Introduction

Chatter in CNC machining—an all-too-familiar nuisance—can wreck your part finish, damage your tooling, and shake your productivity to its core. It’s the unwanted vibration that occurs during cutting, and if you've ever heard that screeching, rattling noise while the machine is running, you’ve encountered it firsthand. But here’s the good news: chatter isn’t some unavoidable monster. With the right knowledge, tools, and strategies, you can kick it to the curb.

Think of it this way: Chatter is to CNC machining what static is to a radio broadcast. It distorts the message, creates inefficiency, and introduces errors. In machining, those errors translate to scrap parts, shorter tool life, and higher costs. So, eliminating chatter isn’t just about improving quality—it’s about boosting your entire operation’s performance and bottom line.

This guide will take you deep into the causes of chatter, how to spot it, and, most importantly, how to eliminate it. Whether you’re an experienced machinist or just getting your feet wet in the CNC world, this step-by-step blueprint will give you actionable tactics to silence chatter and smooth your path to precision.

Understanding CNC Chatter

![How to Eliminate Chatter in CNC Machining]()

Definition and Types of Chatter

CNC chatter refers to self-excited vibrations occurring during a cutting process. It manifests as repetitive waves on the workpiece surface and often produces a high-pitched noise. There are two major types:

1. Regenerative Chatter – Caused by feedback loops between the tool and workpiece from previous cutting passes.

2. Mode Coupling Chatter – Arises when two different vibration modes (like lateral and torsional) couple together.

3. Forced Vibration Chatter – Triggered by external factors like motor imbalance or worn-out bearings.

Each of these types presents a unique challenge, but all have a common result: reduced machining quality and increased wear and tear on equipment. If you're hearing a squeal or noticing ridges on your parts, you're likely dealing with one of these culprits.

Causes of Chatter in CNC Machining

So why does chatter happen? It’s not just one thing—it’s usually a combination of factors:

· Improper Cutting Parameters: Too high a spindle speed or feed rate can amplify vibrations.

· Weak Tooling or Holders: Lack of rigidity or inappropriate tool geometry can initiate vibrations.

· Poor Fixturing: If your part isn’t held securely, any movement can spiral into a chatter episode.

· Machine Condition: Loose guideways, worn ball screws, and misalignment all contribute.

· Material Properties: Some materials are more prone to vibration than others due to their hardness or elasticity.

Identifying the root cause is the first step to silencing the noise—literally and figuratively. You can’t fix what you don’t understand.

How Chatter Affects CNC Machining

Impact Area | Description | Consequences |

Surface Finish | Wavy patterns, irregular tool marks on the workpiece | Poor aesthetics, part rejection, dimensional inaccuracy |

Dimensional Accuracy | Vibrations cause the tool to deviate from the path | Out-of-tolerance parts, reduced functionality |

Tool Wear | Continuous vibration leads to edge chipping and fracture | Frequent tool replacement, higher tooling costs |

Machine Wear | Chatter transfers stress to machine components | Bearing damage, reduced machine life, increased maintenance |

Cycle Time | Slower feed rates needed to avoid chatter | Longer production times, reduced efficiency |

Production Costs | Increased scrap, rework, and tool damage | Higher operational expenses, reduced profit margins |

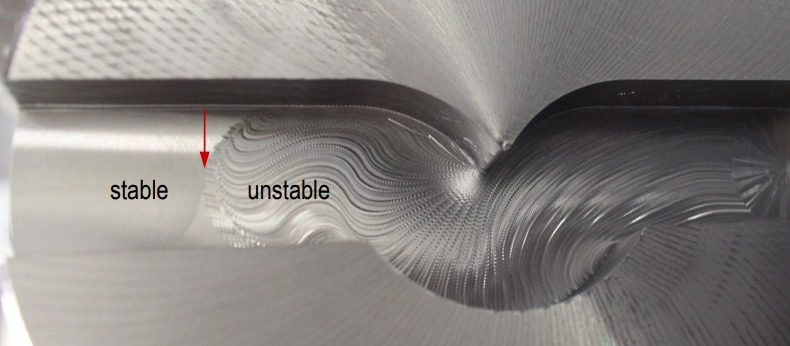

Impact on Surface Finish and Part Quality

One of the most visible consequences of chatter is a poor surface finish. Imagine trying to write with a pen while your hand is trembling—that’s essentially what chatter does to your cutting tool. The vibrations cause irregular tool paths, which leave wave-like patterns on your part.

These imperfections aren’t just cosmetic. They can compromise tight tolerances, introduce structural weaknesses, and lead to part rejections. In industries like aerospace or medical, where precision is everything, that’s a deal-breaker.

Chatter also affects dimensional accuracy. Even if your part looks okay on the surface, the hidden irregularities can lead to performance failures, especially under stress or load.

Tool Wear and Machine Life

Chatter isn't just bad for the part—it’s brutal on your tooling. Continuous vibration causes micro-fractures on the cutting edge, leading to accelerated tool wear. You’ll find yourself replacing end mills or inserts more frequently, which adds up fast.

And let’s not forget about your machine. Prolonged exposure to vibration can loosen bolts, damage bearings, and shorten the life of your CNC equipment. Maintenance costs increase, and unplanned downtime becomes a regular headache.

Production Efficiency and Cost Implications

At the end of the day, chatter hits you where it hurts the most—your wallet. Poor surface finishes require rework or even scrapping parts. Tools need replacing more often. Machines break down unexpectedly. All these factors contribute to:

· Longer cycle times

· Lower throughput

· Increased operational costs

· Missed deadlines

If you’re running a high-volume shop, these losses compound quickly. But even for small operations, the impact is significant. The cost of ignoring chatter is always higher than investing in prevention.

Identifying Chatter During CNC Operations

![How to Eliminate Chatter in CNC Machining]()

Identification Method | Indicators | Tools/Techniques |

Auditory Signs | High-pitched squealing, rattling, or screeching noise during cutting | Operator’s hearing, acoustic emission sensors |

Visual Inspection | Wavy surface finish, shiny streaks, inconsistent cut lines | Post-process part inspection |

Tool Wear Patterns | Unusual wear like chipping or burning on tool edges | Microscope, magnifying lenses |

Heat Generation | Excessive heat or smoke during cutting | Thermal cameras, infrared sensors |

Vibration Measurement | Measured vibrations above acceptable thresholds | Accelerometers, vibration sensors |

Cutting Force Feedback | Spikes in cutting forces during machining | Cutting force dynamometers, torque sensors |

Visual and Auditory Indicators

Chatter is usually loud—and unmistakable. That high-pitched squeal, grinding, or rattling noise is your machine’s way of screaming for help. Don’t ignore it. It’s a red flag that something’s off.

But it’s not just about noise. You’ll also notice:

· Wavy surface patterns (often called "chatter marks")

· Shiny streaks or burnished areas

· Premature tool wear

· Excessive heat or smoke during cutting

These symptoms are easy to spot if you’re paying attention. Make it a habit to inspect parts after every run, especially during roughing or high-speed operations.

Diagnostic Tools and Methods

If you want to go beyond your eyes and ears, diagnostic tools are your best friend. Use:

· Dial indicators to check for machine looseness

· Accelerometers to measure vibration

· Thermal imaging to detect overheating zones

· Cutting force sensors to understand tool engagement

These tools help you pinpoint the source of chatter with surgical precision. You don’t need to guess—you’ll know exactly what needs fixing.

Using Vibration Analysis for Chatter Detection

Vibration analysis is like an MRI for your CNC machine. By analyzing frequency and amplitude, you can identify not just that chatter is happening—but why.

Advanced setups use software that connects to sensors on the spindle, tool holder, and even the workpiece. These systems map out vibration frequencies and correlate them with machine parameters. With this data, you can:

· Adjust speeds to avoid resonant frequencies

· Balance your spindle or tool holder

· Predict when chatter is likely to occur

This proactive approach turns you from a firefighter into a strategist—preventing chatter before it even starts.

Proven Techniques to Eliminate Chatter

Optimizing Cutting Parameters

Getting your cutting parameters right is the single most effective way to silence chatter. Think of it like tuning a musical instrument: small adjustments can make a world of difference in how everything performs.

Spindle Speed and Feed Rate Adjustments

Often, the first move to eliminate chatter is tweaking your spindle speed. Here’s the trick—small changes, even by 10%, can shift your operation out of a resonant frequency range. It’s like hitting the brakes on a feedback loop that’s gone wild.

Use what's known as "spindle speed variation" (SSV)—a CNC feature that varies spindle speed during the cut. This breaks up the rhythm of regenerative chatter, stopping it before it builds up.

Likewise, increasing or decreasing the feed rate can also reduce vibrations. If you're cutting too fast, the tool might be over-engaging with the material, leading to instability. If too slow, the tool may rub rather than cut—also a recipe for chatter.

Key tips:

· Always reference manufacturer-suggested speeds and feeds.

· Use chip load calculators to maintain proper engagement.

· Don’t be afraid to run test cuts with slight variations.

Depth of Cut and Tool Engagement

Another major culprit behind chatter is an excessive depth of cut (DOC) or width of cut (WOC). If your tool is biting off more than it can chew, it’s going to scream—literally.

Try these methods:

· Reduce DOC incrementally until vibrations stabilize.

· Use radial engagement strategies—like trochoidal milling—to keep consistent tool pressure.

· Split up deep cuts into multiple passes.

Balancing how the tool enters the workpiece is essential for stable machining. Sometimes, light but fast passes work better than slow, heavy ones.

Tooling Selection and Tool Geometry

Your cutting tool is the MVP of the operation. But if it’s the wrong type, shape, or material, it can amplify chatter instead of suppressing it.

Tool Material and Coating

Different tool materials offer different stiffness and vibration-dampening properties:

· Carbide tools are more rigid than high-speed steel (HSS), making them better at resisting chatter.

· Coated tools (like TiN or AlTiN) reduce friction, which lowers heat and vibration.

Using the right combination based on your material (aluminum vs. titanium, for example) can make all the difference.

Geometry Adjustments for Stability

The tool’s geometry matters more than most machinists realize. Try:

· Variable helix angles to break up harmonic vibrations.

· Unequal flute spacing to prevent vibration synchronization.

· Shorter overhangs for more rigidity.

· Large core diameters to add strength.

A 3-flute end mill with a variable pitch might outperform a 4-flute with standard geometry when it comes to chatter control. It’s often trial and error, but once you find the sweet spot, you’ll see smoother finishes and quieter runs.

Machine Setup and Maintenance

Fixturing and Workpiece Clamping

If your part isn’t held tightly, it will vibrate. Period. Proper workholding is the foundation of chatter-free machining.

Tips to improve fixturing:

· Use rigid, vibration-dampening vises or clamps.

· Keep the least possible overhang of the workpiece.

· Use step blocks or custom jigs to enhance stability.

· Consider vacuum tables for flat parts—but reinforce their rigidity.

For delicate parts, soft jaws or custom fixtures may be needed to ensure security without deformation.

Machine Rigidity and Alignment

Even the best tools and settings won’t help if your CNC machine itself isn’t up to the task.

Check for:

· Loose slides or ways

· Worn-out ball screws

· Spindle misalignment

· Table vibration during operation

Tightening up these areas can drastically reduce vibration transmission and improve the quality of every cut.

Routine Maintenance and Calibration

Don’t just fix things when they break. Prevent them from breaking.

Build a routine maintenance checklist:

· Lubricate guideways and screws regularly

· Tighten bolts and connections

· Check spindle balance and bearing health

· Re-calibrate axes every few months

A well-maintained machine is a chatter-resistant machine. Preventive care can often eliminate problems before they reach the tool.

Advanced Solutions for Chatter Mitigation

Use of Damped Tool Holders

Damped tool holders are like shock absorbers for your cutting tools. They absorb the energy from vibrations before it reaches critical levels.

These holders often contain materials like polymers or tuned mass dampers inside the holder body. The result? Dramatically reduced vibration, longer tool life, and better finishes.

They are especially effective in deep-pocket milling and long-reach applications where standard tools are prone to resonate.

Variable Pitch and Helix Tools

Tools with a variable pitch or variable helix have flute geometries that are intentionally uneven. This breaks the symmetry of cutting forces and disrupts vibration buildup.

Instead of all flutes engaging the material at the same frequency, the variable spacing spreads out the force load. This reduces the chance of harmonic buildup and practically eliminates regenerative chatter.

Use these for:

· High-speed operations

· Thin-walled parts

· Aerospace-grade materials

Vibration Dampening Systems

Some high-end CNC systems come with built-in vibration dampeners or allow for external add-ons:

· Active dampening systems that use sensors and actuators

· Magnetic dampers for spindle assemblies

· Mass-tuned dampers inside the spindle housing

Though expensive, these systems are invaluable in ultra-precision work where surface finish and dimensional integrity are paramount.

CAM Software and Simulation

Chatter Prediction Through Software

Modern CAM (Computer-Aided Manufacturing) software does more than generate toolpaths—it can now predict chatter before you even touch a piece of material. That’s like having a crystal ball for your machining process.

Advanced software tools use mathematical models and machining dynamics to forecast when chatter is likely to occur based on:

· Material properties

· Tool geometry

· Cutting parameters

· Machine dynamics

With these predictions, you can adjust your setup in the digital phase, saving time, material, and tool life. Programs like MachiningCloud, VERICUT, or NC Simul are industry favorites when it comes to chatter analysis and prevention.

Toolpath Optimization Techniques

Toolpath design directly influences chatter. Certain patterns induce vibrations, while others dampen them naturally.

Here’s what you should do:

· Use high-speed machining strategies like adaptive clearing to reduce tool engagement and stabilize forces.

· Avoid sudden directional changes or sharp corners in your toolpaths.

· Employ constant tool engagement techniques that reduce tool deflection.

Smarter toolpaths mean more balanced cutting forces, which translates into smoother, chatter-free finishes.

Real-time Simulation and Feedback

Some CAM solutions integrate real-time feedback loops using sensors installed on the machine. These systems monitor spindle vibration, cutting force, and acoustic emissions in real-time. If chatter begins to develop, they can:

· Send alerts to the operator

· Automatically adjust feed/speed on-the-fly

· Log data for post-process analysis

This proactive layer of chatter control is especially useful in automated or lights-out machining environments where manual monitoring isn’t feasible.

Operator Training and Best Practices

Importance of Skilled Operators

You can have the best tools, the smartest software, and a rock-solid machine—but if your operator lacks experience, chatter will find a way in.

A well-trained machinist can:

· Hear the difference between good and bad cuts

· Feel subtle vibrations

· Diagnose chatter based on tool marks alone

Skilled operators also know when to intervene, change tools, or adjust settings in real-time. Their instincts, developed over thousands of hours on the shop floor, are irreplaceable.

Encourage continuous education. Invest in your team’s growth. A smart operator is your first line of defense against chatter.

Continuous Learning and Workshops

The machining world evolves rapidly, and staying ahead requires ongoing training. Host or attend:

· In-house workshops focused on chatter diagnostics

· Vendor-led seminars on new tooling and cutting techniques

· Online courses and certifications from platforms like Coursera, Tooling U, or LinkedIn Learning

Knowledge is power—and in CNC machining, it’s the power to reduce scrap, improve quality, and extend machine life.

Industry Examples and Case Studies

Real-World Success Stories

Let’s look at how some companies have eliminated chatter and improved production:

Aerospace Manufacturer in Ohio

Problem: Chatter in deep-pocket aluminum parts

Solution: Switched to variable helix end mills, added damped holders

Result: Reduced cycle time by 30%, improved finish grade from Ra 6.3 µm to Ra 1.2 µm

Automotive Supplier in Germany

Problem: Excessive tool wear and surface defects

Solution: Implemented real-time vibration monitoring with CAM feedback

Result: 40% increase in tool life and fewer rejected parts

Medical Device Shop in California

Problem: Chatter in small titanium implants

Solution: Optimized toolpath strategies, added high-rigidity fixtures

Result: Achieved ±0.005 mm tolerance consistently

These examples show that no matter the industry or material, applying the right strategies leads to real, measurable improvements.

Lessons Learned from CNC Professionals

Talk to any seasoned machinist and they’ll tell you—chatter isn’t just a nuisance; it’s a shop killer. Here's what they’ve learned the hard way:

· Never ignore early signs—chatter always gets worse.

· A rigid setup is more important than a fast setup.

· Test cuts and documentation are your best friends.

· Cheap tooling costs you more in the long run.

Listening to the wisdom of the shop floor is just as important as reading a manual. Real-world experience is gold when it comes to diagnosing and solving chatter.

Common Mistakes to Avoid

Overlooking Machine Calibration

A poorly calibrated machine is like a car with misaligned wheels. Sure, it’ll move—but not smoothly. Regular calibration ensures all axes are aligned, backlash is minimized, and components operate in harmony.

Common missteps:

· Ignoring minor alignment issues

· Skipping scheduled maintenance

· Failing to recalibrate after part crashes

Even brand-new machines can benefit from an early calibration check—don’t assume factory settings are perfect.

Using Improper Tooling

Using the wrong tool is like using a hammer when you need a screwdriver—it’s not just ineffective, it’s damaging.

Common tooling mistakes:

· Long-reach tools for shallow cuts

· Too many flutes for gummy materials

· Ignoring the importance of tool coatings

· Not matching tool geometry to material hardness

Always consult your tooling supplier or rep before running a new job. A five-minute call can save hours of rework.

The Role of Technology in Preventing Chatter

IoT and Smart Machining Systems

The Industrial Internet of Things (IIoT) is transforming CNC machining. Smart sensors embedded in machines, spindles, and tools can collect real-time data on vibrations, temperature, and cutting force.

This data is fed into dashboards or cloud platforms, enabling predictive adjustments like:

· Speed reduction when vibration exceeds limits

· Alerting operators before chatter damages tooling

· Shutting down the machine in case of extreme conditions

These smart systems don’t just detect chatter—they actively work to prevent it.

Predictive Maintenance Tools

Predictive maintenance uses data and analytics to foresee when a machine component will fail. It’s a game-changer for chatter control.

Benefits include:

· Identifying bearing wear before it leads to spindle vibration

· Preventing looseness in linear rails

· Scheduling downtimes without disrupting production

By addressing issues before they cause chatter, predictive maintenance keeps your shop running smoothly and quietly.

Building a Chatter-Free CNC Environment

Integrating Lean Manufacturing

Chatter control fits naturally into lean manufacturing principles. It aligns with reducing waste, optimizing flow, and maintaining consistent quality.

Lean tools that help with chatter:

· Kaizen events to eliminate root causes

· Standard work instructions for machine setup

· 5S programs to maintain a clean, stable environment

A lean, organized workspace reduces the chaos that often breeds chatter.

Standard Operating Procedures (SOPs)

Finally, document everything. Create SOPs that include:

· Ideal cutting parameters for each material

· Machine warm-up and calibration routines

· Tooling selection checklists

· Daily machine inspection guidelines

Clear, accessible SOPs help every operator—new or seasoned—adhere to best practices, keeping chatter at bay consistently.

Conclusion

Chatter might be a common problem in CNC machining, but it’s far from inevitable. With a clear understanding of its causes and a toolbox full of strategic fixes—from tuning cutting parameters to upgrading software and hardware—you can create a quiet, efficient, and productive shop environment.

Don’t let chatter compromise your precision, waste your materials, or erode your profits. Be proactive, stay educated, and treat chatter control as a foundational part of your CNC strategy.

FAQs

1. How do I know if my CNC machine is experiencing chatter?

Look for high-pitched noises during cutting, visible wave patterns on your workpiece, and signs of rapid tool wear or surface damage. Real-time vibration sensors can also help detect it early.

2. Can chatter completely be eliminated?

While it may not be 100% avoidable in all situations, applying proper techniques and tools can reduce it to nearly zero. With experience and the right setup, you can run parts smoothly every time.

3. What’s the most cost-effective way to reduce chatter?

Start with simple fixes like adjusting feed rates or using a shorter tool. Toolpath optimization in your CAM software and better fixturing are also affordable but highly effective.

4. How does temperature affect chatter in CNC machining?

Higher temperatures can lead to thermal expansion, causing misalignment and increasing vibration susceptibility. It’s critical to maintain thermal stability in your cutting environment.

5. Should I change my CAM software to fix chatter?

If your current software lacks simulation or chatter prediction features, upgrading can be worth it. Modern CAM solutions offer powerful analysis tools that help prevent chatter from the programming stage.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu