Is your CNC machine making strange noises or losing precision? That subtle vibration or unexpected downtime might point to a silent saboteur lurking within: damaged bearings in your spindle motor. Bearing damage isn't always obvious, but it's a critical issue that can lead to reduced accuracy, increased wear on other components, expensive repairs, or total spindle failure if left unaddressed.

In this guide, we'll explore everything you need to know about bearing damage in spindle motors—from spotting the early signs to identifying causes and implementing effective prevention strategies. Whether you're a CNC operator, maintenance tech, or hobbyist safeguarding your setup, this resource will help you keep your bearings in top shape, ensuring smooth operation and extended machine life.

Let's uncover the hidden threats and keep your spindle spinning flawlessly!

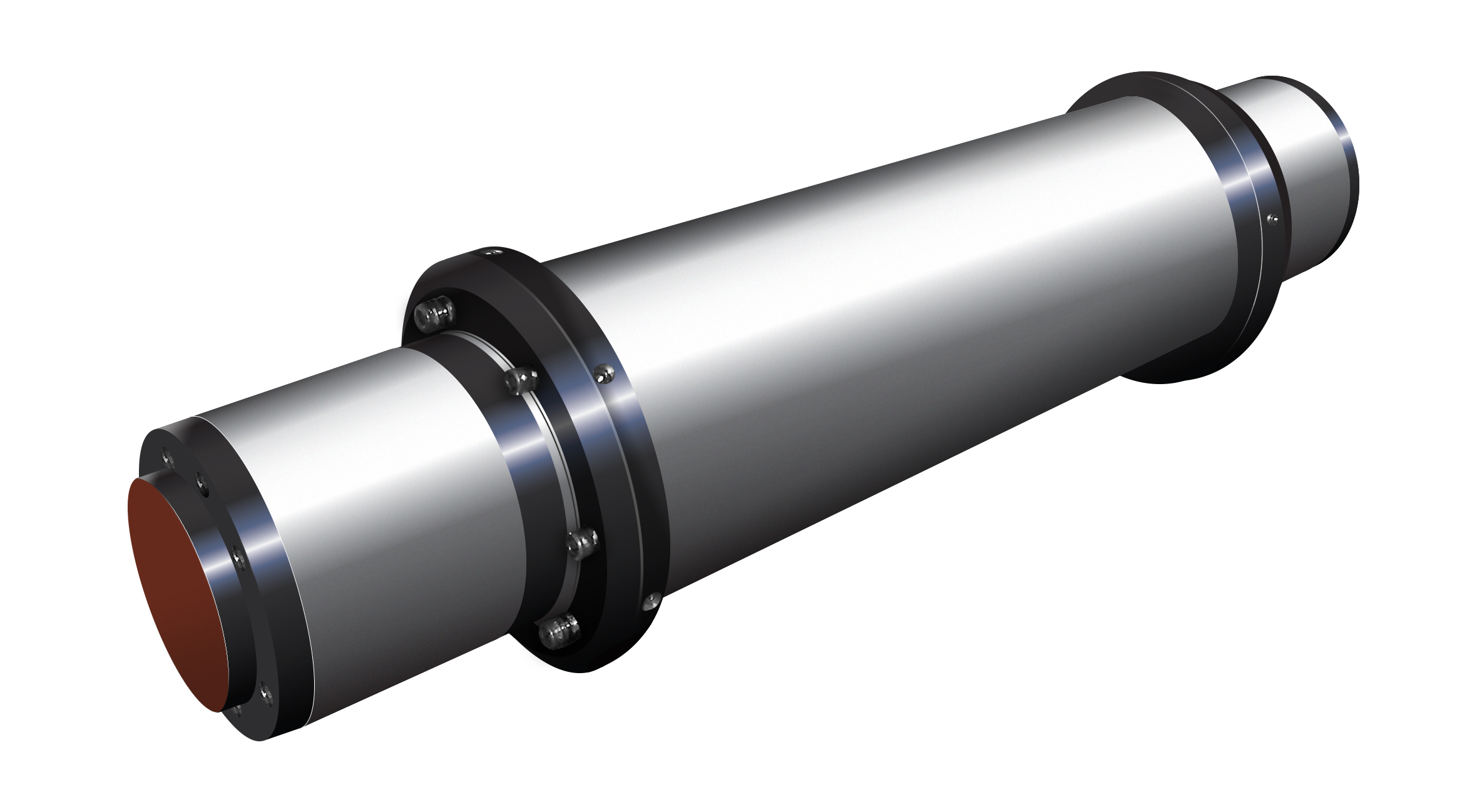

![CNC Spindles]()

Introduction to Spindle Motor Bearings

What Are Spindle Motor Bearings?

At the core of every spindle motor lies a set of bearings—precision-engineered components that support the rotating shaft, enabling high-speed, accurate motion. These bearings reduce friction, absorb loads, and maintain alignment, allowing the spindle to drive cutting tools with the precision required for drilling, milling, and shaping materials.

Bearings come in various types, such as ball, roller, or angular contact, tailored to the spindle's speed, load, and application—be it woodworking, metal fabrication, or composite machining. No matter the type, bearings must operate within tight tolerances to prevent vibration, heat buildup, and wear.

Imagine them as the wheels on a high-performance vehicle—if they wobble or seize, the entire system suffers. Damaged bearings can lead to excessive friction, misalignment, and thermal issues, compromising the spindle's performance. Understanding bearing types, lubrication needs, and load capacities gives you an edge in detecting and preventing damage early.

Importance of Bearing Health in Spindle Motors

Your spindle motor's reliability hinges on its bearings. When bearings degrade, it's not just the rotation that's at risk; it can cause shaft misalignment, increased vibration, ruined workpieces, production delays, and escalating repair costs.

Early signs of damage, like faint vibrations, can escalate to complete failure if ignored. Monitoring bearing condition prevents minor issues from becoming major headaches, saving you from expensive spindle rebuilds.

Moreover, damaged bearings don't isolate their problems—they strain the motor windings, cooling systems, and drive mechanisms. It's a domino effect that no operator wants to trigger.

Bearing integrity is about more than mechanics—it's safety, efficiency, and bottom-line savings. Mastering the causes and prevention of bearing damage is non-negotiable for peak performance.

Common Causes of Bearing Damage in Spindle Motors

| Cause | Description | Effects | Best Practices |

| Overloading the Bearings | Forces beyond design limits from machining tough materials, aggressive cutting depths, or rapid feed rates. | Fatigue cracking, deformation, premature pitting/spalling, or immediate failure (fracture/stall). | Align cutting parameters with bearing ratings; use sharp tools and balanced loads. |

| Inadequate or Contaminated Lubrication | Low lubricant levels, contaminants (debris/water), or leaking seals causing dry contact or abrasive action. | Surface erosion, pitting, increased heat, or seizure. | Use specified lubricants, monitor levels, replace contaminated ones, and check seals. |

| Misalignment or Improper Installation | Assembly errors, thermal expansion, or uneven mounting surfaces causing shaft tilt or misalignment. | Uneven load distribution, accelerated wear, vibration-induced fatigue, or heat. | Use alignment tools during installation, verify post-setup, and check regularly. |

| Contamination from Dust and Debris | Particles infiltrating via poor seals or dirty environments, causing abrasion or corrosion. | Scratches, dents, corrosion, or breakdown. | Use effective seals, air filtration, and regular cleaning. |

| Excessive Vibration or Imbalance | Unbalanced tools or resonant frequencies amplifying oscillations. | Damage to races, fatigue, or heat from constant motion. | Balance tools, isolate vibrations, and monitor with analyzers. |

| High Operating Temperatures | Heat softening materials, thinning lubricants, or causing uneven expansion. | Reduced load capacity, lubricant breakdown, or thermal fatigue cracks. | Optimize cooling, monitor temperatures, and avoid overloads. |

| Electrical Current Passage | Arcing from poor grounding causing surface erosion via electrical discharge. | Surface damage from electrical discharge machining effects. | Ensure proper grounding and use insulated bearings where needed. |

1. Overloading the Bearings

Bearing overloading occurs when mechanical components, such as bearings in spindles or rotating machinery, are subjected to forces that exceed their designed capacity. This issue is particularly prevalent in machining and industrial applications where operational parameters push equipment beyond its limits. Overloading can lead to significant damage, reduced equipment lifespan, and costly downtime.

Causes of Bearing Overloading

Bearings can become overloaded due to a variety of operational and setup-related factors, including:

Machining Tough Materials Without Proper Setup:

l Processing dense or high-strength materials, such as titanium, stainless steel, or other hard alloys, places significant stress on bearings, especially when using light-duty spindles not designed for such loads.

l Inadequate machine setup, such as improper tool selection or insufficient spindle rigidity, amplifies axial (along the axis of rotation) and radial (perpendicular to the axis) loads, overwhelming the bearings.

Aggressive Cutting Depths:

l Excessive cutting depths during machining impose sudden and intense forces on the spindle and bearings. These shock loads can exceed the bearing’s load-carrying capacity, leading to immediate stress and long-term damage.

l Deep cuts without proper incremental steps or toolpath optimization increase the likelihood of overloading.

Rapid Feed Rates Mismatched to Spindle Capabilities:

l High feed rates that are not aligned with the spindle’s design specifications create uneven pressure on bearings. This mismatch causes excessive vibration and dynamic loading, which can destabilize the bearing system.

l Rapid feed rates combined with improper tool or workpiece alignment further exacerbate uneven force distribution.

Improper Machine Design or Operation:

l Using bearings or spindles with insufficient load ratings for the application can lead to overloading even under normal operating conditions.

l Operator errors, such as incorrect programming of CNC machines or neglecting to account for material properties, contribute to excessive forces on bearings.

Effects of Bearing Overloading

When bearings are subjected to forces beyond their design limits, they experience a range of detrimental effects that compromise performance and durability:

Fatigue Cracking in Bearing Races:

l Repeated overloading induces cyclic stress in the bearing races (the inner and outer rings that house the rolling elements). Over time, this leads to fatigue cracking, where micro-cracks form and propagate through the material.

l These cracks weaken the bearing structure, reducing its ability to support loads and increasing the risk of failure.

Deformation from Excessive Loads:

l Excessive forces can cause plastic deformation of bearing components, such as the rolling elements (balls or rollers) or races. This deformation alters the bearing’s geometry, leading to misalignment, increased friction, and reduced precision.

l Deformed bearings may also generate excessive heat, further accelerating wear.

Premature Pitting or Spalling:

l Overloading accelerates surface fatigue, resulting in pitting (small craters) or spalling (flaking of material) on the bearing surfaces. These defects disrupt smooth operation, increase vibration, and hasten bearing failure.

l Pitting and spalling are particularly damaging in high-precision applications, where even minor surface irregularities can affect performance.

Immediate Failure:

l In severe cases, overloading can cause catastrophic failure, such as bearing fracture or spindle stall. A fractured bearing may seize entirely, halting machine operation and potentially damaging other components.

l Sudden failure can also pose safety risks to operators and lead to significant production losses.

Consequences of Bearing Overloading

The consequences of overloading bearings extend beyond the immediate damage to the bearing itself and can have far-reaching operational and financial impacts:

l Reduced Equipment Lifespan: Overloaded bearings wear out faster, necessitating frequent replacements and increasing maintenance costs.

l Increased Downtime: Bearing failures often require extensive repairs, leading to unplanned downtime and disruptions in production schedules.

l Compromised Precision: Deformed or damaged bearings reduce the accuracy of machining processes, potentially leading to defective parts and rework.

l Higher Energy Consumption: Overloaded bearings increase friction, requiring more energy to operate machinery and driving up costs.

l Safety Hazards: Sudden bearing failure or spindle stall can create hazardous conditions, such as flying debris or uncontrolled machine behavior.

Best Practices for Mitigation

Bearing overloading is a preventable issue that arises from improper machining practices, such as using unsuitable materials, aggressive cutting depths, or mismatched feed rates. The resulting fatigue cracking, deformation, pitting, and potential catastrophic failure can lead to reduced equipment lifespan, increased costs, and safety risks. By aligning cutting parameters with bearing capabilities, using sharp tools, balancing loads, and implementing regular maintenance, operators can significantly reduce the risk of overloading. These proactive measures ensure reliable operation, enhance precision, and extend the service life of bearings and associated machinery, ultimately contributing to operational efficiency and cost savings.

2. Inadequate or Contaminated Lubrication

Lubrication is critical for the optimal performance and longevity of bearings in rotating machinery, such as spindles, motors, or other mechanical systems. It reduces friction between moving parts, dissipates heat, and protects surfaces from wear. However, inadequate or contaminated lubrication can lead to severe operational issues, compromising bearing performance and causing premature failure.

Causes of Inadequate or Contaminated Lubrication

Lubrication failures occur due to several factors that disrupt the lubricant’s ability to perform its essential functions:

Low Lubricant Levels:

l Insufficient lubricant in the bearing system results in dry contact between moving surfaces, such as the rolling elements and races. This lack of lubrication increases friction, leading to scoring (scratches or gouges) on bearing surfaces.

l Low levels can stem from infrequent maintenance, improper initial filling, or gradual depletion over time due to evaporation or leakage.

Contaminants in Lubricant:

l Debris, such as dust, dirt, or metal particles, can infiltrate the lubricant, turning it into an abrasive medium. These contaminants grind against bearing surfaces, accelerating wear.

l Water ingress, often due to poor sealing or humid environments, mixes with the lubricant, reducing its viscosity and promoting corrosion or emulsification, which impairs lubrication performance.

Leaking Seals or Skipped Maintenance:

l Worn, damaged, or improperly installed seals allow lubricant to escape, depleting reserves and exposing bearings to contaminants.

l Neglecting regular maintenance schedules, such as failing to check or replenish lubricant levels, leads to inadequate lubrication over time.

Use of Incorrect Lubricants:

l Using lubricants that do not meet the bearing’s specifications (e.g., incorrect viscosity, type, or additives) can fail to provide adequate protection, leading to increased friction and wear.

l Mixing incompatible lubricants, such as combining grease and oil or different grease types, can degrade performance and cause lubrication failure.

Effects of Inadequate or Contaminated Lubrication

When lubrication is inadequate or contaminated, bearings experience a range of detrimental effects that compromise their functionality:

Surface Erosion and Pitting:

l Insufficient lubrication or abrasive contaminants cause surface erosion, where material is worn away from the bearing’s rolling elements or races. This leads to pitting, characterized by small craters on the surface, which disrupts smooth operation.

l Pitting increases vibration and noise, reducing precision and accelerating further damage.

Increased Heat from Friction:

l Without proper lubrication, friction between moving parts generates excessive heat. This elevated temperature can degrade the bearing material, weaken its structure, and cause thermal expansion, leading to misalignment or clearance issues.

l Contaminated lubricants exacerbate heat generation by introducing abrasive particles that increase friction.

Seizure in Extreme Cases:

l In severe cases, the absence of effective lubrication can cause bearings to seize, where the rolling elements and races lock up due to excessive friction or material welding. Seizure halts machinery operation, potentially causing catastrophic failure and damage to surrounding components.

l Seizure is often the result of prolonged dry contact or extreme contamination.

Consequences of Inadequate or Contaminated Lubrication

The consequences of lubrication failures extend beyond the bearings themselves, impacting overall system performance and operational costs:

l Reduced Bearing Lifespan: Inadequate or contaminated lubrication accelerates wear, significantly shortening the service life of bearings and necessitating frequent replacements.

l Increased Maintenance Costs: Damage from lubrication failures leads to costly repairs, including bearing replacement and downtime for maintenance.

l Production Downtime: Bearing failures due to poor lubrication can halt production, leading to missed deadlines and financial losses.

l Compromised Precision: Surface damage and increased friction reduce the accuracy of machinery, affecting product quality in precision industries like aerospace or electronics.

l Safety Risks: Sudden bearing seizure or failure can create hazardous conditions, such as uncontrolled machine behavior or debris generation, posing risks to operators.

Best Practices for Mitigation

Inadequate or contaminated lubrication poses a significant threat to bearing performance, leading to surface erosion, pitting, increased heat, and potential seizure. These issues stem from low lubricant levels, contamination by debris or water, leaking seals, or improper maintenance practices. By using specified lubricants, monitoring levels, replacing contaminated lubricants promptly, and conducting regular seal checks, operators can prevent lubrication-related failures. These proactive measures enhance bearing reliability, extend equipment lifespan, and reduce operational costs, ensuring consistent performance and safety in critical applications.

3. Misalignment or Improper Installation

Proper alignment and installation are critical for the optimal performance and longevity of bearings in rotating machinery, such as spindles, motors, or other mechanical systems. Bearings are designed to operate with precise alignment to ensure even load distribution and smooth operation. Misalignment or improper installation can lead to significant operational issues, accelerated wear, and premature failure.

Causes of Misalignment or Improper Installation

Misalignment or improper installation occurs when bearings are not correctly positioned or secured, leading to operational inefficiencies. Common causes include:

Assembly Errors Causing Shaft Tilt:

l Errors during assembly, such as incorrect mounting of bearings onto shafts or housings, can result in shaft tilt or angular misalignment. This misalignment disrupts the bearing’s ability to rotate smoothly.

l Improper handling, such as applying uneven force during installation or using inappropriate tools, can cause bearings to be misaligned from the outset.

Thermal Expansion Shifting Positions:

l During operation, machinery components may heat up, causing thermal expansion that shifts the position of bearings, shafts, or housings. If not accounted for in the design or installation process, this can lead to misalignment.

l Inadequate clearance or improper preload settings can exacerbate misalignment caused by thermal expansion.

Mounting on Uneven Surfaces:

l Installing bearings on uneven or improperly prepared surfaces, such as warped housings or misaligned machine bases, introduces misalignment from the start.

l Poor machining tolerances or inadequate surface preparation (e.g., debris or burrs on mounting surfaces) can prevent bearings from seating correctly.

Inadequate Installation Procedures:

l Skipping critical steps, such as verifying alignment or torque specifications, during installation can lead to misalignment or improper seating of bearings.

l Lack of training or failure to follow manufacturer guidelines often results in installation errors that compromise bearing performance.

Effects of Misalignment or Improper Installation

When bearings are misaligned or improperly installed, they experience a range of detrimental effects that compromise their functionality and longevity:

Uneven Load Distribution:

l Misalignment causes uneven distribution of forces across the bearing, with certain areas experiencing excessive loads. This accelerates wear on the rolling elements, races, or cages, leading to premature failure.

l Uneven loading can also cause localized stress concentrations, increasing the likelihood of material fatigue.

Vibration-Induced Fatigue:

l Misaligned bearings generate excessive vibration due to uneven rotation or wobbling. This vibration induces cyclic stress, leading to fatigue cracking in bearing components.

l Prolonged vibration can propagate to other machine parts, causing additional wear or damage to the system.

Heat from Added Friction:

l Misalignment increases friction between bearing components, generating excess heat. This heat can degrade lubricants, weaken bearing materials, and cause thermal expansion, further exacerbating misalignment.

l Elevated temperatures reduce the bearing’s precision and efficiency, leading to potential overheating or failure.

Reduced Bearing Lifespan:

l The combined effects of uneven loading, vibration, and increased friction significantly shorten the bearing’s operational life, necessitating frequent replacements and increasing maintenance costs.

Consequences of Misalignment or Improper Installation

The consequences of misalignment or improper installation extend beyond the bearings themselves, impacting overall system performance and operational costs:

l Accelerated Wear and Failure: Uneven loads and vibration accelerate wear, leading to premature bearing failure and reduced equipment lifespan.

l Increased Maintenance Costs: Frequent repairs or replacements due to misalignment-related damage drive up maintenance expenses.

l Production Downtime: Misaligned bearings can cause unexpected failures, halting production and resulting in lost revenue or missed deadlines.

l Compromised Precision: In precision applications, such as CNC machining or robotics, misalignment reduces accuracy, leading to defective products or rework.

l Safety Risks: Excessive vibration or sudden bearing failure can create hazardous conditions, such as component detachment or uncontrolled machine behavior, posing risks to operators.

Best Practices for Mitigation

Misalignment or improper installation of bearings, caused by assembly errors, thermal expansion, or uneven mounting surfaces, leads to uneven load distribution, vibration-induced fatigue, and increased friction. These issues result in accelerated wear, reduced precision, and potential equipment failure, with significant operational and financial consequences. By employing alignment tools, verifying post-setup alignment, accounting for thermal expansion, and conducting regular checks, operators can prevent misalignment-related issues. These proactive measures ensure reliable bearing performance, extend equipment lifespan, and enhance operational efficiency, minimizing downtime and costs in critical applications.

4. Contamination from Dust and Debris

Contamination from dust and debris is a critical concern in environments where precision machinery, such as spindles, bearings, or other mechanical components, operates. These contaminants, which include fine particles like dust, dirt, metal shavings, or other microscopic debris, can infiltrate machinery through various pathways, leading to significant operational inefficiencies and damage.

Causes of Contamination

Dust and debris infiltration typically occurs due to one or more of the following factors:

Poor Sealing Mechanisms:

Inadequate or worn-out seals around machinery components allow external particles to enter critical areas. Over time, seals can degrade due to wear, improper installation, or exposure to harsh environmental conditions, creating gaps for contaminants to penetrate.

Seals that are not designed to withstand specific environmental challenges, such as high dust levels or extreme temperatures, are particularly vulnerable.

Dirty Operating Environments:

Machinery operating in environments with high levels of airborne particulates, such as manufacturing plants, construction sites, or areas with poor air quality, is at greater risk of contamination.

Improper housekeeping practices, such as failing to clean work areas or allowing debris to accumulate near equipment, exacerbate the issue.

Improper Maintenance Practices:

During maintenance or repair, tools, hands, or components that are not properly cleaned can introduce contaminants into the system.

Lubricants contaminated with particles can also act as a vector for introducing debris into machinery.

Airborne Contaminants:

Fine particles suspended in the air, such as pollen, industrial dust, or chemical residues, can settle on or be drawn into machinery through air intake systems or ventilation.

Effects of Contamination

Once dust and debris infiltrate machinery, they can cause a cascade of detrimental effects that compromise performance and longevity. The primary consequences include:

Abrasive Grinding on Surfaces:

Dust and debris, particularly hard particles like metal shavings or silica, act as abrasives when trapped between moving parts. This leads to micro-abrasions or grinding on surfaces such as bearings, spindles, or gears.

Over time, this abrasive action causes wear, reducing the precision and efficiency of components and leading to misalignment or increased friction.

Corrosion from Moisture-Mixed Contaminants:

Contaminants often mix with moisture, either from the environment or from lubricants, creating a corrosive environment. For example, dust containing salts or chemicals can accelerate rust formation on metal surfaces.

Corrosion weakens components, leading to pitting, cracking, or structural failure, which can significantly reduce the lifespan of equipment.

Blocked Lubricant Paths:

Dust and debris can clog lubrication channels, preventing lubricants from reaching critical areas. This results in inadequate lubrication, increasing friction and heat generation.

Blocked paths can also cause uneven lubricant distribution, leading to localized overheating or component failure.

Scratches, Dents, and Eventual Breakdown:

The cumulative effect of abrasion, corrosion, and inadequate lubrication manifests as visible damage, such as scratches, dents, or surface irregularities.

These issues compromise the structural integrity of components, leading to accelerated wear and, ultimately, catastrophic failure of the machinery.

Consequences of Contamination

The consequences of dust and debris contamination extend beyond immediate mechanical damage and can have significant operational and financial impacts:

l Reduced Equipment Efficiency: Contaminated components operate less efficiently, requiring more energy to perform the same tasks and increasing operational costs.

l Increased Maintenance Costs: Frequent repairs or replacements due to contamination-related damage drive up maintenance expenses.

l Downtime and Production Losses: Unexpected breakdowns caused by contamination can halt production, leading to missed deadlines and lost revenue.

l Compromised Product Quality: In precision industries, such as aerospace or electronics manufacturing, contamination can lead to defective products, resulting in rework or customer dissatisfaction.

l Safety Hazards: Damaged or malfunctioning equipment poses risks to operators, potentially leading to accidents or injuries.

Best Practices for Mitigation

Contamination from dust and debris poses a significant threat to the performance and longevity of precision machinery. By understanding the causes—such as poor seals and dirty environments—and the resulting effects, including abrasive wear, corrosion, and lubricant blockages, operators can take proactive steps to mitigate risks. Implementing best practices, such as effective sealing, air filtration, and regular cleaning, can significantly reduce contamination, ensuring reliable operation, minimizing downtime, and extending the service life of critical equipment. By prioritizing contamination control, businesses can enhance efficiency, reduce costs, and maintain high standards of operational excellence.

5. Excessive Vibration or Imbalance

Excessive vibration or imbalance in rotating machinery, such as spindles, motors, or other systems with bearings, poses a significant threat to operational performance and component longevity. These issues arise when tools, rotors, or other rotating elements are unbalanced or when the system operates at resonant frequencies, leading to amplified mechanical stress.

Causes of Excessive Vibration or Imbalance

Excessive vibration or imbalance in machinery typically results from the following factors:

Unbalanced Tools or Rotors:

l Tools, such as cutting tools in machining or rotors in motors, that are not properly balanced generate uneven forces during rotation. This imbalance causes oscillations that stress bearings and other components.

l Imbalance may result from uneven tool wear, improper assembly, or manufacturing defects in rotating elements.

Resonant Frequencies:

l When machinery operates at or near its natural resonant frequency, vibrations are amplified, causing excessive oscillations. This resonance can occur due to improper speed settings or design flaws in the system.

l External factors, such as nearby machinery or environmental vibrations, can also excite resonant frequencies, exacerbating the issue.

Improper Setup or Alignment:

l Misaligned components, such as shafts or couplings, can introduce vibrations by creating uneven force distribution during rotation.

l Loose or improperly secured components, such as tool holders or fixtures, can also contribute to imbalance and vibration.

Wear or Damage in Components:

l Worn bearings, damaged gears, or degraded components can create irregular motion, leading to increased vibration.

l Accumulated debris or contamination in the system can further disrupt balance, amplifying oscillations.

Effects of Excessive Vibration or Imbalance

When machinery experiences excessive vibration or imbalance, bearings and other components suffer a range of detrimental effects:

Amplified Oscillations Damaging Races:

l Excessive vibrations cause repeated impacts and uneven loading on bearing races (the inner and outer rings that house the rolling elements). This leads to surface damage, such as micro-cracks or material deformation, compromising the bearing’s integrity.

l Oscillations can also propagate to other machine components, causing widespread wear.

Fatigue Over Cycles:

l Continuous vibration induces cyclic stress in bearings, leading to fatigue cracking over time. These cracks weaken the bearing structure, increasing the risk of failure.

l Fatigue damage accumulates with each operational cycle, significantly reducing the bearing’s lifespan.

Heat from Constant Motion:

l Vibrations increase friction between bearing components, generating excess heat. This heat can degrade lubricants, weaken bearing materials, and cause thermal expansion, further exacerbating misalignment or clearance issues.

l Prolonged heat generation can lead to overheating, reducing operational efficiency and precision.

Secondary Damage to Machinery:

l Excessive vibration can loosen fasteners, misalign components, or damage adjacent parts, leading to broader system failures.

l In severe cases, unchecked vibrations can cause catastrophic failure, such as bearing seizure or shaft fracture.

Consequences of Excessive Vibration or Imbalance

The consequences of excessive vibration or imbalance extend beyond the bearings, impacting overall system performance and operational costs:

l Reduced Equipment Lifespan: Vibrations accelerate wear, leading to premature failure of bearings and other components, necessitating frequent replacements.

l Increased Maintenance Costs: Damage from vibrations requires costly repairs, including bearing replacement and system realignment.

l Production Downtime: Vibration-induced failures can halt production, resulting in missed deadlines and financial losses.

l Compromised Precision: Excessive vibrations reduce machining accuracy, leading to defective products or rework in precision industries like aerospace or electronics.

l Safety Risks: Severe vibrations can cause component detachment, uncontrolled machine behavior, or debris generation, posing hazards to operators.

Best Practices for Mitigation

Excessive vibration or imbalance, caused by unbalanced tools, resonant frequencies, or improper setup, leads to amplified oscillations, fatigue, and heat generation, damaging bearings and other components. These issues result in reduced equipment lifespan, increased maintenance costs, and compromised precision, with potential safety risks. By balancing tools, isolating vibrations, monitoring with analyzers, and ensuring proper setup, operators can mitigate these risks. These proactive measures enhance machinery reliability, extend service life, and maintain operational efficiency, minimizing downtime and costs in critical applications.

6. High Operating Temperatures

High operating temperatures pose a significant challenge to the performance and longevity of bearings and other rotating machinery components, such as spindles or motors. Excessive heat can degrade materials, impair lubrication, and cause dimensional changes, leading to operational inefficiencies and premature failure.

Causes of High Operating Temperatures

Elevated temperatures in machinery typically arise from a combination of operational, environmental, and maintenance-related factors:

Excessive Friction:

l High friction between bearing components, often due to inadequate lubrication, misalignment, or overloading, generates significant heat.

l Improperly balanced tools or excessive vibration can further increase friction, contributing to elevated temperatures.

Overloading or Aggressive Operation:

l Operating machinery beyond its designed load capacity, such as machining tough materials or using aggressive cutting parameters, increases heat generation due to heightened mechanical stress.

l High speeds or feed rates can amplify heat production, especially in bearings not rated for such conditions.

Inadequate Cooling Systems:

l Insufficient or malfunctioning cooling systems, such as fans, coolant pumps, or heat exchangers, fail to dissipate heat effectively, allowing temperatures to rise.

l Poor ventilation or high ambient temperatures in the operating environment exacerbate heat buildup.

Lubricant Degradation or Improper Selection:

l Lubricants that are not suited for high-temperature applications may thin or break down, reducing their ability to dissipate heat and protect bearing surfaces.

l Contaminated or degraded lubricants can also contribute to increased friction and heat generation.

External Heat Sources:

l Machinery operating near external heat sources, such as furnaces, ovens, or direct sunlight, can experience elevated temperatures that affect bearing performance.

l Inadequate insulation or shielding from external heat sources can compound the issue.

Effects of High Operating Temperatures

When bearings and machinery are subjected to high temperatures, they experience a range of detrimental effects that compromise functionality and durability:

Reduced Load Capacity:

l High temperatures soften bearing materials, such as steel, reducing their hardness and load-carrying capacity. This weakening makes bearings more susceptible to deformation under normal operating loads.

l Softened materials are less able to withstand mechanical stress, accelerating wear and failure.

Lubricant Breakdown:

l Elevated temperatures cause lubricants to thin, oxidize, or break down chemically, reducing their viscosity and effectiveness. This leads to inadequate lubrication, increased friction, and further heat generation.

l Degraded lubricants may form sludge or varnish, clogging lubrication paths and exacerbating wear.

Thermal Fatigue Cracks:

l Repeated exposure to high temperatures induces thermal fatigue, where cyclic heating and cooling cause micro-cracks in bearing surfaces. These cracks propagate over time, weakening the bearing and increasing the risk of catastrophic failure.

l Uneven thermal expansion of components can exacerbate stress concentrations, leading to crack formation.

Dimensional Changes and Misalignment:

l High temperatures cause uneven expansion of bearings, shafts, or housings, leading to misalignment, increased vibration, and uneven load distribution.

l These dimensional changes can reduce bearing clearance, causing binding or increased friction.

Consequences of High Operating Temperatures

The consequences of excessive heat extend beyond the bearings, impacting overall system performance and operational costs:

l Reduced Equipment Lifespan: Softened materials and lubricant breakdown accelerate wear, significantly shortening bearing and machinery lifespan.

l Increased Maintenance Costs: Frequent repairs or replacements due to heat-related damage drive up maintenance expenses.

l Production Downtime: High-temperature-induced failures can halt production, leading to missed deadlines and financial losses.

l Compromised Precision: Thermal expansion and material degradation reduce machining accuracy, affecting product quality in precision industries like aerospace or electronics.

l Safety Risks: Overheated components can fail suddenly, creating hazardous conditions such as bearing seizure, component detachment, or fire risks in extreme cases.

Best Practices for Mitigation

High operating temperatures, caused by excessive friction, overloading, inadequate cooling, or improper lubricants, lead to reduced load capacity, lubricant breakdown, and thermal fatigue cracks. These issues shorten equipment lifespan, increase maintenance costs, and compromise precision, with potential safety risks. By optimizing cooling systems, monitoring temperatures, avoiding overloads, and selecting appropriate lubricants, operators can mitigate heat-related risks. These proactive measures ensure reliable machinery performance, extend service life, and minimize downtime and costs in critical applications.

7. Electrical Current Passage

Electrical current passage through bearings, often caused by poor grounding or stray currents, can lead to significant damage in rotating machinery such as motors, spindles, or generators. This phenomenon, akin to electrical discharge machining (EDM), erodes bearing surfaces and compromises their performance.

Causes of Electrical Current Passage

Electrical current passage occurs when unintended electrical currents flow through bearings, typically due to the following factors:

Poor Grounding:

l Inadequate or improper grounding of machinery allows stray electrical currents to flow through bearings, seeking the path of least resistance to ground.

l Poor grounding can result from faulty wiring, corroded connections, or insufficient grounding systems in the machine or facility.

Stray Currents from Electrical Systems:

l Stray currents may originate from variable frequency drives (VFDs), inverters, or other electrical components commonly used in modern machinery, especially in high-power or high-speed applications.

l Electromagnetic interference (EMI) or induced voltages from nearby electrical equipment can also cause currents to pass through bearings.

Static Electricity Buildup:

l Static charges can accumulate on rotating components, particularly in dry or high-speed environments, leading to discharges through bearings.

l This is common in applications involving non-conductive materials or belts that generate static electricity.

Improper Insulation or Shielding:

l Lack of proper insulation on bearings or surrounding components allows electrical currents to flow through unintended paths.

l Inadequate shielding against electromagnetic fields can exacerbate current passage in sensitive equipment.

Effects of Electrical Current Passage

When electrical currents pass through bearings, they cause a range of detrimental effects, primarily through arcing and electrical discharge machining (EDM) effects:

Surface Erosion via Arcing:

l Electrical arcing between bearing components (e.g., rolling elements and races) creates localized sparks that erode material, similar to EDM. This results in pitting, fluting, or frosted patterns on bearing surfaces.

l These surface defects disrupt smooth operation, increase friction, and accelerate wear.

Micro-Craters and Material Degradation:

l Arcing produces tiny craters or burn marks on bearing surfaces, weakening the material and reducing its load-carrying capacity.

l Over time, these micro-craters lead to spalling (flaking of material), further degrading the bearing’s integrity.

Increased Vibration and Noise:

l Surface damage from arcing causes uneven rotation, leading to increased vibration and noise during operation.

l Vibrations can propagate to other machine components, causing additional wear or misalignment.

Lubricant Degradation:

l Arcing generates heat at contact points, which can degrade or burn lubricants, reducing their effectiveness and leading to increased friction and wear.

l Contaminated or carbonized lubricants may become abrasive, exacerbating surface damage.

Premature Bearing Failure:

l The cumulative effects of surface erosion, vibration, and lubricant breakdown significantly shorten bearing lifespan, leading to premature failure.

l In severe cases, arcing can cause immediate bearing seizure or catastrophic failure.

Consequences of Electrical Current Passage

The consequences of electrical current passage extend beyond the bearings, impacting overall system performance and operational costs:

l Reduced Equipment Lifespan: Surface erosion and material degradation accelerate bearing wear, necessitating frequent replacements.

l Increased Maintenance Costs: Damage from arcing requires costly repairs, including bearing replacement and system downtime.

l Production Downtime: Bearing failures caused by electrical damage can halt production, leading to missed deadlines and financial losses.

l Compromised Precision: Surface defects and increased vibration reduce machining accuracy, affecting product quality in precision industries like electronics or aerospace.

l Safety Risks: Sudden bearing failure or excessive vibration can create hazardous conditions, such as component detachment or electrical hazards, posing risks to operators.

Best Practices for Mitigation

Electrical current passage, often caused by poor grounding, stray currents, or static electricity, erodes bearing surfaces through arcing, leading to pitting, vibration, and lubricant degradation. These effects reduce bearing lifespan, increase maintenance costs, and compromise operational precision, with potential safety risks. By ensuring proper grounding, using insulated bearings, mitigating stray currents, and conducting regular inspections, operators can prevent electrical damage. These proactive measures enhance machinery reliability, extend service life, and minimize downtime and costs in critical applications.

Signs and Symptoms of CNC Spindle Overheating

Spindle motors are critical components in precision machinery, such as CNC machines, lathes, and milling equipment, where bearings play a pivotal role in ensuring smooth, accurate, and efficient operation. Bearing damage, if undetected, can lead to costly downtime, reduced machining quality, and even catastrophic failure of the spindle motor. Early detection is essential to mitigate these risks and extend the lifespan of the equipment.

Abnormal Noises

One of the earliest and most noticeable signs of bearing damage is the presence of unusual sounds emanating from the spindle motor during operation. These noises often indicate underlying issues that, if ignored, can escalate into severe damage. Common abnormal noises include:

l Whining or High-Pitched Sounds: A high-pitched whine typically suggests increased friction within the bearing, often due to insufficient lubrication, wear of the bearing surfaces, or contamination by debris such as dust or metal particles. This sound may intensify as the bearing deteriorates further.

l Grinding or Scraping Noises: Grinding sounds are indicative of significant wear or surface damage, such as pitting or spalling on the bearing races or rolling elements. This can occur when the bearing is subjected to excessive loads, misalignment, or prolonged operation without proper maintenance.

l Clicking or Ticking: Intermittent clicking or ticking noises may point to loose components, such as a damaged cage or rolling elements that are no longer moving smoothly. This can also indicate early-stage fatigue or improper preload in the bearing assembly.

Why It Matters: These noises are often the first audible clues of bearing distress. As friction and wear increase, the sounds become louder and more pronounced, signaling that the bearing is approaching failure. Immediate inspection is critical to diagnose the root cause—whether it’s contamination, misalignment, or material fatigue—and to prevent further damage to the spindle motor.

Action Steps: Use a stethoscope or vibration analysis tools to pinpoint the noise source. Check lubrication levels and quality, inspect for contamination, and verify alignment. If the noise persists, consider disassembling the spindle for a thorough bearing inspection.

Increased Vibration

Excessive vibration is another hallmark of bearing damage in spindle motors. While some level of vibration is normal in rotating machinery, a noticeable increase or change in vibration patterns can indicate serious issues within the bearing assembly. Key aspects include:

l Imbalance: Uneven wear or damage to the bearing can cause the rotor to become imbalanced, leading to excessive shaking. This is often felt as a rhythmic or pulsating vibration during operation.

l Pitting or Surface Damage: Microscopic pits or spalls on the bearing surfaces disrupt smooth rotation, causing irregular vibrations. These defects can result from fatigue, overloading, or contamination.

l Misalignment or Loose Components: Misaligned bearings or loose mounting hardware can amplify vibrations, putting additional stress on the bearing and accelerating wear.

Why It Matters: Increased vibration not only indicates bearing damage but also affects the overall performance of the spindle motor. Excessive shaking can lead to poor machining precision, tool chatter, and damage to other components, such as seals or housings. Over time, unchecked vibration can cause catastrophic failure.

Action Steps: Employ vibration analyzers to quantify vibration levels and identify specific frequencies associated with bearing faults (e.g., ball pass frequency or cage frequency). Regular monitoring can help detect rising vibration trends, indicating advancing damage. If elevated vibrations are detected, inspect the bearing for wear, check alignment, and verify that the rotor is balanced. Early intervention can prevent further deterioration.

Performance Degradation

Bearing damage often manifests as a decline in the spindle motor’s operational performance, affecting its ability to maintain precision, speed, and power. Common symptoms include:

l Loss of Precision: Damaged bearings can cause the spindle to wobble or deviate from its intended path, leading to inaccuracies in machining or cutting operations. This is particularly critical in high-precision applications like CNC machining, where even minor deviations can ruin workpieces.

l Speed Fluctuations: Worn or damaged bearings may create inconsistent resistance, causing the spindle motor to struggle to maintain consistent rotational speeds. This can result in uneven cutting or grinding performance.

l Power Dips or Overloading: As bearings deteriorate, increased friction requires more power to maintain operation, leading to higher energy consumption or intermittent power drops. In severe cases, the motor may stall or fail to start altogether.

Why It Matters: Performance degradation directly impacts the quality of the output and the efficiency of the machinery. For industries reliant on precision and consistency, such as aerospace or automotive manufacturing, even slight performance issues can lead to significant financial losses or safety concerns.

Action Steps: Monitor spindle performance metrics, such as speed stability and power consumption, using diagnostic tools or machine control systems. If degradation is observed, inspect the bearings for wear, check lubrication, and verify that the spindle is properly calibrated. Addressing these issues early can restore performance and prevent further damage.

Discoloration or Odors

Physical changes in the bearing or surrounding components, such as discoloration or unusual odors, are critical warning signs of bearing distress, often linked to overheating or material failure. These symptoms include:

l Discoloration (Bluing or Browning): Overheated bearings may exhibit a blue or brownish tint on their surfaces due to excessive heat generation. This can occur when friction increases due to insufficient lubrication, high loads, or prolonged operation at elevated speeds. Discoloration is a clear sign that the bearing material is undergoing thermal stress, which can weaken its structure.

l Acrid or Burnt Odors: A sharp, acrid smell may indicate that the bearing lubricant is burning off or breaking down due to excessive heat. In some cases, the odor may come from the bearing material itself as it begins to degrade or from nearby components affected by the heat.

Why It Matters: Discoloration and odors signal that the bearing is operating under extreme conditions, which can accelerate wear and lead to imminent failure. Overheating can also damage adjacent components, such as seals, shafts, or housings, increasing repair costs and downtime.

Action Steps: If discoloration or odors are detected, immediately shut down the spindle motor to prevent further damage. Inspect the bearings for signs of overheating, check lubricant condition (e.g., viscosity, contamination), and assess operating conditions (e.g., speed, load, cooling systems). Replace damaged bearings and replenish or upgrade lubrication to prevent recurrence.

Preventive Measures and Best Practices

To minimize the risk of bearing damage and extend the lifespan of spindle motors, consider the following best practices:

l Regular Maintenance: Implement a routine maintenance schedule that includes lubrication checks, alignment verification, and bearing inspections. Use high-quality lubricants suited to the spindle’s operating conditions.

l Vibration Monitoring: Install vibration sensors or use portable analyzers to track vibration levels over time. Set thresholds to trigger alerts when vibrations exceed acceptable limits.

l Lubrication Management: Ensure proper lubrication by monitoring lubricant levels and quality. Use the manufacturer-recommended lubricant type and reapplication intervals to reduce friction and wear.

l Environmental Control: Minimize contamination by maintaining a clean operating environment and using effective seals to protect bearings from dust, debris, or moisture.

l Training and Awareness: Train operators and maintenance personnel to recognize early signs of bearing damage, such as abnormal noises or performance changes, and to report them promptly.

Bearing damage in spindle motors can have significant consequences, but early detection can save both the spindle and the machinery it powers. By staying vigilant for signs such as abnormal noises, increased vibration, performance degradation, and discoloration or odors, operators can identify issues before they escalate. Regular monitoring, proper maintenance, and prompt action are key to ensuring the reliability and longevity of spindle motors. If any of these symptoms are observed, act swiftly to inspect and address the problem, consulting with bearing specialists or the spindle manufacturer as needed to restore optimal performance.

Conclusion

Bearing damage in spindle motors is a stealthy threat that can lead to failure, downtime, and significant costs if left unchecked. By understanding the causes—overload, contamination, and neglect—and using advanced tools like vibration analyzers and imaging technologies, operators can detect issues early and take corrective action. Adhering to maintenance guidelines and implementing environmental controls further protects bearings from harm, ensuring consistent performance and precision. Bearings power the spindle motor, and nurturing them through proactive care and informed strategies is essential for enduring reliability. For tailored solutions, consult with bearing manufacturers or spindle specialists to optimize bearing selection and maintenance for your specific application.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu