Le CNC (kɔmpiuta xexlẽdzesiwo dzi kpɔkpɔ) mɔ̃wo kple mɔ̃ɖaŋudɔ bubu siwo sɔ pɛpɛpɛ me la, servo motors kple spindle motors nye akpa vevi siwo ʋãa ɖoɖoa ƒe dɔwɔwɔ. Togbɔ be wo ame evea siaa nye elektrikmɔ̃ siwo le vevie na CNC-mɔ̃wo ƒe dɔwɔwɔ hã la, wowɔa taɖodzinu siwo to vovo koŋ eye wowɔ wo kple nɔnɔme vovovo siwo wowɔ ɖe woƒe dɔ tɔxɛwo nu. Vovototo siwo le servo motors kple spindle motors dome gɔmesese le vevie ŋutɔ na akpa siwo sɔ tiatia, mɔ̃a ƒe dɔwɔwɔ nyuie wu, kple emetsonu deŋgɔwo gbɔ ɖoɖo le mɔ̃ɖaŋununya si sɔ pɛpɛpɛ me. Nyati sia ƒo nu tso vovototo vevi siwo le mɔ̃ ƒomevi eve siawo dome ŋu, eye wòdzro woƒe dɔwɔwɔwo, aɖaŋuwo, dɔwɔwɔwo, kple dɔwɔwɔ ƒe nɔnɔmewo me be woana eme nakɔ na modzakaɖelawo, mɔ̃ɖaŋudɔwɔla bibiwo, kple mɔ̃ɖaŋudɔwɔlawo.

Nukae nye servo motors?

Servo-mɔ̃wo nye elektrikmɔ̃ tɔxɛ siwo ŋu wotrɔ asi le ŋutɔ be woatsɔ akpɔ teƒe, sesẽme, kple torque dzi nyuie le CNC (kɔmpiuta xexlẽdzesiwo dzi kpɔkpɔ) mɔ̃wo kple mɔ̃ɖaŋudɔ bubu siwo sɔ pɛpɛpɛ me. Woawoe nye ŋusẽ si le megbe na CNC mɔ̃ ƒe asikewo ƒe ʋuʋu pɛpɛpɛ (le kpɔɖeŋu me, x, y, z) alo akpa siwo le robot-mɔ̃wo me, si kpɔa egbɔ be woɖo dɔwɔnuwo alo dɔwɔnuawo ɖe teƒe si woɖo ɖi pɛpɛpɛ. To vovo na mɔ̃ siwo wozãna ɖaa la, servo motors wɔa dɔ le closed-loop control system me, wozãa nyaŋuɖoɖo ƒe mɔ̃wo abe encoders alo resolvers ene tsɔ léa ŋku ɖe woƒe dɔwɔwɔ ŋu ɣesiaɣi hetrɔa asi le eŋu be wòasɔ kple CNC ɖoɖoa ƒe mɔfiamewo. Esia pɛpɛpɛ kple tɔtrɔ ɖe nɔnɔmewo ŋu na servo motors hiã vevie na dɔ siwo bia be woaʋuʋu pɛpɛpɛ eye woakpɔ ŋusẽ ɖe wo dzi le ŋusẽ me le dɔwɔƒewo tso ewɔwɔ dzi va ɖo robot dzi .

Wotrɔ asi le servo-mɔ̃wo ŋu kple nɔnɔme tɔxɛ siwo wɔnɛ be woate ŋu azã wo le dɔ siwo wowɔna pɛpɛpɛ ŋutɔ me. Nu vevi siwo ɖea woƒe dɔwɔwɔ gɔme eye wodea vovototo wo kple mɔ̃ ƒomevi bubuwo, abe spindle motors ene, la le ete:

Closed-loop control

servo motors wɔa dɔ le closed-loop system me, si fia be woxɔa nyatakaka siwo yia edzi tso sensorwo gbɔ (le kpɔɖeŋu me, encoder alo resolvers) be woalé ŋku ɖe woƒe teƒe ŋutɔŋutɔ, duƒuƒu, kple torque ŋu. Wotsɔa nyaŋuɖoɖo sia sɔna kple asixɔxɔ siwo wodi tso CNC dziɖuɖu ƒe ɖoɖoa me, eye woɖɔa vovototo ɖesiaɖe ɖo le ɣeyiɣi ŋutɔŋutɔ me to asitɔtrɔ le mɔ̃a ƒe dɔwɔwɔ ŋu me. Closed-loop control sia kpɔa egbɔ be wowɔa nu pɛpɛpɛ etɔxɛe, si wɔe be servo motors sɔ nyuie na dɔwɔwɔ siwo me teteɖeanyi suesuesuewo gɔ̃ hã ate ŋu akpɔ ŋusẽ ɖe nyonyome dzi, abe CNC machining alo robot arm positioning ene.

High precision

servo motors te ŋu trɔa asi le nu suewo ŋu, si wɔnɛ be woate ŋu aɖoe pɛpɛpɛ vaseɖe milimeta alo degree ƒe akpa sue aɖewo. Nusi sɔ pɛpɛpɛ sia le vevie ŋutɔ na dɔwo abe geometri siwo me wowɔa nu sesẽwo le, do siwo sɔ pɛpɛpɛ kuku, alo dɔwɔnu siwo woatsɔ aɖo wo ɖe teƒe vovovowo le CNC-mɔ̃ siwo me nu geɖe le me. Le kpɔɖeŋu me, le 5-axis CNC mɔ̃ me la, servo motors kpɔa egbɔ be axis ɖesiaɖe ʋãna pɛpɛpɛ be woawɔ akpa siwo gɔme sese sesẽ na yamenutome alo atikewɔwɔ ƒe dɔwo.

Trɔtrɔ ƒe duƒuƒu kple torque

servo motors ate ŋu awɔ dɔ le duƒuƒu vovovowo me eye wòana torque si mewɔa tɔtrɔ o, si wɔe be woate ŋu azãe le mɔ vovovowo nu na dɔwɔwɔ siwo me ŋusẽ le. Woate ŋu awɔ dɔ kabakaba, woaɖe wo dzi akpɔtɔ, alo woatɔ kaba esime wole dziɖuɖu si sɔ pɛpɛpɛ dzi kpɔm, si le vevie na dɔ siwo bia be woawɔ tɔtrɔ kabakaba le ʋuʋu me, abe contouring alo threading le CNC machining me ene. Alesi woate ŋu atrɔ asi le nu ŋu alea la wɔnɛ be servo motors te ŋu trɔna ɖe agba vovovowo kple mɔ̃wo ƒe nudidiwo ŋu.

Zi geɖe la, servo-mɔ̃ siwo ƒe nɔnɔme le sue ŋutɔ

la le sue eye woƒe kpekpeme le bɔbɔe, wowɔ wo be woate ŋu asɔ ɖe CNC mɔ̃wo alo robot-mɔ̃wo ƒe teƒe siwo woxe mɔ na la nu. Woƒe lolome sue la wɔnɛ be woate ŋu aʋuʋu le mɔ si trɔna nu, si me nu geɖe le eye wometsɔa kpekpeme si gbɔ eme kpena ɖe mɔ̃a ƒe akpa siwo le ʋuʋum la ŋu o. Esia le vevie ŋutɔ na dɔ siwo wowɔna kabakaba le afisiwo nusiwo mewɔa dɔ le o dzi ɖeɖe kpɔtɔ le vevie ŋutɔ be woawɔ nu ɖe wo ŋu nyuie ahade pɛpɛpɛ.

Servo Motors Servo Motors ƒomeviwo

ƒe ƒomevi vovovowo va le vovovo, eye wo dometɔ ɖesiaɖe sɔ na dɔ aɖewo koŋ wɔwɔ:

AC Servo Motors : Ŋusẽ to teranoting current dzi, mɔ̃ siawo sesẽ eye wozãnɛ zi geɖe le dɔwɔƒewo ƒe CNC mɔ̃wo me hena woƒe ŋusẽ gã kple woƒe anyinɔnɔ. Zi geɖe la, wotsɔa wo kpena ɖe variable frequency drives (VFDs) ŋu hena dziɖuɖu pɛpɛpɛ.

DC Servo Motors : Powered by direct current, motors siawo le bɔbɔe wu eye wozãnɛ zi geɖe le dɔ suewo alo esiwo me womebiaa nu geɖe le o me, abe modzakaɖela CNC setups ene. Brushed DC servo motors mebɔ o le beléle na wo ƒe hiahiãwo ta, gake brɔs manɔmee ƒe tɔtrɔwo ya wodina be woawɔ dɔ nyuie.

Brushless DC Servo Motors : Esiawo ƒoa viɖe siwo le DC mɔ̃wo ŋu la nu ƒu kple alesi wònɔa anyi didina kple eƒe dɔwɔwɔ nyuie wu, si wɔnɛ be brɔswo mehiã o. Wozãa wo geɖe le egbegbe CNC mɔ̃wo me hena woƒe beléle na wo bɔbɔe kple woƒe dɔwɔwɔ nyuie.

| Servo Motor Type |

Description |

Pros |

Cons |

Dɔwɔwɔwo ƒe |

Nɔnɔme Veviwo . |

| AC Servo Mɔ̃wo . |

Wotrɔ asi le elektrikŋusẽ si trɔna ŋu, eye wowɔ mɔ̃ sesẽ siawo na dɔwɔƒe siwo zãa ŋusẽ geɖe, siwo zi geɖe wotsɔa wo tsakana kple ʋuʋudedi siwo trɔna (VFDs) hena duƒuƒu kple torque dzi kpɔkpɔ pɛpɛpɛ. |

Ŋusẽ gã ƒe dodo, nɔnɔme nyuitɔ kekeake na dɔwɔwɔ atraɖii, dziɖuɖu pɛpɛpɛ kple VFDS, si sɔ na dɔ sesẽ wɔwɔ. |

Ga home si lolo wu le mɔ̃ kple VFD ƒe sesẽ ta, afɔɖoƒe si lolo wu, bia ɖoɖowɔwɔ kple ɖoɖowɔɖi sesẽwo. |

Dɔwɔƒewo ƒe CNC-mɔ̃wo, nutunu gãwo, tomekuku, robotwo, kple nuwo wɔwɔ le wo ɖokui si le ʋuwo/mɔ̃wo me. |

Torque kɔkɔ le duƒuƒu sue, xɔtutu sesẽ, duƒuƒu ƒe didime gbadzaa (1,000–6,000 rpm), zi geɖe la, 1–20 kW ƒe ŋusẽ ƒe dzeside. |

| DC Servo Mɔ̃wo . |

Mɔ̃ siawoe naa ŋusẽe, eye wozãa mɔ̃ siawo bɔbɔe wu eye wozãa wo le dɔ sue siwo me womebiaa nu geɖe le o me. Woate ŋu akpɔe le ɖoɖo siwo me brɔs le alo esiwo me brɔs mele o me, eye brɔswo mebɔ o le beléle na wo ƒe hiahiãwo ta. |

Gazazã nyuie, si le bɔbɔe, si dzi wokpɔna bɔbɔe, si sɔ na dɔwɔwɔ siwo me ŋusẽ mele o. |

Ŋusẽ si seɖoƒe li na, brɔs ƒe tɔtrɔwo ƒe beléle gã (brush vuvu), bɔbɔe be dzoxɔxɔ akpa le ɣeyiɣi didi zazã me. |

Hobbyist CNC setups, kplɔ̃dzimɔ̃ suewo, automation dɔ bɔbɔewo, ŋusẽ sue dɔwɔɖoɖowo abe PCB milling alo kekeli nuŋɔŋlɔ. |

Torque si bɔbɔ ɖe anyi, duƒuƒu ƒe didime si nye 2,000–10,000 rpm, ŋusẽ ƒe dzidzedzekpɔkpɔ zi geɖe 0.1–1 kW, menɔa anyi didina wu AC mɔ̃wo o. |

| Brushless DC servo motors . |

DC-mɔ̃wo ƒe hatsotso sue aɖe, esiawo zãa elektrɔnikmɔ̃wo ƒe tɔtrɔ ɖe brɔswo teƒe, si wɔnɛ be wowɔa dɔ nyuie wu eye wònɔa anyi didina. Wozãnɛ geɖe le egbegbe CNC ɖoɖowo me hena woƒe dɔwɔwɔ ƒe dadasɔ kple beléle na wo bɔbɔe. |

Dɔwɔwɔ nyuie, beléle na, agbenɔƒe didi wu, nɔnɔme si le sue, dɔwɔwɔ nyuie le duƒuƒu ƒe didime si keke ta me. |

Gbãtɔ ƒe asi si lolo wu DC mɔ̃ siwo wotsɔ brɔs wɔe, bia elektrɔnikmɔ̃wo, ŋusẽ si mede AC servo mɔ̃wo nu o hena dɔ sesẽwo wɔwɔ. |

Egbegbe CNC routerwo, robot siwo sɔ pɛpɛpɛ, 3D agbalẽtamɔ̃wo, atikewɔnuwo, kple dɔwɔwɔ siwo bia be kakaɖedzi le wo ŋu ŋutɔ eye woawɔ nu pɛpɛpɛ. |

Dɔwɔwɔ nyuie ŋutɔ (vaseɖe 90%), duƒuƒu ƒe didime si nye 3,000–15,000 rpm, ŋusẽ ƒe dzidzedzekpɔkpɔ nye 0.5–5 kW, dzoxɔxɔ si mebɔ o. |

Akpa si wowɔna le CNC-mɔ̃wo me .

Le CNC-mɔ̃wo me la, servo motors koŋue kpɔa mɔ̃a ƒe fíawo ƒe fli alo rotary ƒe ʋuʋu dzi. Le kpɔɖeŋu me:

Le CNC router me la, servo motors ʋua X, Y, kple Z axes be woatsɔ aɖo spindle alo lãɖeɖe dɔwɔnua ɖe dɔwɔnua dzi pɛpɛpɛ.

Le CNC lathe me la, servo motor ate ŋu akpɔ ŋusẽ ɖe nusi wotsɔ trɔa asi le nu ŋu (si wɔa dɔ abe spindle ene le go aɖewo me) alo dɔwɔnu si wotsɔ lãa nu la ƒe ʋuʋu dzi.

Le mɔ̃ siwo me nu geɖe le me la, servo motors wɔnɛ be woate ŋu aʋuʋu nu sesẽwo, abe thting alo rotating the workpiece or tool in 4- alo 5-axis configurations ene.

Woƒe ŋutete be woana ʋuʋu si sɔ pɛpɛpɛ, si woate ŋu agbugbɔ awɔ la na servo motors hiã vevie be woalé mɔɖeɖe ɖe nu ŋu sesĩe me ɖe asi eye woakpɔ nuwuwu deŋgɔwo le dɔwo abe yamenutome, ʋu, kple atikewɔnuwo wɔwɔ me. To ɖekawɔwɔ kple CNC mɔ̃a ƒe dziɖuɖuɖoɖo me la, servo motors ɖea ɖoɖowɔɖi G-code mɔfiamewo gɔme ɖe ŋutilã ƒe ʋuʋu me, si kpɔa egbɔ be mɔ̃a zɔa dɔwɔnumɔ si nèdi la dzi kple vodada sue aɖe ko.

Nusiwo ŋu woabu ŋutɔŋutɔ .

Ne èle servo-mɔ̃wo tiam alo le wo zãm le CNC ƒe dɔwɔɖoɖowo me la, bu nusiwo gbɔna ŋu:

Nyaŋuɖoɖo ƒe ɖoɖo : Kpɔ egbɔ be mɔ̃a ƒe nyaŋuɖoɖomɔ̃ (le kpɔɖeŋu me, encoder resolution) ɖo wò dɔbiagbalẽvi ƒe nudidi siwo sɔ pɛpɛpɛ gbɔ.

Power and Torque : Tsɔ mɔ̃a ƒe ŋusẽ kple torque sɔ kple agba kple duƒuƒu ƒe nudidi siwo le CNC mɔ̃a ƒe akplɔwo ŋu.

Control System Compatibility : Kpɔe ɖa be servo motor la sɔ kple mɔ̃a ƒe dziɖunu, abe PLC alo CNC kɔmpiuta dɔwɔɖoɖo ene, be woakpɔ egbɔ be wowɔ ɖeka kple wo nɔewo le mɔ si me kuxi aɖeke mele o nu.

Beléle na : Kpɔ nyaŋuɖoɖo ƒe mɔ̃wo, kaƒomɔ̃wo, kple kadodowo ɖa edziedzi be nàxe mɔ ɖe dɔwɔwɔ ƒe nyawo alo elektrikŋusẽ ƒe vodadawo nu.

To servo motors ƒe nyateƒetoto, dziɖuɖu, kple alesi woate ŋu azãe le mɔ vovovowo nu zazã me la, CNC dɔwɔlawo ate ŋu akpɔ nyateƒetoto kple dɔwɔwɔ nyuie etɔxɛe le woƒe mɔ̃ɖaŋununya ƒe dɔwɔwɔwo me, si ana mɔ̃ siawo nanye egbegbe mɔ̃ɖaŋununya si sɔ pɛpɛpɛ ƒe dzogoedzikpe.

Zi afisia dzi be nàƒle Spindle Motors le Amazon.

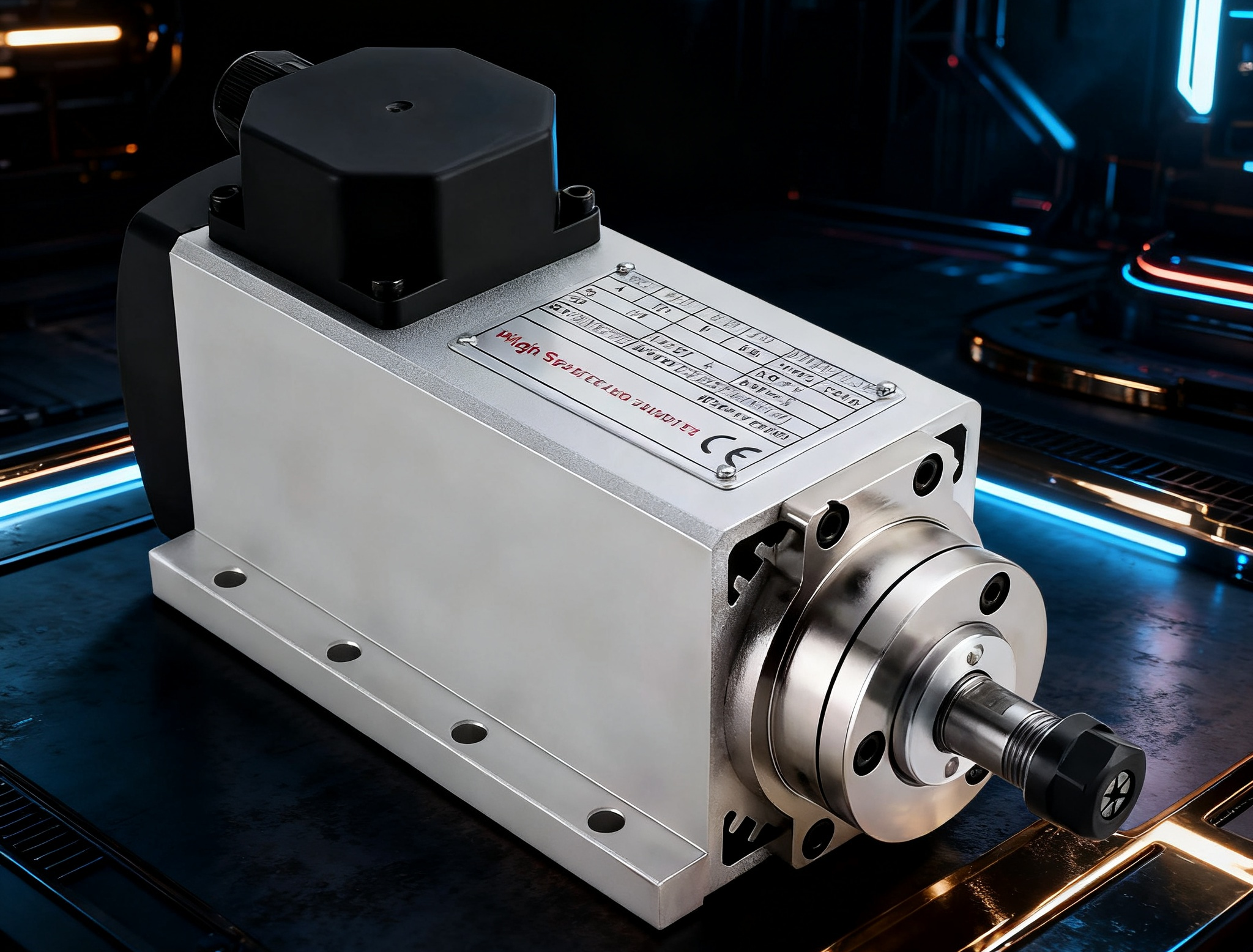

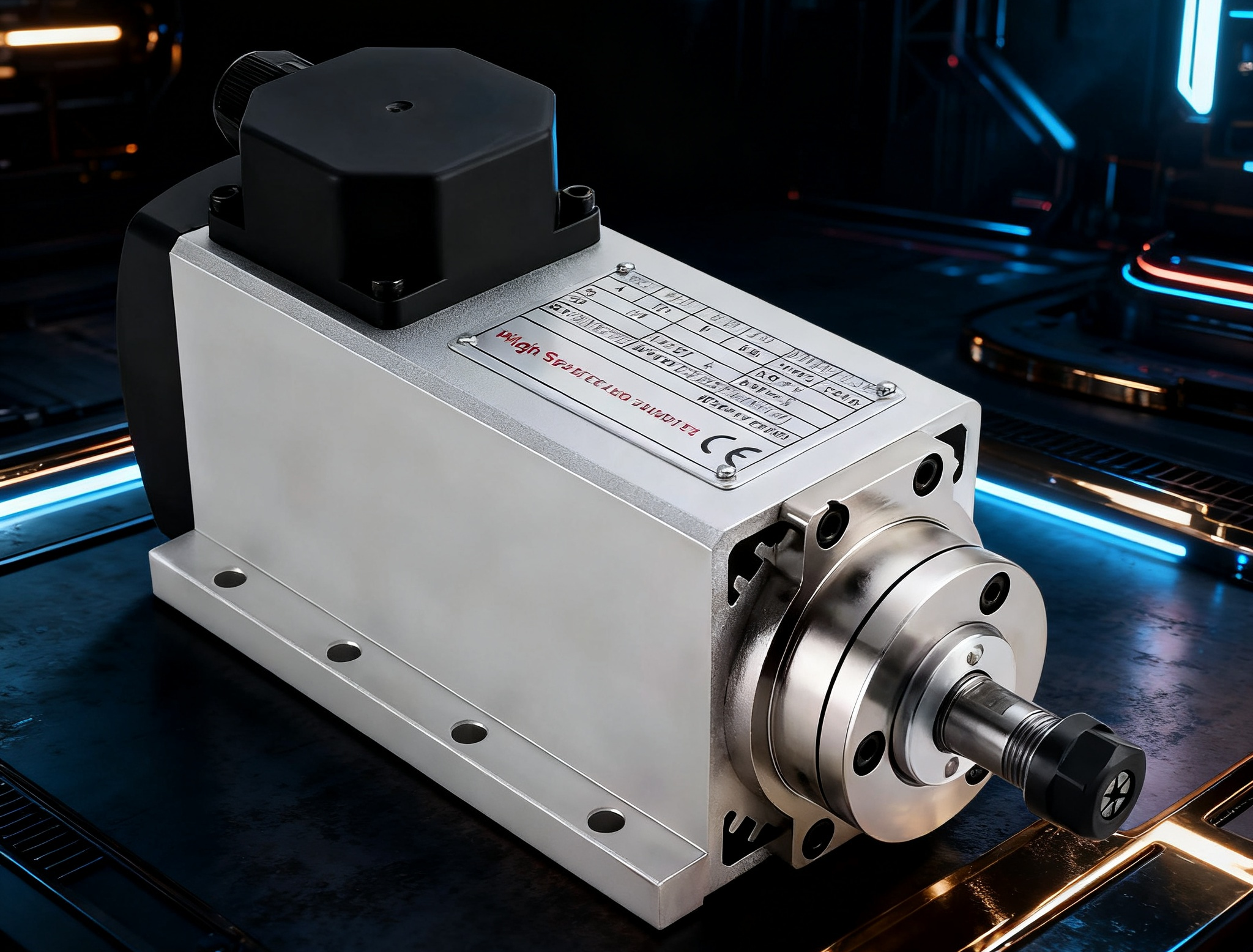

Spindle motors nye elektrikmɔ̃ tɔxɛ siwo wowɔ be woatsɔ aʋu mɔ̃ siwo wotsɔna lãa nu, woe, toa wo me, alo woŋlɔa wo le CNC (kɔmpiuta xexlẽdzesiwo dzi kpɔkpɔ) mɔ̃wo me to mɔ̃ siwo wotsɔ lãa nu alo dɔwɔnu siwo wotsɔ lãa nu le duƒuƒu sesĩe me. Abe CNC-mɔ̃wo ƒe ŋusẽdɔwɔƒe ene la, spindle motors naa ŋusẽ si trɔna kple ŋusẽ si hiã be woatsɔ aɖe nusiwo le dɔwɔnuwo me ɖa, si wɔe be wole vevie ŋutɔ na nɔnɔme si wodi, nuwuwu, kple nyateƒetoto le mɔ̃ɖaŋudɔwo me. To vovo na servo motors, siwo léa ŋku ɖe teƒedzikpɔkpɔ ƒe ɖoɖo si sɔ pɛpɛpɛ ŋu la, wowɔa spindle motors wònyona ɖe edzi be wòatrɔ asi le eŋu ɖaa, si zɔna kabakaba be wòana ŋusẽ si mewɔa tɔtrɔ o la dɔwɔnu alo dɔwɔnua. Wotrɔ asi le wo ŋu be woakpɔ nu vovovowo gbɔ, tso ati falɛfalɛwo dzi va ɖo ga sesẽwo dzi, eye wole nu vevi wɔm le wo zazã me le dɔwɔƒewo abe adzɔnuwo wɔwɔ, atikpakpa, kple gaŋutinunya ene .

Nu vevi siwo le spindle motors ŋu .

Wowɔa spindle motors kple nɔnɔme tɔxɛ siwo wɔnɛ be woate ŋu awɔ dɔ nyuie wu le mɔ̃ɖaŋudɔ siwo bia be woawɔ dɔ sesĩe kple ŋusẽ si woatsɔ awɔ dɔe sesĩe la me. Nu vevi siwo ɖea woƒe dɔwɔwɔ gɔme eye woɖea wo kple mɔ̃ ƒomevi bubuwo, abe servo motors ene, la le ete:

Wotrɔ asi le spindle motors siwo trɔna kabakaba

ŋu be woawɔ dɔ le tɔtrɔ gã aɖe me le miniti ɖeka me (rpm), zi geɖe la, woƒe 6,000 va ɖo 60,000 rpm alo esi wu nenema, le alesi wozãnɛ nu. Ŋutete sia si le du dzi sesĩe la wɔnɛ be woate ŋu awɔ dɔwo abe nuŋɔŋlɔ, micro-milling, alo lãɖeɖe kabakaba ene, afisi dɔwɔnu ƒe tɔtrɔ kabakaba le vevie be woawɔe wòade pɛpɛpɛ eye woawɔe wòanɔ bɔbɔe. Le kpɔɖeŋu me, spindle motor si le du dzi le 24,000 rpm sɔ nyuie na nuŋɔŋlɔ ƒe nɔnɔme siwo gɔme sese sesẽ ɖe ga alo plastik dzi, esime duƒuƒu si bɔbɔ wu (6,000–12,000 rpm) sɔ kple lãɖeɖedɔ siwo kpekpe wu abe milling steel ene.

POWER Delivery

Spindle motors ƒe susu vevitɔe nye be wòana torque kple ŋusẽ si sɔ be woaɖe nusiwo le mɔ̃ɖaŋununya me la ɖa nyuie. Woate ŋu akpɔe le ŋusẽ ƒe dzidzedzekpɔkpɔ ƒe hatsotso aɖe me (0.5–15 kW alo 0.67–20 hp), wotia spindle motors ɖe nusi wotsɔ wɔe ƒe sesẽme kple machining dɔa ƒe sesẽme dzi. Ŋusẽ gã ƒe lãgbalẽgoewo naa ŋusẽ si hiã be woatsɔ atso nusiwo le ʋeʋẽm abe titanium ene, gake ŋusẽ si bɔbɔ ɖe anyi wu la sɔ gbɔ na nusiwo fa wu abe ati alo foam ene. Ŋusẽ nana ƒe susu sia nana be dɔwɔwɔ si nɔa anyi ɖaa le agba vovovowo te.

Open-loop alo closed-loop control

spindle motor geɖewo wɔa dɔ le open-loop systems me, afisi wokpɔa duƒuƒu dzi to variable frequency drive (VFD) si me nyaŋuɖoɖo madzudzɔmadzudzɔe mele o. Esia sɔ gbɔ na dɔwɔwɔ siwo me tɔtrɔ ƒe duƒuƒu si sɔ pɛpɛpɛ le vevie wu teƒe si woɖo ɖi pɛpɛpɛ. Ke hã, spindle deŋgɔwo ate ŋu azã closed-loop control kple feedback devices (le kpɔɖeŋu me, encoders) atsɔ alé duƒuƒu si mewɔa tɔtrɔ o ɖe asi le agba vovovowo te, si ana dɔwɔwɔ nanyo ɖe edzi le dɔ siwo wowɔna pɛpɛpɛ me. Open-loop systems le bɔbɔe wu eye womexɔa ga geɖe wu o, gake closed-loop systems ya naa nusiwo wobia tso ame si la dea pɛpɛpɛ wu.

Cooling systems

spindle motors naa dzoxɔxɔ gã aɖe dona le dɔwɔwɔ ɣeyiɣi didi me, vevietɔ le duƒuƒu sesĩe me alo le agba kpekpewo te. Be woakpɔ esia gbɔ la, wotsɔ fafamɔ̃wo ɖo wo ŋu:

Ya-fafɛ : Zã yaƒomɔ̃wo alo ya si ƒo xlã wo nàtsɔ akaka dzoxɔxɔ, si sɔ na dɔ siwo wowɔna le ɣeyiɣi aɖewo me alo esiwo le titina abe atikpakpa ene. Wole bɔbɔe wu eye woƒe asi bɔbɔ wu gake womewɔa dɔ nyuie le dɔwɔwɔ atraɖii me o.

Tsi-fafɛ : Zã tsifamɔ̃ si me tsi le nàtsɔ alé dzoxɔxɔ nyuitɔ kekeake me ɖe asi, si sɔ nyuie na dɔ siwo zɔna kabakaba alo esiwo xɔa ɣeyiɣi didi abe ga nuŋɔŋlɔ ene. Wonaa dzoxɔxɔ ƒe kaka si de ŋgɔ wu kple dɔwɔwɔ si me ɖoɖoezizi le gake wobiaa beléle bubuwo na fafamɔ̃wo. Fafa nyuie xea mɔ na dzoxɔxɔ ƒe kekeɖenudɔwɔwɔ, ekpɔa akpa siwo le eme ta, eye wòkekea mɔ̃a ƒe agbenɔƒe ɖe enu.

Dɔwɔnu ƒe wɔwɔme ƒe

spindle motors nye dɔwɔnu siwo léa dɔwɔnu, abe ER collets, BT, alo HSK ɖoɖowo ene, be woatsɔ akpɔ nutsotso dɔwɔnuwo abe nuwuƒe, drills, alo nuŋɔŋlɔ ƒe akpawo ene. Dɔwɔnu ƒe nulénu ƒomevi lae ɖoa dɔwɔnu vovovo siwo spindle ate ŋu axɔ eye wòkpɔa ŋusẽ ɖe machining pɛpɛpɛ kple rigidity dzi. Le kpɔɖeŋu me, ER collets nyea nu geɖe wɔwɔ na CNC router siwo wozãna na dɔ vovovowo, gake wodina be HSK xɔlawo nalɔ̃ ɖe dɔwɔwɔ siwo zɔna kabakaba, siwo nye dɔwɔƒewo ƒe dɔwɔwɔ le woƒe clamping kple dadasɔ si le dedie ta. Ne wowɔ ɖeka kple CNC mɔ̃a ƒe dɔwɔnu ƒe tɔtrɔ ƒe ɖoɖoa hã le vevie ŋutɔ na dɔwɔwɔ nyuie.

Akpa si wowɔna le CNC-mɔ̃wo me .

Le CNC-mɔ̃wo me la, spindle motors ƒe dɔe nye be woatrɔ dɔwɔnu si wotsɔ lãa nu alo, le go aɖewo me la, dɔwɔnu si woatsɔ awɔ mɔ̃ɖaŋudɔwoe. Le kpɔɖeŋu me:

Le CNC router me la, spindle motor la trɔa dɔwɔnu si wotsɔ lãa nu be wòakpa nɔnɔmetatawo ɖe ati alo plastic me.

Le CNC-nutumɔ̃ me la, eʋãa nuwuƒe aɖe be wòaɖe nusiwo le gaŋutinuwo me ɖa, si wɔnɛ be geometri siwo sesẽ la nɔa anyi.

Le CNC lathe me la, mɔ̃ si wotsɔa lãgbalẽ wɔe ate ŋu atrɔ asi le dɔwɔnua ŋu wòatrɔ ɖe dɔwɔnu si le teƒe ɖeka si woatsɔ atrɔ dɔwoe ŋu. Woƒe ŋutete be woalé duƒuƒu kple ŋusẽ si nɔa anyi ɖaa me ɖe asi kpɔa egbɔ be wowɔe nyuie le anyigba dzi nyuie eye woɖe nusiwo wotsɔ wɔe ɖa nyuie, si wɔe be wole vevie na dɔ siwo tso nutunu kpekpewo dzi va ɖo nuŋɔŋlɔ si me kɔ dzi.

Nusiwo ŋu woabu ŋutɔŋutɔ .

Ne èle spindle motors tiam alo le wo zãm le CNC dɔwɔɖoɖowo me la, bu nusiwo gbɔna ŋu:

Duƒuƒu kple ŋusẽ ƒe nudidiwo : Tsɔ spindle ƒe rpm kple ŋusẽ ƒe dzidzedzekpɔkpɔ sɔ kple nusi wotsɔ wɔe kple dɔa (le kpɔɖeŋu me, duƒuƒu sesĩe na nuŋɔŋlɔ, high-torque na ga lãɖeɖe).

Cooling needs : Tia ya-fafɛ spindles na ga si mexɔ asi o, ɣeaɖewoɣi zazã alo tsi fafɛ spindles na dɔwɔwɔ atraɖii, sesẽ.

Dɔwɔnu Holder Compatibility : Kpɔ egbɔ be spindle la ƒe dɔwɔnuléla do alɔ dɔwɔnu siwo hiã eye wòasɔ ɖe mɔ̃a ƒe ɖoɖoa nu.

Beléle na : Klɔ spindle la edziedzi, lé ŋku ɖe fafamɔ̃wo ŋu, eye nàlé ŋku ɖe bearings ŋu be nàxe mɔ ɖe dzoxɔxɔ si gbɔ eme, ʋuʋu, alo alidziblanu ƒe ʋuʋu ƒe nyawo nu.

To asitɔtrɔ le duƒuƒu sesĩe, ŋusẽ ɖoɖo sesĩe, kple spindle motors ƒe nɔnɔme tɔxɛ ŋu la, CNC dɔwɔlawo ate ŋu akpɔ nuwo ɖeɖeɖa nyuie kple emetsonu deŋgɔwo le mɔ̃ɖaŋudɔ vovovowo me, si akpe ɖe ʋuʋu ƒe dziɖuɖu si tututu Servo Motors na ŋu.

Vovototo vevi siwo le servo motors kple spindle motors dome .

Servo motors kple spindle motors siaa nye nu vevi siwo le CNC (kɔmpiuta xexlẽdzesiwo dzi kpɔkpɔ) mɔ̃wo me, gake wowɔa dɔ vovovowo, kple atsyãwo kple dɔwɔwɔ ƒe nɔnɔme siwo wowɔ ɖe woƒe akpa tɔxɛwo nu. Togbɔ be Servo Motors bi ɖe ʋuʋu dzi kpɔkpɔ pɛpɛpɛ me hena mɔ̃a ƒe akpa aɖewo ɖoɖo hã la, wowɔa spindle motors nyuie na tɔtrɔ kabakaba be woatsɔ aʋu lãɖeɖe alo mɔ̃wo ƒe dɔwɔwɔwo. Woƒe vovototowo gɔmesese le nu veviwo me—dɔwɔwɔ gbãtɔ, dziɖuɖu ƒe ɖoɖo, duƒuƒu kple torque, dɔwɔwɔwo, aɖaŋuwɔwɔ kple xɔtutu, ŋusẽ ƒe hiahiãwo, kple nyaŋuɖoɖo ƒe mɔnuwo—le vevie ŋutɔ na mɔ̃ nyuitɔ tiatia na wò CNC ɖoɖoa kple dɔwɔwɔ nyuie wu. Le ete la, míetsɔ mɔ̃ ƒomevi eve siawo sɔ kple wo nɔewo tsitotsito, eye míetsɔ kpɔɖeŋu ŋutɔŋutɔwo kplɔe ɖo tsɔ ɖe woƒe akpa siwo wowɔna le CNC-mɔ̃wo me fia.

1. Dɔwɔwɔ Gbãtɔ .

Servo Motors : Wotrɔ asi le servo motors ŋu be woatsɔ akpɔ mɔ̃a ƒe akpa aɖewo ƒe nɔnɔme, woƒe duƒuƒu, kple woƒe zɔzɔ dzi pɛpɛpɛ ŋutɔ. Le CNC mɔ̃wo me la, wokua mɔ̃a ƒe asikewo ƒe fli alo rotary ƒe ʋuʋu (le kpɔɖeŋu me, x, y, z), tsɔ ɖoa dɔwɔnu ƒe ta alo dɔwɔnua ɖe ɖoɖo nu pɛpɛpɛ le mɔfiame siwo wowɔ ɖe ɖoɖo nu nu. Woƒe susu vevitɔe nye ʋuʋu dzi kpɔkpɔ pɛpɛpɛ tsɔ wu be woatsɔ ŋusẽ si woatsɔ awɔ dɔe xoxo.

Spindle Motors : Wotrɔ asi le spindle motors ŋu be wòatrɔ dɔwɔnu siwo wotsɔ lãa nu alo dɔwɔnuwo le duƒuƒu sesĩe me be woawɔ mɔ̃ɖaŋudɔwo abe lãɖeɖe, nutunu, tomekuku, alo nuŋɔŋlɔ ene. Woléa fɔ ɖe ŋusẽ kple duƒuƒu si hiã hena nuwo ɖeɖeɖa alo nɔnɔmewɔwɔ ŋu nana ŋu, wotsɔa tɔtrɔ ƒe dɔwɔwɔ ɖoa nɔƒe gbãtɔ wu teƒe ƒe nyateƒetoto.

Vovototo vevi : Servo mɔ̃wo kpɔa mɔ̃a ƒe akpa aɖewo ƒe nɔƒe kple woƒe ʋuʋu dzi, esime spindle motors ʋua ŋusẽ si trɔna hena mɔ̃wɔwɔ ƒe dɔwɔwɔwo.

2. Dziɖuɖu ƒe ɖoɖo .

Servo Motors : Wɔ dɔ le closed-loop control system me, zã nyaŋuɖoɖo ƒe mɔ̃wo abe encoder alo resolvers tsɔ lé ŋku ɖe teƒe, duƒuƒu, kple torque ŋu le ɣeyiɣi ŋutɔŋutɔ me. CNC dzikpɔla tsɔa mɔ̃a ƒe dɔwɔwɔ ŋutɔŋutɔ sɔna kple asixɔxɔ siwo wodi eye wòtrɔa asi le nusi wotsɔ de eme ŋu be wòaɖɔ teteɖeanyi ɖesiaɖe ɖo, si ana woakpɔ egbɔ be wowɔ nu wòde pɛpɛpɛ eye woate ŋu agbugbɔe awɔ.

Spindle Motors : Zi geɖe la, wozãa open-loop control systems, afisi woɖoa duƒuƒu ƒe ɖoɖo to variable frequency drive (VFD) dzi nyaŋuɖoɖo si me womeɖea asi le o. Spindle-mɔ̃ deŋgɔwo ate ŋu atsɔ nutrenu siwo wotsɔna ƒoa nui la ade eme kple encoders hena duƒuƒu ƒe ɖoɖo si sɔ pɛpɛpɛ le agba vovovowo te, gake esia mebɔ o eye womeléa ŋku ɖe teƒedzikpɔkpɔ ŋu o.

Vovototo vevi : Servo motors ɖoa ŋu ɖe closed-loop control ŋu hena teƒeɖoɖo pɛpɛpɛ, esime spindle motors zãa open-loop systems siwo le bɔbɔe wu zi geɖe hena duƒuƒu ƒe ɖoɖowɔwɔ, kple closed-loop tiatia hena dɔwɔwɔ deŋgɔwo.

3. Duƒuƒu kple Torque .

Servo Motors : Na duƒuƒu si trɔna kple torque kɔkɔ, vevietɔ le duƒuƒu sue me, si wɔe be wosɔ nyuie na ʋuʋu sesĩe si bia be woawɔ kabakaba kabakaba eye woaɖe wo dzi akpɔtɔ. Zi geɖe la, wowɔa dɔ le RPMS si bɔbɔ ɖe anyi wu (le kpɔɖeŋu me, 1,000–6,000 rpm) ne wotsɔe sɔ kple spindle motors, si naa wokpɔa duƒuƒu dzi le duƒuƒu me.

Spindle Motors : Wotrɔ asi le eŋu na tɔtrɔ kabakaba, eye RPMS ƒe 6,000 va ɖo 60,000 alo esi wu nenema, le alesi wozãnɛ nu. Wonaa torque si mewɔa tɔtrɔ o si sɔ nyuie na lãɖeɖe alo etutu, kple dɔwɔwɔ si wowɔ be wòalé duƒuƒu me ɖe asi le agba te tsɔ wu be wòatrɔ asi le teƒe ƒe asitɔtrɔ siwo sɔ pɛpɛpɛ ŋu.

Vovototo vevi : Servo mɔ̃wo ɖoa nɔƒe gbãtɔ le duƒuƒu si le bɔbɔe wu me hena ʋuʋu pɛpɛpɛ, esime spindle motors léa ŋku ɖe rpm kɔkɔwo ŋu kple torque si mewɔa tɔtrɔ o hena mɔ̃ɖaŋudɔwo wɔwɔ.

4. Dɔwɔwɔwo .

Servo Motors : Wozãnɛ na axis ƒe ʋuʋu le CNC mɔ̃wo, robotwo, 3D agbalẽtamɔ̃wo, kple ɖoɖo siwo wowɔna le wo ɖokui si me afisi teƒe si woɖo pɛpɛpɛ le vevie. Kpɔɖeŋu aɖewoe nye dɔwɔnu ƒe ta ʋuʋu le CNC router me, z-axis dzi ɖuɖu le mɔ̃ si wotsɔna ƒoa nu me, alo robot-alɔ siwo le mɔ̃ siwo wowɔna le wo ɖokui si me.

Spindle Motors : Wozãnɛ le mɔ̃ɖaŋununya ƒe dɔwɔwɔwo abe nutunu, tomekuku, nuŋɔŋlɔ, kple tɔtrɔ me, afisi dɔ vevitɔe nye nuwo ɖeɖeɖa alo nɔnɔmewɔwɔ le. Wokpɔa wo le CNC routers, milling machines, lathes, kple engravers, ʋukuku dɔwɔnuwo na dɔwɔwɔwo abe atikpakpa, metalworking, alo PCB wɔwɔ.

Vovototo vevi : Wozãa servo motors hena axis ƒe ʋuʋu pɛpɛpɛ le CNC kple automation systems me, esime spindle motors ʋua lãɖeɖe alo nɔnɔmewɔwɔ ƒe ɖoɖowo le mɔ̃ɖaŋudɔwo me.

5. Aɖaŋuwɔwɔ Kple Xɔtutu .

Servo Motors : Compact and lightweight, si wowɔ na ablaɖeɖe kabakaba kple edziɖeɖe ɖe edzi le multi-axis systems me. Wodea nyaŋuɖoɖo ƒe mɔ̃ siwo wotsɔ wɔ ɖekae (le kpɔɖeŋu me, encoderwo) eme eye wotu wo be woaɖe nusiwo mewɔa dɔ o dzi akpɔtɔ hena ʋuʋu si wɔa nu ɖe ame ŋu. Woƒe xɔtutua tsɔa nuwɔwɔ pɛpɛpɛ kple dɔwɔwɔ si me ŋusẽ le ɖoa nɔƒe gbãtɔ.

Spindle Motors : lolo wu eye wòsẽ wu, wotu be wòanɔ te ɖe duƒuƒu sesĩe kple agba siwo nɔa anyi ɖaa nu le mɔ̃ɖaŋununya me. Wo dometɔ aɖewoe nye fafamɔ̃wo (yaƒoƒo alo tsi fafɛ) be woatsɔ akpɔ dzoxɔxɔ kple dɔwɔnuwo ƒe nulénuwo dzi (le kpɔɖeŋu me, ER collets, BT, HSK) be woatsɔ akpɔ lãɖeɖe dɔwɔnuwo ta, wotea gbe ɖe nusiwo nɔa anyi didi kple ŋusẽ nana dzi.

Vovototo vevi : Servo motors nye compact na dynamic, pɛpɛpɛ ʋuʋu, esime spindle motors ya sesẽ kple fafamɔ̃wo kple dɔwɔnu léle na high-speed machining.

6. Ŋusẽ ƒe nudidiwo .

Servo Motors : Zi geɖe la, ebiaa ŋusẽ si bɔbɔ ɖe anyi wu, eye dzidzedzekpɔkpɔ tso watt ʋee aɖewo dzi va ɖo kilowatt geɖe dzi (le kpɔɖeŋu me, 0.1–5 kW), le alesi wozãnɛ nu. Wotrɔ asi le wo ŋu na ʋuʋu dzi ɖuɖu ƒe dɔ siwo mebiaa ŋusẽ ƒuƒlu o gake wowɔa nu pɛpɛpɛ ŋutɔ.

Spindle Motors : Ele be ŋusẽ ƒe dzidzedzekpɔkpɔwo nade ŋgɔ wu, zi geɖe la, 0.5 kW va ɖo 15 kW alo esi wu nenema (0.67–20 hp), be woatsɔ akplɔ nutsotsodɔ sesẽwo ɖe nusiwo le abe ga, ati, alo nusiwo wotsɔ ƒo ƒui ene dzi. Woƒe ŋusẽ si hiã la ɖe ŋusẽ gã aɖe si hiã be woaɖe nuwo ɖa nyuie la fia.

Vovototo vevi : Servo mɔ̃wo zãa ŋusẽ si bɔbɔ ɖe anyi wu na ʋuʋu dzi kpɔkpɔ, gake spindle motors ya hiã ŋusẽ si lolo wu hena nuɖeɖe kple mɔ̃ɖaŋudɔwɔwɔ.

7. Nyaŋuɖoɖo ƒe mɔnu .

Servo Motors : De nyaŋuɖoɖo ƒe mɔnuwo, abe encoder alo resolvers ene, ɣesiaɣi be woana ɣeyiɣi ŋutɔŋutɔ ŋuti nyatakaka siwo ku ɖe nɔƒe, duƒuƒu, kple torque ŋu. Nyaŋuɖoɖo sia kpɔa egbɔ be woɖɔa wo ɖo pɛpɛpɛ eye woɖɔa vodadawo ɖo, si le vevie ŋutɔ na mɔɖeɖe ɖe nu ŋu sesĩe le CNC dɔwɔwɔwo me.

Spindle Motors : Ate ŋu atsɔ nyaŋuɖoɖo ƒe mɔnuwo ade eme alo womatsɔe ade eme o. Ame geɖe wɔa dɔ nyaŋuɖoɖo manɔmee le mɔ̃ siwo le ʋuʋu ɖi me, eye woɖoa ŋu ɖe VFD-wo ŋu hena duƒuƒu dzi kpɔkpɔ. Spindles deŋgɔwo ate ŋu azã encoders hena closed-loop speed regulation, gake zi geɖe la, position feedback mehiã o elabena woƒe akpa si wowɔna la trɔna, ke menye position o.

Vovototo vevi : Servo motors zãa nyaŋuɖoɖo ɣesiaɣi hena dziɖuɖu pɛpɛpɛ, esime spindle motors ɖoa ŋu ɖe open-loop systems ŋu zi geɖe, kple feedback optional for specific applications.

Kpɔɖeŋu siwo woate ŋu awɔ le CNC mɔ̃wo me .

Be nàɖe akpa siwo servo kple spindle motors wɔna kpe ɖe wo nɔewo ŋu afia la, bu woƒe dɔwɔwɔwo ŋu le CNC milling mɔ̃ si wozãna ɖaa me:

Servo Motors : Kpɔ mɔ̃a ƒe kplɔ̃ alo dɔwɔnu ƒe ta ƒe ʋuʋu dzi le X, Y, kple Z axes la dzi. Le kpɔɖeŋu me, servo motors ɖoa dɔwɔnua ƒe ta ɖe ga si wotsɔ wɔa dɔe dzi pɛpɛpɛ, eye wòkplɔa dɔwɔnumɔ si wowɔ ɖoɖo ɖe eŋu la ɖo be woakpɔ egbɔ be wotsoe pɛpɛpɛ. Le 5-axis CNC mɔ̃ me la, servo motors kpɔa dzogoe ƒe ʋuʋu sesẽwo gbɔ, si wɔnɛ be geometri siwo gɔme sese sesẽ la nɔa anyi.

Spindle Motor : Trɔ milling cutter la le duƒuƒu sesẽ me (le kpɔɖeŋu me, 20,000 rpm) be nàɖe nusiwo le dɔwɔnua me ɖa. Spindle motor la naa ŋusẽ kple duƒuƒu si hiã be woatsɔ awɔ gae, si wɔnɛ be woɖea nusiwo wotsɔ wɔa nu nyuie la ɖa nyuie eye woƒe gowo nɔa gbadzaa.

Kpɔɖeŋu nɔnɔmetata : Ne wole ga yamenutome ƒe akpa aɖe ƒom la, servo motors ʋua dɔwɔnu ƒe ta ɖe coordinate siwo sɔ pɛpɛpɛ ŋu le asike geɖewo dzi, si naa kakaɖedzi be lãtsola la zɔa mɔ nyuitɔ dzi. Le ɣeyiɣi ma ke me la, spindle motor la trɔa asi le lãɖeɖe dɔwɔnua ŋu le 20,000 rpm me be wòaɖe nusi wotsɔ wɔe la ɖa, eye VFD ye kpɔa eƒe duƒuƒu dzi be wòasɔ kple nusi wotsɔ wɔe ƒe nɔnɔmewo kple nutsotso ƒe nudidiwo. Ne wotsɔ mɔ̃ siawo ƒo ƒui la, enaa mɔ̃a te ŋu wɔa akpa aɖe si me nu vovovowo le, si me wowɔa nu wòdea pɛpɛpɛ ŋutɔ.

Tiatiawɔwɔ le servo kple spindle motors dome .

Mɔ̃ si sɔ tiatia na CNC (kɔmpiuta xexlẽdzesiwo dzi kpɔkpɔ) ɖoɖo alo mɔ̃ɖaŋununya ƒe dɔwɔwɔ pɛpɛpɛ bia be woase akpa vovovo siwo servo motors kple spindle motors wɔna la gɔme. Wotrɔ asi le mɔ̃ ƒomevi ɖesiaɖe ŋu na dɔ tɔxɛ aɖewo wɔwɔ le CNC mɔ̃ me, eye servo motors bi ɖe teƒedzikpɔkpɔ ƒe ɖoɖo si sɔ pɛpɛpɛ me kple spindle motors siwo wowɔ nyuie na tɔtrɔ kabakaba kple nusiwo wotsɔ wɔa woe. Le CNC-mɔ̃ akpa gãtɔ me la, mɔ̃ siawo metsia tre ɖe wo nɔewo ŋu o ke boŋ wowɔa dɔ ɖekae be woakpɔ mɔ̃wɔwɔ si de pɛpɛpɛ eye wòwɔa dɔ nyuie. Tiatia si le servo kple spindle motors dome—alo nyametsotso be woawɔ wo ame evea siaa—nɔ te ɖe wò dɔbiagbalẽvia ƒe nudidi tɔxɛwo dzi, siwo dometɔ aɖewoe nye dɔ si ƒomevi woawɔ, nusiwo wotsɔ wɔe, nusiwo hiã pɛpɛpɛ, kple ɖoɖo si wowɔ ɖe ɖoɖoa ŋu. Le ete la, míegblɔ nu vevi siwo ŋu woabu le tiatiawɔwɔ le servo kple spindle motors dome ŋu eye míeɖe alesi wozãa wo ɖekae zi geɖe le CNC mɔ̃wo me la me.

Servo Mɔ̃wo Tiatia .

Servo-mɔ̃woe nye tiatia nyuitɔ ne wò dɔbiagbalẽvia bia be nàkpɔ ŋusẽ ɖe nɔnɔme, sesẽme, kple torque dzi pɛpɛpɛ. Woƒe mɔ̃ siwo wotu ɖe wo nɔewo dzi, siwo ɖoa ŋu ɖe nyaŋuɖoɖo ƒe mɔ̃wo abe encoder alo resolvers ene ŋu la, kpɔa egbɔ be woʋãna pɛpɛpɛ eye woate ŋu agbugbɔ wo awɔ, si wɔe be wole vevie na dɔ siwo hiã ʋuʋu ƒe ʋuʋu si trɔna.

Ɣekaɣie nàtia servo motors:

CNC Axis Movement : Wozãa servo motors tsɔ ʋua X, Y, Z, alo Axes bubuwo (le kpɔɖeŋu me, A, B le 5-axis mɔ̃wo me) le CNC ɖoɖowo me, si ɖoa dɔwɔnu ƒe ta alo dɔwɔwɔ ƒe akpa si sɔ pɛpɛpɛ ŋutɔ. Le kpɔɖeŋu me, le CNC router me la, servo motors ʋua gantry la yia coordinate siwo sɔ pɛpɛpɛ hena lãɖeɖe alo nuŋɔŋlɔ.

Robotics : Le robot alɔwo me la, servo motors kpɔa ƒunukpeƒe ƒe ʋuʋu dzi, si wɔnɛ be woate ŋu atrɔ asi le dɔwo abe kpekpe, welding, alo pick-and-place dɔwo ŋu pɛpɛpɛ.

Automation systems : Wozãa servo motors le mɔ̃ siwo wowɔna le wo ɖokui si me, abe 3D-tamɔ̃wo alo mɔ̃ siwo wotsɔna tsɔa nu ene, afisiwo ɖoɖo pɛpɛpɛ alo duƒuƒu dzi kpɔkpɔ le vevie ŋutɔ.

Dɔdamɔnu Siwo Hiã Micro-Adjustments : Dɔwo abe threading, contouring, alo multi-axis machining be viɖe tso servo motors ƒe ŋutete be woawɔ asitɔtrɔ nyuiwo le teƒe.

Nu vevi siwo ŋu woabu:

Precision Hiahiãwo : Tia servo motors kple high-resolution encoders (le kpɔɖeŋu me, 10,000 pulses le revolution ɖesiaɖe me) na dɔ siwo hiã mɔɖeɖe sesẽwo, abe ya alo atikewɔnuwo wɔwɔ ene.

Torque kple Speed : Kpɔ egbɔ be servo motor ƒe torque kple duƒuƒu ƒe dzidzedzekpɔkpɔwo sɔ kple agba kple ŋusẽ ƒe nudidi siwo le mɔ̃a ƒe asikewo me. Le kpɔɖeŋu me, dɔwɔnu siwo kpekpe wu ate ŋu abia mɔ̃ siwo ƒe tagbɔ kɔ wu.

Control System Compatibility : Kpɔe ɖa be servo motor la sɔ kple wò CNC controller alo PLC hã, si ana nàkpɔ egbɔ be wowɔ ɖeka kple mɔ̃a ƒe kɔmpiuta dɔwɔɖoɖowo.

Beléle na : Wɔ ɖoɖo ɖe nyaŋuɖoɖo ƒe mɔ̃wo kple elektrikŋusẽ ƒe kadodowo me dzodzro edziedzi ŋu be nàxe mɔ ɖe dɔwɔwɔ ƒe nyawo nu, abe encoder misalignment alo wiring faults ene.

Kpɔɖeŋu : Le 5-axis CNC milling machine me la, servo motors ɖoa dɔwɔnu ƒe ta kple dɔwɔwɔ ƒe akpa si sɔ kple millimeter ƒe nyateƒetoto, si wɔnɛ be geometri siwo sesẽ na yamenutome ƒe akpawo.

Tiatia Spindle Motors .

Spindle motors ye nye nusi woate ŋu atia ne wò dɔwɔwɔa ku ɖe tɔtrɔ kabakaba be woaku nu le wo ŋu, woaku to, alo awɔ nuŋɔŋlɔ ƒe ɖoɖowo ŋu. Wotrɔ asi le mɔ̃ siawo ŋu be woana ŋusẽ kple duƒuƒu si mewɔa tɔtrɔ o hena nuwo ɖeɖe ɖa, si wɔe be wole vevie ŋutɔ na mɔ̃ɖaŋudɔwo wɔwɔ le nu vovovowo me.

Ɣekaɣie nàtia Spindle Motors:

Lãɖeɖe kple nutunu : Spindle motors Drive lãɖeɖe dɔwɔnuwo abe end mills alo router bits be woaɖe nusiwo le ati, ga, plastik, alo composites le CNC routers kple milling mɔ̃wo me.

Kuku : Wotrɔa drill bits le duƒuƒu sesẽ me be woawɔ do siwo sɔ pɛpɛpɛ le nuwo, abe gakpo alo aluminum ene, na ʋu alo mɔ̃wo ƒe akpa aɖewo.

Nuŋɔŋlɔ : Wozãa spindle motors siwo zɔna kabakaba hena dɔ tsitotsito, abe etching designs on jewelry, dzesiwo, alo nutome sue dzikpɔƒewo (PCBs) ene.

Trɔtrɔ : Le CNC lathes me la, spindle motors trɔa asi le dɔwɔnua ŋu ɖe dɔwɔnu si le teƒe ɖeka ŋu be wòawɔ akpa siwo le abe ʋuƒo ene, abe shafts alo fittings ene.

Nu vevi siwo ŋu woabu:

Nusi wotsɔ wɔe kple dɔwɔwɔ : Tia spindle motor si si ŋusẽ si sɔ le (le kpɔɖeŋu me, 0.5–15 kW) kple duƒuƒu (le kpɔɖeŋu me, 6,000–60,000 rpm) na nu kple dɔwɔwɔ. Le kpɔɖeŋu me, spindle siwo ŋu ŋusẽ le ŋutɔ, siwo me tsi fafɛ le la sɔ nyuie na ga ɖeɖe, gake ya si me ya fafɛ le la sɔ na atikpakpa.

Cooling System : Tia ya si me wodea yae ƒe spindles na dɔ siwo wowɔna ɣeaɖewoɣi alo spindles siwo me tsi fafɛ le hena dɔwɔwɔ siwo yia edzi ɖaa, siwo zɔna kabakaba be woatsɔ akpɔ dzoxɔxɔ dzi nyuie.

Dɔwɔnu Holder Compatibility : Kpɔ egbɔ be spindle ƒe dɔwɔnulénu (le kpɔɖeŋu me, ER collets, HSK) do alɔ dɔwɔnu siwo hiã eye wòsɔ kple mɔ̃a ƒe dɔwɔnu ƒe tɔtrɔ ƒe ɖoɖoa.

Beléle na : Klɔ spindle la edziedzi, lé ŋku ɖe fafamɔ̃wo ŋu, eye nàsi ami na bearings be nàxe mɔ ɖe nyawo abe alidziblanu ƒe ʋuʋu alo elektrikŋusẽ ƒe ʋuƒo kpuiwo ene nu.

Kpɔɖeŋu : Le CNC router me la, 3 kW tsi-fafɛ spindle motor trɔa router bit le 24,000 rpm be woakpa kpɔɖeŋu siwo me kɔ nyuie le ati sesẽwo me hena xɔmenuwo wɔwɔ.

Zãzã ƒokpli le CNC mɔ̃wo me .

Le CNC mɔ̃ akpa gãtɔ me la, wozãa servo motors kple spindle motors ɖekae, wowɔa woƒe kpeɖeŋutɔ ƒe ŋusẽ ŋudɔ tsɔ ɖoa mɔ̃ɖaŋununya si sɔ pɛpɛpɛ eye wòwɔa dɔ nyuie gbɔ:

Servo Motors for Motion Control : Servo Motors Ðo dɔwɔnu ƒe ta alo dɔwɔwɔ ƒe akpa la ɖe mɔ̃a ƒe asikewo dzi, akpɔ egbɔ be dɔwɔnu si wotsɔ lãa nu la zɔna ɖe dɔwɔnu ƒe mɔ si ŋu wowɔ ɖoɖo ɖo la dzi kple nyateƒetoto kɔkɔ. Le kpɔɖeŋu me, woʋuʋua gantry la le CNC router me alo wotrɔa asi le dɔwɔnu ƒe dzogoe ŋu le 5-axis mɔ̃ me.

Spindle Motors for Machining : Spindle motors trɔa dɔwɔnu alo dɔwɔnu si wotsɔ lãa nu la le duƒuƒu kple ŋusẽ si hiã be woatsɔ awɔ nuwo ɖeɖeɖa, akpɔ egbɔ be wotso nu, ku, alo nuŋɔŋlɔ nyuie.

Kpɔɖeŋu nɔnɔmetata : Le CNC milling machine me la, servo motors ʋua X, Y, kple Z axes be woatsɔ aɖo gadzinu si le dɔwɔnu ƒe ta te, esime spindle motor ƒoa nuwuƒe ƒe nutunu le 20,000 rpm be woaɖe nu, si wɔa akpa aɖe si sɔ pɛpɛpɛ. Servo-mɔ̃awo kpɔa egbɔ be dɔwɔnua zɔa mɔ nyuitɔ dzi, gake spindle motor ya naa ŋusẽ si hiã hena etsotso.

Nusiwo ŋu woabu le beléle na wo ŋu .

Servo kple spindle motors dzi kpɔkpɔ nyuie le vevie ŋutɔ be woakpɔ egbɔ be CNC (kɔmpiuta xexlẽdzesiwo dzi kpɔkpɔ) mɔ̃wo ƒe kakaɖedzi, wo sɔ pɛpɛpɛ, kple woƒe agbenɔƒe didi. Mɔ̃ ƒomevi eveawo siaa wɔa akpa vovovowo—Serco motors hena axis positioning pɛpɛpɛ kple spindle motors hena nusiwo wotsɔna ɖea du sesĩe ɖa—gake wobia beléle edziedzi be woaxe mɔ ɖe nyawo abe vuvu, dzoxɔxɔ si gbɔ eme, alo elektrikŋusẽ ƒe vodadawo ene nu, si me nutome kpuiwo alo alidziblanu ƒe ʋuʋu hã le. To beléle na wo ƒe ɖoɖo siwo woɖo taɖodzinu na la zazã me la, dɔwɔlawo ate ŋu aɖe ɣeyiɣi si woatsɔ awɔ dɔe dzi akpɔtɔ, alé mɔ̃ɖaŋununya ƒe nyateƒetoto me ɖe asi, eye wòana akpa vevi siawo ƒe agbenɔƒe nadidi ɖe edzi. Le ete la, míegblɔ beléle na servo motors kple spindle motors koŋ ŋuti nukpɔsusu tɔxɛwo, si me woɖea afɔɖeɖe siwo woate ŋu awɔ dɔ le la gɔme nyuie be woanɔ nɔnɔme nyuitɔ me.

Servo Mɔ̃wo .

Servo-mɔ̃wo, siwo kpɔa teƒe ƒe nɔnɔme dzi kpɔkpɔ pɛpɛpɛ le CNC-mɔ̃wo me dzi la ɖoa ŋu ɖe mɔ̃ siwo wotu ɖe wo nɔewo ŋu dzi kple nyaŋuɖoɖomɔ̃wo be woalé wo ɖokui ɖe te. Beléle na wo edziedzi kpɔa egbɔ be woƒe dɔwɔwɔ gakpɔtɔ le ɖeka, si xea mɔ na nya siwo ate ŋu agblẽ nu le axis ƒe ʋuʋu alo mɔ̃wɔwɔ pɛpɛpɛ ŋu.

Kpɔ nyaŋuɖoɖo ƒe mɔ̃wo (le kpɔɖeŋu me, encoders)

servo motors zazã edziedzi eye nàdo wo kpɔ zãa nyaŋuɖoɖo ƒe mɔ̃wo abe encoders alo resolvers ene tsɔ léa ŋku ɖe teƒe, duƒuƒu, kple torque ŋu le ɣeyiɣi ŋutɔŋutɔ me. Mɔ̃ siawo ƒe ɖoɖowɔwɔ ɖe ɖoɖo nu, ɖiƒoƒo, alo woƒe vuvu ate ŋu ahe vodada siwo mesɔ o alo esiwo dzi woakpɔ le wo dzi kpɔkpɔ me vɛ.

Nuwɔnawo:

Lé ŋku ɖe encoders alo resolvers ŋu be ke, gbeɖuɖɔ, alo nusiwo gblẽ le ŋutilã me siwo ate ŋu ado kplamatse dzesiwo ƒe nyateƒetoto hã. Klɔe kple avɔ si me ʋuʋudedi mele o kple non-corrosive cleaner.

Do nyaŋuɖoɖo ƒe mɔ̃wo kpɔ ɣeaɖewoɣi to kɔmpiutadziɖoɖo alo dɔwɔnu siwo dɔwɔƒea na la zazã me be woakpɔ egbɔ be wowɔ ɖeka kple CNC-mɔ̃a.

Kpɔ encoder kawo ɖa be kadodo siwo le vuvu alo esiwo le gbadzaa hã, elabena dzesi ƒe gbeƒãɖeɖe si mede ame dzi o ate ŋu ana vodadawo nanɔ teƒe si woaɖoe ɖo.

Edziedzi : Kpɔ ɣleti 3–6 ɖesiaɖe alo dɔwɔwɔ ƒe gaƒoƒo 500–1,000 dzi; calibrate abe alesi wowɔe le adzɔnuwɔƒe ƒe mɔfiamewo, zi geɖe ƒe sia ƒe alo le beléle gã aɖe megbe.

Viɖewo : Eléa nɔƒe ƒe nyateƒetoto me ɖe asi, xea mɔ na dziɖuɖu ƒe vodadawo, eye wòkpɔa egbɔ be dɔwɔwɔ si nɔa anyi ɖaa le dɔwo abe multi-axis machining alo robotwo ene me.

Lé ŋku ɖe awudodo le bearings me kple amisisi ŋu alesi wòhiãe .

Bearing siwo le servo motors me ɖea ʋuʋudedi dzi kpɔtɔna le axis ƒe ʋuʋu kabakaba me, gake vuvu ate ŋu ana ʋuʋu, toɣliɖeɖe, alo be woaɖe wo pɛpɛpɛ dzi akpɔtɔ. Amisisi nyuie ɖea eƒe vuvu dzi kpɔtɔna eye wòléa dɔwɔwɔ nyuie me ɖe asi.

Nuwɔnawo:

Miɖo to toɣliɖeɖe siwo mebɔ o (le kpɔɖeŋu me, nutunu alo humming) alo mizã ʋuʋudedi ƒe numekukumɔ̃ aɖe atsɔ ade dzesi bearing wear. Ʋuʋu fũu akpa fia be ehiã be woalé ŋku ɖe eŋu alo aɖɔlii.

De ami si dɔwɔƒea kafu (le kpɔɖeŋu me, ami alo ami) bearings, nàkpɔ egbɔ be megade ami wòagbɔ eme o, si ate ŋu ahe gbeɖuɖɔ alo ana dzoxɔxɔ naƒo ƒu. Servo-mɔ̃ aɖewo zãa bearing siwo wotre nu siwo mehiã be woasi ami na o gake ele be woalé ŋku ɖe wo ŋu be wodo hã.

Tsɔ bearing siwo wodo la ɖɔ li enumake be woagagblẽ nu le mɔ̃a ƒe ʋuƒo alo rotor ŋu o.

Edziedzi : Kpɔ bearings dzi ɣleti 6 ɖesiaɖe alo 1,000 dɔwɔwɔ ƒe gaƒoƒowo; Amisisi na adzɔnuwɔƒe ƒe nɔnɔmewo, zi geɖe la, gaƒoƒo 500–1,000 ɖesiaɖe na bearing siwo wometre o.

Viɖewo : Eɖea ʋuʋudedi dzi kpɔtɔna, xea mɔ na nusiwo ʋuʋuna ƒe nugbegblẽ, eye wòdidia ʋu ƒe dɔwɔwɔ ɖe edzi.

Kpɔ elektrikŋusẽ ƒe kadodowo dzi be nàxe mɔ ɖe dzesiwo ƒe bu alo nusiwo doa kplamatsee

servo mɔ̃wo ɖoa ŋu ɖe elektrikŋusẽ ƒe kadodo siwo li ke ŋu hena ŋusẽ kple dzesiwo ɖoɖo ɖe mɔ̃a kple nyaŋuɖoɖomɔ̃wo dzi. Kadodo siwo me mekɔ o, siwo xɔ dzo, alo esiwo gblẽ ate ŋu ana dzesiwo nabu, ado kplamatse wo, alo elektrikŋusẽ ƒe vodadawo abe nutome kpuiwo ene.

Nuwɔnawo:

Kpɔ ŋusẽ kple dzesi ƒe kawo ɖa be wole gbagbãm, xɔ dzo, alo woƒe nugbɔ siwo me mekɔ o hã. Kpe kadodoawo sesĩe eye nàɖɔli ka siwo gblẽ.

Zã multimeter nàtsɔ alé ŋku ɖe elektrikŋusẽ ƒe ʋuʋu kple edziyiyi ŋu le kaƒomɔ̃wo me be nàkpɔ egbɔ be elektrikŋusẽ si ŋu kakaɖedzi le la le eŋu.

Akpoxɔnu ƒe dzesi ka siwo tso elektrikŋusẽ ƒe nutsotso (EMI) gbɔ to wo tsɔtsɔ yi na ŋusẽ gã ƒe akpawo abe spindle motors alo VFDS ene me.

Enuenu : Kpɔ kadodowo ɣleti sia ɣleti alo dɔwɔwɔ ƒe gaƒoƒo 500 ɖesiaɖe; Wɔ ŋkuléle ɖe nu ŋu tsitotsito le beléle na wo ƒe tsatsam edziedzi me.

Viɖewo : Exea mɔ na dzesi ƒe bu, eɖea elektrikŋusẽ ƒe vodada ƒe afɔku dzi kpɔtɔna, eye wòkpɔa egbɔ be kadodo si ŋu kakaɖedzi le kple CNC dzikpɔla la.

Spindle Motors .

Spindle motors, siwo wowɔ be woatsɔ atrɔ asi le wo ŋu kabakaba eye woaɖe wo ɖa la, hiã beléle na wo be woatsɔ akpɔ dzoxɔxɔ, ʋuʋudedi, kple nya siwo ku ɖe dɔwɔnuwo ŋu gbɔ. Beléle na ame nyuie xea mɔ na dɔwɔwɔ ƒe gbegblẽ kple kpododonu si xɔa ga geɖe, abe elektrikŋusẽ ƒe ʋuƒo kpuiwo alo mɔ̃wo ƒe nugbegblẽ ene.

Dzadzɛ dɔwɔnu léle kple collets be woaxe mɔ ɖe dɔwɔnu runout

dɔwɔnu nulénuwo (le kpɔɖeŋu me, ER collets, BT, HSK) kple collets dedie lãɖeɖe dɔwɔnuwo na spindle. Ðiƒoƒo, gbeɖuɖɔ, alo nusiwo gblẽ ate ŋu ana dɔwɔnu naƒu (wobbling), si ana mɔ̃ɖaŋununya ƒe nyonyome manyo o, ʋuʋudedi nadzi ɖe edzi, alo nuteɖeamedzi le spindle la ŋu.

Nuwɔnawo:

Klɔ dɔwɔnu siwo wotsɔna léa nu ɖe nu ŋu kple esiwo wotsɔna ƒoa nu ɖe nu ŋu le dɔwɔnu ɖesiaɖe ƒe tɔtrɔ megbe to avɔ si me lint mele o kple non-corrosive cleaner zazã me be nàɖe fafanu ƒe nugbagbevi siwo susɔ, chips, alo ke ɖa.

Lé ŋku ɖe eŋu be nàkpɔe be yedo, dents, alo ŋlɔe ɖe dɔwɔnua dzikpɔla ƒe taper alo collet dzi, si ate ŋu ana woawɔ nu ɖe ɖoɖo nu. Tsɔ akpa siwo gblẽ la ɖɔ li enumake.

Zã dial indicator nàtsɔ adzidze dɔwɔnu ƒe runout le eɖoɖo vɔ megbe; Runout si wu 0.01 mm fia kuxi aɖe si bia be woaɖɔe ɖo.

Edziedzi : Dzadzɛ le dɔwɔnu ɖesiaɖe ƒe tɔtrɔ alo gbesiagbe le zazã vevie me; Kpɔ awudodo ɣleti sia ɣleti alo dɔwɔwɔ ƒe gaƒoƒo 500 ɖesiaɖe ɖa.

Viɖewo : Eléa mɔ̃ɖaŋununya me ɖe asi pɛpɛpɛ, eɖea ʋuʋudedi dzi kpɔtɔna, eye wòxea mɔ na spindle kple dɔwɔnuwo ƒe vuvu kabakaba.

Lé fafamɔ̃wo (ya alo tsi) me ɖe asi be woaxe mɔ ɖe dzoxɔxɔ si gbɔ eme

ƒe mɔ̃wo nu nana dzoxɔxɔ gã aɖe dona le dɔwɔwɔ kabakaba alo ɣeyiɣi didi me, si bia be woafa fafa nyuie be woaxe mɔ ɖe dzoxɔxɔ si gbɔ eme nu, si ate ŋu ana nusiwo xea mɔ na dzoxɔxɔ alo woƒe akpa aɖewo nado kpo nu.

Nuwɔnawo:

Na ya-fafɛ spindles : Klɔ fafa ƒe asikewo kple fesrewo edziedzi be woaɖe ke alo gbeɖuɖɔ siwo xea mɔ na ya ƒe sisi ɖa. Kpɔ egbɔ be yaƒoƒomɔ̃wo me kɔ nyuie be woalé fafa ƒe dɔwɔwɔ me ɖe asi.

Le tsi-fafɛ spindles : lé ŋku ɖe fafanu ƒe agbɔsɔsɔme le tsidzraɖoƒea, topping dzi kple tsi si wɔla kafu. Kpɔ hoses, fittings, kple cooling jacket la ɖa be tsi alo xɔ dzo hã le eme hã. Klɔ ɖoɖoa me ɣleti 6–12 ɖesiaɖe be nàɖe tsiƒuƒu alo ƒumegbewo ɖa.

Zã dzoxɔxɔ ƒe nɔnɔmetatawo nàtsɔ ade dzesi teƒe siwo dzoxɔxɔ le, si fia be fafamɔ̃a ƒe dɔmawɔmawɔ nyuie alo vodada siwo ate ŋu ado mo ɖa.

Edziedzi : Kpɔ ya-fafɛ ɖoɖowo kwasiɖa sia kwasiɖa; Lé ŋku ɖe tsifamɔ̃ ƒe ɖoɖowo ŋu kwasiɖa sia kwasiɖa hena fafanu ƒe agbɔsɔsɔ kple ɣleti sia ɣleti hena tsi si le dodom; Flush tsi-fafɛ ɖoɖowo ɣleti 6–12 ɖesiaɖe.

Viɖewo : Exea mɔ na dzoxɔxɔ si gbɔ eme, eɖea dzoxɔxɔ ƒe nuteɖeamedzi dzi kpɔtɔna ɖe windings kple bearings dzi, eye wòkekea spindle ƒe agbenɔƒe ɖe enu.

Monitor bearings na ʋuʋu alo toɣliɖeɖe, si fia be ate ŋu anye be wear

spindle motor bearings, zi geɖe ceramic alo gakpo, doa alɔ high-speed rotation. Do alo dadasɔmakpɔmakpɔ ate ŋu ana ame naʋuʋu alo toɣliɖeɖe si gbɔ eme, si ana be woaɖe nusiwo le alidziblanu dzi la dzi akpɔtɔ, woaɖe alidziblanua dzi akpɔtɔ, alo woƒe mɔ̃a nagblẽ.

Nuwɔnawo:

Se toɣliɖeɖe siwo mesɔ o (le kpɔɖeŋu me, nutunu, ʋuʋudedi) le dɔwɔwɔ me, si fia be bearing ƒe vuvu alo mesɔ o.

Zã vibration analyzer nàtsɔ adzidze bearing vibration levels, atsɔ wo asɔ kple manufacturer baselines be woakpɔ nyawo kaba.

Amisisi na bearings le ewɔla ƒe mɔfiamewo nu (ne wometre enu o), zã ami alo ami si woɖo ɖi. Tsɔ bearing siwo wodo la ɖɔ li enumake be woagagblẽ nu le spindle shaft alo rotor la ŋu o.

Frequency : Kpɔ ʋuʋudedi kple toɣliɖeɖe dzi gbesiagbe alo kwasiɖa sia kwasiɖa le dɔwɔwɔ me; Wɔ bearing checks tsitotsito le ɣleti 3–6 ɖesiaɖe me alo 500–1,000 dɔwɔwɔ ƒe gaƒoƒo.

Viɖewo : Exea mɔ na mɔ̃wo ƒe gbagbã, léa mɔ̃ɖaŋununya ƒe nyateƒetoto me ɖe asi, eye wòɖea afɔku si le edzadzraɖo si xɔa ga geɖe me dzi kpɔtɔna.

Nyanuwuwuw

Servo motors kple spindle motors nye akpa vevi aɖewo le CNC (kɔmpiuta xexlẽdzesiwo dzi kpɔkpɔ) mɔ̃wo kple mɔ̃ɖaŋununya ƒe ɖoɖo siwo sɔ pɛpɛpɛ me, eye wo dometɔ ɖesiaɖe wɔa akpa aɖe si kpe ɖe eŋu gake wòto vovo si ʋãa ɖoɖo siawo ƒe dɔwɔwɔ bliboa. Servo motors bi ɖe ʋuʋu dzi kpɔkpɔ pɛpɛpɛ nana me, si wɔnɛ be woate ŋu aɖo mɔ̃ ƒe asikewo alo akpa aɖewo ɖe teƒe si sɔ pɛpɛpɛ le dɔwɔwɔwo abe CNC mɔ̃ɖaŋudɔwo, robotwo, kple nuwo wɔwɔ le wo ɖokui si ene me. To vovo na ema la, wowɔa spindle motors hena duƒuƒu sesĩe, si ƒe ŋusẽ lolo ŋutɔ, si naa ŋusẽ si hiã be woatsɔ aku lãɖeɖedɔwɔnuwo alo dɔwɔnu siwo woatsɔ awɔ dɔwo abe milling, tomekuku, alo nuŋɔŋlɔ ene. To woƒe vovototo veviwo gɔmesese me—dziɖuɖu ƒe ɖoɖowo, dɔwɔwɔwo, aɖaŋuwɔwɔ, duƒuƒu kple torque ƒe nɔnɔmewo, ŋusẽ ƒe hiahiãwo, kple nyaŋuɖoɖo ƒe mɔnuwo—ate ŋu awɔ nyametsotso siwo ŋu wonya nu tsoe atsɔ awɔ CNC ƒe dɔwɔwɔ nyuie wu eye woakpɔ emetsonu deŋgɔwo.

Servo kple spindle motors ƒe nuwɔwɔ aduadue nye nusi na CNC mɔ̃wo te ŋu trɔna ɖe nɔnɔme vovovowo ŋu eye wowɔa dɔ nyuie. Servo-mɔ̃wo kpɔa egbɔ be woɖo dɔwɔnu ƒe ta alo dɔwɔnua ɖe teƒe si woɖoa nu ɖe ɖoɖo nu pɛpɛpɛ, esime spindle motors naa ŋusẽ si trɔna si hiã hena nuawo ɖeɖe ɖa nyuie alo woƒe nɔnɔme wɔwɔ. Le kpɔɖeŋu me, le CNC-nutumɔ̃ me la, servo motors kpɔa X, Y, kple Z axes la dzi be woawɔ ɖe dɔwɔnu ƒe mɔ si sɔ pɛpɛpɛ dzi, esime mɔ̃ si wotsɔna ƒoa nu la trɔa dɔwɔnu si wotsɔna lãa nu la le duƒuƒu sesẽ me be wòawɔ akpa si le gbadzaa, si sɔ pɛpɛpɛ. Mɔ̃ ƒomevi eveawo siaa tiatia nyuie kple wo dzi kpɔkpɔ le vevie ŋutɔ be woaƒo asa na nyawo abe alidziblanu ƒe ʋuʋu, elektrikŋusẽ ƒe ʋuƒo kpuiwo, alo mɔ̃wo ƒe gbagbã, si ana woakpɔ egbɔ be wole pɛpɛpɛ eye kakaɖedzi le wo ŋu ɣesiaɣi.

Le amesiwo le CNC-mɔ̃wo tutu, wo dodo ɖe ŋgɔ, alo wo zazã me la, bu wò dɔbiagbalẽvia ƒe didi tɔxɛwo ŋu nyuie—abe nusiwo ƒomevi hiã, nudidi siwo sɔ pɛpɛpɛ, kple dɔwɔwɔ ƒe tsatsam ene—ne èle servo kple spindle motors tiam. Tia servo motors siwo ƒe torque si sɔ, nyaŋuɖoɖo ƒe ɖeɖefia, kple controller ƒe sɔsɔ na axis control si sɔ pɛpɛpɛ, eye nàtia spindle motors kple ŋusẽ, duƒuƒu, kple fafa ƒe ɖoɖo nyuitɔ be wòasɔ kple wò mɔ̃ɖaŋudɔwo. Beléle na wo edziedzi, siwo dometɔ aɖewoe nye dzadzɛnyenye, amisisi, nyaŋuɖoɖo ƒe mɔ̃ ƒe dzidzedzekpɔkpɔ na servo mɔ̃wo, kple fafamɔ̃ dzi kpɔkpɔ na spindle motors, le vevie ŋutɔ be woalé dɔwɔwɔ me ɖe asi eye woakeke mɔ̃a ƒe agbenɔƒe ɖe enu. To servo kple spindle motors ƒe ŋusẽ siwo kpe ɖe wo nɔewo ŋu zazã kple beléle na wo do ŋgɔ ƒe dɔwɔwɔ me la, àte ŋu akpɔ emetsonu tɔxɛwo le mɔ̃ɖaŋudɔwo kple nuwo wɔwɔ le wo ɖokui si ƒe dɔwo me, akpɔ egbɔ be wowɔ dɔ nyuie, wole pɛpɛpɛ, eye woanɔ anyi eteƒe nadidi le wò CNC dɔwɔwɔwo me.

Zi afisia dzi be nàwɔ Zhong Hua Jiang ƒe agbalẽdzraɖoƒea ƒe kɔpi.

Zhong Hua Jiang ƒe agbalẽdzraɖoƒe 2025.pdf .

Zhong Hua Jiang ƒe agbalẽdzraɖoƒe 2025.pdf .

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu