋudedi, kple eƒe gbagbã mlɔeba:

Ŋusẽ si abrasion, xɔxlɔ̃, kple amisisi si mesɔ gbɔ o ƒe ŋusẽkpɔɖeamedziwo dzena abe nusiwo woate ŋu akpɔ ene, abe ʋuʋudedi, aɖuɖɔ, alo anyigba ƒe nɔnɔme madzɔmadzɔwo ene.

Nya siawo gblẽa nu le akpa vovovoawo ƒe wɔwɔme ƒe blibonyenye ŋu, si wɔnɛ be mɔ̃awo ƒe vuvu kabakaba eye mlɔeba la, wotsia anyi vevie.

Nusiwo dona tso ɖiƒoƒo me .

Ke kple gbeɖuɖɔ ƒe ɖiƒoƒo me tsonuawo keke ta wu mɔ̃ɖaŋununya ƒe nugbegblẽ enumake eye woate ŋu akpɔ ŋusẽ gã aɖe ɖe dɔwɔwɔ kple ganyawo dzi:

l Dɔwɔnuwo ƒe dɔwɔwɔ nyuie dzi ɖe kpɔtɔ : Akpa siwo me dɔlékuiwo le la mewɔa dɔ nyuie o, si bia ŋusẽ geɖe wu be woawɔ dɔ mawo ke eye woadzi dɔwɔwɔ ƒe gazazãwo ɖe edzi.

l Dzadzraɖo ƒe ga si dzi ɖe edzi : Wodzraa wo ɖo enuenu alo woɖɔlia wo le nusiwo gblẽ le ɖiƒoƒo ŋu ta la ʋua beléle na wo ƒe gazazãwo.

l Ɣeyiɣi si woatsɔ awɔ dɔe kple nusiwo wowɔna ƒe bublu : Vovototo siwo womele mɔ kpɔm na o siwo ɖiƒoƒo hena vɛ ate ŋu atɔ te ewɔwɔ, si ana be ɣeyiɣi mamlɛawo nagato wo ŋu o eye ga si woakpɔ la nabu.

l Adzɔnuwo ƒe nyonyome si gblẽ : Le dɔwɔƒe siwo sɔ pɛpɛpɛ, abe yamenutomeyimɔ̃ alo elektrɔnikmɔ̃wo wɔwɔ ene la, ɖiƒoƒo ate ŋu ana woawɔ nusiwo gblẽ, si ana woagbugbɔ awɔ dɔ alo asisiwo ƒe dzimaɖitsitsi.

l Dedienɔnɔ ƒe afɔkuwo : Dɔwɔnu siwo gblẽ alo esiwo mewɔa dɔ nyuie o hea afɔkuwo vɛ na dɔwɔlawo, si ate ŋu ahe afɔku alo abixɔxɔ vɛ.

Nu nyuitɔ kekeake siwo woawɔ atsɔ aɖe edzi akpɔtɔ .

Ðiƒoƒo tso ke kple gbeɖuɖɔ me nye afɔku gã aɖe na mɔ̃ siwo wɔa dɔ pɛpɛpɛ ƒe dɔwɔwɔ kple agbenɔƒe didi. Ne wose nusiwo gbɔ wòtso gɔme—abe nutrenu siwo mede ame dzi o kple nuto ƒoɖiwo ene—kple nusiwo dona tso eme, siwo dometɔ aɖewoe nye abrasive wear, corrosion, kple ami ƒe mɔxexe la, dɔwɔlawo ate ŋu awɔ afɔɖeɖe siwo woawɔ do ŋgɔ atsɔ aɖe afɔkuwo dzi akpɔtɔ. Nu nyuitɔ kekeake siwo wowɔna, abe nutrenu nyuiwo, ya ƒe ʋuʋu, kple dzadzɛnyenye edziedzi ene, zazã ate ŋu aɖe ɖiƒoƒo dzi akpɔtɔ ŋutɔ, akpɔ egbɔ be wowɔ dɔ si ŋu kakaɖedzi le, ɣeyiɣi si woatsɔ awɔ dɔe dzi akpɔtɔ, eye wòadidi dɔwɔnu veviwo ƒe dɔwɔwɔ ƒe agbenɔƒe ɖe edzi. To ɖiƒoƒo dzi kpɔkpɔ ɖoɖo ɖe nɔƒe gbãtɔ me la, asitsahawo ate ŋu ana dɔwɔwɔ nanyo ɖe edzi, aɖe gazazãwo dzi akpɔtɔ, eye woalé dɔwɔwɔ nyuie ƒe dzidzenu kɔkɔwo me ɖe asi.

5. Ʋuʋu alo dadasɔmakpɔmakpɔ fũ .

Mɔ̃ siwo trɔna ƒe ʋuʋu fũ alo dadasɔmakpɔmakpɔ, abe spindles, mɔ̃wo, alo mɔ̃ bubu siwo ŋu bearing le ene, nye afɔku gã aɖe na dɔwɔwɔ ƒe dɔwɔwɔ kple akpa aɖewo ƒe agbenɔƒe didi. Nya siawo doa mo ɖa ne dɔwɔnuwo, rotors, alo nu bubu siwo trɔna la meda sɔ o alo ne ɖoɖoa wɔa dɔ le resonant frequency me, si wɔnɛ be mɔ̃ɖaŋununya ƒe nuteɖeamedzi si dzi ɖe edzi la doa ŋusẽe.

Nusiwo hea ʋuʋudedi alo dadasɔmakpɔmakpɔ vɛ .

Zi geɖe la, nu siwo gbɔna ƒe ʋuʋu alo mɔ̃wo ƒe ʋuʋu fũu akpa tsoa mɔ̃wo me:

Dɔwɔnu alo rotors siwo meda sɔ o:

l Dɔwɔnuwo, abe dɔwɔnu siwo wotso le mɔ̃wo me alo rotors le mɔ̃wo me ene, siwo meda sɔ nyuie o la wɔa ŋusẽ siwo mesɔ o le tɔtrɔ me. Dadasɔ sia hea ʋuʋudedi siwo tea nuteɖeamedzi bearings kple akpa bubuwo vɛ.

l Meda sɔ o ate ŋu atso dɔwɔnu ƒe vuvu si mesɔ o, ƒoƒo ƒu nyuie, alo nusiwo le tɔtrɔm ƒe wɔwɔme ƒe gbɔdzɔgbɔdzɔ gbɔ.

Resonant frequencywo:

l Ne mɔ̃wo le dɔ wɔm le eƒe dzɔdzɔme ƒe gbeɖiɖi ƒe tsɔtsɔme alo te ɖe eŋu la, wodoa ŋusẽ ʋuʋudediwo, si wɔnɛ be ʋuʋudedi si gbɔ eme la nɔa anyi. Resonance sia ate ŋu adzɔ le duƒuƒu ƒe ɖoɖo siwo mesɔ o alo aɖaŋu ƒe vodada siwo le ɖoɖoa me ta.

l Nusiwo le gota, abe mɔ̃ siwo te ɖe wo ŋu alo nutomeʋuʋu ene, hã ate ŋu ado dzidzɔ na gbeɖiɖi siwo ɖina zi geɖe, si ana nyaa nagado gã ɖe edzi.

Ðoɖo si mesɔ o alo ɖoɖowɔwɔ ɖe ɖoɖo nu:

l Akpa siwo mesɔ o, abe shafts alo couplings ene, ate ŋu ahe ʋuʋudedi vɛ to ŋusẽ ƒe mama si mesɔ o wɔwɔ le tɔtrɔɣi me.

l Akpa siwo le gbadzaa alo esiwo me womedea se ɖo o, abe dɔwɔnu alo nusiwo wotsɔna léa nu ɖe te ene, hã ate ŋu akpe asi ɖe dadasɔmakpɔmakpɔ kple ʋuʋu ŋu.

Do alo gblẽ le akpa aɖewo ŋu:

l Bearings siwo wodo, gears siwo gblẽ, alo akpa siwo gblẽ ate ŋu ahe ʋuʋu si mesɔ o vɛ, si ana ʋuʋudedi nadzi ɖe edzi.

l Gbegblẽ alo ɖiƒoƒo si ƒo ƒu ɖe ɖoɖoa me ate ŋu agblẽ nu le dadasɔ ŋu geɖe wu, si ana ʋuʋudediwo nado ŋusẽe.

Nusiwo dona tso ʋuʋudedi alo dadasɔmakpɔmakpɔ me .

Ne mɔ̃wo to ʋuʋu alo dadasɔmakpɔmakpɔ fũ me la, bearings kple akpa bubuwo kpea fu le nu vovovo siwo gblẽa nu le ame ŋu me:

Amplified oscillations siwo gblẽa nu le duɖimekeke ŋu:

l Vibrations si gbɔ eme hea ŋusẽkpɔɖeamedziwo enuenu kple agbatsɔtsɔ ɖe bearing duɖimekekewo dzi (ememe kple egodo ƒe asigɛ siwo me nusiwo le ʋuʋum la le). Esia hea nugbegblẽ le anyigba ŋu, abe micro-cracks alo nusiwo wotsɔ wɔa nu ene, si gblẽa nu le bearing la ƒe fɔmaɖimaɖi ŋu.

l Oscillations ate ŋu akaka ɖe mɔ̃a ƒe akpa bubuwo hã, si ana wòavuvu le afisiafi.

Ðeɖiteameŋu le tsatsamwo ŋu:

l Ʋuʋu si yia edzi ɖaa hea cyclic stress vɛ le bearings me, si wɔnɛ be ɖeɖiteameŋu ƒe ʋuʋu le ɣeyiɣi aɖe megbe. gbagbãƒe siawo nana bearing la ƒe wɔwɔme gbɔdzɔna, si wɔnɛ be kpododonu ƒe afɔkua dzina ɖe edzi.

l Ðeɖiteameŋu ƒe nugbegblẽwo ƒoa ƒu ɖe dɔwɔwɔ ƒe ɣeyiɣi ɖesiaɖe me, si ɖea bearing ƒe agbenɔƒe dzi kpɔtɔna ŋutɔ.

Dzoxɔxɔ si tsoa ʋuʋu ɣesiaɣi me:

l Vibrations dzia ʋuʋudedi ɖe edzi le bearing components dome, si hea dzoxɔxɔ si sɔ gbɔ vɛ. Dzoxɔxɔ sia ate ŋu agblẽ amiwo me, ana bearing-nuawo nagbɔdzɔ, eye wòana dzoxɔxɔ nakeke ɖe enu, si gagblẽa nu ɖe edzi le mɔ si mesɔ o alo eƒe ʋuʋu ƒe nyawo nu.

l Dzoxɔxɔ si nɔa anyi didi ate ŋu ana dzoxɔxɔa naxɔ dzo akpa, si aɖe dɔwɔwɔ nyuie dzi akpɔtɔ eye wòawɔ nu pɛpɛpɛ.

Mɔ̃wo ƒe nugbegblẽ le ame ŋu evelia:

l Ʋuʋu fũ ate ŋu aɖe nusiwo wotsɔ blaa nu, akpa siwo mesɔ o, alo agblẽ nu le akpa siwo te ɖe wo nɔewo ŋu dzi, si ana be ɖoɖoa ƒe kpododonu nakeke ta wu.

l Le nɔnɔme sesẽwo me la, ʋuʋudedi siwo ŋu womede dzesi o ate ŋu ana ame nado kpo nu vevie, abe bearing seizure alo shaft fracture ene.

Ʋuʋu alo dadasɔmakpɔmakpɔ si gbɔ eme me tsonu .

Nusiwo dona tso ʋuʋu alo dadasɔmakpɔmakpɔ fũ me keke ta wu bearings, si kpɔa ŋusẽ ɖe ɖoɖoa ƒe dɔwɔwɔ bliboa kple dɔwɔwɔ ƒe gazazãwo dzi:

l Dɔwɔnu siwo dzi woɖe kpɔtɔ ƒe agbenɔƒe : Vibrations kabakaba do, si wɔnɛ be bearings kple akpa bubuwo ƒe kpododonu kaba, si hiã be woaɖɔli wo enuenu.

l Beléle na wo ƒe gazazãwo dzi ɖe edzi : Nusiwo gblẽ le ʋuʋu ŋu bia be woadzra wo ɖo le ga geɖe me, siwo dometɔ aɖewoe nye bearing ɖɔliɖɔli kple ɖoɖoa gbugbɔgaɖoanyi.

l Nuwɔwɔ ƒe dɔwɔwɔ ƒe ɖiɖi : kpododonu siwo ʋuʋuna ate ŋu atɔ te ewɔwɔ, si ana ɣeyiɣi mamlɛtɔ siwo meto vovo o kple ga si bu na ame.

l Promised Precision : Ʋuʋu fũ akpa ɖea mɔ̃ɖaŋununya ƒe nyateƒetoto dzi kpɔtɔna, si hea nusiwo gblẽ alo gbugbɔgawɔ le dɔwɔƒewo abe yamenutomeyimɔ̃ alo elektrɔnikmɔ̃wo ene me.

l Dedienɔnɔ ƒe afɔkuwo : Ʋuʋudedi sesẽwo ate ŋu ahe akpa aɖewo ɖeɖeɖa vɛ, mɔ̃ ƒe nuwɔna si dzi womeɖu o, alo gbeɖuɖɔ wɔwɔ, si ahe afɔku vɛ na dɔwɔlawo.

Nu nyuitɔ kekeake siwo woawɔ atsɔ aɖe edzi akpɔtɔ .

Ʋuʋu alo dadasɔmakpɔmakpɔ fũ, si tso dɔwɔnu siwo meda sɔ o, gbeɖiɖi siwo ɖina, alo ɖoɖo si mesɔ o gbɔ la, hea ʋuʋudedi, ɖeɖiteameŋu, kple dzoxɔxɔ ƒe dzidziɖedzi vɛ, si gblẽa bearings kple akpa bubuwo. Nya siawo nana be dɔwɔnuwo ƒe agbenɔƒe dzi ɖena kpɔtɔna, wozãa beléle na xɔa ƒe gazazãwo dzi ɖe edzi, eye woɖea wo dzi kpɔtɔna pɛpɛpɛ, eye afɔku siwo ate ŋu ado mo ɖa le dedienɔnɔ me ate ŋu anɔ eme. To dɔwɔnuwo dadasɔ, ʋuʋudediwo ɖeɖe ɖe aga, ŋkuléle ɖe nu ŋu kple numekukumɔ̃wo, kple egbɔkpɔkpɔ be woɖo wo nyuie me la, dɔwɔlawo ate ŋu aɖe afɔku siawo dzi akpɔtɔ. Afɔɖeɖe siawo siwo wowɔna do ŋgɔ la doa mɔ̃wo ƒe kakaɖedzi ɖe ŋgɔ, wodidia dɔwɔwɔ ƒe agbenɔƒe ɖe edzi, eye woléa dɔwɔwɔ nyuie me ɖe asi, si ɖea ɣeyiɣi si woatsɔ awɔ dɔe kple gazazãwo dzi kpɔtɔna le dɔ veviwo wɔwɔ me.

6. Dzoxɔxɔ si le dɔ wɔm le dɔwɔwɔ me kɔkɔ .

Dzoxɔxɔ si nu sẽ ŋutɔ nye kuxi gã aɖe na bearings kple mɔ̃ bubu siwo trɔna, abe spindles alo motors ene ƒe dɔwɔwɔ kple woƒe agbenɔƒe didi. Dzoxɔxɔ si gbɔ eme ate ŋu agblẽ nu le nuwo ŋu, agblẽ nu le amisisi ŋu, eye wòahe tɔtrɔwo vɛ, si ana be dɔwɔwɔ ƒe dɔmawɔmawɔ nyuie kple kpododonu kaba.

Nusiwo gbɔ dzoxɔxɔ si le dɔ wɔm le ŋutɔ tsona .

Zi geɖe la, dzoxɔxɔ si kɔ le mɔ̃wo me dona tso nusiwo ku ɖe dɔwɔwɔ, nutome, kple beléle na wo ŋu ƒe ƒuƒoƒo me:

Friction si gbɔ eme:

l Friction si sɔ gbɔ le bearing components dome, zi geɖe la, le amisisi si mesɔ o, eƒe tsɔtsɔ ɖe ɖoɖo nu, alo agbatsɔtsɔ fũ ta, hea dzoxɔxɔ gã aɖe vɛ.

l Dɔwɔnu siwo da sɔ le mɔ gbegblẽ nu alo ʋuʋudedi si gbɔ eme ate ŋu ana ʋuʋudedi nadzi ɖe edzi, si ana dzoxɔxɔ si kɔ na ame nadzi ɖe edzi.

Agbatsɔtsɔ fũ alo dɔwɔwɔ sesẽe:

l Mɔ̃ siwo wɔa dɔ wu eƒe agba ƒe ŋutete si woɖo, abe mɔ̃ɖaŋunu sesẽwo wɔwɔ alo lãɖeɖe ƒe nɔnɔme sesẽwo zazã ene, dzia dzoxɔxɔ wɔwɔ ɖe edzi le mɔ̃ɖaŋununya ƒe nuteɖeamedzi si nu sẽ ta.

l Duƒuƒu sesĩe alo nuɖuɖu ƒe agbɔsɔsɔ ate ŋu ado ŋusẽ dzoxɔxɔ ƒe wɔwɔ, vevietɔ le bearings siwo womeɖo na nɔnɔme mawo o me.

Fafamɔ̃ siwo mesɔ gbɔ o:

l fafamɔ̃ siwo mesɔ gbɔ o alo esiwo mewɔa dɔ nyuie o, abe yaƒomɔ̃wo, fafanu ƒe pɔmpiwo, alo dzoxɔxɔ ɖɔliɖɔli ene, mete ŋu kakaa dzoxɔxɔ nyuie o, si wɔnɛ be dzoxɔxɔa dzina ɖe edzi.

l Ya manyomanyo alo yame ƒe dzoxɔxɔ gã si le dɔwɔwɔ ƒe nɔnɔme me nana dzoxɔxɔ ƒe dzidziɖedzi dzina ɖe edzi.

Ami ƒe gbegblẽ alo tiatia si mesɔ o:

l Ami siwo mesɔ na dzoxɔxɔ si me dzoxɔxɔ le o ate ŋu aɖiɖi alo agblẽ, si aɖe woƒe ŋutete be woakaka dzoxɔxɔ dzi akpɔtɔ eye woakpɔ bearing ƒe anyigbawo ta.

l Ami siwo me ɖi le alo esiwo gblẽ hã ate ŋu akpe ɖe wo ŋu be ʋuʋudedi kple dzoxɔxɔ ƒe dzidziɖedzi nadzi ɖe edzi.

Dzoxɔxɔtsoƒe siwo tso egodo:

l Mɔ̃ siwo wɔa dɔ le gota dzoxɔxɔtsoƒewo gbɔ, abe dzodoƒewo, dzodoƒewo, alo ɣe ƒe keklẽ tẽ ene, ate ŋu akpɔ dzoxɔxɔ si kɔ si kpɔa ŋusẽ ɖe bearing ƒe dɔwɔwɔ dzi.

l Nusiwo womexɔna nyuie o alo ametakpɔnu tso dzoxɔxɔtsoƒe siwo le gota ate ŋu ana nyaa nagasẽ ɖe edzi.

Dɔlékuiwo ƒe dzoxɔxɔ gã ƒe ŋusẽkpɔɖeamedziwo .

Ne wotsɔ bearing kple mɔ̃wo de dzoxɔxɔ gãwo me la, wokpɔa nu vovovo siwo gblẽa nu le ame ŋu si gblẽa nu le dɔwɔwɔ kple nusiwo nɔa anyi didina ŋu:

Agbatsɔtsɔ ƒe ŋutete dzi ɖe kpɔtɔ:

l Dzoxɔxɔ gãwo nana bearing-nuawo, abe gakpo ene, naa woƒe sesẽme kple agbatsɔtsɔ ƒe ŋutete dzi ɖena kpɔtɔna. Gbɔdzɔgbɔdzɔ sia nana bearings te ŋu trɔna bɔbɔe le dɔwɔwɔ ƒe agba siwo sɔ me.

l Nusiwo wofa la mete ŋu nɔa te ɖe mɔ̃ɖaŋununya ƒe nuteɖeamedzi nu boo o, si wɔnɛ be wovuvuna kabakaba eye womete ŋu doa kpo nu o.

Ami ƒe gbagbã:

l Dzoxɔxɔ si dzina ɖe edzi nana amiwo nɔa sue, wowɔa oxidation, alo gblẽa nu le atikewo ŋu, si ɖea woƒe ʋeʋẽ kple dɔwɔwɔ dzi kpɔtɔna. Esia hea amisisi si mesɔ o, ʋuʋudedi si dzina ɖe edzi, kple dzoxɔxɔ bubu vɛ.

l Ami siwo gblẽ ate ŋu awɔ ʋuʋudedi alo varnish, axe ami ƒe mɔwo eye wòagblẽ nu le wo ŋu.

Dzoxɔxɔ ƒe ɖeɖiteameŋu ƒe gbagbãƒewo:

l Dzoxɔxɔ si nu sẽna enuenu hea dzoxɔxɔ ƒe ɖeɖiteameŋu vɛ, afisi dzoxɔxɔ kple fafa si tsoa tsikpe me hea micro-cracks vɛ le bearing surfaces me. gbagbãƒe siawo kaka le ɣeyiɣi aɖe megbe, si wɔnɛ be bearing la gbɔdzɔna eye wòdzia afɔku si le afɔku gã aɖe me ɖe edzi.

l Dzoxɔxɔ ƒe kekeɖenudɔwɔwɔ si mesɔ o ate ŋu ana nuteɖeamedzi ƒe agbɔsɔsɔ nagado gã ɖe edzi, si ana be gbagbã nadzɔ.

Dimensional ƒe tɔtrɔwo kple misalignment:

l Dzoxɔxɔ gãwo nana bearings, shafts, alo housings kekena ɖe enu le mɔ si mesɔ o nu, si wɔnɛ be woƒe ʋuʋu, ʋuʋuna ɖe edzi, kple agbawo mama mesɔna o.

l Dimensional changes siawo ate ŋu aɖe bearing clearance dzi akpɔtɔ, si ana be woblaa nu alo dzina ɖe edzi.

Dzoxɔxɔ gã si le dɔwɔwɔ me me tsonu .

Dzoxɔxɔ si gbɔ eme me tsonuawo keke ta wu bearings, si kpɔa ŋusẽ ɖe ɖoɖoa ƒe dɔwɔwɔ bliboa kple dɔwɔwɔ ƒe gazazãwo dzi:

l Dɔwɔnu siwo dzi woɖe kpɔtɔ ƒe agbenɔƒe : Nu siwo wofa kple ami ƒe gbagbã kabakaba kabakaba, bearing kple mɔ̃wo ƒe agbenɔƒe si le kpuie ŋutɔ.

l Dzadzraɖo ƒe ga si dzi ɖe edzi : Wodzraa wo ɖo enuenu alo woɖɔlia wo le dzoxɔxɔ ƒe nugbegblẽ le ame ŋu ta ʋua beléle na wo ƒe gazazãwo.

l Nuwɔwɔ ƒe dɔwɔwɔ ƒe ɖiɖi : kpododonu siwo ƒe dzoxɔxɔ de ŋgɔ ate ŋu atɔ te ewɔwɔ, si ana be ɣeyiɣi mamlɛawo nato wo ŋu eye woabu ga.

l Promised Precision : Dzoxɔxɔ ƒe kekeɖenudɔwɔwɔ kple nuwo ƒe gbegblẽ ɖea mɔ̃ɖaŋununya ƒe nyateƒetoto dzi kpɔtɔna, si kpɔa ŋusẽ ɖe adzɔnuwo ƒe nyonyome dzi le nusiwo wowɔna pɛpɛpɛ abe yamenutomeyimɔ̃ alo elektrɔnikmɔ̃wo ene me.

l Dedienɔnɔ ƒe afɔkuwo : Akpa siwo xɔ dzo akpa ate ŋu ado kpo nu, si ana nɔnɔme siwo me afɔku le abe bearing seizure, component detachment, alo dzo ƒe afɔkuwo le nɔnɔme siwo gbɔ eme me.

Nu nyuitɔ kekeake siwo woawɔ atsɔ aɖe edzi akpɔtɔ .

Dzoxɔxɔ gã si le dɔwɔwɔ me, si tsoa ʋuʋudedi fũ, agbatsɔtsɔ fũ, fafa si mesɔ gbɔ o, alo ami siwo mesɔ o gbɔ la hea agbatsɔtsɔ ƒe ŋutete dzi ɖeɖe kpɔtɔ, ami ƒe gbagbã, kple dzoxɔxɔ ƒe ɖeɖiteameŋu ƒe gbagbãwo vɛ. Nya siawo nana dɔwɔnuwo ƒe agbenɔƒe nɔa kpuie, wodzia beléle na wo ƒe gazazãwo ɖe edzi, eye woɖea asi le wo ŋu pɛpɛpɛ, eye afɔku siwo ate ŋu ado mo ɖa le dedienɔnɔ me. To fafamɔ̃wo zazã nyuie wu, ŋkuléle ɖe dzoxɔxɔ ŋu, alesi woaƒo asa na agba siwo wu tsɔtsɔ, kple ami siwo sɔ tiatia me la, dɔwɔlawo ate ŋu aɖe afɔku siwo do ƒome kple dzoxɔxɔ dzi akpɔtɔ. Afɔɖeɖe siawo siwo wowɔna do ŋgɔ la kpɔa egbɔ be mɔ̃ siwo ŋu kakaɖedzi le la wɔa dɔ nyuie, woadidi subɔsubɔ ƒe agbenɔƒe ɖe edzi, eye woaɖe ɣeyiɣi si woatsɔ awɔ dɔe kple gazazãwo dzi akpɔtɔ le dɔ veviwo wɔwɔ me.

7. Elektrikŋusẽ ƒe ɣeyiɣi ƒe didime .

Elektrikŋusẽ ƒe ʋuʋu toa bearings, si zi geɖe tso anyigba alo ʋuʋudedi siwo metra o gbɔ la, ate ŋu agblẽ nu le mɔ̃ siwo trɔna abe mɔ̃wo, ʋuƒo siwo wotsɔna ƒoa ʋuƒoe, alo mɔ̃ siwo naa elektrikŋusẽ ene ŋu vevie. Nudzɔdzɔ sia, si sɔ kple elektrikŋusẽ ƒe mɔ̃ si me woɖea tsi le (EDM), tsia dzi eye wògblẽa nu le woƒe dɔwɔwɔ ŋu.

Nusiwo hea elektrikŋusẽ ƒe mɔzɔzɔ vɛ .

Elektrikŋusẽ ƒe mɔ̃a dzɔna ne elektrikŋusẽ siwo womeɖo be woawɔ o si to bearingwo me, zi geɖe la, le nusiwo gbɔna ta:

Grounding si mede ame dzi o:

l Mɔ̃wo ƒe anyigba si mesɔ o alo esi mesɔ o nana elektrikŋusẽ si tra mɔ la toa bearings me, eye wòdia mɔ si dzi womate ŋu atsi tre ɖe anyigba ŋu boo o.

l Anyigba manyomanyo ate ŋu atso kaƒoƒo siwo gblẽ, kadodo siwo xɔ dzo, alo anyigbaɖoɖo siwo mesɔ gbɔ le mɔ̃a alo dɔwɔƒea gbɔ o gbɔ.

Elektrikŋusẽ ƒe mɔ̃wo ƒe sisi siwo tra mɔ:

l elektrikŋusẽ si trana ate ŋu atso frequency drive siwo trɔna (VFDs), inverters, alo elektrikŋusẽ ƒe akpa bubu siwo wozãna zi geɖe le egbegbe mɔ̃wo me, vevietɔ le dɔ siwo ŋu ŋusẽ le alo esiwo zɔna kabakaba ŋutɔ me.

l Elektrikŋusẽ ƒe nutete (EMI) alo elektrikŋusẽ si wodo tso elektrikdɔwɔnu siwo te ɖe eŋu me hã ate ŋu ana elektrikŋusẽ nato bearings me.

Elektrikŋusẽ si meʋãna o ƒe ƒuƒoƒo:

l static charges ate ŋu aƒo ƒu ɖe akpa siwo trɔna dzi, vevietɔ le nuto siwo me tsi mele o alo esiwo le du dzi sesĩe me, si ana tsi nado to bearings me.

l Esia bɔ ɖe dɔ siwo ku ɖe nusiwo me ŋusẽ mele o alo alidziblanu siwo naa elektrikŋusẽ si meʋãna o ŋu me.

Nusiwo wotsɔna xea mɔ na dzoxɔxɔ alo ametakpɔnu siwo mesɔ o:

l Nusiwo wotsɔna xea mɔ na dzoxɔxɔ ƒe anyimanɔmanɔ le bearingwo alo akpa siwo ƒo xlãe ŋu nana elektrikŋusẽ sina toa mɔ siwo womeɖo be woawɔ o me.

l Ametakpɔnu si mesɔ o ɖe elektrikŋusẽ ƒe agblewo ŋu ate ŋu ana elektrikŋusẽ ƒe mɔzɔzɔ nagado gã ɖe edzi le dɔwɔnu siwo sea veve la me.

Elektrikŋusẽ ƒe mɔ̃ ƒe dɔwɔwɔ ƒe ŋusẽkpɔɖeamedziwo .

Ne elektrikŋusẽ to bearings me la, wohea nu gbegblẽ vovovowo vɛ, vevietɔ to arcing kple elektrikŋusẽ ƒe dzodzo ƒe mɔ̃wo (EDM) ƒe ŋusẽkpɔɖeamedziwo me:

Anyigba ƒe ʋuʋu to Arcing dzi:

l Elektrikŋusẽ ƒe arcing le bearing components dome (le kpɔɖeŋu me, rolling elements kple races) wɔa teƒeteƒewo ƒe dzobibi siwo gblẽa nu le nuwo ŋu, abe EDM ene. Esia wɔnɛ be dowo, ʋuʋudedi, alo esiwo me wofa tsikpe ɖo la nɔa bearing-dziwo dzi.

l Anyigba ƒe nɔnɔme ƒe gbegblẽ siawo gblẽa nu le dɔwɔwɔ nyuie ŋu, dzia ʋuʋudedi ɖe edzi, eye wògblẽa nu kabakaba.

Micro-craters kple nuwo ƒe gbegblẽ:

l arcing naa do suesuesuewo alo dzobibi ƒe dzesiwo nɔa bearing-dzi, si wɔnɛ be nusi wotsɔ wɔe la gbɔdzɔna eye wòɖea eƒe agbatsɔtsɔ ƒe ŋutete dzi kpɔtɔna.

l Le ɣeyiɣi aɖe megbe la, micro-crater siawo hea spalling (aflaking of material) vɛ, si gagblẽa bearing la ƒe fɔmaɖimaɖi me ɖe edzi.

Ʋuʋu kple toɣliɖeɖe si dzi ɖe edzi:

l Anyigba ƒe nugbegblẽ tso arcing gbɔ hea tɔtrɔ si mesɔ o vɛ, si wɔnɛ be ʋuʋu kple toɣliɖeɖe dzina ɖe edzi le dɔwɔwɔ me.

l Vibrations ate ŋu akaka ɖe mɔ̃a ƒe akpa bubuwo dzi, si ana be woagavuvu alo mesɔ ɖe wo nɔewo nu o.

Ami ƒe gbegblẽ:

l arcing naa dzoxɔxɔ nɔa teƒe siwo woate ŋu aƒo ka na, si ate ŋu agblẽ alo atɔ dzo amiwo, si ana woƒe dɔwɔwɔ dzi naɖe akpɔtɔ eye wòahe ʋuʋudedi kple vuvu ƒe dzidziɖedzi vɛ.

L Ami siwo me dɔlékuiwo le alo esiwo me carbon le ate ŋu azu ʋuʋudedi, si ana anyigba ƒe akpa si le anyigba dzi nagagblẽ nu le eŋu.

Bearing ƒe kpododonu do ŋgɔ na ɣeyiɣi si woɖo nɛ:

l Nusiwo dzɔna le anyigba ƒe ʋuʋu, ʋuʋudedi, kple ami ƒe gbagbã ƒe ŋusẽkpɔɖeamedziwo ƒe ƒuƒoƒo ɖea bearing ƒe agbenɔƒe dzi ɖena kpɔtɔna ŋutɔ, si hea kpododonu kaba vɛ.

l Le dɔléle sesẽwo me la, arcing ate ŋu ana bearing seizure alo afɔku gã aɖe nado kpo nu.

Elektrikŋusẽ ƒe mɔzɔzɔ me tsonuwo .

Elektrikŋusẽ ƒe mɔzɔzɔ me tsonuwo keke ta wu bearings, si kpɔa ŋusẽ ɖe ɖoɖoa ƒe dɔwɔwɔ bliboa kple dɔwɔwɔ ƒe gazazãwo dzi:

l Dɔwɔnu siwo dzi woɖe kpɔtɔ ƒe agbenɔƒe : Anyigba ƒe ʋuʋu kple nusiwo wotsɔ wɔe ƒe gbegblẽ kabakaba bearing ƒe vuvu, si hiã be woaɖɔli wo enuenu.

l Dzadzraɖo ƒe ga si dzi ɖe edzi : Nusiwo gblẽ tso Arcing gbɔ bia be woadzra wo ɖo le ga geɖe me, siwo dometɔ aɖewoe nye bearing replacement kple system downtime.

l Nuwɔwɔ ƒe dɔwɔwɔ ƒe ɖiɖi : Bearing ƒe kpododonu siwo elektrikŋusẽ ƒe gbegblẽ hena vɛ ate ŋu atɔ te ewɔwɔ, si ana be ɣeyiɣi mamlɛawo nato ŋuwò eye wòagblẽ ga.

l Nusiwo gblẽ le eŋu : Anyigba ƒe nɔnɔme madeamedziwo kple ʋuʋudedi ƒe dzidziɖedzi ɖea mɔ̃ɖaŋununya ƒe nyateƒetoto dzi kpɔtɔna, si kpɔa ŋusẽ ɖe adzɔnuwo ƒe nyonyome dzi le dɔwɔƒe siwo sɔ pɛpɛpɛ abe elektrɔnikmɔ̃wo alo yamenutomeyimɔ̃ ene me.

l Dedienɔnɔ ƒe afɔkuwo : Bearing ƒe kpododonu kpata alo ʋuʋu fũ ate ŋu ahe nɔnɔme siwo me afɔku le vɛ, abe akpa aɖewo ɖeɖeɖa alo elektrikŋusẽ ƒe afɔkuwo ene, si ahe afɔkuwo vɛ na dɔwɔlawo.

Nu nyuitɔ kekeake siwo woawɔ atsɔ aɖe edzi akpɔtɔ .

Elektrikŋusẽ ƒe ʋuʋu, si zi geɖe la, anyigba manyomanyo, elektrikŋusẽ si tra mɔ, alo elektrikŋusẽ si meʋãna o gbɔe wòtsona, eye wògblẽa anyigba to arcing me, si wɔnɛ be do, ʋuʋu, kple ami ƒe gbegblẽ. Nusiwo wògblẽna le ame ŋu siawo ɖea bearing ƒe agbenɔƒe dzi kpɔtɔna, edzia beléle na ga ƒe gazazãwo ɖe edzi, eye wòɖea dɔwɔwɔ ƒe nyateƒetoto dzi kpɔtɔna, eye afɔku siwo ate ŋu anɔ dedienɔnɔ me. Ne wokpɔ egbɔ be wole anyigba nyuie, to bearing siwo me tsi mele o zazã, tsi si me mekɔ o dzi ɖeɖe kpɔtɔ, kple ŋkuléle ɖe wo ŋu edziedzi me la, dɔwɔlawo ate ŋu axe mɔ ɖe elektrikŋusẽ ƒe gbegblẽ nu. Afɔɖeɖe siawo siwo wowɔna do ŋgɔ la doa mɔ̃wo ƒe kakaɖedzi ɖe ŋgɔ, wodidia subɔsubɔ ƒe agbenɔƒe ɖe edzi, eye woɖea ɣeyiɣi si woatsɔ awɔ dɔe kple gazazãwo dzi kpɔtɔna le dɔ veviwo wɔwɔ me.

Dzesiwo kple dzesiwo le CNC spindle ƒe dzoxɔxɔ si gbɔ eme ŋu .

Spindle motors nye akpa vevi aɖewo le mɔ̃ siwo sɔ pɛpɛpɛ me, abe CNC mɔ̃wo, lathes, kple nutunu siwo wotsɔna ƒoa nu ene, afisi bearings wɔa akpa vevi aɖe le egbɔkpɔkpɔ me be woawɔ dɔ nyuie, wòade pɛpɛpɛ, eye wòawɔ dɔ nyuie. Bearing damage, ne womekpɔe dze sii o la, ate ŋu ana ɣeyiɣi si woatsɔ atɔ te ga geɖe, mɔ̃ɖaŋununya ƒe nyonyome dzi naɖe akpɔtɔ, eye spindle motor la nado kpo dɔwɔwɔ vevie gɔ̃ hã. Ele vevie be woade dzesi afɔku siawo kaba eye wòana dɔwɔnuwo ƒe agbenɔƒe nadidi ɖe edzi.

toɣliɖeɖe siwo mesɔ o .

Dzesi gbãtɔ siwo ɖe dzesi wu be wole nu gblẽm le ame ŋu dometɔ ɖekae nye gbeɖiɖi siwo mebɔ o siwo dona tso spindle motor la me le dɔwɔwɔ me ƒe anyinɔnɔ. Zi geɖe la, toɣliɖeɖe siawo ɖea nya siwo le ete siwo ne woŋe aɖaba ƒu wo dzi la, woate ŋu adzi ɖe edzi ava zu nusiwo gblẽna vevie. Toɣliɖeɖe siwo mebɔ o dometɔ aɖewoe nye:

l whining alo high-pitched sounds : Zi geɖe la, gbeɖiɖi si ƒe gbeɖiɖi de dzi la ɖenɛ fiana be ʋuʋudedi dzina ɖe edzi le bearing la me, zi geɖe la, ami si mesɔ gbɔ o, bearing la ƒe akpa siwo me mekɔ o, alo ɖiƒoƒo to gbeɖuɖɔwo abe ke alo ga ƒe akpa aɖewo ene gbɔ. Gbeɖiɖi sia ate ŋu asẽ ɖe edzi ne bearing la le gbegblẽm ɖe edzi.

l Toɣliɖeɖewo tutu alo wo ƒoƒo : Gbeɖiɖiwo ƒoƒo nye nusi ɖee fia be nu gblẽ le eŋu vevie alo eƒe gowo gblẽ, abe do alo spalling le bearing races alo rolling elements dzi ene. Esia ate ŋu adzɔ ne wotsɔ agba siwo gbɔ eme, siwo mesɔ ɖe ɖoɖo nu o, alo dɔwɔwɔ ɣeyiɣi didi aɖe de bearing la me beléle nyui manɔmee.

l Ne èzi edzi alo dze egɔme la , toɣliɖeɖe siwo nɔa anyi ɣeaɖewoɣi alo esiwo le ɖiɖim la ate ŋu afia akpa siwo le gbadzaa, abe atɔ si gblẽ alo nusiwo le ʋuʋum siwo megale ʋuʋum nyuie o ene. Esia ate ŋu afia ɖe ɖeɖiteameŋu si le gɔmedzedzea me alo esi mesɔ o le bearing ƒe ƒuƒoƒoa me hã.

Nusita wòle vevie : Toɣliɖeɖe siawoe nyea nuxaxa ƒe kpeɖodzinya gbãtɔ siwo woate ŋu ase zi geɖe. Ne ʋuʋudedi kple vuvu la, gbeɖiɖiawo va le sesẽm ɖe edzi eye wòdzena nyuie wu, si fia be bearing la le kpododonu gogom. Ele vevie ŋutɔ be woalé ŋku ɖe nusi gbɔ wòtso ŋu enumake—eɖanye be eƒo ɖi, eƒe nɔnɔme si mesɔ o, alo ɖeɖiteameŋu le ŋutilã me o—eye wòaxe mɔ ɖe nu bubu siwo agblẽ nu le spindle motor la ŋu nu.

Dɔwɔwɔ ƒe Afɔɖeɖewo : Zã stethoscope alo vibration analysis tools nàtsɔ ade dzesi toɣliɖeɖetsoƒea. Kpɔ amisisi ƒe agbɔsɔsɔme kple eƒe nyonyome ɖa, lé ŋku ɖe ɖiƒoƒo ŋu, eye nàkpɔe ɖa be wowɔ ɖe ɖoɖo nu hã. Ne toɣliɖeɖea gakpɔtɔ li la, bu eŋu kpɔ be yeaɖe aŋea ɖa be woatsɔ alé ŋku ɖe eŋu nyuie hã.

Ʋuʋudedi ƒe dzidziɖedzi .

Ʋuʋu fũ akpa nye dzesi bubu si ɖea bearing ƒe nugbegblẽ le spindle motors ŋu. Togbɔ be ʋuʋudedi ƒe seƒe aɖe sɔ le mɔ̃ siwo trɔna me hã la, ʋuʋudedi ƒe nɔnɔmewo ƒe dzidziɖedzi alo tɔtrɔ ɖedzesi aɖe ate ŋu afia nya veviwo le bearing ƒe ƒuƒoƒoa me. Nu vevi siwo le eme dometɔ aɖewoe nye:

l Dadasɔmanɔmanɔ : Nusi mesɔ o alo nusi gblẽ le bearing la ŋu ate ŋu ana rotor la nagada asɔ o, si ana woaʋuʋu akpa. Wosena le wo ɖokui me zi geɖe be esia nye ʋuʋudedi si me ʋuʋudedi le alo ʋuʋudedi si le ʋuʋum le dɔwɔwɔ me.

l Pitting or surface damage : Nusuekpɔmɔ̃ ƒe dowo alo spalls siwo le bearing surfaces dzi gblẽa nu le wo nɔewo ŋu gbadzaa, si wɔnɛ be ʋuʋudedi siwo mesɔ o la nɔa anyi. Ðeɖiteameŋu, agbatsɔtsɔ fũ, alo ɖiƒoƒo ate ŋu atso nɔnɔme madeamedzi siawo gbɔ.

l Misalignment alo Loose Components : Bearings alo loose mounting hardware ate ŋu ado ŋusẽ ʋuʋudediwo, atsɔ nuteɖeamedzi bubuwo ade bearing la dzi eye woatsɔe aƒu du kabakaba.

Nusita wòle vevie : Menye ɖeko ʋuʋudedi si dzi ɖe edzi fia be bearing gblẽ ko o ke ekpɔa ŋusẽ ɖe spindle motor ƒe dɔwɔwɔ bliboa hã dzi. Ʋuʋu fũ ate ŋu ana mɔ̃wo ƒe dɔwɔwɔ pɛpɛpɛ, dɔwɔnuwo ƒe dzeɖoɖo, kple nu bubuwo abe nutrenuwo alo xɔwo ene nagblẽ nu le wo ŋu nyuie o. Le ɣeyiɣi aɖe megbe la, ʋuʋudedi si womekpɔ o ate ŋu ahe afɔku gã aɖe vɛ.

Dɔwɔwɔ ƒe afɔɖeɖewo : Zã ʋuʋudedi ƒe numekukuwo nàtsɔ ade dzesi ʋuʋudedi ƒe agbɔsɔsɔme eye nàde dzesi frequency tɔxɛ siwo do ƒome kple bearing faults (le kpɔɖeŋu me, ball pass frequency alo cage frequency). ŋkuléle ɖe nu ŋu edziedzi ate ŋu akpe ɖe ame ŋu be woade dzesi ʋuʋudedi ƒe nɔnɔme siwo le dzidzim ɖe edzi, si fia be nusiwo gblẽ le wo ŋu le ŋgɔ yim. Ne wokpɔ ʋuʋudedi siwo kɔ la, lé ŋku ɖe bearing la ŋu be evuvu hã, lé ŋku ɖe alignment ŋu, eye nàkpɔe ɖa be rotor la da sɔ hã. Nudede dɔa me kaba ate ŋu axe mɔ ɖe eƒe gbegblẽ nu.

Dɔwɔwɔ ƒe Gbegblẽ .

Bearing damage dzena zi geɖe abe spindle motor ƒe dɔwɔwɔ ƒe dɔwɔwɔ dzi ɖe kpɔtɔ ene, si gblẽa nu le eƒe ŋutete be wòalé pɛpɛpɛ, duƒuƒu, kple ŋusẽ me ɖe asi dzi. Dzesi siwo bɔ dometɔ aɖewoe nye:

l Nuwɔwɔ pɛpɛpɛ : Bearings siwo gblẽ ate ŋu ana spindle la naʋuʋu alo atra ɖa tso mɔ si woɖo nɛ gbɔ, si ana be mɔ̃ siwo me mekɔ o le mɔ̃ alo lãɖeɖedɔwo me. Esia le vevie ŋutɔ le dɔ siwo wowɔna pɛpɛpɛ abe CNC ƒe mɔ̃ɖaŋudɔwo ene me, afisi teteɖeanyi suesuesuewo gɔ̃ hã ate ŋu agblẽ nu le wo ŋu le.

l Duƒuƒu ƒe tɔtrɔ : Bearing siwo wodo alo esiwo gblẽ ate ŋu ahe tsitretsitsi si mesɔ o vɛ, si ana spindle motor la naʋli vevie be yealé tɔtrɔ ƒe duƒuƒu si nɔa anyi ɖaa me ɖe asi. Esia ate ŋu ana be woalã wo le mɔ si mesɔ o nu alo awɔ nututudɔ.

l Power dips alo overloading : Ne bearings le gbegblẽm la, friction si dzi ɖe edzi bia ŋusẽ geɖe wu be woalé dɔwɔwɔ me ɖe asi, si ana ŋusẽzazã geɖe wu alo ŋusẽ ƒe ɖiɖi na ame ɣeaɖewoɣi. Le nɔnɔme sesẽwo me la, mɔ̃a ate ŋu atɔ alo ado kpo egɔme kura.

Nusita wòle vevie : Dɔwɔwɔ ƒe gbegblẽ kpɔa ŋusẽ ɖe nusi wowɔ ƒe nyonyome kple mɔ̃awo ƒe dɔwɔwɔ nyuie dzi tẽ. Le dɔwɔƒe siwo ɖoa ŋu ɖe nusiwo sɔ pɛpɛpɛ kple woƒe ɖekawɔwɔ ŋu, abe yamenutomeyimɔ̃wo alo ʋuwo wɔwɔ ene gome la, dɔwɔwɔ ƒe nya sue aɖewo gɔ̃ hã ate ŋu ahe gakuxi gãwo alo dedienɔnɔ ƒe nyawo vɛ.

Dɔwɔwɔ ƒe Afɔɖeɖewo : Kpɔ spindle ƒe dɔwɔwɔ ƒe xexlẽdzesiwo dzi, abe duƒuƒu ƒe liƒo kple ŋusẽzazã ene, to dɔwɔnu siwo wotsɔ dia dɔléle alo mɔ̃wo dzi kpɔkpɔ ƒe ɖoɖowo zazã me. Ne wokpɔ be wogblẽ la, lé ŋku ɖe bearings la ŋu be wodo hã, lé ŋku ɖe amisisi ŋu, eye nàkpɔe ɖa be woɖɔ spindle la ɖo nyuie hã. Nya siawo gbɔ kpɔkpɔ kaba ate ŋu ana dɔwɔwɔ nagaɖo ame ŋu eye wòaxe mɔ ɖe nu bubu siwo agblẽ le ame ŋu nu.

Amadede ƒe tɔtrɔ alo ʋeʋẽ lilili .

Tɔtrɔ ŋutɔŋutɔ siwo le akpa siwo le bearing alo nusiwo ƒo xlãe me, abe amadede ƒe tɔtrɔ alo ʋeʋẽ siwo mebɔ o ene, nye nuxlɔ̃amedzesi vevi siwo fia be nuxaxa le fu ɖem na ame, eye zi geɖe la, edo ƒome kple dzoxɔxɔ si gbɔ eme alo nusiwo le lãme na ame. Dzesi siawo dometɔ aɖewoe nye:

l Amadede ƒe tɔtrɔ (bluing alo browning) : Bearings siwo me dzo le akpa ate ŋu aɖe amadede blɔ alo aŋutiɖiɖi afia le woƒe anyigba dzi le dzoxɔxɔ si gbɔ eme ta. Esia ate ŋu adzɔ ne ʋuʋudedi dzi ɖe edzi le amisisi si mesɔ gbɔ o, agba gãwo, alo dɔwɔwɔ ɣeyiɣi didi le duƒuƒu si kɔkɔ ta. Amadede ƒe tɔtrɔ nye dzesi si me kɔ be dzoxɔxɔ ƒe nuteɖeamedzi, si ate ŋu ana eƒe wɔwɔme nagbɔdzɔ.

L ACRID alo dzobibiwo : ʋeʋẽ lilili si le ʋeʋẽm ate ŋu afia be ami si wotsɔna ƒoa nu la le dzo dam alo le gbagbãm le dzoxɔxɔ si gbɔ eme ta. Le go aɖewo me la, ʋeʋẽa ate ŋu atso nusi wotsɔ ƒoa nu la ŋutɔ me esi wòdzea anyi alo tsoa akpa siwo te ɖe eŋu siwo ŋu dzoxɔxɔa gblẽ nu le la gbɔ.

Nusita wòle vevie : Amadede ƒe tɔtrɔ kple ʋeʋẽwo ɖenɛ fiana be bearing la le dɔ wɔm le nɔnɔme siwo gbɔ eme me, si ate ŋu ana wòavuvu kabakaba eye wòahe kpododonu vɛ kpuie. Dzoxɔxɔ si gbɔ eme ate ŋu agblẽ nu le akpa siwo te ɖe wo nɔewo ŋu hã ŋu, abe nutrenuwo, asikewo, alo xɔwo ene, si ana nuwo ɖɔɖɔɖo ƒe gazazãwo nadzi ɖe edzi eye woadzudzɔ ɣeyiɣi.

Afɔɖeɖewo : Ne wokpɔ amadede ƒe tɔtrɔ alo ʋeʋẽwo la, tsi spindle motor la enumake be wòagagblẽ nu le eŋu o. Kpɔ bearings la ɖa be dzoxɔxɔ si gbɔ eme o, lé ŋku ɖe ami ƒe nɔnɔme ŋu (le kpɔɖeŋu me, viscosity, contamination), eye nàda dɔwɔwɔ ƒe nɔnɔmewo kpɔ (le kpɔɖeŋu me, duƒuƒu, agba, fafamɔ̃wo). Tsɔ bearing siwo gblẽ la ɖɔ li eye nàgbugbɔ amisisi aɖo ɖe wò alo adoe ɖe ŋgɔ be wòagadzɔ o.

Afɔɖeɖe siwo woawɔ atsɔ axe mɔ ɖe dɔlélea nu kple nu nyuitɔ siwo woawɔ .

Be nàɖe afɔku si le nusiwo gblẽ le wo ŋu me dzi akpɔtɔ eye woaɖe spindle motors ƒe agbenɔƒe dzi akpɔtɔ la, bu nu nyuitɔ siwo gbɔna ŋu:

l Beléle na wo edziedzi : Wɔ beléle na wo ƒe ɖoɖowɔɖi si wowɔna edziedzi si me amisisi ƒe dodokpɔwo, alignment verification, kple bearing inspections le. Zã ami deŋgɔ siwo sɔ ɖe spindle ƒe dɔwɔwɔ ƒe nɔnɔmewo nu.

l Vibration Monitoring : De vibration sensors alo zã portable analyzers tsɔ lé ŋku ɖe ʋuʋudedi ƒe dzidzenuwo ŋu le ɣeyiɣi aɖe megbe. Ðo dzidzenuwo be woaʋã nuxlɔ̃amewo ne ʋuʋudediwo wu seɖoƒe siwo dzi woda asi ɖo.

l Amisisi dzikpɔkpɔ : Kpɔ egbɔ be amisisi nyuie to ŋkuléle ɖe amisisi ƒe agbɔsɔsɔ kple eƒe nyonyome ŋu me. Zã ami ƒomevi si adzɔha la kafu la ƒe ƒomevi kple ɣeyiɣi siwo wogbugbɔ zãna la nàtsɔ aɖe ʋuʋudedi kple vuvu dzi akpɔtɔ.

l Nutomedzikpɔkpɔ : Ðe ɖiƒoƒo dzi kpɔtɔ to dɔwɔwɔ ƒe nɔnɔme dzadzɛ me léle ɖe asi kple nutrenu nyuiwo zazã atsɔ akpɔ bearingwo ta tso ke, gbeɖuɖɔ, alo tsi me.

l Hehenana kple nyanyanana : Hehenana dɔwɔlawo kple beléle na dɔwɔlawo be woade dzesi dzesi gbãtɔ siwo fia be wole nu gblẽm, abe toɣliɖeɖe siwo mesɔ o alo dɔwɔwɔ ƒe tɔtrɔ ene, eye woagblɔ wo kaba.

Bearing damage le spindle motors me ate ŋu ahe emetsonu veviwo vɛ, gake ekpɔkpɔ kaba ate ŋu axɔ na spindle kple mɔ̃ siwo wòna ŋusẽ siaa. Ne wole ŋudzɔ ɖe dzesiwo abe toɣliɖeɖe siwo mesɔ o, ʋuʋudedi ƒe dzidziɖedzi, dɔwɔwɔ ƒe gbegblẽ, kple amadede ƒe tɔtrɔ alo ʋeʋẽwo ene ŋu la, dɔwɔlawo ate ŋu ade dzesi nyawo hafi woado ɖe ŋgɔ. Kpɔkpɔ nyuie, beléle na wo nyuie, kple afɔɖeɖe kaba nye nu vevi siwo ana kakaɖedzi nanɔ spindle motors ƒe kakaɖedzi kple agbenɔƒe didi ŋu. Ne wokpɔ dzesi siawo dometɔ aɖe la, wɔ nu kaba be wòalé ŋku ɖe kuxia ŋu ahakpɔ egbɔ, eye nàbia gbee na bearing eŋutinunyalawo alo spindle wɔla alesi wòhiã be woagbugbɔ awɔ dɔ nyuie wu.

Nyanuwuwuw

Bearing damage le spindle motors me nye afɔku si le adzame si ate ŋu ahe kpododonu, ɣeyiɣi si woatɔ te, kple gazazã gãwo ne womekpɔ egbɔ o. To nusiwo gbɔ wòtsona—agbatsɔtsɔ, ɖiƒoƒo, kple ɖekematsɔleme—kple dɔwɔnu deŋgɔwo abe Vibration Analyzers kple Imaging Technologies zazã me ene la, dɔwɔlawo ate ŋu ade dzesi nyawo kaba eye woawɔ ɖɔɖɔɖo. Mɔfiamewo dzi wɔwɔ kple nutomedzikpɔkpɔ dzi wɔwɔ ɖe edzi kpɔa bearingwo ta tso nuveviwɔame me, si wɔnɛ be wowɔa dɔ nyuie eye wowɔa nu pɛpɛpɛ. Bearings Power the Spindle motor, kple wo nyinyi to beléle na wo do ŋgɔ kple aɖaŋu siwo ŋu wonya nu tsoe me le vevie na kakaɖedzi si anɔ anyi ɖaa. Le egbɔkpɔnu siwo wowɔ ɖe ɖoɖo nu gome la, bia bearing wɔlawo alo spindle eŋutinunyalawo be woawɔ bearing tiatia kple beléle na wò dɔ tɔxɛa.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu