CNC (Ɔridinatɛri jatebɔcogo) masinw na ani baarakɛminɛn wɛrɛw la minnu bɛ se ka kɛ ka ɲɛ, servo motɛriw ni spindle motɛriw ye fɛn nafamaw ye minnu bɛ sistɛmu baarakɛcogo ɲɛminɛ. Hali ni u fila bɛɛ ye kuran motɛriw ye minnu nafa ka bon CNC sitɛmuw baara la, u bɛ baara kɛ ni kuntilenna ye min tɛ kelen ye kosɛbɛ, wa u dabɔra ni jogo danfaralenw ye minnu bɛ bɛn u jɔyɔrɔ kɛrɛnkɛrɛnnenw ma. Danfara minnu bɛ servo motɛriw ni spindle motɛriw cɛ, olu faamuyali nafa ka bon kosɛbɛ walasa ka yɔrɔ ɲumanw sugandi, ka masinw ka baara kɛcogo ɲuman sɔrɔ, ani ka ɲɛtaa caman sɔrɔ masinw na minnu bɛ kɛ ka ɲɛ. Nin barokun in bɛ danfaraba don nin mɔtɛri suguya fila ninnu cɛ, k’u ka baarakɛcogo sɛgɛsɛgɛ, u dilanni, u kɛcogo, ani u baarakɛcogo walasa ka jɛya di ɲɛnajɛlajɛlaw, masinw dilannikɛlaw ma, ani ɛntɛrinɛti injiniyɛriw ma.

Servo motɛriw ye mun ye?

Servo motɛriw ye kuran motɛri kɛrɛnkɛrɛnnenw ye minnu dilannen don walasa ka jɔyɔrɔ, teliya, ani girinya tigitigiw kɔlɔsi CNC (ɔridinatɛri jatebɔcogo) masinw na ani ɛntɛrinɛti baarakɛcogo wɛrɛw. U ye fanga ye min bɛ CNC masin ka aksidanw (misali la, X, Y, Z) walima u yɔrɔw lamagacogo tigitigi de bila robo-sitɛmuw kɔnɔ, k’a lajɛ ko baarakɛminɛnw walima baarakɛminɛnw bɛ jɔ i n’a fɔ porogaramulen. Servo Motors tɛ i n’a fɔ standard motors, u bɛ baara kɛ ni kunnafoni-di-minɛnw ye minnu datugulen don, ka baara kɛ ni hakilina-minɛnw ye i n’a fɔ kodɔnnaw walima ɲɛnabɔlaw ka to ka u ka baarakɛcogo kɔlɔsi ani k’a ladilan walasa ka bɛn CNC sitɛmu ka cikanw ma. O tiɲɛni ni ladamuni bɛ kɛ sababu ye ka servo motɛriw kɛ fɛn nafamaw ye baarakɛminɛnw na minnu bɛ lamaga tigitigiw ni kunnafoni dinamikiw de wajibiya iziniw kɔnɔ k’a ta u dilanni na ka se robow ma .

Servo motɛriw dilannen don ni jogo kɛrɛnkɛrɛnnenw ye minnu bɛ se ka kɛ sababu ye ka baara kɛ ni u ye baarakɛcogo la min bɛ se ka kɛ ni tiɲɛni ye. Fɛn kolomaw bɛ duguma minnu b’u ka baarakɛcogo ɲɛfɔ ani k’u ni motɛri suguya wɛrɛw danfara Bɔ ɲɔgɔn na, i n’a fɔ spindle motɛriw:

Servo moteurs dagalenw

bɛ baara kɛ ni sigida datugulen ye, o kɔrɔ ye ko u bɛ jaabi banbali sɔrɔ ka bɔ sensɛriw la (misali la, kodɔnnaw walima ɲɛnabɔlanw) walasa k’u jɔyɔrɔ, u teliya ani u girinya yɛrɛ kɔlɔsi. O hakilina in bɛ suma ni nafa ɲininenw ye minnu bɛ bɔ CNC kunnafonisɛbɛn na, wa danfara minnu bɛ yen, olu bɛ latilen waati yɛrɛ la ni motɛri bɔli ladilanni ye. Nin kunnafoni dagalen in bɛ kɛ sababu ye ka tiɲɛni danma kɛ, ka servo motɛriw kɛ fɛn ɲumanw ye baarakɛyɔrɔw la, hali fɛn misɛnninw bɛ se ka nɔ bila u ka jogo ɲuman na, i n’a fɔ CNC masinw walima robo bolo jɔyɔrɔ.

Servo motɛriw minnu bɛ se ka kɛ ka ɲɛ

, olu bɛ se ka ladilan ni mikro-labɛnni ye, o bɛ kɛ sababu ye ka jɔyɔrɔ tigitigi sɔrɔ ka jigin ka se milimɛtɛrɛ walima degere kelen ma. O ɲɛfɔli in nafa ka bon kosɛbɛ baara dɔw la i n’a fɔ jateminɛ gɛlɛnw kɛli, dingɛ tigitigiw sɔgɔli, walima jɔyɔrɔfalen baarakɛminɛnw CNC masin caman kɔnɔ. Misali la, 5-axis CNC masin na, servo motɛriw b’a lajɛ ko aksidan kelen-kelen bɛɛ bɛ taa ɲɛ ka ɲɛ walasa ka yɔrɔ gɛlɛnw dilan aerospace walima furakɛli baara kama.

Teliya caman ɲɔgɔnna ani torque

servo motɛriw bɛ se ka baara kɛ teliya suguya caman na ani ka torque basigilen di, o b’a to u bɛ se ka kɛ fɛn caman ye baarakɛcogo barikamaw kama. U bɛ se ka teliya, ka teliya, walima ka jɔ joona ka sɔrɔ ka kuntigiya tigitigi mara, o min nafa ka bon baara minnu na, minnu bɛ lamaga teliya la, i n’a fɔ contouring walima threading CNC machining kɔnɔ. O sɛgɛsɛgɛli bɛ kɛ sababu ye ka servo motɛriw bɛ se ka ladamu ni doni caman ye ani ka masinw ɲini.

A ka c’a la, servo moteurs compact design

bɛ kɛ fɛn fitininw ye ani u ka nɔgɔn, u dilannen don walasa u ka se ka don CNC masinw walima robotic systems yɔrɔ gɛlɛnw kɔnɔ. U bonya fitinin bɛ se ka lamaga-lamagali fangama, caman-caman kɛ k’a sɔrɔ u ma girinya kojugu fara masin ka lamaga-lamagali yɔrɔw kan. O nafa ka bon kɛrɛnkɛrɛnnenya la teliyaba baarakɛcogo la, yɔrɔ minnu na fɛnɲɛnamafagalanw dɔgɔyali nafa ka bon kosɛbɛ jaabi ni tiɲɛni na.

Servo motɛri suguyaw

servo motɛriw bɛ sɔrɔ fɛn caman na, u kelen-kelen bɛɛ bɛ bɛn baara kɛrɛnkɛrɛnnenw ma:

AC servo moteurs : A bɛ baara kɛ ni kuran ɲɔgɔnna ye, o motɛriw bɛ sabati ani u bɛ kɛ ka caya izini CNC masinw na u ka fanga ni u ka muɲuli ka bon. U ka teli ka fara ɲɔgɔn kan ni fɛn caman sɛgɛsɛgɛli ye (VFDw) walasa ka u kunbɛn tigitigi.

DC servo moteurs : A bɛ baara kɛ ni kuran tilennen ye, o motɛriw ka nɔgɔn ani u bɛ kɛ tuma caman na baarakɛcogo fitininw na walima minnu tɛ fɛn caman ɲini, i n’a fɔ Hobbyist CNC sigicogo. DC servo motɛriw brushed ka dɔgɔn ka da a ladonni magow kan, ka sɔrɔ brushless versions ka fisa ni baarakɛcogo ɲuman ye.

Brushless DC servo moteurs : Ninnu bɛ DC motɛriw nafaw fara ɲɔgɔn kan ni u ka muɲuli ni u ka baarakɛcogo ɲuman ye, o bɛ burusi mago bɔ. U bɛ baara kɛ kosɛbɛ bi CNC masinw na u ladonni dɔgɔyali n’u baarakɛcogo ɲuman kama.

| servo moteur suguya |

ɲɛfɔli |

pros |

. |

applications |

key characteristics |

| AC Servo Motors . |

O motɛri barikama ninnu bɛ baara kɛ ni kuran caman ye, minnu bɛ kɛ ka kɛɲɛ ni fanga caman ye, minnu bɛ kɛ ka fara ɲɔgɔn kan ni fɛn caman sɛgɛsɛgɛli ye (VFDw) walasa ka teliya tigitigi ni torque control sɔrɔ. |

Sebaaya bɔli, muɲuli ɲuman ka ɲɛsin baarakɛcogo ma, kɔrɔsili tigitigi ni VFDw ye, minnu bɛnnen don baara gɛlɛnw ma. |

Muɲu ka caya ka da motɛrɛ ni VFD ka gɛlɛya kan, senna-tɛgɛrɛ min ka bon, o bɛ sigili ni porogaramu gɛlɛnw de wajibiya. |

Industrie CNC masinw, mansinw dilanni, jirituru, robotiki, ani otomatiki baarakɛlaw ka baarakɛyɔrɔw la. |

Torque (kurunba) ka bon ni teliya dɔgɔman ye, a jɔli barikama, a teliya hakɛ (1000–6.000 rpm), a ka c’a la 1–20 kW fanga hakɛ. |

| DC servo moteurs . |

O motɛriw bɛ baara kɛ ni kuran tilennenw ye, wa u bɛ baara kɛ ni u ye baara fitininw na walima minnu tɛ fɛn caman ɲini. A bɛ sɔrɔ cogoyaw la minnu bɛ kɛ ni bruise walima brushless ye, ni brushed ka dɔgɔ ka da a ladonni magow kan. |

A musaka ka dɔgɔ, a ka nɔgɔn, a ka nɔgɔn, a bɛ se ka baara kɛ ni a ye, a bɛnnen don baarakɛcogo dɔgɔmanw na. |

Seko ni dɔnko danma, burusi buruw bɛ ni ladonniba ye (brush wear), u bɛ se ka sumaya kojugu baara jan kɔnɔ. |

Hobbyist CNC setups, desktop router misɛnninw, otomatiki baara nɔgɔmanw, baarakɛminɛnw minnu fanga ka dɔgɔ i n’a fɔ PCB milling walima yeelenbɔlan. |

Torque duguma, teliya hakɛ bɛ se 2000–10.000 rpm ma, fanga hakɛw bɛ kɛ 0,1–1 kW ye, a tɛ mɛn ka tɛmɛ AC motɛriw kan. |

| Moteurs de DC servo min tɛ burusi ye . |

DC motɛriw kulu fitinin dɔ, olu bɛ baara kɛ ni ɛntɛrinɛti ye burusi nɔ na, o bɛ baara kɛcogo ɲuman ni a muɲuni di. A bɛ baara kɛ kosɛbɛ bi CNC sigidaw la walasa u ka baara kɛcogo ɲuman ani u ladonni dɔgɔyali. |

Baarakɛcogo ɲuman, ladonni dɔgɔyali, ɲɛnamaya jan, dilancogo fitinin, baarakɛcogo ɲuman teliya hakɛ caman na. |

A daminɛ musaka ka bon ni DC motɛriw brushed ye, o bɛ ɛntɛrinɛti kunkankow de wajibiya, fanga ka dɔgɔ ni AC servo motɛriw ye baara gɛlɛnw na. |

CNC routeurs moderne, robotiques précision, 3D imprimantes, médicales, ani applications minnu bɛ dannaya ni tiɲɛniba de wajibiya. |

Baarakɛcogo ɲuman (ka se 90%), teliya hakɛ bɛ se 3000–15000 ma, fanga hakɛ ye 0,5–5 kW ye, funteni dɔgɔyali. |

J1Enamaya CNC masinw na .

CNC sitɛmuw kɔnɔ, servo motɛriw de bɛ fɔlɔ ka masina ka aksidanw ka layini walima u ka wuli-wulicogo kɔrɔsi. I n'a fo:

CNC router kɔnɔ, servo moteurs bɛ X, Y ani Z nɛgɛw boli walasa ka spindle walima tigɛminɛn bila ka ɲɛ baarakɛminɛn kan ka ɲɛ.

CNC lathe kɔnɔ, servo motɛri bɛ se ka baarakɛminɛn jiginni kunbɛn (a bɛ kɛ ni sɔgɔli ye ko dɔw la) walima tigɛminɛn lamagacogo.

Masina caman na, servo motɛriw bɛ se ka lamaga gɛlɛnw kɛ, i n’a fɔ baarakɛminɛn walima baarakɛminɛn jiginni walima a jiginni 4- walima 5-axis cogoyaw la.

U ka se ka lamagacogo tigitigi di, min bɛ se ka segin-ka-bɔ, o b’a to servo motɛriw nafa ka bon walasa ka muɲuli gɛlɛnw mara ani ka fini ɲumanw sɔrɔ baarakɛcogo la i n’a fɔ aerospace, mobili, ani furakɛli minɛnw dilanni. Ni CNC masin ka kunnafoni-falen-falen-minɛn ye ɲɔgɔn Dòn, Servo Motors bɛ G-Code cikanw baara-yɔrɔ-ko Kɛ farikolo-ɲɛnajɛw la, k’a Jira ko masin bɛ tugu baarakɛminɛnw sira ɲininen kɔ ni fili fitinin ye.

Jateminɛ kɛcogo ɲumanw .

Ni aw bɛ Servo Motors sugandi walima ka baara kɛ n’a ye CNC baarakɛminɛnw kɔnɔ, aw bɛ nin fɛn ninnu jateminɛ:

Feedback System : Aw ye a lajɛ ko motɛrɛ ka hakilinata-minɛn (misali la, encodeur resolution) bɛ aw ka baarakɛminɛn ka tiɲɛni wajibiyalenw dafa.

Se ni torque : Aw bɛ motɛrɛ fanga ni a girinya bɛn CNC masin ka doni ni teliya wajibiyalenw ma.

Contrôle system compatibilité : Aw ye a lajɛ ni servo moteur bɛ se ka baara kɛ ni masin ka controleur ye, i n’a fɔ PLC walima CNC porogaramu, walasa ka se ka don ɲɔgɔn na cogo la min tɛ se ka kɛ.

Ladonni : Aw bɛ to ka hakilinaw lajɛ minnu bɛ kɛ ka hakilinaw di, ka wiriya, ani ka ɲɔgɔn sɔrɔ walasa ka baarakɛcogo koɲɛw walima kuran tiɲɛniw bali.

Ni servo motɛriw ka tiɲɛni, u ka kuntigiya ani u ka fɛn caman kɛli ye, CNC baarakɛlaw bɛ se ka tiɲɛni ni baarakɛcogo ɲuman sɔrɔ u ka masinko taabolo la, o bɛ kɛ sababu ye ka o motɛriw kɛ bi fɛnw ye minnu bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye.

Aw bɛ nin yɔrɔ digi walasa ka Spindle Motors san Amazon kan.

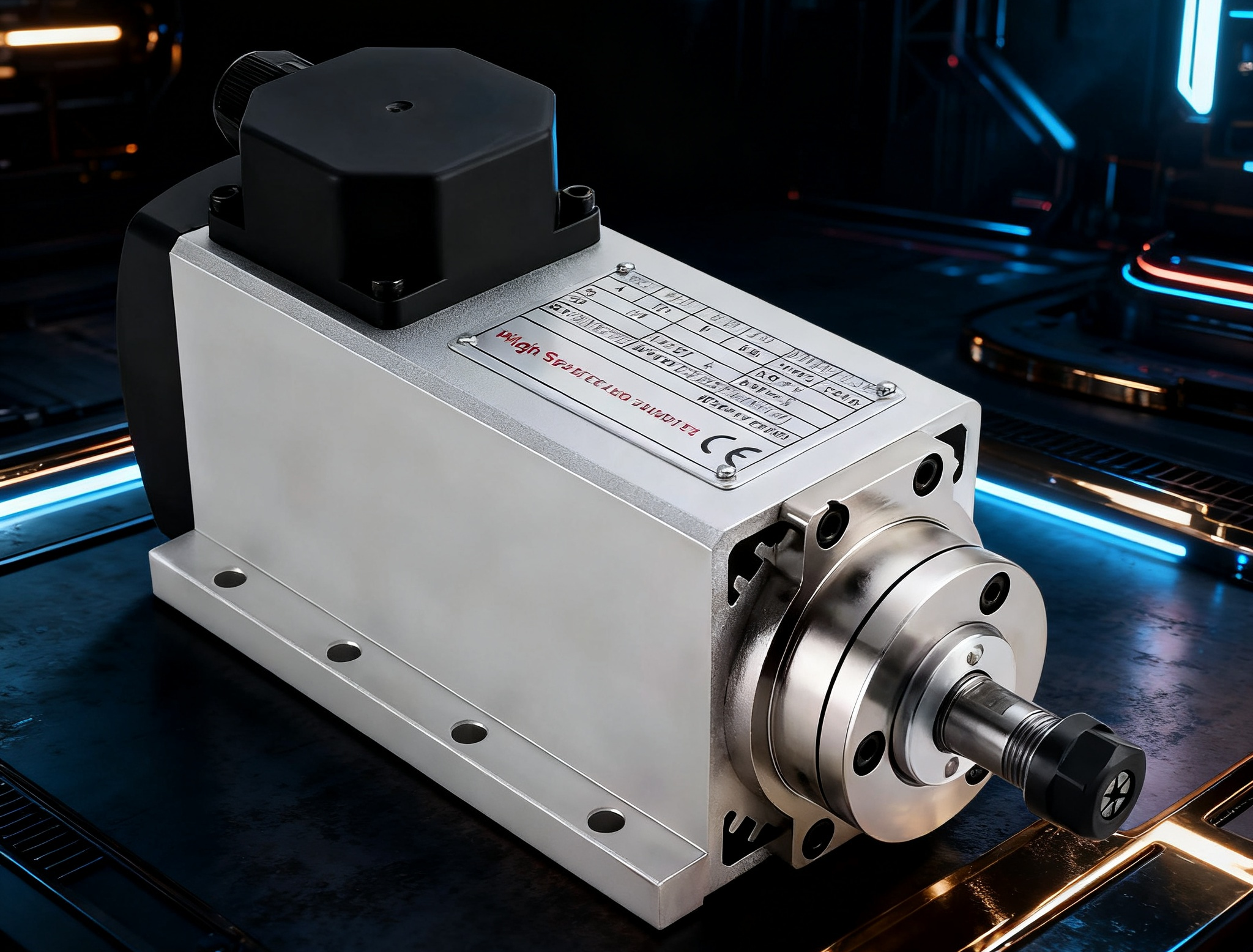

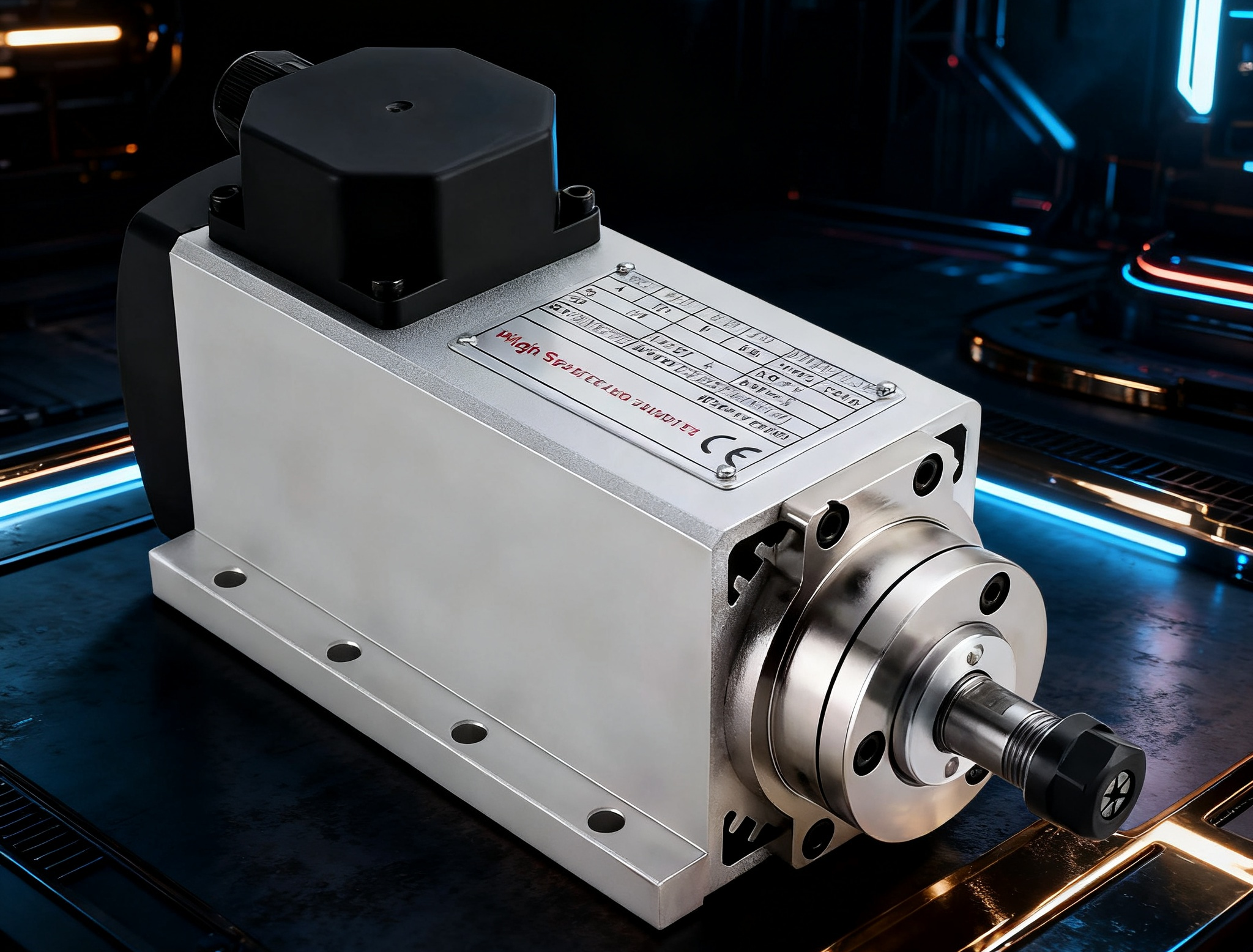

Spindle motɛriw ye kuran motɛri kɛrɛnkɛrɛnnenw ye minnu dilannen don walasa ka tigɛcogo, sɔgɔli, sɔgɔli, walima jabɔcogo boli CNC (ɔridinatɛri jatebɔcogo) masinw na, u kɛtɔ ka tigɛminɛnw walima baarakɛminɛnw wuli teliya la. I n’a fɔ CNC sitɛmuw fangatigi, spindle motɛriw bɛ wuli fanga ni fanga di min ka kan ka kɛ walasa ka fɛnw bɔ baarakɛminɛnw na, o b’a to u nafa ka bon kosɛbɛ walasa ka se ka masina baara kɛcogo, a laban ani a tiɲɛni sɔrɔ. A tɛ i n’a fɔ servo motɛriw, minnu bɛ sinsin jɔyɔrɔko tigitigi kan, spindle motɛriw bɛ ɲɛ ka ɲɛ walasa ka wuli teliya la, min bɛ kɛ teliya la walasa ka fanga sabatilen di baarakɛminɛn walima baarakɛminɛn ma. U dabɔra ka fɛn caman minɛ, k’a ta kungo nɔgɔlenw na ka taa a bila nɛgɛ gɛlɛnw na, wa u nafa ka bon kosɛbɛ baarakɛyɔrɔw la i n’a fɔ fɛn dilanni, jirifeere, ani nɛgɛ baara .

Spindle Motors ka baarakɛcogo jɔnjɔnw .

Spindle motɛriw bɛ jɔ ni jogo kɛrɛnkɛrɛnnenw ye minnu b’a to u bɛ se ka tɛmɛ masinko baara kan min bɛ kɛ ni jiginni teliyaba ye ani fanga dicogo barikama. Fɛn kolomaw bɛ duguma minnu b’u ka baarakɛcogo ɲɛfɔ ani k’u ni motɛri suguya wɛrɛw danfara Bɔ, i n’a fɔ servo motɛriw:

Motɛri minnu bɛ wuli teliya la

, olu dilannen don walasa ka baara kɛ ni jiginniba ye miniti kelen kɔnɔ (RPM), a ka c’a la, u bɛ daminɛ 6000 na ka se 60000 ma walima ka tɛmɛ o kan, ka kɛɲɛ ni a kɛcogo ye. O teliya seko in b’a to u bɛ se ka baara dɔw kɛ i n’a fɔ ja, micro-milling, walima teliyaba tigɛ, yɔrɔ min na baarakɛminɛnw jiginni teliya nafa ka bon kosɛbɛ walasa ka fɛnw tiɲɛ ani ka u kɛ cogo nɔgɔman na. Misali la, spindle motɛri min bɛ baara kɛ ni 24.000 rpm ye, o ka ɲi kosɛbɛ walasa ka fɛn gɛlɛnw ja nɛgɛ walima plastiki kan, k’a sɔrɔ teliya dɔgɔyali (6000–12000 rpm) bɛ bɛn tigɛ baara girinmanw ma i n’a fɔ nɛgɛmugu.

Seko ni dɔnko

Spindle motɛriw ka sinsin fɔlɔ ye ka girinya ni fanga caman di walasa ka fɛnw bɔ ka ɲɛ masinw senfɛ. A bɛ sɔrɔ fanga hakɛw la (0,5–15 kW walima 0,67–20 HP), spindle motɛriw bɛ sugandi ka da fɛn gɛlɛya kan ani masin baara fanga kan. Spindles minnu fanga ka bon, olu bɛ torque (kurunba) di min ka kan ka kɛ ka fɛn caman tigɛ i n’a fɔ titanium (titanium), ka sɔrɔ ka spindles (spindles) minnu fanga ka dɔgɔn, olu bɛ se ka kɛ fɛn nɔgɔmanw ye i n’a fɔ jiri walima fomu. Nin sinsin kɛli fanga dicogo kan, o bɛ baara kɛcogo basigilen sabati doni suguya caman kɔrɔ.

Open-loop walima closed-loop control

spindle moteur caman bɛ baara kɛ da wulilenw na, yɔrɔ min na teliya bɛ kunbɛn ni fɛn caman sɛgɛsɛgɛli ye (VFD) k’a sɔrɔ a ma jaabi di. O bɛ Se ka Kɛ baarakɛcogo la yɔrɔ minnu na jiginni teliya tigitigi ka gɛlɛn ka Tɛmɛ jɔyɔrɔ tigitigi kan. Nka, spindles kɔrɔlenw bɛ se ka baara kɛ ni lock-loop control ye ni feedback minɛnw ye (misali la, encodeurs) walasa ka teliya basigilen mara doni caman jukɔrɔ, ka baara kɛcogo ɲɛ ka ɲɛ kosɛbɛ baara minnu bɛ kɛ ni tiɲɛni ye kosɛbɛ. Open-loop systems ka nɔgɔn ani u musaka ka dɔgɔ, k’a sɔrɔ sigida datugulenw bɛ tiɲɛni caman di baarakɛcogo caman na.

Fɔɲɔ-

minɛnw bɛ funteni caman Bɔ baara janya waati la, kɛrɛnkɛrɛnnenya la teliyaba la walima doni girinmanw kɔrɔ. Walasa k’o ɲɛnabɔ, u bɛ ni nɛnɛbɔlanw ye:

Air-cooled : Aw bɛ fiɲɛbɔlanw walima fiɲɛ laminiw kɛ ka funteni jɛnsɛn, min bɛnnen don baara dɔw ma minnu bɛ kɛ waati ni waati walima minnu bɛ kɛ ni jiri ye i n’a fɔ jiribaara. U ka nɔgɔn ani u sɔngɔ ka nɔgɔn nka u tɛ se ka baara kɛ ka ban.

Ji nɛnɛnen : Aw bɛ nɛnɛmadalan jilama kɛ walasa ka funteni hakɛ ɲuman mara, min ka ɲi teliyaba walima baara minnu bɛ kɛ ni nɛgɛ ye i n’a fɔ nɛgɛ ja. U bɛ funteni bɔli ɲuman di ani ka baara kɛ ka ɲɛ nka u bɛ ladonni wɛrɛw kɛ nɛnɛmadalanw na. Nɛnɛ nafama bɛ funteni bonya bali, ka kɔnɔna yɔrɔw lakana, ka motɛri ɲɛnamaya janya.

Baarakɛminɛn minnu bɛ kɛ ni baarakɛminɛnw

ye, olu bɛ ni baarakɛminɛnw ye, i n’a fɔ ER Collets, BT, walima HSK sitɛmuw, walasa ka tigɛminɛnw lakana i n’a fɔ laban mansinw, jirisunw, walima ja. Baarakɛminɛn minɛyɔrɔ suguya bɛ baarakɛminɛn hakɛ dantigɛ min bɛ se ka kɛ ni spindle ye ani ka nɔ bila masinw ka tiɲɛni ni u ka gɛlɛya la. Misali la, ER Collets bɛ se ka kɛ fɛn caman ye CNC routeurs caman na, ka sɔrɔ HSK tigiw ka fisa teliyaba, izini baarakɛcogo la k’a sababu kɛ u sirili n’u balansi lakananen ye. Bɛn ni CNC masin ka baarakɛminɛnw caman cili ye, o fana nafa ka bon kosɛbɛ walasa ka baara kɛ ka ɲɛ.

J1Enamaya CNC masinw na .

CNC sitɛmuw kɔnɔ, spindle motɛriw de bɛ tigɛminɛn wuli walima, a dɔw la, baarakɛminɛn min bɛ kɛ ka masinw baara. I n'a fo:

CNC router kɔnɔ, spindle motɛri bɛ tigɛminɛn dɔ wuli walasa ka fɛnw ja jiri walima plastiki la.

CNC mansin dɔ kɔnɔ, a bɛ laban-minɛn dɔ Lawuli walasa ka fɛnw Bɔ nɛgɛ baarakɛminɛnw na, ka jateminɛ-ko gɛlɛnw Dabɔ.

CNC lathe kɔnɔ, spindle moteur bɛ se ka baarakɛminɛn wuli ka kɛɲɛ ni tigɛminɛn jɔlen ye walasa ka baara kɛ. U ka se ka teliya ni fanga sabatilen mara, o bɛ kɛ sababu ye ka dugukolo sanfɛla finiw sɔrɔ minnu ka ɲi kosɛbɛ ani ka fɛnw bɔ ka ɲɛ, o b’a to u nafa ka bon baara minnu na, k’a ta mansin gɛlɛnw na ka se ja nɔgɔlen ma.

Jateminɛ kɛcogo ɲumanw .

Ni aw bɛ Spindle Motors sugandi walima ka baara kɛ ni u ye CNC baarakɛcogo la, aw bɛ nin fɛn ninnu jateminɛ:

Teliya ni fanga wajibiyalenw : Aw bɛ spindle ka rpm ni fanga hakɛ bɛn ni fɛn ni baara ye (misali la, teliyaba ka ɲɛsin ja ma, nɛgɛ tigɛcogo ɲuman).

Nɛnɛ magow : Aw bɛ fiɲɛ nɛnɛma sɔgɔlenw sugandi walasa ka u kɛ fɛn ye min musaka ka dɔgɔ, waati ni waati walima ji nɛnɛma bɛ kɛ ka u kɛ baara la min bɛ kɛ tuma bɛɛ, teliya la.

Baarakɛminɛnw minɛcogo ɲuman : Aw ye aw jija Spindle ka baarakɛminɛn minɛbaga ka baarakɛminɛnw dɛmɛ minnu ka kan ka kɛ, wa a bɛ se ka baara kɛ ni masin ka sigicogo ye.

Ladonni : Aw bɛ to ka sɔgɔsɔgɔninjɛ saniya, ka nɛnɛbɔlanw kɔlɔsi, ani ka birikiw lajɛ walasa ka sumaya kojugu, yɛrɛyɛrɛ, walima cɛsirilan sɛgɛnbaliya bali.

Ni u ye teliyaba jiginni, fanga lasecogo barikama, ani fɛn kɛrɛnkɛrɛnnenw dilan minnu bɛ kɛ ni fɛnw ye minnu bɛ kɛ ka fɛnw sɔgɔ, CNC baarakɛlaw bɛ se ka fɛnw bɔli ɲuman sɔrɔ ani ka ɲɛtaa caman sɔrɔ masinko baara caman na, ka se ka lamagacogo tigitigi dafa min bɛ sɔrɔ servo motɛriw fɛ.

Danfaraba minnu bɛ servo motɛriw ni spindle motɛriw cɛ .

Servo motɛriw ni spindle motɛriw ye fɛn nafamabaw ye CNC (ɔridinatɛri jatebɔcogo) masinw na, nka u bɛ baara kɛ ni kuntilenna danfaralenw ye, ni dilancogo ni baarakɛcogo cogoyaw bɛ bɛn u jɔyɔrɔ kɛrɛnkɛrɛnnenw ma. Hali ni Servo Motors bɛ tɛmɛ lamaga-lamagali tigitigi kan ka ɲɛsin jɔyɔrɔfalen masin yɔrɔw ma, spindle motɛriw bɛ ɲɛ ka ɲɛ walasa teliyaba ka wuli ka tigɛ walima ka masinw tigɛ walima ka masinw kɛ. U ka danfara faamuyali fɛn kolomaw kan, n’o ye baarakɛcogo fɔlɔ ye, kɔrɔsili sira, teliya ni girinya, baarakɛcogo, dilancogo ni jɔli, fanga wajibiyalenw, ani hakilinaw dicogo — o nafa ka bon walasa ka motɛri ɲuman sugandi i ka CNC sitɛmu kama ani ka baara kɛcogo ɲuman sɔrɔ. Dugujukɔrɔ, an bɛ nin motɛri suguya fila ninnu suma ɲɔgɔn na k’u ɲɛfɔ, o kɔfɛ, misali nafamaw bɛ sɔrɔ walasa k’u jɔyɔrɔ jira CNC masinw na.

1. Baarakɛcogo fɔlɔ .

Servo Motors : Servo motɛriw dilannen don walasa ka masinw yɔrɔw jɔyɔrɔ, u teliya ani u lamagacogo kɔlɔsi ni tiɲɛniba ye. CNC masinw na, u bɛ masina ka aksidanw (misali la, X, Y, Z) lamagacogo tilennen walima u lamagacogo lamaga, ka baarakɛminɛn kunkolo walima baarakɛminɛn bila ka ɲɛ ka kɛɲɛ ni cikan bolodalenw ye. U ka baara fɔlɔ ye lamaga-lamagali tigitigi ye sanni ka kɛ fanga-dafalen ye.

Spindle Motors : Spindle Motors bɛ dilan walasa ka tigɛminɛnw walima baarakɛminɛnw wuli ni teliyaba ye walasa ka masina baara kɛ i n’a fɔ tigɛ, sɔgɔli, sɔgɔli, walima ja. U bɛ u sinsin fanga ni teliya lasecogo kan min ka kan ka kɛ fɛnw bɔli la walima u cogoya la, ka jiginni kɛcogo bila jɔyɔrɔ fɔlɔ la ka tɛmɛ jɔyɔrɔ tiɲɛni kan.

Danfaraba : Servo motɛriw bɛ masinw yɔrɔw jɔcogo n’u lamagacogo ɲɛnabɔ, ka sɔrɔ spindle motɛriw bɛ wuli-wuli fanga ɲɛminɛ masinko taabolo la.

2. Kunnafoni-falen-falen-yɔrɔ .

Servo Motors : A bɛ baara kɛ ni kunnafoni-falen-falen-minɛn ye min datugulen don, ka baara kɛ ni hakilina-minɛnw ye i n’a fɔ kodɔnnaw walima ɲɛnabɔlanw walasa ka jɔyɔrɔ, teliya ani girinya kɔlɔsi waati yɛrɛ la. CNC kunnafonisɛbɛn bɛ motɛri ka baarakɛcogo yɛrɛ suma ni nafa ɲininenw ye ani ka donnakow ladilan walasa ka fɛn o fɛn bɛ se ka kɛ, o bɛ se ka kɛ sababu ye ka tiɲɛni caman kɛ ani ka segin-ka-bɔ.

Spindle Motors : A ka c’a la, u bɛ baara kɛ ni da wulilenw kunnafoni-di-sira ye, yɔrɔ min na teliya bɛ labɛn ni fɛn caman sɛgɛsɛgɛli ye (VFD) ni jaabi banbali tɛ. Spindle moteurs sanfɛtaw bɛ se ka daga datugulenw kunnafoni ni kodɔnnaw ye walasa ka teliya ladilancogo tigitigi sɔrɔ doni suguya caman kɔrɔ, nka o tɛ caman ye wa a tɛ sinsin jɔyɔrɔfalen kan.

Danfaraba : Servo motɛriw bɛ u jigi da u jɔyɔrɔ dafalen kan walasa ka u jɔyɔrɔ tigitigi sɔrɔ, k’a sɔrɔ spindle motɛriw ka teli ka baara kɛ ni da wulilenw ye minnu bɛ se ka da wuli teliya labɛnni kama, ni dakun datugulen sugandiliw ye baarakɛcogo kɔrɔw kama.

3. Teliya ni girinya .

Servo Motors : A bɛ teliya caman ni girinyaba di, kɛrɛnkɛrɛnnenya la ni teliya dɔgɔman ye, o b’a to u ka ɲi kosɛbɛ lamaga-lamagali fangamaw ma minnu bɛ teliya teliya ni teliya la. A ka ca a la u bɛ baara kɛ ni rpm dɔgɔmanw ye (misali la, 1000–6.000 rpm) ni i ye a suma ni spindle motɛriw ye, ka teliya ka se ka teliya kunbɛn.

Spindle Motors : A dabɔra teliya caman jiginni kama, ni RPMw bɛ daminɛ 6000 na ka se 60000 ma walima ka tɛmɛ o kan, ka kɛɲɛ ni a kɛcogo ye. U bɛ torque (torque) min bɛ Sɔ̀rɔ o la min bɛ Sɔ̀rɔ kà Tigɛ walima kà 'sèn Sɔrɔ, ni baarakɛcogo bɛ Labɛn teliya la doni kɔrɔ sanni ka Kɛ jɔyɔrɔ-falen tigitigiw ye.

Danfaraba : Servo motɛriw bɛ fɔlɔ ka girinyaba bila teliya la lamaga tigitigi kama, ka sɔrɔ spindle motɛriw bɛ sinsin RPM caman kan ni torque basigilen ye masinko baara kama.

4. Baarakɛcogo .

Servo Motors : A bɛ baara kɛ ni aksidan lamaga ye CNC masinw na, robotiki, 3D sɛbɛnnikɛlanw na, ani otomatiki sitɛmuw yɔrɔ minnu na jɔyɔrɔ tigitigi nafa ka bon kosɛbɛ. Misaliw ye baarakɛminɛn kunkolo jiginni ye CNC router kɔnɔ, ka z-axis mara milling machine kɔnɔ, walima ka robow boli ni automatique assembly siraw ye.

Spindle Motors : Baara bɛ kɛ masinw na i n’a fɔ sɔgɔli, sɔgɔli, ja, ani tigɛli, yɔrɔ min na baara fɔlɔ ye fɛnw bɔli walima u cogoya ye. U bɛ sɔrɔ CNC routeurs, milling machines, lathes, ani gravures, driving backers for applications i n’a fɔ jiribaara, nɛgɛ baara, walima PCB dilanni.

Danfaraba : Servo motɛriw bɛ kɛ ka aksidan lamagacogo tigitigi sɔrɔ CNC ni otomatiki siraw la, ka sɔrɔ ka spindle motɛriw boli tigɛ walima ka u cogoya kɛcogo ɲɛnabɔ masinko baara la.

5. A dilanni ni a jɔli .

Servo Motors : A ka surun ani a ka nɔgɔn, a dabɔra teliya ni teliya teliya la axis multi-axis systems kɔnɔ. U bɛ jaabi-minɛnw (misali la, kodɔnnaw) don u kɔnɔ ani u bɛ jɔ walasa ka inertia (inertia) dɔgɔya walasa ka jaabi di. U jɔli bɛ baara kɛcogo ɲuman ni baarakɛcogo barikama bila jɔyɔrɔ fɔlɔ la.

Spindle Motors : A ka bon ani a ka barika ka bon, a jɔlen don walasa ka jiginni teliyaba ni doni sabatilenw muɲu masin dilanni waati. U dɔw ye nɛnɛbɔlanw ye (a bɛ nɛnɛ walima ji nɛnɛna) walasa ka funteni ni baarakɛminɛnw mara (misali la, ER Collets, BT, HSK) walasa ka tigɛminɛnw lakana, ka sinsin muɲuli ni fanga dili kan.

Danfaraba : Servo motɛriw bɛ compact for dynamic, precise motion, ka sɔrɔ spindle motɛriw bɛ sabati ni nɛnɛma siraw ye ani baarakɛminɛnw minɛbagaw ye teliyaba masinw kama.

6. Seko ni dɔnko wajibiyalenw .

Servo motɛriw : A ka c’a la, u bɛ fanga dɔgɔya, ni jatebɔw bɛ daminɛ watti damadɔw la ka se kilowati caman ma (misali la, 0,1–5 kW), ka kɛɲɛ ni a kɛcogo ye. U dabɔra lamaga-lamagali baaraw kama minnu bɛ fanga raw dɔgɔya nka u bɛ se ka tiɲɛni caman ɲini.

Spindle Motors : fanga hakɛ ka ca, a ka c’a la, 0,5 kW fo 15 kW walima ka tɛmɛ o kan (0,67–20 HP), walasa ka tigɛ baara gɛlɛnw boli fɛnw kan i n’a fɔ nɛgɛ, jiri walima fɛnɲɛnamafagalanw. U ka fanga wajibiyalenw b’a jira ko fanga nafama ka kan ka kɛ walasa ka fɛnw bɔ yen ka ɲɛ.

Danfaraba : Servo motɛriw bɛ fanga dɔgɔya lamaga-lamagali kama, ka sɔrɔ spindle motɛriw bɛ fanga caman de wajibiya fɛnw bɔli ni u dilanni na.

7. Feedback fɛɛrɛ .

Servo Motors : Aw bɛ hakilinaw di tuma bɛɛ, i n’a fɔ kodɔnnaw walima ɲɛnabɔlanw, walasa ka kunnafoniw di waati yɛrɛ la jɔyɔrɔ, teliya ani girinya kan. Nin jaabi in bɛ a to a ka se ka kɔrɔsili ni filiw latilen tigitigi, o nafa ka bon kosɛbɛ walasa ka muɲuli gɛlɛnw mara CNC baarakɛcogo la.

Spindle Motors : A bɛ se ka kɛ walima a tɛ se ka kɛ hakilinaw ye. Mɔgɔ caman bɛ baara kɛ k’a sɔrɔ u ma hakilina sɔrɔ da wulilenw na, u bɛ u jigi da VFDw kan teliya kɔlɔsili kama. Spindles kɔrɔlenw bɛ se ka baara kɛ ni kodɔnnaw ye walasa ka teliya sariya dagalen labɛn, nka jɔyɔrɔko jaabi tɛ mako ɲɛ bawo u jɔyɔrɔ ye wulili ye, a tɛ jɔyɔrɔko ye.

Danfaraba : Servo motɛriw bɛ baara kɛ ni hakilinaw ye tuma bɛɛ walasa ka kunnafoni tigitigiw di, k’a sɔrɔ spindle motɛriw ka teli ka u jigi da da wulilenw kan, ni hakilinaw ye minnu bɛ se ka kɛ baara kɛrɛnkɛrɛnnenw kama.

Misali nafamaw CNC masinw kɔnɔ .

Walasa ka servo ni spindle motɛriw jɔyɔrɔw jira ɲɔgɔn na, aw bɛ u ka baara kɛtaw jateminɛ CNC milling masin na min bɛ kɛ cogoya la:

Servo Motors : Aw bɛ masin ka tabali walima baarakɛminɛn kunkolo lamagacogo kɔlɔsi X, Y ani Z bɔgɔlanw kan. Misali la, Servo Motors bɛ baarakɛminɛn kunkolo bila nɛgɛ baarakɛminɛn dɔ kan tigitigi, ka tugu baarakɛminɛn sira bolodalen na walasa ka tigɛcogo tigitigiw sɔrɔ. CNC masin 5 kɔnɔ, servo motɛriw bɛ angular mouvement complexew minɛ, minnu bɛ se ka kɛ sababu ye ka jateminɛ gɛlɛnw kɛ.

Spindle Motor : A bɛ sɔgɔlilan wuli teliya la (misali la, 20.000 rpm) walasa ka fɛnw bɔ baarakɛminɛn na. Spindle motɛri bɛ fanga ni teliya di min ka kan ka kɛ walasa ka nɛgɛw bɔ, ka fɛnw bɔ ka ɲɛ ani ka u ɲɛda kɛ cogo nɔgɔman na.

Misali la : ni nɛgɛ aerospace yɔrɔ dɔ bɛ sɔgɔ, servo motɛriw bɛ baarakɛminɛn kunkolo wuli ka taa coordinates tigitigiw la axes caman kan, ka a lajɛ ni tigɛlan bɛ sira ɲuman ta. O waati kelen na, spindle motɛri bɛ tigɛminɛn lamaga ni 20.000 rpm ye walasa ka fɛnw bɔ, n’a teliya bɛ kɔlɔsi VFD fɛ walasa ka fɛn in cogoyaw n’a tigɛcogo bɛn. O motɛriw faralen ɲɔgɔn kan, u bɛ se ka masin in kɛ ka yɔrɔ gɛlɛn dɔ dilan, min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ.

Sugandili kɛ servo ni spindle motɛriw cɛ .

Motɛri bɛnnen sugandili CNC (ɔridinatɛri jatebɔcogo) sitɛmu walima a baarakɛcogo tigitigi kan, o bɛ se ka kɛ sababu ye ka servo motɛriw ni spindle motɛriw jɔyɔrɔ danfaralenw faamuya. Motɛri suguya kelen-kelen bɛɛ dabɔra baara kɛrɛnkɛrɛnnenw kama CNC masin kɔnɔ, ni servo motɛriw bɛ se ka baara kɛ ni jɔyɔrɔw ye minnu bɛ se ka baara kɛ ni u jɔyɔrɔ ye tigitigi ani ni spindle motɛriw ye minnu bɛ se ka wuli teliya la ani ka fɛnw bɔ. CNC sigida fanba la, o mɔtɛriw tɛ ɲɔgɔn ta nka u bɛ baara kɛ ɲɔgɔn fɛ walasa ka masinw sɔrɔ minnu bɛ tiɲɛ ani minnu bɛ baara kɛ ka ɲɛ. Sugandili min bɛ kɛ servo ni spindle motɛriw cɛ —walima a latigɛ ka o fila bɛɛ lajɛlen kɛ — o bɛ bɔ i ka baarakɛminɛn ka wajibi kɛrɛnkɛrɛnnenw na, i n’a fɔ baara suguya, fɛnw, fɛn tigitigiw, ani sistɛmu labɛncogo. Dugujukɔrɔ, an bɛ jateminɛ jɔnjɔnw ɲɛfɔ walasa ka se ka servo ni spindle motɛriw sugandi ani k’a ɲɛfɔ u bɛ baara kɛ ɲɔgɔn fɛ cogo min na CNC masinw kɔnɔ.

Servo Motors sugandili .

Servo motɛriw ye sugandili ɲuman ye ni i ka baarakɛminɛn bɛ a ɲini ka a jɔyɔrɔ, a teliya ani a girinya kunbɛn tigitigi. U ka kunnafoni-falen-falen-minɛnw, minnu bɛ tali Kɛ hakilinaw-minɛnw na i n’a fɔ kodɔnnaw walima ɲɛnabɔli-minɛnw, olu bɛ lamaga-lamagali tigitigiw ni segin-seginlenw Latigɛ, o b’a To u nafa ka bon baarakɛminɛnw na minnu bɛ lamaga-lamagali fangama wajibiya.

Servo Motors ka kan ka sugandi waati min na:

CNC axis lamaga : servo motɛriw bɛ kɛ ka X, Y, Z, walima aksidan wɛrɛw boli (misali la, A, B 5-axis masinw kɔnɔ) CNC sitɛmuw kɔnɔ, ka baarakɛminɛn kunkolo walima baarakɛminɛn bila ni tiɲɛniba ye. Misali la, CNC router kɔnɔ, servo motɛriw bɛ gantry lamaga walasa ka coordinates tigitigiw tigɛ walasa ka tigɛ walima ka ja.

Robotiki : Robotiki bolow la, servo motɛriw bɛ jogindaw lamagacogo ɲɛnabɔ, ka se ka manipule tigitigi kɛ baara dɔw la i n’a fɔ u lajɛli, u welding, walima u ka pick-and-place baarakɛcogo.

Automation Systems : Servo motɛriw bɛ baara kɛ ni masinw ye minnu bɛ kɛ ni otomatiki ye, i n’a fɔ 3D sɛbɛnnikɛlanw walima fɛnw lasecogo, yɔrɔ minnu na jɔyɔrɔko tigitigi walima teliya kɔlɔsili nafa ka bon kosɛbɛ.

Baara minnu bɛ kɛ ni mikro-labɛnniw ye : Baara minnu bɛ kɛ i n’a fɔ fɛnw dilanni, u dilanni, walima u dilanni masin caman bɛ nafa sɔrɔ servo motɛriw ka seko la ka jɔyɔrɔfalen ɲumanw kɛ.

Jateminɛ jɔnjɔnw:

Precision needs : Servo moteurs sugandi ni kodɔnnaw ye minnu bɛ se ka kɛ fɛn ye (misali la, 10.000 pulses per revolution) walasa ka baarakɛminɛnw sɔrɔ minnu bɛ muɲuli gɛlɛnw ɲini, i n’a fɔ aerospace walima furakɛli minɛnw dilanni.

Torque ni teliya : Aw bɛ a lajɛ ko Servo motɛri ka girinya ni a teliya hakɛw bɛ bɛn masin ka aksidanw doni ni u ka fanga ma. Misali la, baarakɛminɛn girinmanw bɛ se ka kɛ ni motɛriw ye minnu ka bon kosɛbɛ.

Control System Compatibility : Aw ye a lajɛ ni Servo motɛri bɛ se ka baara kɛ ni aw ka CNC controleur walima PLC ye, ka a jira ko a bɛ se ka don ɲɔgɔn na ni masin ka porogaramuw ye.

Ladonni : Aw bɛ to ka sɛgɛsɛgɛli kɛ hakilinaw kan minnu bɛ sɔrɔ hakilinaw kan ani kuran jɛɲɔgɔnyaw walasa ka baarakɛcogo koɲɛw bali, i n’a fɔ encodeur ka ɲɔgɔndanbaliya walima wiring faults.

Misali : 5-axis CNC milling machine kɔnɔ, Servo Motors bɛ baarakɛminɛn kunkolo ni baarakɛminɛn bila ni mililimɛtiri fitinin ye, o bɛ se ka kɛ sababu ye ka jateminɛ gɛlɛnw kɛ aerospace yɔrɔw la.

Sugandili kɛ spindle moteurs .

Spindle motɛriw ye taa-ka-segin sugandili ye ni i ka baarakɛcogo sinsinnen bɛ teliya caman jiginni kan walasa ka tigɛ, ka fɛnw sɔgɔ, walima ka ja kɛ. O motɛriw dabɔra ka fanga ni teliya basigilen di fɛnw bɔli ma, o b’a to u nafa ka bon kosɛbɛ masinko baara la fɛn suguya caman na.

Waati min na ka Spindle Motors sugandi:

Tigɛ ni sɔgɔli : Spindle Motors bɛ tigɛminɛnw boli i n’a fɔ laban mansinw walima router bits walasa ka fɛnw bɔ jiri, nɛgɛ, plastiki, walima fɛnɲɛnamafagalanw na CNC routerw ni mansinw kɔnɔ.

Drilling : U bɛ drill bits wuli teliya la walasa ka dingɛ tigitigiw dilan fɛnw na, i n’a fɔ nɛgɛ walima aluminiyɔmu, mobili walima masin yɔrɔw kama.

Jala : Spindle motɛri teliyaba bɛ kɛ ka baara caman kɛ, i n’a fɔ etching dilancogo biyew, taamasiyɛnw, walima ciriw sɛbɛnnenw (PCB) kan.

Yɛlɛma : CNC lathes kɔnɔ, spindle motɛriw bɛ baarakɛminɛn wuli ka kɛɲɛ ni baarakɛminɛn jɔlen ye walasa ka silinda yɔrɔw cogoya, i n’a fɔ shafts walima fittings.

Jateminɛ jɔnjɔnw:

Fɛnw ni baara : Spindle motɛri sugandi min fanga ka bon (misali la, 0,5–15 kW) ani teliya (misali la, 6000–60.000 rpm) ka ɲɛsin fɛnw ni baara ma. Misali la, fanga caman bɛ minnu na, minnu bɛ nɛnɛ ji la, olu ka ɲi nɛgɛ tigɛcogo la, k’a sɔrɔ fiɲɛ nɛnɛma bɛ bɛn jiriw ma.

Cooling System : Aw bɛ fiɲɛ nɛnɛma sɔgɔlenw sugandi baara dɔw kama minnu bɛ kɛ waati ni waati walima minnu bɛ nɛnɛ ji la walasa ka teliya ka baara kɛ walasa ka funteni kunbɛn ka ɲɛ.

Baarakɛminɛnw minɛcogo : Aw bɛ a lajɛ ko Spindle ka baarakɛminɛnw marayɔrɔ (misali la, ER Collets, HSK) bɛ baarakɛminɛnw dɛmɛ minnu wajibiyalen don, wa a bɛ bɛn masin ka baarakɛminɛnw caman cili ma.

Ladonni : Aw bɛ to ka sɔgɔsɔgɔninjɛ saniya, ka nɛnɛbɔlanw kɔlɔsi, ani ka tulumafɛnw kɛ ka u bali ka kow bali i n’a fɔ cɛsirilan sɔgɔli walima kuran kurukuruw.

Misali : CNC router kɔnɔ, 3 kW ji-nɛnɛ-spindle motɛri bɛ router bit wuli ni 24.000 rpm ye walasa ka patterns intricate intricate jiri gɛlɛnw na mebɛriw dilanni na.

Baara kɛli ni ɲɔgɔn ye CNC masinw na .

CNC masin fanba la, servo motɛriw ni spindle motɛriw bɛ baara kɛ ɲɔgɔn fɛ, k’u fanga dafalenw ta walasa ka masinw sɔrɔ tigitigi ani ka baara kɛ ka ɲɛ:

Servo Motors for Motion Control : Servo Motors bɛ baarakɛminɛn kunkolo walima baarakɛminɛn bila masin ka aksidanw kan, k’a lajɛ ko tigɛminɛn bɛ tugu baarakɛminɛn sira bolodalen na min bɛ tiɲɛniba kɛ. Misali la, u bɛ gantiri lamaga CNC router kɔnɔ walima ka baarakɛminɛnw kɛrɛ ladilan 5-axis masin kɔnɔ.

Spindle Motors for Machining : Spindle Motors bɛ tigɛminɛn walima baarakɛminɛn wuli teliya ni fanga wajibiyalen na walasa ka fɛnw bɔli kɛ, ka tigɛcogo ɲuman sabati, ka fɛnw sɔgɔ, walima ka u ja.

Misali la : CNC milling machine kɔnɔ, servo moteurs bɛ X, Y ani Z axes boli walasa ka nɛgɛ baarakɛminɛn dɔ bila baarakɛminɛn kun kɔrɔ, ka sɔrɔ spindle motɛri bɛ laban mansin dɔ lamaga ni 20.000 rpm ye walasa ka fɛnw bɔ yen, ka yɔrɔ tigitigi dɔ dilan. Servo motɛriw b’a lajɛ ko baarakɛminɛn bɛ sira ɲuman ta, ka sɔrɔ sɔgɔli motɛri bɛ fanga di min ka kan ka tigɛ.

Ladonni jateminɛw .

Servo ni spindle motɛriw ladonni ɲuman nafa ka bon kosɛbɛ walasa ka CNC (ɔridinatɛri jatebɔcogo) masinw ka dannaya, u ka tiɲɛni, ani u ka ɲɛnamaya jan sɔrɔ. Motɛri suguya fila bɛɛ bɛ jɔyɔrɔ danfaralenw na—servo motɛriw walasa ka aksidan jɔyɔrɔ tigitigi sɔrɔ ani ka mɔtɛriw sɔrɔ minnu bɛ se ka fɛnw bɔ teliya la, nka u bɛ to ka ladonni kɛ walasa ka ko dɔw bali i n’a fɔ sɛgɛn, sumaya kojugu, walima kuran filiw, i n’a fɔ kurukuruniw walima cɛsirilanw ka sɛgɛn. Ni baarakɛlaw bɛ ladonni kɛcogo laɲinitaw waleya, baarakɛlaw bɛ se ka baara jɔli waati dɔgɔya, ka masinw tiɲɛni sabati, ani ka nin yɔrɔ kolomaw ɲɛnamaya janya. Dugujukɔrɔ, an bɛ ladonniko jateminɛ kɛrɛnkɛrɛnnenw ɲɛfɔ servo motɛriw ni spindle motɛriw kan, ka fɛɛrɛ tigɛlenw ɲɛfɔ walasa u ka to cogo ɲuman na.

Servo Moteurs .

Servo Motors, minnu ka baara ye ka jɔyɔrɔko tigitigi sɔrɔ CNC masinw na, olu bɛ u jigi da sigida datugulenw kan ni hakilinata-minɛnw ye walasa ka tiɲɛni mara. Ladonni tuma bɛɛ b’a to u ka baara kɛcogo bɛ to cogo kelen na, ka koɲɛw bali minnu bɛ se ka aksidan lamagacogo walima masinw ka tiɲɛni tiɲɛ.

Aw bɛ to ka hakilinaw lajɛ ani ka u jateminɛ (misali la, kodɔnnaw)

servo motɛriw bɛ baara kɛ ni hakilinaw ye i n’a fɔ kodɔnnaw walima ɲɛnabɔlanw walasa ka jɔyɔrɔ, teliya ani girinya kɔlɔsi waati yɛrɛ la. O minɛn ninnu kɔnɔ, u bɛ se ka kɛ fɛn ye min tɛ tiɲɛ, walima ka u sɛgɛn, o bɛ se ka kɛ sababu ye ka filiw kɛ minnu tɛ tiɲɛ ye walima ka filiw kɛ.

Waleyaw:

Aw bɛ kodɔnnaw walima u ɲɛnabɔbagaw sɛgɛsɛgɛ ni buguri, nɔgɔ, walima farikolo tiɲɛniw tɛ minnu bɛ se ka taamasiɲɛw tiɲɛni bali. Aw bɛ a saniya ni finimugu ye min tɛ fɛn kɛ ani min tɛ sɔgɔ.

Aw bɛ hakilinaw jateminɛ waati ni waati ni porogaramuw walima baarakɛminɛnw ye minnu bɛ di u ma, minnu bɛ di walasa ka bɛn CNC ɲɛminɛbaga ma.

Aw bɛ encodeur kabɔriw lajɛ ni u sɛgɛnnen don walima ni u bɛ ɲɔgɔn sɔrɔ, barisa taamasiɲɛw cicogo jugu bɛ se ka kɛ sababu ye ka jɔyɔrɔ fili.

A ka ca a la : aw bɛ a lajɛ ani ka a saniya kalo 3–6 o kalo 3–6 walima baarakɛwaati 500–1000; Aw bɛ a jateminɛ i n’a fɔ a dilannikɛlaw ka laadilikanw, a ka ca a la san o san walima a ladonniba kɔfɛ.

Nafaw : A bɛ jɔyɔrɔ tiɲɛni mara, ka kɔrɔsili filiw bali, ani ka baarakɛcogo basigilen sabati baara dɔw la i n’a fɔ masin caman dilanni walima robotiki.

Aw bɛ a lajɛ ni a sɛgɛnnen don birikiw la ani ni tulu ye i n’a fɔ a mago bɛ cogo min na .

Bearings in servo motors bɛ dɔ bɔ ɲɔgɔnkanu na aksidan teliya lamaga waatiw la, nka sɛgɛn bɛ se ka kɛ sababu ye ka dɔ fara yɛrɛyɛrɛli kan, mankan, walima ka dɔ bɔ a tiɲɛni na. Ni tulumafɛn bɛnnen don, o bɛ sɛgɛn dɔgɔya ani ka baara kɛ ka ɲɛ.

Waleyaw:

Aw bɛ mankanw lamɛn minnu tɛ deli ka kɛ (misali la, sɔgɔli walima sɔgɔli) walima aw bɛ baara kɛ ni jiginni sɛgɛsɛgɛlikɛlan ye walasa ka birikiw sɛgɛncogo dɔn. Yɛrɛyɛrɛli kojugu b’a jira ko a ka kan ka sɛgɛsɛgɛli kɛ walima ka fɛn wɛrɛw bila a nɔ na.

Aw bɛ tulumafɛn (misali la, tulu walima tulu) kɛ birikiw la, ka a lajɛ ni a tɛ se ka tulu kɛ ka tɛmɛ, o bɛ se ka nɔgɔw sama walima ka funteni caman sɔrɔ. Servo motɛri dɔw bɛ baara kɛ ni birikiw ye minnu datugulen don, minnu tɛ tulumafɛnw wajibiya nka u ka kan ka lajɛ ni u sɛgɛnnen don.

Aw bɛ birikiw falen joona walasa ka motɛri walima rotor tiɲɛni bali.

FREQUE (FRESKILE) : Aw bɛ birikiw lajɛ kalo 6 o kalo 6 walima baarakɛwaati 1000; Aw bɛ tulu kɛ a dilannikɛla kelen na, a ka ca a la lɛri 500–1000 o lɛri 500–1000 bɛ sɔrɔ birikiw la minnu tɛ siri.

Nafaw : A bɛ dɔ bɔ ɲɔgɔnkanu na, ka tiɲɛni bali, ani ka motɛrɛ ka ɲɛnamaya janya.

Aw bɛ kuran jɛgɛnw kɔlɔsi walasa ka taamasiyɛnw tiɲɛni walima u balili bali

ka u jigi da kuran ɲɔgɔndan sabatilenw kan fanga ni taamasiyɛnw cili kama ka taa kɔrɔsili ni jaabiw dicogo minɛnw ma. Jɛɲɔgɔnya minnu bɛ lafiya, minnu bɛ sɔgɔ, walima minnu tiɲɛna, olu bɛ se ka kɛ sababu ye ka taamasiyɛnw tiɲɛ, ka u bali, walima ka kuran fili i n’a fɔ kurukuruw.

Waleyaw:

Aw bɛ fanga ni taamasiɲɛ kabɔliw lajɛ ni u bɛ se ka fɛnw tigɛ, ka u sɔgɔ, walima ka u bila yɔrɔ la minnu tɛ u labɔ. Aw bɛ ɲɔgɔndanw siri ani ka kabali tiɲɛnenw falen.

Aw bɛ multimɛtiri kɛ walasa ka a lajɛ ni a bɛ se ka wuli ka bɔ a nɔ na ani ka tɛmɛ ni wiring ye walasa ka fanga dicogo dafalen sɔrɔ.

Shield signal cables from electromagnetic interference (EMI) ni u bɛ taa ni u ye ka bɔ fanga caman yɔrɔw la i n’a fɔ spindle moteurs walima VFDw.

Frequency : Aw bɛ ɲɔgɔndanw lajɛ kalo o kalo walima baarakɛwaati 500 o 500; Aw bɛ sɛgɛsɛgɛli caman kɛ ladonni kɛcogo kɔrɔ la.

Nafaw : A bɛ taamasiɲɛw tiɲɛni bali, ka kuran tiɲɛni farati dɔgɔya, ani ka kumaɲɔgɔnya dafalen sɔrɔ ni CNC ɲɛmɔgɔ ye.

Moteurs de spindle .

Spindle Motors, minnu dabɔra teliya caman jiginni kama ani fɛnw bɔli kama, u bɛ ladonni wajibiya walasa ka funteni, yɛrɛyɛrɛ ani baarakɛminɛnw ɲɛnabɔ. Ladonni ɲuman bɛ baarakɛcogo tiɲɛni ni dɛsɛ musakabaw bali, i n’a fɔ kuran kurukuruw walima masinw tiɲɛni.

Baarakɛminɛnw ni kɔkiliw saniyalenw walasa ka baarakɛminɛnw dilanni baarakɛminɛnw mara

(misali la, ER Collets, BT, HSK) ani Collets Secure Cutting Tools to the Spindle. Nɔgɔ, nɔgɔ, walima tiɲɛni bɛ se ka kɛ sababu ye ka baarakɛminɛnw tiɲɛ (wuli), ka kɛ sababu ye ka masinw cogoya jugu sɔrɔ, ka yɛrɛyɛrɛli caya, walima ka degun sɔrɔ sɔgɔsɔgɔninjɛ kan.

Waleyaw:

Baarakɛminɛn minnu bɛ sɔrɔ ani ka kɔkiliw saniya baarakɛminɛn kelen-kelen bɛɛ kɔfɛ, olu bɛ Changer ni fini ye min tɛ fɛn kɛ ani min tɛ sɔgɔ walasa ka nɛnɛma tolenw, chips, walima buguri bɔ.

Aw bɛ a lajɛ ni aw bɛ sɛgɛn, ni aw bɛ a sɛgɛsɛgɛ, walima ni aw bɛ a sɛgɛsɛgɛ baarakɛminɛn minɛbaga ka taper walima a ka koli la, o bɛ se ka kɛ sababu ye ka ɲɔgɔn sɔrɔ cogo jugu la. Aw bɛ a yɔrɔ tiɲɛnenw falen joona.

Aw bɛ baara kɛ ni dilan jiralan ye walasa ka baarakɛminɛnw bolicogo suman a sigili kɔfɛ; Runout min bɛ tɛmɛ 0,01 mm kan, o bɛ gɛlɛya jira min bɛ a ɲini ka latilen.

Frequency : A bɛ saniya baarakɛminɛn kelen-kelen bɛɛ Changement walima don o don baara gɛlɛn senfɛ; Aw bɛ a lajɛ ni aw bɛ a don kalo o kalo walima baarakɛwaati 500 o 500.

Nafaw : A bɛ masinw ka tiɲɛni mara, ka yɛrɛyɛrɛli dɔgɔya, ani ka sɛgɛn ni baarakɛminɛnw sɛgɛnni bali ka kɔn u waati ɲɛ.

Aw bɛ nɛnɛbɔlanw (fiɲɛ walima ji) mara walasa ka

sɔgɔsɔgɔninjɛ motɛriw bali minnu bɛ sumaya kojugu, olu bɛ funteniba lase u ma teliya la walima u ka baara janyalen na, o bɛ nɛnɛ ɲuman wajibiya walasa ka sumaya kojugu bali, o bɛ se ka kɛ sababu ye ka fɛnw tiɲɛ walima ka u yɔrɔw tiɲɛ.

Waleyaw:

Ni fiɲɛ bɛ sɔrɔ a la : nɛnɛma finmanw ni fiɲɛbɔlanw bɛ to ka buguri walima nɔgɔw bɔ minnu bɛ fiɲɛ bɔli bali. Aw bɛ aw jija fiɲɛbɔlanw ka jɛya walasa ka nɛnɛ kɛcogo ɲuman sabati.

Walasa ka ji nɛnɛma sɔrɔ : Aw bɛ nɛnɛmadalan hakɛw kɔlɔsi jidagayɔrɔ la, ka a sanfɛla kɛ ni ji ye min bɛ kɛ ka a dilan. Aw bɛ hosew, fɛnw, ani nɛnɛ jakite lajɛ ni u bɛ bɔ walima ni u bɛ sɔgɔsɔgɔ. Aw bɛ sistɛmu ko kalo 6–12 o kalo 6 walasa ka nɔgɔ walima jɛgɛw bɔ.

Aw bɛ baara kɛ ni funteni jateminɛ ye walasa ka yɔrɔ funtenimaw dɔn, o b’a jira ko nɛnɛbɔlan nafa tɛ walima ko fili minnu bɛ se ka kɛ.

Frequency : Aw bɛ fiɲɛ-nɛnɛ-sitɛmuw lajɛ dɔgɔkun o dɔgɔkun; Aw bɛ ji nɛnɛma sigidaw kɔlɔsi dɔgɔkun o dɔgɔkun nɛnɛmadalanw hakɛ la ani kalo o kalo walasa ka ji bɔ; Ji-nɛnɛ-sɔgɔsɔgɔninjɛ-minɛnw bɛ sɔrɔ kalo 6–12 o kalo 6.

Nafaw : A bɛ sumaya kojugu bali, ka funteni degunw dɔgɔya wulicogo ni birikiw kan, ani ka spindle lifespan janya.

Monitor bearings for vibration or noise, o b’a jira ko se bɛ se ka kɛ ni

spindle moteur bearings ye, tuma caman na, seramiki walima nɛgɛ, o bɛ teliya jiginni dɛmɛ. A sɛgɛnni walima a balanbaliya bɛ se ka kɛ sababu ye ka yɛrɛyɛrɛ walima ka mankan bɔ, o bɛ na ni tiɲɛni ye, ka cɛsiri kɛ ka cɛsiri kɛ, walima ka farikoloɲɛnajɛ kɛ.

Waleyaw:

Aw bɛ mankanw lamɛn minnu tɛ kelen ye (misali la, sɔgɔli, sɔgɔli) opereli senfɛ, o b’a jira ko u bɛ sɛgɛn walima ko u tɛ bɛn ɲɔgɔn ma.

Aw bɛ baara kɛ ni yɛrɛyɛrɛ sɛgɛsɛgɛlikɛlan ye walasa ka jiginni hakɛw jateminɛ, k’u suma ni dilanbagaw ka basigiw ye walasa ka koɲɛw dɔn joona.

Lubricate bearings per u dilannikɛla ka laadilikanw (n’a ma datugu), ka baara kɛ ni tulu walima tulu kofɔlen ye. Aw bɛ birikiw falen joona walasa ka tiɲɛni bali ka kɛ sɔgɔlilan walima rotor ye.

FREQUETION : Aw bɛ yɛrɛyɛrɛ ni mankan kɔlɔsi don o don walima dɔgɔkun o dɔgɔkun baarakɛtuma na; Aw bɛ sɛgɛsɛgɛli caman kɛ kalo 3–6 o kalo 3–6 walima baarakɛwaati 500–1000.

Nafaw : A bɛ masinw tiɲɛni bali, a bɛ masinw ka tiɲɛni mara, ani ka dɔ bɔ a dilancogo musaka la.

Kuncɛli

Servo motɛriw ni spindle motɛriw ye fɛnw ye minnu nafa ka bon kosɛbɛ CNC (ɔridinatɛri jatebɔcogo) masinw na ani fɛn tigitigiw la, u kelen-kelen bɛɛ bɛ jɔyɔrɔ dafalen nka danfaralen kɛ min bɛ nin sigida ninnu ka baarakɛcogo bɛɛ lajɛlen ɲɛminɛ. Servo Motors bɛ tɛmɛ lamaga-lamagali tigitigi diliko kan, o bɛ kɛ sababu ye ka masinw walima fɛnw jɔyɔrɔ tigitigi di baarakɛcogo la i n’a fɔ CNC masin, robotiki, ani otomatiki. O ni spindle motɛriw tɛ kelen ye, u dilannen don teliya la, fanga caman jiginni kama, o bɛ fanga di min ka kan ka kɛ walasa ka tigɛminɛnw walima baarakɛminɛnw boli baara dɔw kama i n’a fɔ sɔgɔli, sɔgɔli, walima ja. U ka danfara jɔnjɔnw faamuyali fɛ—kunnafoni siratigɛ la, baarakɛcogo, dilancogo, teliya ani girinya jogo, fanga wajibiyalenw, ani hakilinaw dicogo—baarakɛlaw bɛ se ka latigɛw kɛ walasa ka CNC baarakɛcogo ɲɛ ani ka ɲɛtaa caman sɔrɔ.

Servo ni spindle motɛriw ka jɛɲɔgɔnya de bɛ CNC masinw kɛ fɛn ye min bɛ se ka kɛ fɛn caman ye ani min bɛ se ka kɛ. Servo motɛriw b’a lajɛ ko baarakɛminɛn kunkolo walima baarakɛminɛn bɛ bila ni tiɲɛni ye, ka sɔrɔ sɔgɔli motɛriw bɛ wuli fanga di min ka kan ka kɛ walasa ka fɛnw bɔ walima ka u cogoya ɲuman sɔrɔ. Misali la, CNC sɔgɔli masin kɔnɔ, servo motɛriw bɛ X, Y ani Z nɛgɛw mara walasa ka baarakɛminɛn sira tigitigi dɔ tugu, ka sɔrɔ sɔgɔlilan bɛ tigɛminɛn wuli ni teliyaba ye walasa ka yɔrɔ nɔgɔlen, tiɲɛnen sɔrɔ. Motɛri suguya fila ninnu sugandili ɲuman n’u ladonni nafa ka bon kosɛbɛ walasa ka u yɛrɛ tanga kow ma i n’a fɔ cɛsirilan sɛgɛn, kuran kurukuruw, walima masinw ka dɛsɛw, o bɛ a to a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ cogo min na.

Mɔgɔ minnu bɛ CNC sitɛmuw jɔ, ka u sɛmɛntiya, walima ka u baara, aw bɛ aw ka baarakɛcogo ɲinini kɛrɛnkɛrɛnnenw jateminɛ kosɛbɛ—i n’a fɔ fɛn suguya, fɛn tigitigiw, ani baara kɛcogo—ni aw bɛ servo ni spindle motɛriw sugandi. Servo Motors sugandi ni torque bɛnnen ye, ni feedback resolution ye, ani controleur compatibilité ye walasa ka axis control tigitigi sɔrɔ, ani ka spindle moteurs sugandi ni fanga, teliya ani nɛnɛma sira bɛnnen ye walasa ka bɛn i ka masin baara ma. Ladonni tuma bɛɛ, i n’a fɔ saniya, tulumafɛnw, jaabiminɛnw ka jateminɛ kɛ servo motɛriw la, ani nɛnɛbɔlanw ladonni na, o nafa ka bon walasa ka baara kɛcogo sabati ani ka motɛri si hakɛ janya. Ni aw ye servo ni spindle motɛriw fanga dafalenw ta ani ka ladonni nafama waleya, aw bɛ se ka nafa kɛrɛnkɛrɛnnenw sɔrɔ masinw ni otomatiki baara la, ka baarakɛcogo ɲuman, tiɲɛni, ani muɲuli sabati aw ka CNC baarakɛtaw la.

Aw ye nin yɔrɔ digi walasa ka Zhong Hua Jiang ka gafesɛbɛn telesarse.

Zhong Hua Jiang Catalogue 2025.pdf .

Zhong Hua Jiang Catalogue 2025.pdf .

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu