Ku-CNC (amanani e-computer control control) nezinye izinhlelo zobunjiniyela zokunemba, ama-servo motors kanye nama-spindle motors yizakhi ezibalulekile eziqhuba ukusebenza kohlelo. Ngenkathi bobabili yi-Electric Motors ebalulekile ekusebenzeni kwezinhlelo ze-CNC, zisebenza ngezinjongo ezahlukahlukene futhi zenzelwe izici ezihlukile ezihambisana nezindima zazo ezithile. Ukuqonda umehluko phakathi kwama-servo motors kanye nama-spindle motors kubalulekile ekukhetheni izinto ezilungile, ukwenza kahle ukusebenza komshini, nokuthola imiphumela ephezulu yemishini. Le ndatshana idlulela ekuhlukanisweni okusemqoka phakathi kwalezi zinhlobo ezimbili zemoto, icubungula imisebenzi yazo, imiklamo, izinhlelo zokusebenza, kanye nezimpawu zokusebenza ukuhlinzeka ukucaciselwa kwabakwaHobbyists, amamakethi ochwepheshe kanye nonjiniyela.

Yini ama-servo motors?

Ama-servo motors akhethekile kakhulu ama-motor kagesi aklanyelwe ukulawulwa okuqondile kwesikhundla, velocity, ne-torque ku-CNC (amanani wenombolo yamanani) noma ezinye izinhlelo zobunjiniyela. Bangamandla okushayela ngemuva kokunyakaza okunembile kwezimbazo zomshini we-CNC (isib., X, y, Z) noma izakhi ezinhlelweni zamarobhothi, ukuqinisekisa ukuthi amathuluzi noma amathuluzi asebenza kahle njengoba ahlelwe. Ngokungafani nama-motors ajwayelekile, ama-servo motors asebenza ngaphakathi kohlelo lokulawula okuvaliwe, asebenzisa amadivaysi okuphendula anjenge-encoders noma ama-resolvers ukuze aqaphe ngokuqhubekayo futhi alungise ukusebenza kwawo ukuze ahambisane nemiyalo yohlelo lwe-CNC. Lokhu kunembe nokuzivumelanisa nezimo kwenza ama-servo motors asemqoka imisebenzi edinga ukunyakaza okuqondile nokulawulwa okunamandla ezimbonini ezisukela ekwenzeni amarobhothi

I-Servo Motors yenziwe ngezimpawu ezithile ezinika amandla ukusetshenziswa kwazo kuzicelo ezinobumba. Ngezansi kunezici ezibalulekile ezichaza ukusebenza kwazo futhi zizihlukanise kwezinye izinhlobo zezimoto, ezinjenge-spindle motors:

Ukulawulwa kokulawulwa kokuvaliwe kwe-

servo kusebenza ohlelweni oluvaliwe, okusho ukuthi bathola impendulo eqhubekayo kusuka ezinzwa (isib. Le mpendulo iqhathaniswa namanani afunekayo kusuka ohlelweni lokulawula i-CNC, futhi noma yikuphi ukungafani kulungiswa ngesikhathi sangempela ngokulungisa ukuphuma kwemoto. Lokhu kulawulwa okuvaliwe-loop kuqinisekisa ukunemba okuhlukile, okwenza ama-servo motors alungele izinhlelo zokusebenza lapho ukuphambuka okuncane kungathinta ikhwalithi, njengokuma kwemishini ye-CNC noma indawo ye-CNC.

Ukunemba okuphezulu

kwe-servo Motors kuyakwazi ukulungiswa okuncane, okuvumela ukuma okunembile phansi izingxenyana zamamilimitha noma iziqu. Lokhu kunemba kubalulekile emisebenzini efana ne-geometries eyinkimbinkimbi ye-geometries, ukumba izimbobo eziqondile, noma amathuluzi wokubeka emishini ye-CNC ye-multi-axis CNC. Isibonelo, emshinini we-CNC we-CNC we-5-axis, i-servo motors iqinisekisa ukuthi i-axis ngayinye ihamba kahle ukudala izingxenye eziyinkimbinkimbi ze-aerospace noma izinhlelo zezokwelapha.

Ijubane eliguqukayo kanye neTorque

Servo Motors kungasebenza ngaphesheya kwejubane elibanzi futhi ukuletha i-torque engaguquki, kubenze basebenziseka kalula ngezinhlelo zokusebenza ezinamandla. Bangasheshisa, banciphise, noma bayeke ngokushesha ngenkathi begcina ukulawulwa okuqondile, okubalulekile ukuze imisebenzi edinga ukuguqulwa okusheshayo ku-Motion, njengokuthwebula imishini ye-CNC. Lokhu kuguquguquka kuvumela ama-servo motors ukuzivumelanisa nemithwalo ehlukahlukene kanye nezidingo zemishini.

I-compact design

servo motors ijwayele ukuhlangana futhi okulula, yenzelwe ukulingana ngaphakathi kwezikhala ezicindezelwe zemishini ye-CNC noma ama-robotic system. Ubukhulu babo obuncane kwenza ukunyakaza okunamandla, okujikelezayo kwe-axis ngaphandle kokungeza isisindo ngokweqile ezingxenyeni ezihambayo zomshini. Lokhu kubaluleke kakhulu kwizicelo ezisheshisa kakhulu lapho kunciphisa i-inertia kubalulekile ukuphendula kanye nokunemba.

Izinhlobo ze-servo Motors

servo Motors eza ngezinto ezimbalwa ezihlukile, ngalinye lilungele izinhlelo zokusebenza ezithile:

I-AC Servo Motors : Inikwe amandla ngokushintshana kwamanje, la ma-motors aqinile futhi asetshenziswa kakhulu emishini ye-CNC yezimboni ngamandla awo aphezulu nokuqina. Zivame ukubhabhangqwana ngokushayela okujwayelekile okujwayelekile (VFDS) ngokulawulwa okuqondile.

I-DC Servo Motors : Inikwe amandla yi-Direct yamanje, la ma-motors alula futhi avame ukusetshenziswa ezinhlelweni ezincane noma ezifunwayo ezifunwayo, njenge-hobbyist CNC Setups. I-DC Servo Motors ayijwayelekile ngenxa yezidingo zokulungiswa, ngenkathi izinguqulo ezingenamsebenzi zikhethwa ngokusebenza kahle.

I-Brushireless DC Servo Motors : Lokhu kuhlanganisa izinzuzo ze-DC Motors ngokuqina okuthuthukile kanye nokusebenza kahle, ukuqeda isidingo samabhulashi. Zisetshenziswa kabanzi emishinini yanamuhla ye-CNC ngokulungiswa kwazo okuphansi nokusebenza okuphezulu.

| I-Servo motor hlobo |

Development |

Prons |

Cons |

application |

Izici |

| I-AC Servo Motors |

Inikwe amandla ngokushintshana kwamanje, lawa ma-robust motors enzelwe izinhlelo zokusebenza zezimboni eziphakeme, ezivame ukubhangqwa ngama-drivest frequency drives (VFDS) ngejubane eliqondile kanye ne-torque control. |

Ukukhishwa kwamandla okuphezulu, ukuqina kokuqina okuhle kokusebenza okuqhubekayo, ukulawulwa okuqondile ngama-VFS, alungele imisebenzi esindayo. |

Izindleko eziphakeme ngenxa yokuxaka kwezimoto kanye ne-VFD, izinyawo ezinkulu, kudinga ukusetha okuyinkimbinkimbi nohlelo. |

Imishini ye-CNC ye-Industrial CNC, ukugaya okukhulu, ukumba, amarobhothi kanye nezenzekayo ezimbonini zezimoto / ze-aerospace. |

I-torque ephezulu ngejubane eliphansi, ukwakhiwa okuqinile, uhla lwejubane olubanzi (1,000-6,000 rpm), ngokuvamile isilinganiso samandla esingu-1 kuya ku-1 KW. |

| Dc servo motors |

Inikwe amandla yi-Direct yamanje, la ma-motors alula futhi asetshenziswa ezinhlelweni ezincane noma ezifunwa kancane. Kutholakala ekucushweni okuhlanganisiwe noma okungenamkhawulo, okunama-brush ajwayelekile ngenxa yezidingo zokulungisa. |

Okubizayo, kungasindi, amasistimu alula okulawula, alungele izinhlelo zokusebenza ezinamandla aphansi. |

Ukukhishwa kwamandla okulinganiselwe, izinguqulo ezihlanganisiwe zinesondlo esiphakeme (ukugqoka ibhulashi), zithambekele ekushiseni ngokweqile ukusetshenziswa isikhathi eside. |

Ukusetha kwe-CNCS ye-CNC, ama-couters amancane wedeskithophu, imisebenzi elula ezenzakalelayo, izinhlelo zokusebenza ezinamandla aphansi afana ne-PCB milling noma ukubhala okukhanyayo. |

I-torque ephansi, uhla lwejubane le-2000-10,000 RPM, izilinganiso zamandla ngokuvamile 0.1-1 kw, ezingapheli kakhulu kune-ac motors. |

| I-Brushiless DC Servo Motors |

I-subset ye-DC Motors, lokhu kusebenzisa ukuhanjiswa nge-elekthronikhi esikhundleni samabhulashi, kunikeza ukusebenza kahle nokuqina. Kusetshenziswa kabanzi ezinhlelweni zesimanje ze-CNC ngokulinganisela kwazo kokusebenza nokulungiswa okuphansi. |

Ukusebenza kahle okuphezulu, ukulungiswa okuphansi, isikhathi eside sokuphila, ukwakheka okuhle, ukusebenza okuhle kulo lonke uhla lwejubane elikhulu. |

Izindleko eziphakeme zokuqala kunama-motor we-DC Motors, zidinga abalawuli bama-elekthronikhi, amandla amancane kune-AC Servo Motors ngemisebenzi esindayo. |

Ama-routers anamuhla we-CNC, ama-robotic anembile, amaphrinta we-3D, imishini yezokwelapha, kanye nezinhlelo zokusebenza ezidinga ukuthembeka okuphezulu nokunemba. |

Ukusebenza kahle okuphezulu (kuze kube ngu-90%), ububanzi bejubane le-3,000-15,000 RPM, izilinganiso zamandla ezi-0.5-5 kW, isizukulwane esishisayo esishisayo. |

Indima emishini ye-CNC

Kuzinhlelo ze-CNC, ama-Servo Motors abhekene nomsebenzi wokulawula umugqa noma ukunyakaza kwe-rotary kwezimbazo zomshini. Ngokwesibonelo:

Ku-CNC Router, i-Servo Motors ishayela i-X, y, kanye nama-axes okufaka ithuluzi lokusika ngokunembile ngaphezulu komsebenzi.

Kwi-CNC LATE, i-servo motor ingalawula ukujikeleza kwe-workpiece (esebenza njenge-spindle kwezinye izimo) noma ukunyakaza kwethuluzi lokusika.

Emishinini ye-multi-axis, ama-servo motors anika amandla ukunyakaza okuyinkimbinkimbi, njengokuthambisa noma ukujikeleza umsebenzi noma ithuluzi ekucushweni kwe-4 noma ku-5-axis.

Amandla abo okunikeza ukunyakaza okunembile, okuphindaphindiwe kwenza ama-servo motors asemqoka ukubekezelela ukubekezelela okuqinile futhi afinyelele ukuqedela okuphezulu kuzinhlelo zokusebenza ezifana ne-aerospace, izimoto, kanye nokukhiqiza amadivayisi wezokwelapha. Ngokuhlanganisa nohlelo lokulawula lomshini we-CNC, ama-servo motors ahumusha imiyalo ehlelwe kahle ye-G-Code ibe ukunyakaza ngokomzimba, ukuqinisekisa ukuthi umshini ulandela i-Toolt yephutha elincane ngephutha elincane.

Ukucatshangelwa Okusebenzayo

Lapho ukhetha noma usebenzisa ama-servo motors kuzinhlelo zokusebenza ze-CNC, cabanga ngokulandelayo:

Uhlelo Lokuphendula : Qinisekisa idivaysi yokuphendula nge-motor (isib. Ukulungiswa kwe-Encoder) kuhlangabezana nezidingo zokunemba zohlelo lwakho lokusebenza.

Amandla neTorque : Qondanisa amandla we-motor ne-torque kumthwalo nezidingo zejubane lezikhangiso ze-CNC.

Ukulawula uhlelo lokulawula : qinisekisa ukuthi i-servo motor iyahambisana nesilawuli somshini, njenge-software ye-PLC noma i-CNC, ukuqinisekisa ukuhlanganiswa komthungo.

Isondlo : Hlola njalo amadivaysi okuphendula, i-wiring, nokuxhumeka ukuvikela izindaba zokusebenza noma amaphutha kagesi.

Ngokufaka ukunemba, ukulawula, nokuguquguquka kwama-servo motors, abasebenza ngokusebenza kwe-CNC bangafinyelela ukunemba okuhlukile nasekusebenzeni kwemishini yabo, okwenza la ma-motors abe yitshe lesisekelo sobunjiniyela banamuhla obunembile.

Chofoza lapha ukuthenga ama-spindle motors e-Amazon.

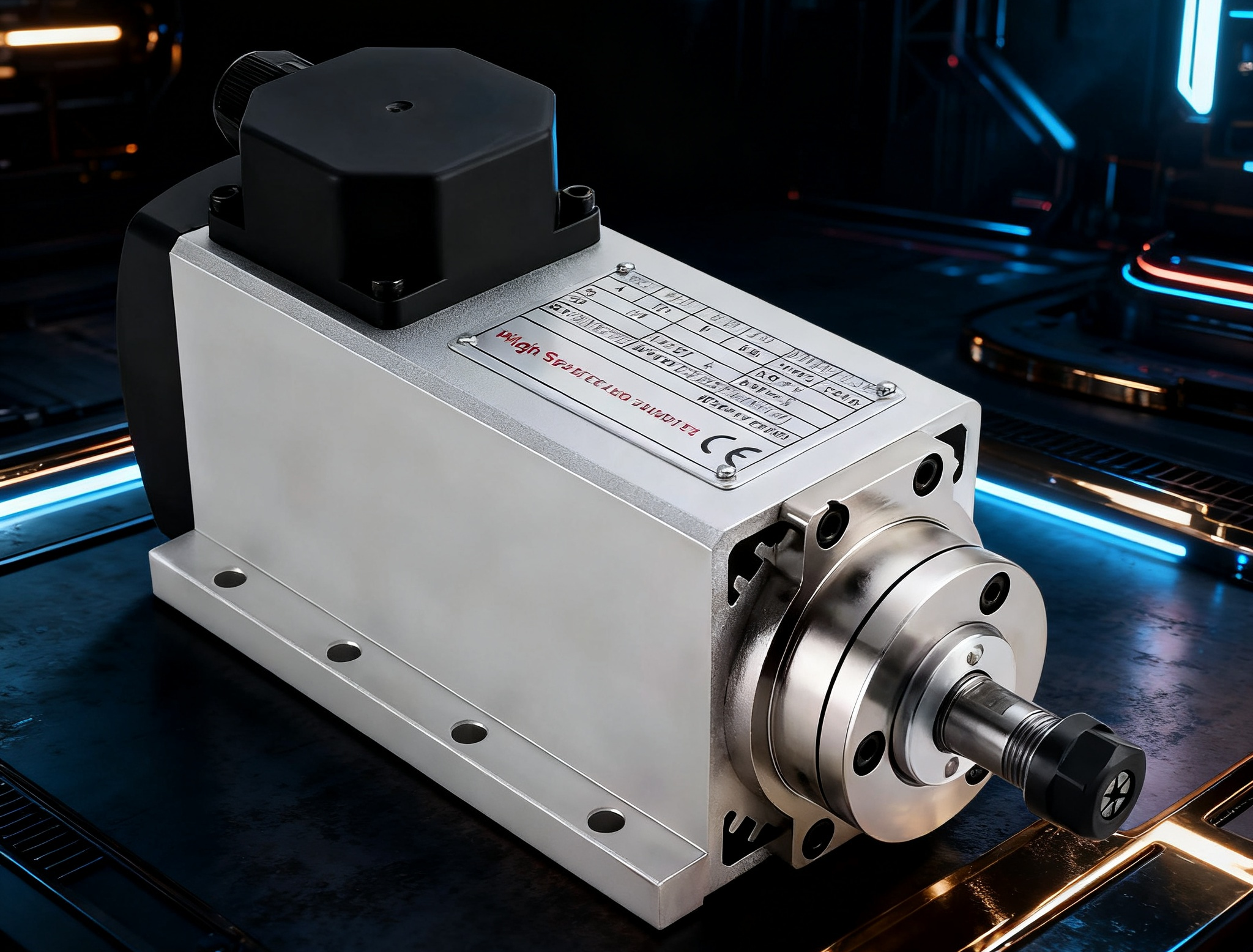

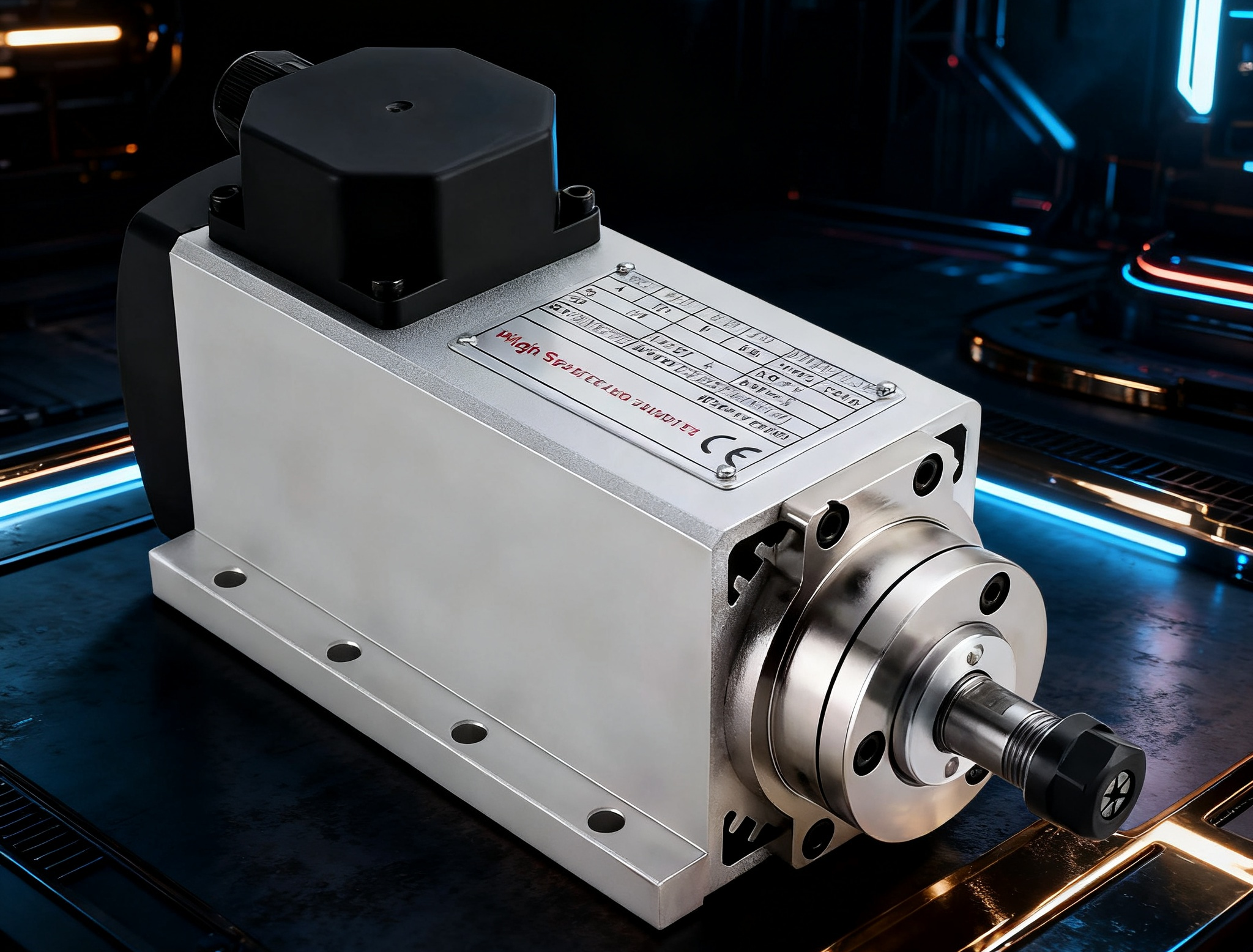

I-Spindle Motors ikhethekile kagesi Motors enjiniyela ukushayela ukusika, ukugaya, ukumba, noma ukubhala izinqubo ku-CNC (amanani wenombolo yamanani) ngamathuluzi okusika ajikelezayo noma ngejubane eliphakeme. Njengomsebenzi we-Powerhouse ye-CNC Systems, ama-spindle motors ahlinzeka ngamandla ajikelezayo namandla adingekayo ukususa impahla evela kwezindawo zokusebenza, ukuzenza abe nzima ngokuthola ukwakheka okufisayo, ukuqeda, kanye nokunemba emisebenzini oyifunayo. Ngokungafani ne-servo motors, egxile ekuphathweni okunembile okuthe xaxa, ama-spindle motors enzelwe ukujikeleza okuqhubekayo, okusheshayo okusheshayo ukuletha amandla angaguquki kuthuluzi noma i-workpiepe. Zenzelwe ukuphatha izinhlobonhlobo zezinto zokwakha, kusuka ehlathini elithambile kuya ezinsimbi ezinzima, futhi zibalulekile kwizicelo ezimbonini ezinjengezimboni ezinjengokukhiqiza, ngokhuni kanye nokusebenza kwensimbi

Izici ezibalulekile ze-Spindle Motors

I-Spindle Motors yakhelwe ngezimpawu ezithile ezibenza bakwazi ukugqama emisebenzini emishini edinga isivinini esikhulu sokushintshana nokulethwa kwamandla okuqinile. Ngezansi kunezici ezibalulekile ezichaza ukusebenza kwazo futhi zizihlukanise kwezinye izinhlobo zezimoto, njenge-servo motors:

Ama-motor ahamba ngesivinini aphezulu

aklanyelwe ukusebenza ngokuguqukela okuphezulu ngomzuzu (i-RPM), ngokuvamile kusuka ku-6,000 kuya ku-60,000 RPM noma ngaphezulu, kuya ngesicelo. Lokhu kwejubane eliphezulu kakhulu kuyabavumela ukuba benze imisebenzi efana nokuqoshwa, ukugaya okuncane, noma ukusika okusheshayo, lapho ukujikeleza kwamathuluzi okusheshayo, lapho ukujikeleza kwamathuluzi okusheshayo kubalulekile ukuze uqede ngokunemba nangokuqedwa okubushelelezi. Isibonelo, i-spindle motor egijima ku-24,000 RPM ilungele ukuqhafaza ama-design ayinkimbinkimbi ngensimbi noma ngeplastiki, ngenkathi ijubane eliphansi (6,000-12,000 RPM) Insimbi Esindayo njengensimbi Yokusika.

Ukulethwa kwamandla

ukugxila okuyisisekelo kwama-spindle motors ukuletha i-torque eyanele namandla okususa ngendlela efanele ngesikhathi semishini. Kutholakala ezinhlobonhlobo zezilinganiso zamandla (0.5-15 kW noma 0.67-20 HP), ama-spindle motors akhethiwe ngokuya ngobulukhuni bokwaziswa kanye nokuqina kwemishini. Izikhonkwane ezinamandla amakhulu zinikeza i-torque edingekayo yokusika izinto eziminyene njenge-titanium, ngenkathi ama-spindle aphansi anele anele izinto ezithambile ezinjengokhuni noma igwebu. Lokhu kugxila ekulethweni kwamandla kuqinisekisa ukusebenza okungaguquki ngaphansi kwemithwalo ehlukahlukene.

Ukuvula okuvulekile noma okuvaliwe-loop kulawulwa

ama-spindle ama-spindle amaningi asebenza ezinhlelweni ezivulekile, lapho ijubane lilawulwa yi-frequency frequency drive (VFD) ngaphandle kwempendulo eqhubekayo. Lokhu kwanele ukufaka izinhlelo zokusebenza lapho ijubane elinembile lokujikeleza lubaluleke kakhulu kunokuma ngqo. Kodwa-ke, ama-spindles athuthukile angasebenzisa ukulawulwa okuvalekile kwamadivayisi afakiwe (isib. Ama-Encoder) ukuze alondoloze isivinini esingaguquki ngaphansi kwemithwalo ehlukahlukene, ethuthukisa ukusebenza emisebenzini enokunemba ephezulu. Amasistimu we-Open-Loop alula futhi abize kakhulu, ngenkathi amasistimu avaliwe-loop anikeza ukunemba okukhulu kwezicelo ezifunwayo.

Ama-Systems apholile

ama-Spindle Motors akhiqiza ukushisa okubalulekile ngesikhathi sokusebenza isikhathi eside, ikakhulukazi ngesivinini esikhulu noma ngaphansi kwemithwalo esindayo. Ukuphatha lokhu, bahlome ngezinhlelo zokupholisa:

I-Air-sedd : Sebenzisa abalandeli noma umoya ohlelekile ukuze ulahlekelwe ukushisa, kufanelekile ngemisebenzi emincane noma ephakathi nendawo enjengokusebenza ngokhuni. Balula futhi bangabizi kakhulu kepha basebenza kangako ekusebenzeni okuqhubekayo.

I-Water-sedd : Sebenzisa okupholile uketshezi ukuze kugcinwe amazinga okushisa afanele, elungele imisebenzi enesivinini esikhulu noma isikhathi eside njengokuqopha kwensimbi. Banikela ngokusetshenziswa okuphezulu kokushisa kanye nokuthula okuthule kepha badinga ukulungiswa okwengeziwe kwezinhlelo ezipholile. Ukupholisa okusebenzayo kuvimbela ukwanda okushisayo, kuvikela izinto zangaphakathi, futhi kwandise impilo yemoto.

Ama-motors okuhambisana nawokuzwana okuhambisana

namathuluzi afakwe amathuluzi, anjenge-er collet, ama-bt, noma ama-HSK amasistimu, ukuvikela amathuluzi okusika anjenge-End Mills, ukushayela, noma ukubhebhethekisa izingcezu. Uhlobo lwe-Holter Holder lunquma uhla lwamathuluzi i-spindle angahlalisa futhi kuthinta ukunemba kwemishini nokuqina. Isibonelo, ama-er collets ahlukahlukene ngama-router e-CNC ajwayelekile, ngenkathi abanikazi be-HSK bethandwa ngesivinini esikhulu, izinhlelo zezimboni ngenxa yokuqubuka nokulinganisela kwabo okuphephile. Ukuhambisana nohlelo lokushintsha ithuluzi le-CNC lomshini nakho kubalulekile ekusebenzeni kahle.

Indima emishini ye-CNC

Kuzinhlelo ze-CNC, ama-spindle motors anesibopho sokujikeleza ithuluzi lokusika noma, kwezinye izikhathi, umsebenzi wokwenza umsebenzi wemishini. Ngokwesibonelo:

Kwi-CNC Router, i-Spindle motor ijikeleza ithuluzi lokusika ukuze libhale amaphethini ngokhuni noma ngopulasitiki.

Emishinini yokugaya kwe-CNC, ishayela isigayo sokuphela ukuze ususe izinto ezivela kwizisebenzi zensimbi, zidale ama-geometries ayinkimbinkimbi.

Kwi-CNC LATE, i-spindle motor ingashintshanisa i-workppiecle ngokumelene nethuluzi lokusika elimisiwe lokuguqula imisebenzi. Amandla abo okugcina isivinini esingaguquki namandla aqinisekisa indawo ephezulu yekhwalithi ephezulu nokususwa okusebenzayo kwezinto, okwenza kube kubalulekile ukuze imisebenzi isukela ekushayweni okusindayo komsebenzi.

Ukucatshangelwa Okusebenzayo

Lapho ukhetha noma usebenzisa ama-spindle motors kuzinhlelo zokusebenza ze-CNC, cabanga ngokulandelayo:

zejubane nezamandlaIzidingo

Izidingo Zokupholisa : Khetha izindonga ezipholile zomoya zokusebenzisa izindleko, ukusetshenziswa kwezikhathi ezithile noma izikhala ezipholile zamanzi zokuqhubeka, okusheshayo okusebenzayo.

Ukuvumelana okuphathekayo kwethuluzi : qiniseka ukuthi umnikazi wamathuluzi we-spindle usekela amathuluzi adingekayo futhi uyahambisana nokusetha komshini.

Isondlo : Hlanza njalo i-spindle, qapha amasistimu wokupholisa, futhi uhlole ama-bearings ukuvikela ukweqiwa ngokweqile, ukudlidliza, noma amabhande ahlasele ngezinkinga.

Ngokuvimbela ukujikeleza okusheshayo, ukulethwa kwamandla okuqinile, kanye nokwakhiwa okukhethekile kwama-spindle motors, abaqhubi be-CNC bangafinyelela ukususwa okusebenzayo kanye nemiphumela ephezulu yokwalulwa kwezinhlelo zokusebenza ezinobubanzi obunikezwe yi-servo motors enikezwe yi-servo motors.

Umehluko Osemqoka phakathi kwe-servo motors kanye nama-spindle motors

Ama-motor we-servo kanye nama-spindle motors zombili izingxenye ezibucayi ku-CNC (amanani e-computer control), kepha zisebenzela izinhloso ezihlukile, ngemiklamo kanye nezimpawu zokusebenza ezihambelana nezindima zazo ezithile. Ngenkathi i-servo Motors ihamba phambili ekuphatheni okunembile kokulawulwa kokuma kwezinto zomshini, ama-spindle motors enzelwe ukujikeleza okusheshayo ukushayela izinqubo zokusika noma zokushayela. Ukuqonda umehluko wabo kuzo zonke izinto ezibalulekile - umsebenzi oyinhloko, uhlelo lokulawula, isivinini kanye ne-torque, izinhlelo zokusebenza, ukuklama kanye nemishini yokuphendula - kubalulekile ekukhetheni imoto efanelekile ngohlelo lwakho lwe-CNC nokusebenza kahle. Ngezansi, siqhathanisa lezi zinhlobo ezimbili zezimoto ngokuningiliziwe, zilandelwa yizibonelo ezingokoqobo zokubonisa izindima zazo emishini ye-CNC.

1. Umsebenzi oyinhloko

I-Servo Motors : I-Servo Motors yakhelwe ukulawula isikhundla, velocity, nokuhamba kwezingxenye zomshini ngokunemba okuphezulu. Kumashini we-CNC, aqhuba ukunyakaza okuqondile noma okujikelezayo kwamambeza omshini (isib. Ukugxila kwabo okuyisisekelo kuphathwe ngokuqondile ukunyakaza kwe-Motion esikhundleni sokulethwa kwamandla okuluhlaza.

I-Spindle Motors : Ama-spindle motors azoshintshana ukuze ajikeleze amathuluzi okusika noma ama-arganies ngesivinini esikhulu ukwenza imisebenzi emishini efana nokusika, ukugaya, ukumba noma ukuqopha. Bagxila ekuletheni amandla nesivinini esidingekayo ekususweni kwezinto ezibonakalayo noma ukwakheka, ukubeka phambili ukusebenza kokushintshana ngokunemba kwesikhashana.

Umehluko osemqoka : I-Servo Motors ilawula ukuma nokunyakaza kwezakhi zomshini, ngenkathi ama-spindle motors ashayela amandla ajikelezayo ngezinqubo zemishini.

2. Uhlelo lokulawula

I-Servo Motors : Sebenza ohlelweni lokulawula ovaliwe, kusetshenziswa amadivaysi okuphendula anjenge-Encoders noma ama-resolvers ukuqapha isikhundla, isivinini, ne-torque ngesikhathi sangempela. Isilawuli se-CNC siqhathanisa ukusebenza kwangempela kwe-motor kumanani afunekayo futhi silungisa okokufaka ukulungisa noma yikuphi ukuphambuka, ukuqiniseka ngokunemba okuphezulu nokuphindaphinda.

I-Spindle Motors : Ngokuvamile sebenzisa amasistimu wokulawula avulekile, lapho ijubane lilawulwa yi-frequency frequency drive (VFD) ngaphandle kwempendulo eqhubekayo. Ama-motors aphezulu we-spindle angafaka phakathi ukulawulwa okuvaliwe kwe-loop ngama-encoders wokulawulwa kwejubane okunembile ngaphansi kwemithwalo ehlukahlukene ngaphansi kwemithwalo ehlukahlukene, kepha lokhu akujwayelekile futhi akugxile ekuphathweni kwezikhathi ezithile.

Umehluko osemqoka : I-Servo Motors intune ekuphathweni okuvaliwe-loop ukuze i-imeyili yokuma okuhle, kanti ama-spindle motors ajwayele ukusebenzisa amasistimu avulekile we-loop ukuze uthole umthetho wejubane, ngezinketho ezivaliwe.

3. Ijubane ne-torque

I-Servo Motors : nikeza isivinini esiguqukayo kanye ne-torque ephezulu, ikakhulukazi ngejubane eliphansi, ukuzenza elungele ukunyakaza okunamandla okudinga ukushesha okusheshayo nokukhohlisa. Ngokuvamile basebenza ngama-rpms aphansi (isib. 1,000-6,000 RPM) ngokuqhathaniswa nama-spindle motors, ukubeka phambili ukulawula ngejubane.

I-Spindle Motors : Yakhelwe ukujikeleza okusheshayo, nge-RPMS esukela ku-6,000 kuya ku-60,000 noma ngaphezulu, kuya ngesicelo. Bahlinzeka nge-torque engaguquki eyenzelwe ukusika noma ukugaya, ngokusebenza okuhambisana nokugcina isivinini ngaphansi komthwalo kunokuba kulungiswa okunembile.

Umehluko osemqoka : I-Servo Motors yabeka phambili i-torque ephezulu ngejubane eliphansi ngokunyakaza okuqondile, ngenkathi ama-spindle motors agxila kuma-RPM aphezulu ane-torque engaguquki yemisebenzi yemishini.

4. Izicelo

I-Servo Motors : isetshenziselwa ukunyakaza kwe-axis emitshinini ye-CNC, ama-robotic, amaphrinta we-3D kanye nezinhlelo ezenzakalelayo lapho ukuma okunembile kubucayi. Izibonelo zifaka ukuhambisa ikhanda lethu lekhanda ku-CNC Router, elawula i-Z-axis emshinini wokugaya, noma ukushayela izingalo zamarobhothi emigqeni yomhlangano ozenzakalelayo.

I-Spindle Motors : Iqashwe ngezinqubo zemisebenzi efana nokugaya, ukumba, ukubhala, nokujika, lapho umsebenzi oyinhloko ukususwa kwezinto ezibonakalayo noma ukwakheka. Zitholakala kuma-routers e-CNC, imishini yokugaya, ama-lathe, kanye nemibhangqwa, amathuluzi okushayela wezicelo ezinjengokusebenza kwensimbi, noma ukukhiqizwa kwe-PCB.

Umehluko osemqoka : I-Servo Motors isetshenziselwa ukunyakaza kwe-axis eqondile ku-CNC kanye nezinhlelo ezenzakalelayo, ngenkathi ama-spindle motors aqhuba izinqubo zokusika noma zokubumba izicelo zemisebenzi.

5. Design nokwakha

I-Servo Motors : I-compact futhi engasindi, yenzelwe ukusheshisa okusheshayo nokukhohlisa ezinhlelweni ze-multi-axis. Bafaka amadivaysi okuphendula ahlanganisiwe (isib. Ama-Encoders) futhi bakhelwe ukunciphisa i-Intertia ngokunyakaza okuphendulayo. Ukwakhiwa kwabo kubeka phambili ukunemba nokusebenza okunamandla.

I-Spindle Motors : Okukhule kakhulu futhi okwengeziwe, okwakhelwe ukubekezelela isivinini esiphakeme sokujikeleza kanye nemithwalo eqhubekayo ngesikhathi semishini. Kubandakanya amasistimu wokupholisa (apholile umoya noma apholile amanzi) ukuphatha abanikazi bokushisa kanye namathuluzi (isib.

Umehluko osemqoka : I-Servo Motors iyi-compact for most enamandla, ukunyakaza okuqondile, ngenkathi ama-spindle motors anamandla ngezinhlelo zokupholisa kanye nabaphethe ithuluzi lejubane eliphakeme.

6. Izidingo zamandla

I-Servo Motors : Ngokuvamile idinga amandla aphansi, ngezilinganiso ezisukela kuma-watts ambalwa ukuya kuma-kilowatts amaningana (isib., 0.1-5 kw), kuya ngohlelo lokusebenza. Zenzelwe imisebenzi yokulawula ukunyakaza efunwa amandla amancane amancane kodwa ukunemba okuphezulu.

I-Spindle Motors : Yiba nezilinganiso eziphakeme zamandla, ngokujwayelekile u-0.5 kw kuya ku-15 kw noma ngaphezulu (0.67-20 HP), ukushayela imisebenzi esezingeni elisheshayo ezintweni ezinjengensimbi, izinkuni, noma ama-composites. Izidingo zazo zamandla zibonisa isidingo samandla aphezulu ukususa impahla kahle.

Umehluko osemqoka : I-Servo Motors isebenzisa amandla aphansi okulawulwa kokunyakaza, kanti ama-spindle motors adinga amandla aphezulu okususwa kwezinto ezibonakalayo kanye nemishini.

7. Indlela Yokuphendula

I-Servo Motors : Faka phakathi izindlela zokuphendula, ezinjengama-encoders noma ama-resolvers, ukuhlinzeka ngedatha yesikhathi sangempela esikhundleni, isivinini, ne-torque. Le mpendulo iqinisekisa ukulawulwa okuqondile kanye nokulungiswa kwephutha, okubucayi kokugcina ukubekezelela okuqinile ku-CNC Operations.

I-Spindle Motors : Meyi noma ingafaki izindlela zokuphendula. Abaningi basebenza ngaphandle kwempendulo ezinhlelweni ezivulekile, zincike kuma-VFDs okulawulwa kwejubane. Ama-spindles athuthukile angasebenzisa ama-enceders wokulawulwa kwesivinini okuvaliwe, kepha impendulo yezithunzi ngokujwayelekile imvamisa ayinasidingo selokhu indima yawo ayiguquki, hhayi kubeka kahle.

Umehluko osemqoka : I-Servo Motors ihlala isebenzisa impendulo ngokulawulwa okuqondile, ngenkathi ama-spindle motors avame ukuncika ezinhlelweni ezivulekile, ngempendulo yokuzikhethela kwezicelo ezithile.

Izibonelo ezingokoqobo emishini ye-CNC

Ukubonisa izindima ezihambisanayo ze-servo ne-spindle motors, cabanga ngemisebenzi yazo emshinini ojwayelekile we-CNC milling:

I-Servo Motors : Lawula ukunyakaza kwetafula lomshini noma ikhanda lamathuluzi eceleni kwe-X, y, kanye no-Z AXES. Isibonelo, ama-servo motors abeka i-Tool Head ngokufanele phezu kwensimbi yensimbi, kulandela i-Toolpath ehleliwe ukuze uqinisekise ukusikeka okunembile. Emshini we-CNC we-5-axis, i-servo Motors ukuphatha ukunyakaza okuyinkimbinkimbi, okunika amandla i-geometries eyinkimbinkimbi.

I-Spindle Motor : Ijikeleza umsiki wokugaya ngejubane eliphezulu (isib. I-spindle motor ihambisa amandla futhi ijubane elidingekayo ukugaya insimbi, ukuqinisekisa ukususwa okusebenzayo kwezinto ezibonakalayo kanye nokuqedwa kwendawo ebushelelezi.

Isibonelo Isimo : Lapho kugaya ingxenye yensimbi ye-aerospace, i-servo Motors ihambisa ikhanda le-Tool to Real Coordinates kanye nama-axes amaningi, ukuqinisekisa ukuthi umsiki ulandela indlela efanele. Ngasikhathi sinye, i-spindle motor spins ithuluzi lokusika ku-20,000 RPM ukususa impahla, ngejubane layo elawulwa yi-VFD ukufanisa izakhiwo zezinto ezibonakalayo kanye nokusika izidingo. Ngokubambisana, laba bantu banika amandla umshini ukukhiqiza ingxenye eyinkimbinkimbi, enobumba.

Ukukhetha phakathi kwe-servo ne-spindle motors

Ukukhetha i-motor efanelekile ye-CNC (uhlelo lokulawula amanani ekhompyutha) noma uhlelo lokusebenza lobunjiniyela bokunemba kudinga ukuqonda izindima ezihlukile zama-servo motors nama-spindle motors. Uhlobo ngalunye lwe-motor lwenzelwe imisebenzi ethile ngaphakathi komshini we-CNC, ngama-servo motors adlula ngokuqondile okuthe xaxa kanye nama-spindle motors enzelwe ukujikeleza okusheshayo nokususwa kwezinto ezibonakalayo. Kuzinhlelo eziningi ze-CNC, la ma-motors awagcini ngokukhethekile kepha asebenzisane ukufezekisa imishini eqondile futhi ephumelelayo. Ukukhetha phakathi kwe-servo kanye nama-spindle motors - noma isinqumo sokuhlanganisa konke-kuncike kwizidingo ezithile zohlelo lwakho lokusebenza, kufaka phakathi uhlobo lomsebenzi, impahla, izidingo zokunemba, kanye nokucushwa kohlelo. Ngezansi, sichaza ukucatshangelwa okubalulekile kokukhetha phakathi kwama-servo kanye nama-spindle motors futhi uchaze ukuthi zisetshenziswa kanjani ngokuvamile emishini ye-CNC.

Ukukhetha ama-servo motors

I-Servo Motors iyindlela efanelekile lapho uhlelo lwakho lokusebenza lifuna ukulawula okuqondile ngaphezulu kwesikhundla, velocity, ne-torque. Izinhlelo zabo zokulawula ezivaliwe, ezincike kumadivayisi wempendulo njengama-encoders noma ama-resolvers, qinisekisa ukunyakaza okunembile nangokuphindaphindiwe, okwenza babalulekile ukuthi imisebenzi edinga ukulawulwa kwe-Most Motion.

Ungakhetha Kanjani I-Servo Motors:

I-CNC AXS Movement : I-Servo Motors isetshenziselwa ukushayela i-X, y, z, noma izengezo ezingezekile (isib. A, b emishini engu-5-axis) kuzinhlelo ze-CNC, ukubeka inhloko yamathuluzi noma indawo yokusebenza ngokunemba okuphezulu. Isibonelo, kwi-CNC Router, i-Servo Motors ihambisa i-gantry ibe izixhumanisi eziqondile zokusika noma ukuqoshwa.

Amarobhothi : Ezingalweni ze-robotic, ama-servo motors alawule ukunyakaza okuhlangene, okwenza ukuba nokukhohlisa okunembile kwemisebenzi efana nomhlangano, ukuthuka, noma imisebenzi yokuthatha indawo.

Izinhlelo ze-automation : I-Servo Motors isetshenziswa emishini ezenzakalelayo, enjengabaphrinti be-3D noma amasistimu wokuhambisa, lapho ukuma okunembile noma ukulawulwa kwejubane kubalulekile.

Izicelo ezidinga ukulungiswa kwe-micro-micro : imisebenzi efana ne-highting, ukuthuthumela, noma inzuzo ye-multi-axis machining kusuka kumandla we-servo motors ukwenza ushintsho oluhle.

Ukucatshangelwa okubalulekile:

Izidingo zokunemba : Khetha ama-servo motors anama-encomer aphezulu (isib. I-10,000 pulses ngenguquko ngayinye) izicelo ezidinga ukubekezelelana okuqinile, njengokukhiqiza amadivaysi ezokwelapha noma e-Medical device device.

I-Torque ne-Speed : Qinisekisa ukuthi i-vorso motor motor i-torque kanye nezilinganiso zejubane liqondanisa umthwalo kanye nezidingo ezinamandla zama-axes omshini. Isibonelo, izindawo zokusebenza ezisindayo zingadinga ama-motor aphezulu we-torque.

Ukulawulwa kohlelo lokulawula : Qinisekisa ukuthi i-servo motor iyahambisana nesilawuli sakho se-CNC noma i-PLC, iqinisekise ukuhlanganiswa komthungo nesoftware yomshini.

Isondlo : Hlela ukuhlolwa okujwayelekile kwamadivayisi okuphendula kanye nokuxhunywa ngogesi ukuvikela izindaba zokusebenza, njengokuhlasela kokuhlaseli noma amaphutha we-wiring.

Isibonelo : Emishinini ye-CNC-axis CNC yokugaya, i-Servo Motors ibeka ikhanda lamathuluzi kanye nokusebenza kwe-Millimeter ngokunemba, okunika amandla i-geometries eyinkimbinkimbi yezingxenye ze-aerospace.

Ukukhetha ama-spindle motors

I-Spindle Motors yi-Go-to Choil lapho uhlelo lwakho lokusebenza lugxila ekujikelezeni okusheshayo ukuze ushayele ukusika, ukumba, noma izinqubo zokuqopha. Lawa ma-motors aklanyelwe ukuletha amandla angaguquki kanye nesivinini sokususwa kwezinto ezibonakalayo, ukuzenza ukuba abucayi ngemisebenzi emishini kuzo zonke izinto ezahlukahlukene.

Ukukhetha nini ama-spindle motors:

Ukusika nokugaya : Amathuluzi we-spindle drive cutting amathuluzi anjenge-End Mills noma ama-router bits ukususa impahla ngokhuni, insimbi, epulasitiki, noma ama-composites kuma-CNC Routers nemishini yokugaya.

Ukushayela : Bajikeleza ama-drill bits ngejubane eliphezulu ukudala izimbobo eziqondile ezintweni zokwakha, njengensimbi noma i-aluminium, izingxenye zezimoto noma zemishini.

Ukuqopha : Ama-spindle asheshe asetshenziselwa umsebenzi onemininingwane, njengoku-etching design ngobucwebe, izibonakaliso, noma amabhodi wesifunda aphrintiwe (ama-PCB).

Ukujika : Ku-CNC Lages, ama-spindle motors ajikeleza i-workpiece ngokumelene nethuluzi lokumisa ukulola izingxenye ze-cylindrical, njengezinhlanzi noma ukufakwa.

Ukucatshangelwa okubalulekile:

Material and Task : Khetha i-spindle motor ngamandla anele (isib. 0.5-15 kw) nesivinini (isib. 6,000-60,000 RPM) ngokoqobo nomsebenzi. Isibonelo, amandla aphezulu, izikhonkwane ezipholile amanzi zilungele ukusika insimbi, ngenkathi izikhala ezipholile zomoya zihambisana nokhuni.

Uhlelo lokupholisa : Khetha izindonga ezipholile zomoya zemisebenzi emincane noma imichilo epholile yamanzi yokuqhubeka, okusheshayo okusebenzayo ukuphatha ukushisa ngempumelelo.

Ukuvumelana okuphathekayo kwethuluzi : qinisekisa umnikazi wamathuluzi we-spindle (isib.

Isondlo : Hlanza njalo i-spindle, qapha amasistimu wokupholisa, bese uthambisa ama-bearings ukuvikela izindaba ezinjenge-BEBT SLACKINGING noma amasekethe amafushane kagesi.

Isibonelo : E-CNC Router, i-3 KW motor ye-spindle motor ijikeleza i-router kancane ku-24,000 RPM ukuze ibambe amaphethini ayinkimbinkimbi e-Hardwood Production.

Ukusetshenziswa okuhlanganisiwe emishini ye-CNC

Emishinini eminingi ye-CNC, ama-servo motors kanye nama-spindle motors asetshenziswa ndawonye, aqinisekise amandla abo okuhambisana nokuthola imininingwane eqondile nesebenza kahle:

I-Servo Motors yokulawula ukunyakaza : I-Servo Motors ibeka ikhanda lamathuluzi noma i-workpiepe emasondweni omshini, ukuqinisekisa ukuthi ithuluzi lokusika lilandela i-Toolpath yohlelo ngokunemba okuphezulu. Isibonelo, bahambisa i-gantry ku-CNC router noma balungise ithuluzi lamathuluzi emshinini we-5-axis.

I-Spindle Motors for Machching : Spindle Motors zishintshanisa ithuluzi lokusika noma i-workpiepe ngejubane elidingekayo namandla okwenza ukususwa kwezinto ezibonakalayo, ukuqinisekisa ukusikwa okusebenzayo, ukumba, noma ukuqoshwa.

Isibonelo Isimo : Kumshini we-CNC Minsing, i-Servo Motors Drayivu i-X, y, kanye noZ Ama-servo motors aqinisekisa ukuthi ithuluzi lilandela indlela eyiyo, ngenkathi imoto ye-spindle ihambisa amandla adingekayo ngokusika.

Ukucatshangelwa Kwesondlo

Ukulungiswa okufanele kwe-servo kanye nama-spindle motors kubalulekile ekuqinisekiseni ukuthembeka, ukunemba, kanye nokuphila isikhathi eside kwe-CNC (amanani wenombolo yamanani e-computer). Zombili izinhlobo zezimoto zisebenzela izindima ezihlukile ze-servo Motors zokuma okunembile kwe-Axis Ngokusebenzisa imikhuba yokulungisa okuhlosiwe, abahlinzeki banganciphisa isikhathi sokuphumula, qhubeka nokunemba kwemishini, futhi bandise isikhathi sokuphila kwalezi zinto ezibucayi. Ngezansi, sichaza ukucatshangelwa okuqondile kokulungiswa kwama-motor we-servo kanye nama-spindle motors, kuchaza izinyathelo ezisebenzisekayo ukuze uzigcine esimweni esifanele.

I-Servo Motors

I-Servo Motors, ebhekele ukulawulwa okuqondile kokungemuva kwemishini ye-CNC, incike ezinhlelweni ezivaliwe zeLoop ngamadivayisi okuphendula ukuze alondoloze ukunemba. Isondlo ejwayelekile iqinisekisa ukusebenza kwayo ihlala ihlala iguquguqukayo, ukuvikela izingqinamba ezingavumelanisa ukunyakaza kwe-axis noma ukucaciswa kwemishini.

Hlola njalo futhi ulinganise amadivaysi okuphendula (isib. Ama-Encoders)

Ama-Servo Motors asebenzisa amadivaysi okuphendula njengama-encoders noma ama-resolvers ukuqapha isikhundla, isivinini, ne-torque ngesikhathi sangempela. Ukuphathwa kabi, ukungcola, noma ukugqokwa kwalawa madivayisi kungaholela ekumiseni okunembile noma amaphutha okulawula.

Izenzo:

Hlola ama-encoders noma aphoxe ngothuli, imfucumfucu, noma ukulimala komzimba okungaphazamisa ukunemba kwesiginali. Hlanza ngendwangu yama-lint-free kanye nesihlanza esingawonakanayo.

Linganisa amadivaysi okuphendula ngezikhathi ezithile usebenzisa isoftware noma amathuluzi anikelwe ngumakhi wokuqinisekisa ukuhambisana nomlawuli we-CNC.

Hlola izintambo ze-encoder ukuze ugqoke noma ukuxhumana okuvulekile, njengoba ukudluliswa kwesiginali okungalungile kungadala amaphutha wokubeka.

Imvamisa : Hlola futhi uhlanze njalo ezinyangeni ezi-3-6 noma amahora angama-500-1,000 okusebenza; Zilinganise ngokwemihlahlandlela yomenzi yomenzi, ngokujwayelekile ngonyaka noma ngemuva kokulungiswa okukhulu.

Izinzuzo : Kugcina ukunemba kwesikhashana, kuvimbela amaphutha okulawula, futhi kuqinisekisa ukusebenza okungaguquki kwimisebenzi efana nemishini ye-multi-axis noma amarobhothi.

Hlola ukugqokwa ku-bearings bese ugcoba njengoba kudingeka

Ama-Bearings e-Servo Motors anciphisa ukungqubuzana ngesikhathi sokunyakaza okusheshayo, kepha ukugqoka kungaholela ekutheni ukwenyuka kokudlidliza, umsindo, noma ukucaciswa okuncishisiwe. Ukuthambisa okufanele kunciphise ukugqoka futhi kugcina ukusebenza okubushelelezi.

Izenzo:

Lalela imisindo engajwayelekile (isib. Ukugaya noma ukuthambisa) noma usebenzise inhlawulo yokudlidliza ukuthola ukugqoka. Ukudlidliza ngokweqile kukhombisa isidingo sokuhlolwa noma ukushintshwa.

Faka isicelo sokuthambisa okunconyelwe umkhiqizi (isib. Amanye ama-servo motors asebenzisa amabhere avaliwe adinga ukugcotshwa kepha kufanele ahlolwe.

Faka esikhundleni izimbotshana ezigqokwa ngokushesha ukuvikela ukulimala kwemoto noma e-rotor.

Imvamisa : Hlola ama-bearings njalo ezinyangeni eziyi-6 noma amahora ayi-1 000 okusebenza; Gcoba ngemininingwane yomakhi, imvamisa njalo ngamahora angama-500-1,000 amabhere angavaliwe.

Izinzuzo : Yehlisa ukungqubuzana, kuvimbela ukulimala okuvezwe ukudlidliza, futhi kunwebe isikhathi sokuphila kwemoto.

Gada ukuxhumeka kukagesi ukuvikela ukulahleka kwesiginali noma ukuhlukaniswa kwe

-servo Motors ancike ekuxhumekeni kukagesi ezinzile kwamandla nokudluliselwa kwesiginali kwizilawuli zempendulo. Okuxekethile, okuhlangene, noma ukuxhumeka okulimele kungadala ukulahleka kwesiginali, ukuphazamiseka, noma amaphutha kagesi afana nemibuthano emifushane.

Izenzo:

Hlola amandla nezintambo zesiginali zokuthambisa, ukugqwala, noma ama-terminals axegayo. Qinisekisa ukuxhumeka bese ubeka kabusha izintambo ezilimele.

Sebenzisa i-multimeter ukubheka i-voltage engaguquki nokuqhubeka kwe-wiring ukuqinisekisa ukulethwa kwamandla okuthembekile.

Izintambo zesiginali yesivikelo kusuka ekuphazanyisweni kwe-elekthronikhi (i-EMI) ngokuzihambisa kude nezingxenye zamandla aphezulu njenge-spindle motors noma ama-VFD.

Imvamisa : Bheka ukuxhumana njalo ngenyanga noma amahora angama-500 okusebenza; Yenza ukuhlolwa okuningiliziwe ngesikhathi semijikelezo yokulungisa ejwayelekile.

Izinzuzo : Vimbela ukulahleka kwesiginali, kunciphisa ingozi yamaphutha kagesi, futhi kuqinisekise ukuxhumana okuthembekile nesilawuli se-CNC.

Spindle motors

I-Spindle Motors, yenzelwe ukujikeleza okusheshayo nokususwa kwezinto ezibonakalayo, dinga ukulungiswa ukuphatha ukushisa, ukudlidliza kanye nezinkinga ezihlobene nethuluzi. Ukunakekelwa okufanele kuvimbela ukonakaliswa kokusebenza nokuhluleka okubizayo, okufana nemibuthano emifushane kagesi noma ukulimala kwemishini.

Ama-Hlaluzi lokuhlanza amathuluzi okuvimbela

abanikazi bamathuluzi wamathuluzi wokugijima (isib. Ukungcola, imfucumfucu, noma umonakalo kungadala ithuluzi lamathuluzi (i-bubbling), okuholela kwikhwalithi yokwebiwa kwemishini, ukwengeza ukudlidliza, noma ukucindezela esiqwini.

Izenzo:

Abanikazi bethuluzi elihlanzekile nama-collets ngemuva kokushintsha kwethuluzi ngalinye besebenzisa indwangu yamahhala ye-lint kanye nokuhlanzeka okulimazayo ukususa izinsalela ezipholile, ama-chip, noma uthuli.

Hlola ukugqokwa, ama-dents, noma ukuklwebheka ku-taper yomnikazi wamathuluzi noma i-collet yamathuluzi, okungadala ukuphathwa kabi. Faka esikhundleni izingxenye ezilimele ngokushesha.

Sebenzisa inkomba yokudayela ukukala i-TOOL RUNOUTAUT ngemuva kokufakwa; I-Runtout idlula i-0.01 mm ikhombisa inkinga edinga ukulungiswa.

Imvamisa : Hlanza ngemuva kokushintshwa kwamathuluzi noma nsuku zonke ngesikhathi sokusetshenziswa kanzima; Hlola ukugqoka njalo ngenyanga noma amahora angama-500 okusebenza.

Izinzuzo : Igcina ukunemba kwemishini, yehlisa ukudlidliza, futhi ivimbele ukugqoka ngaphambi kwesikhathi ku-spindle namathuluzi.

Gcina izinhlelo zokupholisa (umoya noma zamanzi) ukuvikela

ukushisa ngokweqile ama-spindle motors ngesikhathi sokushisa okuphezulu noma ngokusebenza isikhathi eside, edinga ukupholisa okusebenzayo ukuvikela ukonakala ngokweqile noma ukwehluleka kwengxenye.

Izenzo:

Okwezifiso ezipholile zomoya : Hlanza amaphiko okupholisa kanye nabalandeli njalo ukuze ususe uthuli noma imfucumfucu evimba umoya. Qinisekisa ukuthi ama-vents acacile ukuze alondoloze ukusebenza kahle kokupholisa.

Okwe-Spindles Elehlile Amanzi : Gada amazinga apholile ku-reservoir, uphakamisa uketshezi olunconyiwe lomkhiqizi. Hlola ama-hoses, ukufakwa, kanye nejakhethi epholile yokuvuza noma ukugqwala. Flush uhlelo njalo ezinyangeni ezi-6 kuya kwezi-12 ukususa i-sediment noma i-algae.

Sebenzisa ukucabanga okushisayo ukuthola izindawo ezishisayo, okukhombisa ukungasebenzi kahle kohlelo lokupholisa noma amaphutha angaba khona.

Imvamisa : Bheka amasistimu apholile womoya masonto onke; Gada amasistimu apholile amanzi masonto onke ngamazinga apholile kanye nakwenyanga okuvuzayo; Amasistimu apholile amanzi njalo ezinyangeni eziyi-6 kuya kwezi-12.

Izinzuzo : Kuvimbela ukushisa ngokweqile, kunciphisa ukucindezelwa okushisayo kuma-windings kanye nasebhejisweni, futhi kunwebe isikhathi sokuphila kwe-spindle.

Ukuqapha ama-bearings wokudlidliza noma umsindo, okubonisa ukuthi kungenzeka ukugqoka

izimoto ze-spindle motor, imvamisa u-ceramic noma insimbi, uxhase ukujikeleza okusheshayo. Ukugqoka noma ukungalingani kungadala ukudlidliza noma umsindo ngokweqile, okuholela ekunciphiseni ukunemba, ukuncipha kwebhande, noma ukulimala kwezimoto.

Izenzo:

Lalela imisindo engajwayelekile (isib. Ukugaya, ukugqama) ngesikhathi sokusebenza, okukhombisa ukugqoka noma ukuphathwa kabi.

Sebenzisa ukuhlaziya okudlidliza ukukala ukuthwala amazinga okudlidliza, kuqhathanise kubo abakhiqizi bamakhasimende ukuthola izindaba kusenesikhathi.

Lubricate bezala ngemihlahlandlela ngayinye yomenzi (uma ingavaliwe), isebenzisa amafutha acacisiwe noma uwoyela. Faka esikhundleni izimbotshana ezigqokwa ngokushesha ukuvikela ukulimala kwe-spindle shaft noma e-rotor.

Imvamisa : qapha ukudlidliza nomsindo nsuku zonke noma masonto onke ngesikhathi sokusebenza; Yenza amasheke anemininingwane enemininingwane njalo ezinyangeni ezi-3-6 noma amahora angama-500-1,000 asebenza.

Izinzuzo : Vimbela ukwehluleka kwemishini, kugcina ukunemba kwemishini, futhi kunciphisa ubungozi bokulungiswa okubizayo.

Ukugcina

Ama-motors we-servo kanye nama-spindle motors ayizinto ezisemqoka ku-CNC (amanani okulawula amanani) nezinhlelo zobunjiniyela zokunemba, ngalinye lidlala indima ehambisanayo kodwa ehlukile eshayela ukusebenza kwalezi zinhlelo. I-Servo Motors Excer ekuletheni ukulawulwa okuqondile okuqondile, inika amandla ukuma okunembile kwezimbazo zomshini noma izakhi kuzinhlelo zokusebenza ezinjengezimashini ze-CNC, amarobhothi kanye ne-automation. Ngokuphambene nalokho, ama-spindle motors enziwe ngejubane elikhulu, ukujikeleza kwamandla aphezulu, ukuhlinzeka ngamandla adingekayo ukushayela amathuluzi okusika noma ukusebenza kwemisebenzi njengokugaya, ukumba, noma ukuqopha. Ngokuqonda amasistimu abo asemqoka ahlukile, izinhlelo zokusebenza, ukuklama, isivinini kanye nezimpawu ze-torque, izidingo zamandla, kanye nezidingo zokuphendula zingenza izinqumo ezinolwazi zokwenza kahle ukusebenza kwe-CNC futhi kufinyelelwe imiphumela ephezulu.

I-Synergy phakathi kweStoro neSpindle Motors yikho okwenza imishini ye-CNC iguquguquke kangaka futhi isebenze. I-Servo Motors iqinisekisa ukuthi i-head head noma i-workpiepe ibeka ngokunemba kokunemba, kanti ama-spindle motors aletha amandla okujikeleza adingekayo ekususeni okusebenzayo noma ukwakheka. Isibonelo, emshinini we-CNC milling, ama-servo motors alawule ama-X, y, kanye nama-axs alandele ithuluzi elinembile, ngenkathi i-spindle motor ijikeleza ithuluzi lokusika ngesivinini esikhulu ukukhiqiza ingxenye ebushelelezi, enembile. Ukukhetha kahle kanye nokugcinwa kwezimoto zombili kubalulekile ekugwemeni izingqinamba ezinjengeBelt Slackerining, imibuthano emifushane kagesi, noma ukwehluleka kwemishini, ukuqiniseka okungaguquki nokwethembeka.

Ngalezo zokwakha, ukuthuthuka, noma ukusebenza kwe-CNC amasistimu, cabanga ngokucophelela izimfuno ezithile zohlelo lwakho lokusebenza - njengohlobo lwezinto ezibonakalayo, izidingo zokunemba, nomjikelezo wokuqondisa, lapho ukhetha ama-servo kanye nama-spindle motors. Khetha ama-motor we-servo ane-torque efanelekile, ukulungiswa kwempendulo, kanye nokuhambisana okulawulwa kokulawulwa kwe-axis eqondile, bese ukhetha ama-spindle motors ngamandla afanele, isivinini, kanye nohlelo lokupholisa ukufanisa imisebenzi yakho mailmailining. Ukulungiswa okujwayelekile, okubandakanya ukuhlanza, ukuthambisa idivaysi yedivayisi ye-servo motors, kanye nokunakekelwa kohlelo lokupholisa kwama-spindle motors, kubalulekile ukuze ulondoloze ukusebenza futhi unwebe isikhathi sokuphila kwemoto. Ngokufaka amandla amandla ahambisanayo we-servo kanye nama-spindle motors kanye nokusebenzisa ukulungiswa okusebenzayo, ungathola imiphumela ekhethekile emisebenzini kanye nemisebenzi ezenzakalelayo, ukuqinisekisa ukusebenza kahle, ukunemba, nokuqina ekusebenzeni kwakho kwe-CNC.

Chofoza lapha ukulanda ikhathalogi kaZhong Hua Joung.

Ikhathalogi kaZhong Hua Juang 2025.pdf

Ikhathalogi kaZhong Hua Juang 2025.pdf

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu