Kpɔkplɔyiɖeme

Chatter le CNC Machining—si nye fuɖename si wonya nyuie akpa—ate ŋu agbã wò akpaa ƒe nuwuwu, agblẽ nu le wò dɔwɔnuwo ŋu, eye wòaʋuʋu wò dɔwɔwɔ wòazu eƒe akpa vevitɔ. Enye ʋuʋudedi si womelɔ̃ o si dzɔna le lãɖeɖe me, eye ne èse toɣliɖeɖe ma si le ɣli dom, si le ʋuʋum esime mɔ̃a le du dzi kpɔ la, ke wò ŋutɔe do goe. Gake nya nyuiae nye esi: Chatter menye lã wɔadã aɖe si womate ŋu aƒo asa na o. Ne ènya nu tso eŋu nyuie, dɔwɔnuwo, kple aɖaŋu siwo sɔ la, àte ŋu aƒoe ɖe mɔa ƒe akpa si woɖoa ʋua ɖo la nu.

Bu eŋu alea: dzeɖoɖoe nye be woawɔ cnc machining nusi static nye na radio dzi nyadzɔdzɔwo. Etrɔa asi le gbedasia ŋu, ewɔa dɔmawɔmawɔ nyuie, eye wòhea vodadawo vɛ. Le mɔ̃ɖaŋudɔwɔwɔ me la, vodada mawo gɔmee nye akpa siwo woɖe ɖe vovo, dɔwɔnu siwo le kpuie wu, kple gazazã siwo lolo wu. Eyata, chatter ɖeɖeɖa menye nyonyome ƒe nyonyo ko o—eku ɖe wò dɔwɔwɔ bliboa ƒe dɔwɔwɔ kple gakpɔkpɔ ŋu.

Mɔfiame sia akplɔ wò ayi nusiwo gbɔ dzeɖoɖo tso, alesi nàde dzesii, kple vevietɔ wu la, alesi nàɖee ɖae me. Eɖanye mɔ̃ɖaŋudɔwɔla bibie nènye alo wò afɔwo xɔ tsi le CNC xexeame ko o, afɔɖeɖe ɖesiaɖe ƒe nɔnɔmetata sia ana aɖaŋu siwo woate ŋu awɔ dɔ le la wò be nàzi ɖoɖoe le dzeɖoɖo me eye nàna wò mɔ nasɔ pɛpɛpɛ.

CNC chatter gɔmesese .

Gɔmesese kple ƒomevi siwo nye chatter .

CNC ƒe nyahehe fia ʋuʋudedi siwo me woɖea wo ɖokui le siwo dzɔna le lãɖeɖe ƒe ɖoɖo aɖe me. Eɖea eɖokui fiana abe ƒutsotsoe siwo wogbugbɔ gblɔna ene le dɔwɔnua ƒe anyigba dzi eye zi geɖe la, ewɔa toɣliɖeɖe si ƒe gbeɖiɖi le kɔkɔm. Ƒomevi vevi evee li:

1. Regenerative chatter – si tso nyaŋuɖoɖo ƒe ʋuƒo siwo le dɔwɔnu kple dɔwɔwɔ ƒe akpa si tso lãɖeɖe ƒe mɔɖeɖe siwo va yi gbɔ gbɔ.

2. Mode coupling chatter – doa mo ɖa ne vibration mode vovovo eve (abe lateral kple torsional ene) srɔ̃tɔ ɖekae.

3. Wozi ʋuʋu ƒe ʋuʋudedi dzi – si gotagomenuwo abe motor imbalance alo bern-out bearings ene ʋãna.

Kuxi tɔxɛ aɖe le wo ƒomevi siawo dometɔ ɖesiaɖe ŋu, gake wo katã me tsonu bɔ: mɔ̃ɖaŋununya ƒe nyonyome dzi ɖeɖe kpɔtɔ kple dɔwɔnuwo ƒe vuvu dzi ɖeɖe kpɔtɔ. Ne èle ɣlidodo aɖe sem alo le togbɛwo dzi kpɔm le wò akpawo ŋu la, ke anɔ eme be èle nu wɔm kple fɔɖila siawo dometɔ ɖeka.

Nusiwo hea dzeɖoɖo vɛ le CNC Machining .

Eyata nukatae dzeɖoɖo dzɔna? Menye nu ɖeka koe wònye o—zi geɖe la, enyea nusiwo ƒo ƒu nye:

· Lãɖeɖe ƒe nɔnɔme siwo mesɔ o : Spindle ƒe duƒuƒu alo nuɖuɖu ƒe tsɔtsɔme kɔkɔ akpa ate ŋu ado ŋusẽ ʋuʋudediwo.

· Dɔwɔnu alo nulénu siwo gbɔdzɔ : Sesẽmawɔmawɔ alo dɔwɔnu ƒe nɔnɔme si mesɔ o ate ŋu adze ʋuʋudedi gɔme.

· Fixturing poor : Ne womelé wò akpaa ɖe te dedie o la, ʋuʋu ɖesiaɖe ate ŋu atsa le chatter episode me.

· Mɔ̃a ƒe nɔnɔme : guideways siwo le gbadzaa, ball screws siwo wodo, kple misalignment katã kpea asi ɖe eŋu.

· Nuwo ƒe nɔnɔmewo : Nu aɖewo te ŋu ʋuʋuna bɔbɔe wu bubuwo le woƒe sesẽme alo woƒe elasticity ta.

De dzesi nusi gbɔ wòtsoe nye afɔɖeɖe gbãtɔ si ana toɣliɖeɖea nazi ɖoɖoe—le nyateƒe me kple le kpɔɖeŋunyagbɔgblɔ nu. Màte ŋu aɖɔ nusi gɔme mèse o la ɖo o.

Alesi chatter kpɔa ŋusẽ ɖe CNC machining dzii .

Nusiwo woate ŋu awɔ dɔ ɖe ame dzi . |

Nuɖᴐɖᴐ |

Metsonu vɔ̃wo |

Anyigba ƒe nuwuwu . |

Wavy Patterns, dɔwɔnu ƒe dzesi siwo mewɔ ɖeka kple ɖoɖo o le dɔwɔnua dzi . |

Atsyɔ̃ɖoɖo madeamedzi, akpa aɖe ƒe gbegbe, didime ƒe masɔmasɔ . |

Dimensional ƒe nyateƒetoto . |

Vibrations nana dɔwɔnua toa mɔa dzi . |

Akpa siwo me womeɖea mɔ ɖe nu ŋu le o, dɔwɔwɔ dzi ɖeɖe kpɔtɔ . |

Dɔwɔnu ƒe awudodo . |

Ʋuʋu yi ŋgɔe hea nugbɔ ƒe ʋuʋu kple gbagbã vɛ . |

Dɔwɔnuwo ɖɔliɖɔli enuenu, dɔwɔnuwo ƒe asi si lolo wu . |

Mɔ̃ ƒe awudodo . |

Chatter tsɔa nuteɖeamedzi yia mɔ̃ ƒe akpa aɖewo dzi . |

Bearing damage, mɔ̃ ƒe agbenɔƒe dzi ɖeɖe kpɔtɔ, beléle na edzi ƒe dzidziɖedzi . |

Ɣeyiɣi si woatsɔ anɔ tsatsam . |

Nuɖuɖu ƒe agbɔsɔsɔ si le blewu wu si hiã be woaƒo asa na dzeɖoɖo . |

Nuwɔwɔ ƒe ɣeyiɣi didi wu, dɔwɔwɔ nyuie dzi ɖe kpɔtɔ . |

Nuwɔwɔ ƒe gazazãwo . |

Nusiwo gblẽ, woƒe dɔwɔwɔ le wo ŋu, kple nusiwo gblẽ le wo ŋu dzi ɖe edzi . |

Dɔwɔwɔ ƒe gazazã siwo lolo wu, viɖekpɔkpɔ ƒe vovototowo dzi ɖeɖe kpɔtɔ . |

Ŋusẽkpɔɖeamedzi ɖe anyigba ƒe nuwuwu kple akpa ƒe nyonyome dzi .

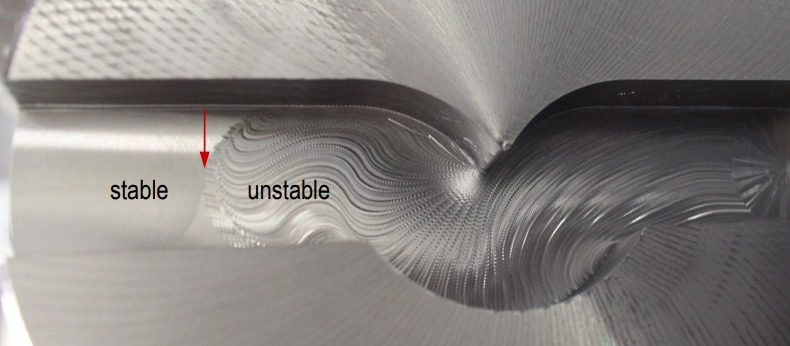

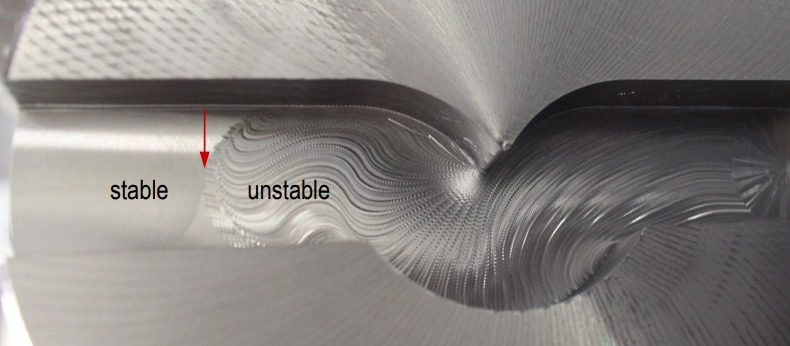

Nusiwo dona tso dzeɖoɖo me wu dometɔ ɖekae nye be eƒe gowo me mekɔ nyuie o. Kpɔe ɖa le susu me be yeadze agbagba be yeatsɔ nuŋlɔti aŋlɔ nu esime wò asi le ʋuʋum—ema koŋue nye nusi chatter wɔna ɖe wò nutsotso dɔwɔnua dzi. Vibrations la hea dɔwɔnu ƒe mɔ siwo mewɔ ɖeka kple ɖoɖo o vɛ, siwo gblẽa nɔnɔme siwo le abe ƒutsotsoewo ene ɖi le wò akpa dzi.

Menye atsyɔ̃ɖoɖo koe blibomademade siawo nye o. Woate ŋu agblẽ nu le mɔɖeɖe ɖe nu ŋu sesĩe ŋu, ahe xɔtuɖoɖowo ƒe gbɔdzɔgbɔdzɔwo vɛ, eye woahe akpa aɖe ƒe gbegbe vɛ. Le dɔwɔƒewo abe yamenutomeyimɔ̃ alo atikewɔwɔ ene me, afisi nusianu nye nusianu le la, ema nye nubabla-gbãtɔ.

Chatter hã kpɔa ŋusẽ ɖe didime ƒe nyateƒetoto dzi. Ne wò akpaa dze nyuie le anyigba dzi gɔ̃ hã la, nu madzɔmadzɔ siwo woɣla la ate ŋu ahe dɔwɔwɔ ƒe kpododonuwo vɛ, vevietɔ le nuteɖeamedzi alo agba me.

Dɔwɔnu ƒe awudodo kple mɔ̃ ƒe agbenɔnɔ .

Menye ɖeko dzeɖoɖo megblẽa nu le akpaa ŋu o—ewɔa ŋutasẽnu ɖe wò dɔwɔnuwo ŋu. Ʋuʋu madzudzɔmadzudzɔe nana micro-fractures nɔa lãɖeɖe ƒe nugbɔ, si wɔnɛ be dɔwɔnu ƒe vuvu kabakaba. Àkpɔe be yexɔa nuwuƒe alo nusiwo wotsɔ dea eme la ɖɔliɖɔli zi geɖe wu, si ƒoa ƒu kabakaba.

Eye míagaŋlɔ wò mɔ̃a be o. Ne èle ʋuʋudedi me ɣeyiɣi didi la, ate ŋu aɖe boltwo ɖa, agblẽ nu le bearings ŋu, eye wòana wò CNC dɔwɔnuwo ƒe agbenɔƒe nadidi ɖe edzi. Gazazãwo dzina ɖe edzi, eye ɣeyiɣi si ŋu womewɔ ɖoɖo ɖo o va zua taɖuame edziedzi.

Nuwɔwɔ ƒe dɔwɔwɔ nyuie kple gazazã ƒe gɔmesese .

Le ŋkekea ƒe nuwuwu la, Chatter ƒoa wò le afisi wòvea ame wu le—wò gakotoku. Anyigba ƒe go siwo mewu enu nyuie o la bia be woagbugbɔ awɔ akpa aɖewo alo woaɖe wo ɖa gɔ̃ hã. Dɔwɔnuwo hiã be woaɖɔli wo zi geɖe wu. Mɔ̃wo gblẽna le vome. Nu siawo katã kpena ɖe ame ŋu be:

· Ɣeyiɣi didi wu ƒe tsatsam .

· Totoɖeme si bɔbɔ ɖe anyi wu .

· Dɔwɔwɔ ƒe gazazãwo dzi ɖe edzi .

· Ɣeyiɣi mamlɛtɔ siwo woda .

Ne èle fiase si me wodzraa nu geɖe le dzi kpɔm la, nusiwo bu siawo ƒoa ƒu kabakaba. Gake le dɔwɔwɔ suewo gɔ̃ hã gome la, ŋusẽkpɔɖeamedzia ɖe dzesi ŋutɔ. Ga si woatsɔ aŋe aɖaba aƒu dzeɖoɖo dzi la sɔ gbɔ wu gadede mɔxexe ɖe enu me ɣesiaɣi.

De dzesi dzeɖoɖo le CNC dɔwɔwɔwo me .

Mɔnukpɔkpɔ ƒe mɔnu . |

Dzesiwo . |

Dɔwɔnuwo/Aɖaŋudɔwo . |

Dzesi siwo wotsɔ sea nyawoe . |

Toɣliɖeɖe si le ɖiɖim sesĩe, si le ʋuʋum, alo toɣliɖeɖe si le ɖiɖim sesĩe le etsotso me . |

Dɔdzikpɔla ƒe nyadɔdrɔ̃, gbeɖiɖi ƒe dzoxɔxɔ ƒe sensorwo . |

Nukpɔkpɔ me dzodzro . |

Wavy ƒe anyigba ƒe nuwuwu, fli siwo le keklẽm, fli siwo wotso siwo mewɔ ɖeka o . |

Akpa aɖe me dzodzro le dɔwɔwɔ megbe . |

Dɔwɔnu ƒe awudodo ƒe nɔnɔmewo . |

Dodo si mebɔ o abe chipping alo dzobibi le dɔwɔnu ƒe gowo dzi ene . |

Nusuekpɔmɔ̃, ŋkumeɖonu siwo dzina ɖe edzi . |

Dzoxɔxɔ ƒe dzidzime . |

Dzoxɔxɔ alo dzudzɔ si gbɔ eme le etsotso me . |

Dzoxɔxɔ fotoɖemɔ̃wo, infrared sensorwo . |

Vibration dzidzedze . |

Wodzidze ʋuʋudedi siwo wu dzidzenu siwo dzi woda asi ɖo . |

Accelerometers, ʋuʋudedi ƒe sensorwo . |

Lãɖeɖe ŋusẽ ƒe nyaŋuɖoɖo . |

Spikes le lãɖeɖe ŋusẽwo me le machining . |

Lãɖeɖe ŋusẽ dynamometers, torque sensors . |

Nukpɔkpɔ kple nusese ƒe dzesiwo .

Zi geɖe la, dzeɖoɖo sesẽna—eye ɖikeke mele eme o. Toɣliɖeɖe ma si le ɖiɖim sesĩe, si le ƒoƒom, alo le ʋuʋum lae nye wò mɔ̃a ƒe ɣlidodo be woakpe ɖe ye ŋu. Mègaŋe aɖaba ƒu edzi o. Enye aflaga dzĩ be nane le dodom.

Gake menye toɣliɖeɖe koe wònye o. Àde dzesii hã be:

· Ƒutsotsoewo ƒe anyigbadzinɔnɔmewo (zi geɖe la, woyɔa wo be 'nyaʋiʋli ƒe dzesiwo') .

· Streaks siwo le keklẽm alo teƒe siwo wotɔ dzoe .

· Dɔwɔnu ƒe Do si Do Ŋgɔ Na .

· Dzoxɔxɔ alo dzudzɔ si gbɔ eme le etsotso me .

Dzesi siawo kpɔkpɔ le bɔbɔe ne èle to ɖom. Na wòanye numame na wò be nàlé ŋku ɖe akpa aɖewo ŋu le duƒuƒu ɖesiaɖe megbe, vevietɔ le dɔwɔwɔ na ame le ʋuʋudedi me alo le dɔwɔwɔ kabakaba me.

Dɔwɔnu Siwo Wotsɔ Kpɔa Dɔlélewo Gbɔ Kple Mɔnuwo .

Ne èdi be yeayi ŋgɔ wu wò ŋkuwo kple towo la, ke dɔwɔnu siwo wotsɔ dia dɔlélewoe nye xɔ̃wò vevitɔ. Zã:

· Dial indicators be woalé ŋku ɖe mɔ̃a ƒe ʋuʋu ŋu .

· Accelerometers be woatsɔ adzidze ʋuʋudedi .

· Dzoxɔxɔ ƒe nɔnɔmetatawo ɖeɖe be woatsɔ ade dzesi teƒe siwo dzoxɔxɔ si gbɔ eme le .

· Lãɖeɖe ŋusẽ sensorwo be woase dɔwɔnu ƒe nuwɔwɔ gɔme .

Dɔwɔnu siawo kpena ɖe ŋuwò nèdea dzesi afisi wogblɔa nya le kple amekoko ƒe nyateƒetoto. Mehiã be nàsusui o—ànya nusiwo tututu hiã be woaɖɔ ɖo.

Vibration Analysis zazã hena chatter detection .

Vibration analysis le abe MRI na wò CNC mɔ̃ ene. Ne èku nu me le edziyiyi kple amplitude ŋu la, menye ɖeko nàte ŋu ade dzesii be dzeɖoɖo ma le dzɔdzɔm ko o—ke boŋ nusitae ..

Setup deŋgɔwo zãa kɔmpiutadziɖoɖo siwo doa ka kple sensor siwo le spindle la dzi, dɔwɔnulénu, kple dɔwɔnua gɔ̃ hã. Nuɖoanyi siawo wɔa ʋuʋudedi ƒe ɣeyiɣiwo ƒe nɔnɔmetata eye wotsɔa wo doa ƒome kple mɔ̃ ƒe nɔnɔmewo. Ne èzã nyatakaka siawo la, àte ŋu:

· Trɔ asi le duƒuƒu ŋu be nàƒo asa na gbeɖiɖi ƒe tsɔtsɔme .

· Da sɔ le wò spindle alo dɔwɔnu dzraɖoƒe .

· Gblɔ ɣeyiɣi si me dzeɖoɖo ate ŋu adzɔ .

Mɔnu sia si wowɔna tsɔ doa vevie nu la trɔa wò tso dzotsilawo gbɔ wòzua aɖaŋuɖola—si xea mɔ na dzeɖoɖo hafi wòdzea egɔme gɔ̃ hã.

Aɖaŋu siwo ŋu kpeɖodzi le be woatsɔ aɖe chatter ɖa .

Nutsotso ƒe nɔnɔmewo ƒe nyonyome .

Wò lãɖeɖe ƒe nɔnɔmewo xɔxɔ nyuie nye mɔ ɖeka kolia si wɔa dɔ wu si dzi nàto atɔ te chatter. Bu eŋu abe haƒonu aɖe tutu ene: Asitɔtrɔ suesuesuewo ate ŋu ana vovototo nanɔ alesi nusianu wɔa dɔe me.

Spindle ƒe duƒuƒu kple nuɖuɖu ƒe tsɔtsɔme ƒe asitɔtrɔwo .

Zi geɖe la, afɔɖeɖe gbãtɔ si nàwɔ atsɔ aɖe dzeɖoɖoa ɖae nye be nàtrɔ asi le wò spindle ƒe duƒuƒu ŋu. Aɖaŋuae nye esi—trɔtrɔ suewo, to 10% gɔ̃ hã me, ate ŋu atrɔ wò dɔwɔwɔ le gbeɖiɖi ƒe tsɔtsɔme ƒe didime si sɔ me. Ele abe brek ƒoƒo ɖe nyaŋuɖoɖo ƒe ʋuƒo si dzo le eme ene dzi.

Zã nusi woyɔna be 'spindle speed variation' (SSV) —CNC ƒe nɔnɔme si toa vovo le spindle ƒe duƒuƒu le lãɖeɖe me. Esia gblẽa nu le nya siwo wogblɔna be woagagblɔ nya sia si nye regenerative chatter la ŋu, si wɔnɛ be wòtsia enu hafi wòtua wo ɖo.

Nenema ke nuɖuɖu ƒe agbɔsɔsɔ dzi ɖeɖe kpɔtɔ alo edzi ɖeɖe kpɔtɔ hã ate ŋu aɖe ʋuʋudedi dzi akpɔtɔ. Ne èle lãa lãm kabakaba akpa la, dɔwɔnua ate ŋu anye nusi me nuawo le fũ akpa, si ana mali ke. Ne dɔwɔnua le blewu akpa la, ate ŋu atutui tsɔ wu be woatsoe—si hã nyea nuƒoƒo ƒe mɔnu.

Aɖaŋuɖoɖo Veviwo:

· Ɣesiaɣi la, nufiamewo wɔla ƒe duƒuƒu kple nuɖuɖuwo.

· Zã chip load calculators nàtsɔ alé nuwɔwɔ nyuie me ɖe asi.

· Mègavɔ̃ be yeaƒu du dodokpɔ ƒe lãɖeɖewo kple tɔtrɔ sue aɖewo o.

Depth of cut and tool engagement .

Nu vevi bubu si gbɔ wòtsona le dzeɖoɖo me enye be woatsoe wòagbɔ eme (DOC) alo eƒe kekeme (WOC) . Ne wò dɔwɔnua le ɖuɖum wu alesi wòate ŋu aɖui la, anye ɣlidodo—le nyateƒe me.

Te mɔnu siawo kpɔ:

· Ðe doc dzi kpɔtɔ vivivi vaseɖe esime ʋuʋudediwo nali ke.

· Zã radial engagement strategies —abe trochoidal milling ene—be woana dɔwɔnu ƒe nyaƒoɖeamenu si mewɔa tɔtrɔ o nanɔ anyi.

· Ma lãɖeɖe goglowo ɖe pass geɖe me.

Dadasɔ le alesi dɔwɔnua gena ɖe dɔwɔnua me le vevie na mɔ̃ɖaŋununya si li ke. Ɣeaɖewoɣi la, bɔbɔe gake kabakaba toa eme wɔa dɔ nyuie wu blewuu, kpekpewo.

Dɔwɔnuwo Tiatia kple Dɔwɔnu ƒe Nɔnɔme .

Dɔwɔnu si nàtsɔ atsoe nye MVP si le dɔwɔwɔa me. Gake ne enye ƒomevi, nɔnɔme, alo nu si mesɔ o la, ate ŋu ado ŋusẽ dzeɖoɖo le esi teƒe be wòatsi enu.

Dɔwɔnu ƒe nu kple nutrenu .

Dɔwɔnu vovovowo naa sesẽme kple ʋuʋudedi-dampening ƒe nɔnɔme vovovowo:

· Carbide dɔwɔnuwo sesẽ wu gakpo siwo zɔna kabakaba (HSS), si wɔe be wobi ɖe tsitretsitsi ɖe dzeɖoɖo ŋu me nyuie wu.

· Dɔwɔnu siwo ŋu wofa nu ɖo (abe tin alo altin ene) ɖea ʋuʋudedi dzi kpɔtɔna, si ɖea dzoxɔxɔ kple ʋuʋudedi dzi kpɔtɔna.

Zã ƒokpli nyuitɔ si wotu ɖe wò nu dzi (Aluminum vs. Titanium, le kpɔɖeŋu me) ate ŋu ana vovototoa katã nado.

Geometry ƒe asitɔtrɔwo hena liƒo .

Dɔwɔnua ƒe nɔnɔme le vevie wu alesi mɔ̃ɖaŋudɔwɔla akpa gãtɔ kpɔe dze sii. Dze agbagba:

· Helix dzogoe siwo trɔna tsɔ gbãa harmonic vibrations.

· Flute dometsotso si mesɔ o be woaxe mɔ ɖe ʋuʋudedi ƒe wɔwɔ ɖekae nu.

· Overhangs kpuiwo hena sesẽ geɖe wu.

· Nu vevi gãwo ƒe didimewo be woatsɔ akpe ɖe ŋusẽ ŋu.

3-flute end mill si ƒe kɔkɔme trɔna ate ŋu awɔ dɔ wu 4-flute kple geometry si wozãna ɖaa ne wole chatter control ŋu bum. Zi geɖe la, dodokpɔ kple vodadae wònyena, gake ne ènya ke ɖe teƒe vivia ŋu ko la, àkpɔ nuwuwu siwo le bɔbɔe wu kple duƒuƒu siwo me ɖoɖoezizi le wu.

Mɔ̃wo ƒe Ðoɖowɔwɔ Kple Wo Dzi Kpɔkpɔ .

FixTuring kple dɔwɔwɔ ƒe akpawo ƒe klatsa .

Ne womelé wò akpaa ɖe te sesĩe o la, aʋuʋu. Ɣeyiɣi. nyuie Dɔwɔwɔ nye mɔ̃ɖaŋununya ƒe ɖoɖo si me womeƒoa nu le o ƒe gɔmeɖoanyi.

Aɖaŋuɖoɖo siwo ana fixturing nanyo ɖe edzi:

· Zã vises siwo me ʋuʋudedi le, siwo me ʋuʋudedi le . alo clamps

· Na woawɔ dɔ si woate ŋu awɔ akpa si woate ŋu atsɔ awɔ dɔe la dzi. le dɔa ƒe

· Zã afɔɖeɖewo alo jigs siwo wowɔ ɖe ɖoɖo nu nàtsɔ ana liƒoa nanyo ɖe edzi.

· Bu kplɔ̃ siwo me woɖea ya le ŋu na akpa gbadzawo—gake nàdo ŋusẽ woƒe sesẽ.

Le akpa siwo mebɔbɔ o gome la, aɖu falɛfalɛwo alo nusiwo wowɔ ɖe ɖoɖo nu be woakpɔ egbɔ be wole dedie evɔ womatrɔ o. woate ŋu ahiã

Mɔ̃a ƒe sesẽ kple eƒe ɖoɖowɔwɔ .

Dɔwɔnu kple ɖoɖo nyuitɔwo kekeake gɔ̃ hã maɖe vi aɖeke o ne wò CNC mɔ̃a ŋutɔ mewɔ ɖe dɔa dzi o.

Kpɔe ɖa be:

· Slide alo mɔ siwo dzi wometo o .

· Bɔlƒoƒo ƒe ʋuƒo siwo wodo .

· Spindle ƒe masɔmasɔ .

· Tabla ƒe ʋuʋu le dɔwɔwɔ me .

Nuto siawo me toto sesĩe ate ŋu aɖe ʋuʋudedi ƒe kaka dzi akpɔtɔ ŋutɔ eye wòana lãɖeɖe ɖesiaɖe ƒe nyonyome nanyo ɖe edzi.

Beléle na wo edziedzi kple wo dzidzedze .

Mègaɖɔ nuwo ɖo ko ne wogbã o. xe mɔ na wo be woagagbã o.

Tu beléle na xɔa ƒe ɖaseɖigbalẽ si wowɔna edziedzi:

· Si ami na mɔfiadzesiwo kple gaviwo edziedzi .

· Kpe boltwo kple kadodowo sesĩe .

· Kpɔ spindle ƒe dadasɔ kple bearing lãmesẽ .

· Gbugbɔ do gas ɖe te le ɣleti ʋɛ aɖewo ɖesiaɖe me .

Mɔ̃ si ŋu wodzra ɖo nyuie nye mɔ̃ si te ŋu nɔa te ɖe dzeɖoɖo nu. Zi geɖe la, beléle na ame ate ŋu aɖe kuxiwo ɖa hafi woaɖo dɔwɔnua gbɔ.

Egbɔkpɔnu Deŋgɔwo hena Chatter Mitigation .

Dɔwɔnu siwo wotsɔ léa nu ɖe asi zazã .

Dɔwɔnu siwo wotsɔna léa nu ɖe asi le abe shock absorbers ene na wò dɔwɔnu siwo wotsɔ lãa nu la. Woxɔa ŋusẽ si tso ʋuʋudedi me hafi wòɖoa afisiwo wòle vevie le.

Zi geɖe la, nusiwo le abe polymers alo tuned mass dampers ene nɔa nulénu siawo me le nulénu ƒe ŋutilã me. Nusi do tso emea? Vibration si dzi ɖe kpɔtɔ ŋutɔ, dɔwɔnu ƒe agbenɔƒe didi wu, kple eƒe nuwuwu nyuie wu.

Wowɔa dɔ nyuie ŋutɔ le kotoku me nutunu kple dɔwɔwɔ didi siwo me wozãa dɔwɔnu siwo wozãna ɖaa le bɔbɔe be woate ŋu aɖiɖi bɔbɔe la me.

Dɔwɔnu siwo trɔna kple helix .

Dɔwɔnu siwo ƒe gbeɖiɖi ƒe kɔkɔme trɔna alo helix si trɔna la ƒe flute geometriwo le wo si siwo woɖoe koŋ mesɔ o. Esia gblẽa nu le ŋusẽ siwo wotso ƒe sɔsɔme ŋu eye wògblẽa ʋuʋudedi ƒe ƒuƒoƒo me.

Le esi teƒe be saŋkuwo katã naƒo nu tso nuawo ŋu le ɣeyiɣi ɖeka me la, dometsotso si trɔna la kakaa ŋusẽ ƒe agbaa. Esia ɖea mɔnukpɔkpɔ si li be woaƒo ƒu ɖekae dzi kpɔtɔna eye wòɖea nya siwo wogblɔna be woagava dze wo nɔewo ŋu la ɖa kloe.

Zã esiawo na:

· Dɔwɔna siwo zɔna kabakaba .

· Akpa siwo ƒe gliwo le tsɛ .

· Yamenutome-Grade Nuwo .

Vibration Dampening Systems .

CNC ɖoɖo deŋgɔ aɖewo va kple ʋuʋudedi ƒe ʋuƒo siwo wotu ɖe eme alo woɖe mɔ ɖe gotagome kpeɖeŋutɔwo ŋu:

· Active dampening systems siwo zãa sensorwo kple actuators .

· Magnetic dampers na spindle assemblies .

· Damper siwo wowɔ le agbɔsɔsɔ gã me le spindle ƒe xɔa me .

Togbɔ be exɔ asi hã la, ɖoɖo siawo xɔ asi ŋutɔ le dɔwɔwɔ si me wowɔa nu pɛpɛpɛ le ŋutɔ me afisi anyigba ƒe nɔnɔme ƒe nuwuwu kple didime ƒe blibonyenye le vevie wu.

CAM Kɔmpiutadziɖoɖowo Kple Simulation .

Dzeɖoɖo ƒe nyagblɔɖi to kɔmpiutadziɖoɖowo dzi .

Egbegbe CAM (kɔmpiuta-kpekpeɖeŋu wɔwɔ) kɔmpiuta dɔwɔɖoɖoa wɔa nu geɖe wu dɔwɔnu ƒe mɔwo wɔwɔ ko—ate ŋu agblɔ nya siwo woatsɔ aƒo nui ɖi azɔ hafi nàka asi nu aɖe ŋu gɔ̃ hã. Ema le abe kristalo-bɔl si le asiwò na wò mɔ̃ɖaŋudɔwɔwɔ ene.

Dɔwɔnu deŋgɔwo zãa akɔntabubu ƒe kpɔɖeŋuwo kple mɔ̃ɖaŋudɔwɔwɔ ƒe ŋusẽ tsɔ gblɔa nya ɖi ne chatter ate ŋu adzɔ le:

· Nuwo ƒe Nɔnɔmewo .

· Dɔwɔnu ƒe nɔnɔmetata .

· Lãɖeɖe ƒe nɔnɔmewo .

· Mɔ̃a ƒe Ŋusẽkpɔɖeamedzi .

Ne ègblɔ nya siawo ɖi la, àte ŋu atrɔ asi le wò ɖoɖoa ŋu le dijitaal ƒe akpaa dzi, si ana ɣeyiɣi, nu, kple dɔwɔnu ƒe agbenɔƒe nanɔ anyi. Ðoɖowo abe machiningcloud , vericut , alo NC Simul nye dɔwɔƒewo ƒe nusiwo wolɔ̃na wu ne wole nu ƒom tso dzeɖoɖo kple mɔxexe ɖe enu ŋu.

Dɔwɔnuwo ƒe mɔ ƒe nyonyome ƒe mɔnuwo .

Toolpath ƒe ɖoɖowɔwɔ kpɔa ŋusẽ ɖe dzeɖoɖo dzi tẽ. Kpɔɖeŋu aɖewo hea ʋuʋudedi vɛ, gake bubuwo ya ɖea wo dzi kpɔtɔna le dzɔdzɔme nu.

Nusi wòle be nàwɔe nye esi:

· Zã mɔ̃ɖaŋununya ƒe mɔnu siwo zɔna kabakaba abe Adaptive Clearing ene be nàɖe dɔwɔnuwo ƒe gomekpɔkpɔ le eme dzi akpɔtɔ eye nàna ŋusẽwo nali ke.

· Ƒo asa na mɔfiame ƒe tɔtrɔ kpata alo dzogoe ɖaɖɛwo le wò dɔwɔnumɔwo me.

· Zã dɔwɔnu siwo wozãna ɣesiaɣi siwo ɖea dɔwɔnu ƒe ʋuʋu dzi kpɔtɔna.

Dɔwɔnu siwo me nunya le wu fia be woatso lãɖeɖe ƒe ŋusẽ siwo da sɔ wu, si gɔmee nye be woawu enu nyuie wu, si me chatter mele o.

Ɣeyiɣi ŋutɔŋutɔ ƒe nɔnɔmetata kple nyaŋuɖoɖo .

CAM solutions aɖewo ƒoa ɣeyiɣi ŋutɔŋutɔ ƒe nyaŋuɖoɖo ƒe ʋuƒo siwo wozãna le mɔ̃a dzi la nu ƒu. Nuɖoanyi siawo léa ŋku ɖe spindle ƒe ʋuʋu, ŋusẽ si wotso, kple gbeɖiɖi ƒe dodo ŋu le ɣeyiɣi ŋutɔŋutɔ me. Ne dzeɖoɖo dze egɔme la, woate ŋu:

· Ðo nuxlɔ̃amewo ɖe dɔwɔƒea .

· Trɔ asi le nuɖuɖu/sesẽme ŋu le eɖokui si le yameʋua me .

· Nuŋlɔɖiwo ŋuti nyatakakawo hena numekuku le dɔwɔwɔ vɔ megbe me dzodzro .

Esia proactive layer of chatter control ɖea vi ŋutɔ le automated alo lights-out machining nuto siwo me asi ŋkuléle ɖe nu ŋu mate ŋu awɔ o.

Hehenana dɔwɔlawo kple nuwɔna nyuitɔwo .

Vevienyenye si le dɔwɔla bibiwo ŋu .

Dɔwɔnu nyuitɔwo kekeake, kɔmpiutadziɖoɖo si me nunya le wu, kple mɔ̃ sesẽ si le abe kpe ene ate ŋu anɔ asiwò—gake ne nuteƒekpɔkpɔ mele wò dɔwɔƒea si o la, Chatter akpɔ mɔ aɖe si dzi nàto age ɖe eme.

Mɔ̃ɖaŋudɔwɔla si xɔ hehe nyuie ate ŋu:

· Se vovototo si le lãɖeɖe nyui kple gbegblẽ dome .

· Se le eɖokui me be yeʋuʋu le mɔ si menya kpɔna dzea sii bɔbɔe o nu .

· Woanɔ te ɖe dɔwɔnu ƒe dzesiwo ɖeɖeko dzi akpɔ dzeɖonya .

Dɔwɔla bibiwo hã nya ɣeyiɣi si woade nu eme, atrɔ dɔwɔnuwo, alo atrɔ asi le ɖoɖowo ŋu le ɣeyiɣi ŋutɔŋutɔ me. Woƒe dzɔdzɔmeŋutete siwo woto vɛ le gaƒoƒo akpe geɖe me le fiasea me la nye esiwo womate ŋu aɖɔ li o.

De sukudede atraɖii ƒe dzi ƒo. De ga wò ƒuƒoƒoa ƒe dzidziɖedzi me. Smart operator nye wò ametakpɔnu gbãtɔ si nètsɔ kpɔa ame ta.

Nusɔsrɔ̃ kple dɔwɔƒewo ƒe nusɔsrɔ̃ si yia edzi ɖaa .

Mɔ̃ɖaŋununya ƒe xexeame trɔna kabakaba, eye ŋgɔgbe nɔnɔ bia hehexɔxɔ si ayi edzi. Amedzroxɔla alo vava:

· Dɔwɔƒe siwo le aƒea me siwo ku ɖe dzeɖoɖo ƒe dɔlélewo didi ŋu .

· Nudzralawo ƒe nusɔsrɔ̃ siwo ku ɖe dɔwɔnu yeyewo kple lãɖeɖe ƒe mɔnuwo ŋu .

· Internet dzi nusɔsrɔ̃wo kple ɖaseɖigbalẽwo tso mɔ̃wo abe Coursera, Tooling U, alo LinkedIn Nusɔsrɔ̃ ene .

Sidzedze nye ŋusẽ—eye le CNC ƒe mɔ̃ɖaŋudɔwɔwɔ me la, enye ŋusẽ si woatsɔ aɖe nu gbagbãwo dzi akpɔtɔ, ana woƒe nyonyome nanyo ɖe edzi, eye woadidi mɔ̃a ƒe agbenɔƒe ɖe edzi.

Dɔwɔƒewo ƒe Kpɔɖeŋuwo Kple Nudzɔdzɔwo Ŋuti Numekukuwo .

Xexeame ŋutɔŋutɔ ƒe dzidzedzekpɔkpɔ ŋutinyawo .

Mina míalé ŋku ɖe alesi dɔwɔƒe aɖewo ɖe dzeɖoɖo kple nuwɔwɔ ɖe edzii ɖa ŋu:

Yamenutomemɔ̃wɔƒe le Ohio .

Kuxi: Dzeɖoɖo le aluminum ƒe akpa siwo le kotoku me goglo me .

Egbɔkpɔnu: Wotrɔ asi le helix end mill siwo trɔna ŋu, wotsɔ damped holders kpee .

Emetsonu: Ɣeyiɣi si wotsɔ nɔa tsatsam ƒe ɣeyiɣi dzi ɖe kpɔtɔ 30%, eƒe nuwuwu ƒe dzeside si nyo wu tso RA 6.3 μm va ɖo RA 1.2 μm .

Ʋuwɔƒe si le Germany .

Kuxi: Dɔwɔnuwo ƒe vuvu fũu akpa kple woƒe gowo ƒe gbegblẽ .

Egbɔkpɔnu: Wowɔ dɔ le ɣeyiɣi ŋutɔŋutɔ me ʋuʋu dzi kpɔkpɔ kple CAM ƒe nyaŋuɖoɖo .

Emetsonu: Dɔwɔnu ƒe agbenɔƒe ƒe dzidziɖedzi 40% kple akpa siwo wogbe la ʋɛ aɖewo .

Atikewɔnuwo ƒe fiase le California .

Kuxi: Nyaʋiʋli le titanium sue siwo wotsɔ dea ame me ŋu .

Egbɔkpɔnu: Dɔwɔnu ƒe mɔnu ƒe mɔnu siwo wowɔ nyuie wu, nusiwo wotsɔna ƒoa nuwoe siwo ƒe sesẽme lolo ŋutɔ kpe ɖe wo ŋu

Emetsonu: Woɖo ±0.005 mm ƒe mɔɖeɖe ɖe nu ŋu ɣesiaɣi .

Kpɔɖeŋu siawo ɖee fia be dɔwɔƒe alo ŋutilãmenuwo ka kee woɖanye o, mɔnu nyuiwo zazã hea ŋgɔyiyi ŋutɔŋutɔ siwo woate ŋu adzidze vɛ.

Nusiwo wosrɔ̃ tso CNC ƒe dɔwɔlawo gbɔ .

Ðo dze kple mɔ̃ɖaŋudɔwɔla ɖesiaɖe si nya nu tso eŋu eye woagblɔe na wò—chatter isn’t just a fuɖename ko; Enye fiase me amewula. Nusi wosrɔ̃ le mɔ sesẽ nu enye si:

· Mègaŋe aɖaba ƒu dzesi gbãtɔwo dzi gbeɖe o—nyaʋiʋlia nu sẽna ɖe edzi ɣesiaɣi.

· Ðoɖo sesẽ aɖe le vevie wu ɖoɖo si wowɔna kabakaba.

· Dodokpɔ ƒe ɖeɖe kple nuŋlɔɖiwo nye xɔ̃wò veviwo.

· Dɔwɔnu siwo mexɔ asi o ƒe asi bɔbɔna na wò wu le ɣeyiɣi didi aɖe megbe.

Nunya si le fiasea ƒe gɔme sese le vevie abe alesi wòaxlẽ mɔfiamegbalẽe ene. Nuteƒekpɔkpɔ le xexeame ŋutɔŋutɔe nye sika ne wole nyahehewo didi kple wo gbɔ kpɔkpɔ ŋu bum.

vodada siwo bɔ be woaƒo asa na .

Mɔ̃wo ƒe dzidzedzekpɔkpɔ le mɔ̃ dzi kpɔkpɔ .

Mɔ̃ si womeɖɔ ɖo nyuie o la le abe ʋu si ƒe tasiaɖamfɔwo mesɔ o ene. Kakaɖedzitɔe la, aʋuʋu—gake menye nyuie o. Dzidzedzekpɔkpɔ edziedzi kpɔa egbɔ be wotsɔ axeswo katã ɖe ɖoɖo nu, woɖea megbedede dzi kpɔtɔna, eye akpa vovovoawo wɔa dɔ le ɖekawɔwɔ me.

Afɔɖeɖe siwo mesɔ o siwo bɔ:

· Aɖabaŋeŋe ƒu nya sue siwo ku ɖe nuwo ƒe sɔsɔ ɖe ɖoɖo nu ŋu .

· Dzadzraɖo si woɖo be woadzra ɖo

· Dodomake be woagagbugbɔ aɖɔ akpa aɖe o le eƒe akpa aɖe ƒe gbagbã vɔ megbe .

Mɔ̃ yeyewo gɔ̃ hã ate ŋu akpɔ viɖe tso dodokpɔ ƒe dodokpɔ kaba me—mègasusui be dɔwɔƒe ƒe ɖoɖowo de blibo o.

Dɔwɔnu siwo mesɔ o zazã .

Dɔwɔnu si mesɔ o zazã le abe hammer zazã ne èhiã screwdriver ene—menye nusi mewɔa dɔ o koe wònye o, ke boŋ egblẽa nu.

Vodada siwo bɔ ɖe dɔwɔnuwo me:

· Dɔwɔnu siwo keke ta hena lãɖeɖe siwo me goglo o .

· Flutes geɖe akpa na gummy nuawo .

· Aɖabaŋeŋe ƒu dɔwɔnu siwo wotsɔ blaa nu ƒe vevienyenye dzi .

· Dɔwɔnu ƒe geometry si sɔ kple ŋutilãmenuwo ƒe sesẽme .

Kpɔ wò dɔwɔnudzrala alo rep ɣesiaɣi hafi nàwɔ dɔ yeye aɖe. Aɖabaƒoƒo atɔ̃ ƒe kaƒoƒo ate ŋu ana woagagbugbɔ awɔ dɔ gaƒoƒo geɖe.

Akpa si mɔ̃ɖaŋununya wɔna le mɔxexe ɖe dzeɖoɖo nu me .

IoT kple smart machining ɖoɖowo .

Industrial Internet of Things (IIOT) le CNC mɔ̃ɖaŋudɔwo trɔm. Smart sensors siwo wotsɔ de mɔ̃wo, spindles, kple dɔwɔnuwo me ate ŋu aƒo ɣeyiɣi ŋutɔŋutɔ ŋuti nyatakaka siwo ku ɖe ʋuʋudedi, dzoxɔxɔ, kple lãɖeɖe ƒe ŋusẽ ŋu nu ƒu.

Wotsɔa nyatakaka sia naa dashboard alo alilikpo ƒe mɔ̃wo, si wɔnɛ be woate ŋu atrɔ asi le nyagblɔɖiwo ŋu abe:

· Duƒuƒu dzi ɖeɖe kpɔtɔ ne ʋuʋudedi wu seɖoƒewo .

· Nuxlɔ̃ame dɔwɔlawo hafi chatter nagblẽ nu le dɔwɔnuwo ŋu

· Mɔ̃a ƒe nutsitsi ne nɔnɔmeawo sesẽ .

Menye ɖeko smart systems siawo dea dzesi dzeɖoɖo ko o—wowɔa dɔ veviedodotɔe be yewoaxe mɔ ɖe enu.

Dɔwɔnu Siwo Wozãna Le Beléle Na Nyawo Me .

Beléle na nya siwo wogblɔ ɖi la zãa nyatakakawo kple numekukuwo tsɔ kpɔa ɣeyiɣi si mɔ̃ aɖe ƒe akpa aɖe ado kpo nu. Enye fefe-trɔla na chatter control.

Viɖeawo dometɔ aɖewoe nye:

· De dzesi bearing vuvu hafi wòahe spindle ʋuʋu .

· Mɔxexe ɖe nusiwo le gbadzaa nu le linear rails me .

· Ðoɖowɔwɔ ɖe ɣeyiɣi siwo woatsɔ atɔ te nu ŋu evɔ womagblẽ nu le nuwɔwɔ ŋu o .

To nyawo gbɔ kpɔkpɔ hafi woahe dzeɖoɖo vɛ me la, beléle na wò fiasea nana wò fiasea nɔa du dzi nyuie eye wònɔa anyi kpoo.

CNC ƒe nɔnɔme si me dzeɖoɖo mele o tutuɖo .

Integrating Lean Manufacturing .

Chatter control sɔ le dzɔdzɔme nu ɖe lean manufacturing principles me . Ewɔa ɖeka kple gbeɖuɖɔ dzi ɖeɖe kpɔtɔ, sisi nyuie wu, eye wòléa nyonyome si nɔa anyi ɖaa me ɖe asi.

Lean dɔwɔnu siwo kpena ɖe ame ŋu le dzeɖoɖo me:

· Kaizen nudzɔdzɔwo be woaɖe nusiwo gbɔ wòtsona ɖa .

· Dɔwɔwɔ ƒe mɔfiame siwo sɔ na mɔ̃wo ɖoɖo .

· 5S ƒe ɖoɖowo be woalé nuto si le dzadzɛ, si li ke la me ɖe asi .

Dɔwɔƒe si me lãmesẽ mele o, si ŋu wowɔ ɖoɖo ɖo la ɖea zitɔtɔ si dzia dzeɖoɖo zi geɖe la dzi kpɔtɔna.

Dɔwɔwɔ ƒe ɖoɖo siwo wozãna ɖaa (SOPS) .

Mlɔeba la, ŋlɔ nusianu ɖi. Wɔ SOP siwo dometɔ aɖewoe nye:

· Nutsotso ƒe nɔnɔme nyuitɔ kekeake na nu ɖesiaɖe .

· Mɔ̃wo ƒe dzoxɔxɔ kple dzidzedzekpɔkpɔ ƒe ɖoɖowo .

· Dɔwɔnuwo Tiatia ƒe Dzesidewo .

· Gbesiagbe Mɔ̃wo Me Dzodzro ƒe Mɔfiamewo .

SOP siwo me kɔ, siwo ŋu woate ŋu ake ɖo, kpena ɖe dɔwɔla ɖesiaɖe ŋu—yeye alo amesi nya nu tso eŋu—lɔ̃ ɖe nuwɔna nyuitɔwo dzi, be woaƒo nya ta ɣesiaɣi.

Nyanuwuwuw

Chatter ate ŋu anye kuxi si bɔ le CNC machining me, gake menye nusi womate ŋu aƒo asa na kura o. Ne èse nusiwo gbɔ wòtso kple dɔwɔnuɖaka si yɔ fũ kple aɖaŋuɖoɖowo gɔme nyuie—tso tuning lãɖeɖe ƒe nɔnɔmewo dzi va ɖo kɔmpiuta dɔwɔɖoɖowo kple xɔtunuwo dodo ɖe ŋgɔ dzi—la, àte ŋu awɔ fiase si me ɖoɖoezizi le, si wɔa dɔ nyuie, eye wòwɔa dɔ nyuie.

Mègana chatter naɖe asi le wò nuwɔwɔ pɛpɛpɛ ŋu, agblẽ wò nuwo dome, alo agblẽ nu le wò viɖewo ŋu o. Wɔ nu do ŋgɔ, nɔ agbalẽsrɔ̃nyawo me, eye nàwɔ nu ɖe dzeɖoɖo dzi ɖuɖu ŋu abe wò CNC ƒe aɖaŋuɖoɖo ƒe akpa vevi aɖe ene.

Nya siwo wobiaa amewo .

1. Aleke mawɔ anya nenye be nye CNC mɔ̃a le chatter teƒe kpɔm?

Di toɣliɖeɖe siwo le ɖiɖim sesĩe le lãɖeɖe, ƒutsotsoe ƒe nɔnɔme siwo wokpɔna le wò dɔwɔnu dzi me, kple dzesi siwo fia be dɔwɔnuawo ƒe vuvu kabakaba alo woƒe gowo gblẽ. Ɣeyiɣi ŋutɔŋutɔ me ʋuʋudedi ƒe sensorwo hã ate ŋu akpe ɖe ŋuwò nàde dzesii kaba.

2. Ðe woate ŋu aɖe chatter ɖa keŋkeŋa?

Togbɔ be ɖewohĩ womate ŋu aƒo asa na 100% le nɔnɔme ɖesiaɖe me o hã la, aɖaŋu nyuiwo zazã kple dɔwɔnuwo zazã ate ŋu aɖe edzi akpɔtɔ wòade zero kloe. Ne èto nuteƒekpɔkpɔ kple ɖoɖo nyuitɔ me la, àte ŋu awɔ akpa aɖewo nyuie ɣesiaɣi.

3. Nukae nye mɔ si dzi woato aɖe dzeɖoɖo dzi akpɔtɔ si me ga mele o wu?

Dze egɔme kple ɖɔɖɔɖo bɔbɔewo abe nuɖuɖu ƒe agbɔsɔsɔme tɔtrɔ alo dɔwɔnu kpui aɖe zazã ene. Toolpath optimization le wò CAM kɔmpiuta dɔwɔɖoɖo kple better fixturing hã nye asi gake wowɔa dɔ ŋutɔ.

4. Aleke dzoxɔxɔ kpɔa ŋusẽ ɖe chatter dzi le CNC machining me?

Dzoxɔxɔ si lolo wu ate ŋu ana dzoxɔxɔ nakeke ɖe enu, si ana amewo nasɔ ɖe ɖoɖo nu eye woadzi vibration bɔbɔe ɖe edzi. Ele vevie ŋutɔ be nàlé dzoxɔxɔ ƒe liƒo ɖe te le wò lãɖeɖe ƒe nɔnɔme me.

5. Ðe wòle be matrɔ nye CAM kɔmpiuta dɔwɔɖoɖoa be wòaɖɔ chatter ɖoa?

Ne wò kɔmpiuta dɔwɔɖoɖo si li fifia mekpɔ alesi wowɔa nu ɖe ame ŋu alo nya siwo wogblɔna ɖi o la, tɔtrɔ ɖe nɔnɔmea ŋu ate ŋu aɖe vi. Egbegbe CAM ƒe kuxiwo gbɔkpɔnu naa numekukudɔwɔnu sẽŋu siwo kpena ɖe ame ŋu be woaxe mɔ ɖe dzeɖoɖo ƒe akpaa nu.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu