A cikin CNC (Kayayyakin Kamfanin kwamfuta) injunan yanar gizo da sauran daidaitattun aikace-aikacen injiniya, Servo Moors da Spindle Motors da Spindle suna da mahimmanci kayan haɗin gwiwa wanda ke fitar da aikin tsarin. Duk da yake duka masu lantarki ne ke dangantaka da aikin CNC, dalilai daban-daban na asali kuma suna tsara su zuwa takamaiman matsayin su. Fahimtar bambance-bambance tsakanin motormoro da kuma motsawar Motsa mai mahimmanci yana da mahimmanci don zaɓin abubuwan da suka dace, kuma cimma sakamako mai inganci, da kuma cimma sakamako mai inganci a cikin daidaitaccen tsarin. Wannan labarin ya cancanci cikin mahimman bayanai tsakanin waɗannan nau'ikan Motors, bincika ayyukansu, fastoci, da halayen aikin, da injin ƙwararru, da injiniyoyi masu ƙwararru, da injiniyoyi.

Menene Motors Servo?

Motoran Mottoci suna da kwastomomi masu ƙwarewa musamman waɗanda aka tsara don ainihin ikon sarrafa matsayi, sarrafa kwamfuta na kwamfuta) injunan CNC (Aikace-aikacen Kamfanin kwamfuta) injunansu. Su ne tayin tuki a bayan ingantaccen motsi na kayan cnc (misali, x, y, z) ko kayan haɗin gwiwa a cikin kayan robotic, suna tabbatar da cewa an sanya su daidai kamar yadda ake shirin nema. Ba kamar daidaitattun motoci ba, Motors Servo suna aiki a cikin tsarin sarrafawa na rufewa, suna amfani da na'urorin biyan kuɗi kamar baƙi ko daidaita su don dacewa da umarnin tsarin CNC. Wannan daidai da daidaitawa da motocin servo motorsable don ayyuka na buƙatar ainihin motsi da kuma ƙarfin iko a masana'antu da ke faruwa daga masana'antu

Motors Servo ana amfani da injiniya tare da takamaiman halaye waɗanda ke ba da damar amfani da su a aikace-aikacen su. Da ke ƙasa akwai kayan fasali waɗanda ke ayyana ayyukansu da rarrabe su daga wasu nau'ikan motoci, kamar su spindle motors:

Rufewar Motoc

Perco Motors suna aiki a cikin tsarin rufewa, ma'ana suna karɓar ci gaba da bayani daga na'urori masu sirri (eg, ogoders) don lura da ainihin matsayin, saurin, da Torque. Ana kwatanta wannan amsar da ƙimar da ake so daga tsarin sarrafa CNC, da duk wani rashin fahimta ana gyara su a cikin ainihin lokaci ta hanyar daidaita kayan aikin. Wannan ikon rufewa yana tabbatar da daidaito na musamman, yin motocin Servo da kyau don aikace-aikace inda har ƙimar ƙungiyoyi na iya shafar inganci, kamar su ɗimbin kayan Cnc.

Babban daidaici

Setri Motors suna da ikon daidaitattun ƙananan-iri, ba da izinin daidaitawa ƙasa zuwa guntu na millimita ko digiri. Wannan daidaitaccen yana da mahimmanci don ayyuka kamar miling hadaddun geomet guda, ko kayan aikin hakoma a cikin injin CTN na CRN Multis. Misali, a cikin injin 5-Axis CNC, Servo Moors tabbatar da cewa kowane axis yana motsawa daidai don ƙirƙirar sassan da aka yi wa Aerospace ko aikace-aikacen likita.

M sauƙin da sauri da Torque

Server Motor na iya aiki a duk fannoni daban-daban na saurin aiki da isar da su, yana sa su m turanci. Zasu iya hanzarta, kashe, ko dakatar da sauri yayin da muke da mahimmanci don ayyukan da ke buƙatar sauya canje-canje, kamar abin dariya ko abin da yake ciki a cikin abin da ke cikin CNC. Wannan sassauci yana bawa motors Servo don dacewa da ɗumbin kaya da buƙatun Mamfara.

Comparamin

Motor Motlor Motoral yawanci karami ne da lightweight, wanda aka tsara don dacewa a cikin sararin samaniya na injunan CTN ko tsarin robotic. Girman ƙaramin girmansu yana ba da ƙarfin ƙarfin aiki, motsi da yawa ba tare da ƙara yawan adadin nauyin na'ura ba. Wannan yana da mahimmanci musamman ga aikace-aikace masu sauri inda rage ragewar inertia yana da matukar muhimmanci ga amsawa da daidaito.

Iri na Motors na Servo

Motors Servo Motor suna zuwa cikin bambance-bambancen da yawa, kowannensu ya dace da takamaiman aikace-aikace:

Motors AC Servo Mota : An yi amfani da shi na yanzu, waɗannan motors suna da ƙarfi da kuma yawanci ana amfani da su a masana'antar CTN masana'antu don babban iko da kuma karko. An haɗa su sau da yawa tare da mitar mitoci na (vfds) don ingantaccen iko.

DC Servo Motors : An yi amfani da shi ta hanyar kai tsaye, waɗannan motors suna da sauki kuma galibi ana amfani dasu a cikin karami ko karancin buƙatu, kamar saitin saƙo na Hobbyist CNC. Motar DC Setri Motors ba su da kowa gama gari saboda bukatun kulawa, yayin da aka fi son m jupsed don inganci.

Motors DC Servo Motors : Wadannan hada fa'idodin DC Motors tare da ingoran doci tare da ingancin karko da inganci, kawar da bukatar brashes. An yi amfani da su sosai a cikin injunan CNN na zamani don masu ƙarancin kulawa da babban aiki.

| Servet Motar Motoci Batun Batun Aikace- |

aikacen |

Aikace |

- |

aikace |

Maɓuɓɓuga |

| Motors AC SERET |

An tsara waɗannan da ake amfani da shi a yanzu, an tsara waɗannan masu roborts don aikace-aikacen masana'antu masu ƙarfi na haɓaka (vfds) don madaidaicin sauri da sarrafawa. |

Babban iko na iko, kyakkyawan yanki don ci gaba da aiki, madaidaici sarrafawa tare da vfds, dace da ayyuka masu nauyi. |

Babban farashi mai girma saboda mawuyacin hali, sawun mafi girma, yana buƙatar saiti da shirye-shirye. |

Motocin CNC masana'antu, Maɗaukaki-sikeli, hako, Robotics, da kuma atomatik a cikin kayan aiki / Aerospace masana'antu. |

High torque a ƙananan gudu, robusti gini, kewayon sauri mai yawa (1,000-6,000 rpm), yawanci 1-20 cwing of the rating. |

| DC Servo Moors |

An ƙarfafa ta kai tsaye, waɗannan motors suna da sauki kuma ana amfani da su a cikin ƙaramin aikace-aikacen ko karancin buƙata. Akwai shi a cikin goge ko kayan shafawa mai ban sha'awa, tare da goge kasancewa ƙasa da gama gari saboda buƙatun kulawa. |

Tsarin tsada, tsarin sarrafawa mai sauƙi, ya dace da aikace-aikacen mai ƙarancin ƙarfi. |

Lethured Power fitarwa, Brudiri iri suna da babban tabbatarwa (buroshi na goge), yana iya yin zafi a cikin tsawan tsawan tsawan lokaci. |

Hobbyist CNC saiti, karamin tebur na tebur, sauƙaƙan ayyuka na sauki, aikace-aikacen wuta mai ƙarfi kamar PCB na PCB ko ƙyallen. |

Hardarancin Torque, kewayon rpm na 2,000-10,000, ma'aunin wutar lantarki yawanci 0.1-1 m da actors. |

| Motors na DC Servo na DC Servo |

Subset na DC Motors, waɗannan suna amfani da gargaukan lantarki maimakon goge, suna ba da ingantaccen inganci da karko. Amfani da shi a cikin tsarin CNC na zamani don daidaitawar su da ƙarancin kulawa. |

Babban inganci, ƙarancin kulawa, yana da tsayi na lifepan, babban ƙira, kyakkyawan kyakkyawan yanayi a duk faɗin kewayon sauri. |

Babban farashi mai girma fiye da goge DC Motors, yana buƙatar masu kula da lantarki, ƙasa da iko fiye da AC Servo Motors don ayyuka masu nauyi. |

Hanyoyi na yau da kullun, ka'idodi na yau da kullun, firintocin 3D, kayan aikin likita, da aikace-aikacen suna buƙatar babban abin dogaro da daidaito. |

Babban inganci (har zuwa 90%), kewayon sauri na 3,000-15,000 rpm, ƙarfin wuta na 0.5-5 kW, low zafi nassi. |

Matsayi a cikin injayen CNC

A cikin tsarin CNC, Motors Servores ne da ke da alhakin sarrafa layin layi ko motsi na groups na injin. Misali:

A cikin na'urorin CNC mai ba da hanya, Servo Moors ya fitar da x, y, da Z axes don sanya spindle ko kayan aiki daidai akan aikin.

A cikin CNC Lathet, mit servo na iya sarrafa juyawa na aikin gida (aiki a matsayin spindle a wasu lokuta) ko motsi na kayan yankan.

A cikin injunan da Multi-Axis, Motors suna ba da hadaddun motsi, kamar ta karkatar da kayan aikin ko kayan aiki a cikin 4- ko kuma 5-axis sanyi.

Iliminsu na samar da madaidaici, maimaitawa motsi yana da mahimmanci don ci gaba da yarda da su kamar Aerospace, masana'antar wayar ta atomatik. Ta hanyar haɗa tsarin sarrafawa na CNC, Mota Mottivers Fassara shirye-shiryen shirin cikin jiki, tabbatar da injin ya biyo da kayan aikin da ake so.

M la'akari

Lokacin da zaɓar ko amfani da Motors Servo a aikace-aikacen CNC, la'akari da masu zuwa:

Tsarin bayani : tabbatar da na'urar da ke tattare da motar (misali, ƙudurin zango) ya sadu da daidaitaccen buƙatun aikace-aikacen ku.

Power da Torque : dace da ikon motar da Torque zuwa kayan aiki da buƙatun hanzari na gatura na CNC.

Yarda da daidaituwa ta Kulawa : Tabbatar da cewa motar servo ta dace da mai sarrafa injin, kamar software na PLC ko Software na CNC, don tabbatar da haɗin kai.

Kulawa : Binciken na'urorin A kai a kai a kai, wayoyi, da kuma haɗin don hana batutuwa ko kurakuran lantarki.

Ta hanyar ɗaukar daidai, iko, da kuma natsuwa na Servo Motors, masu ba da aiki na CNC na iya cimma daidaito na musamman da ingorar da injin din su na zamani.

Danna nan don siyan stovors a kan Amazon.

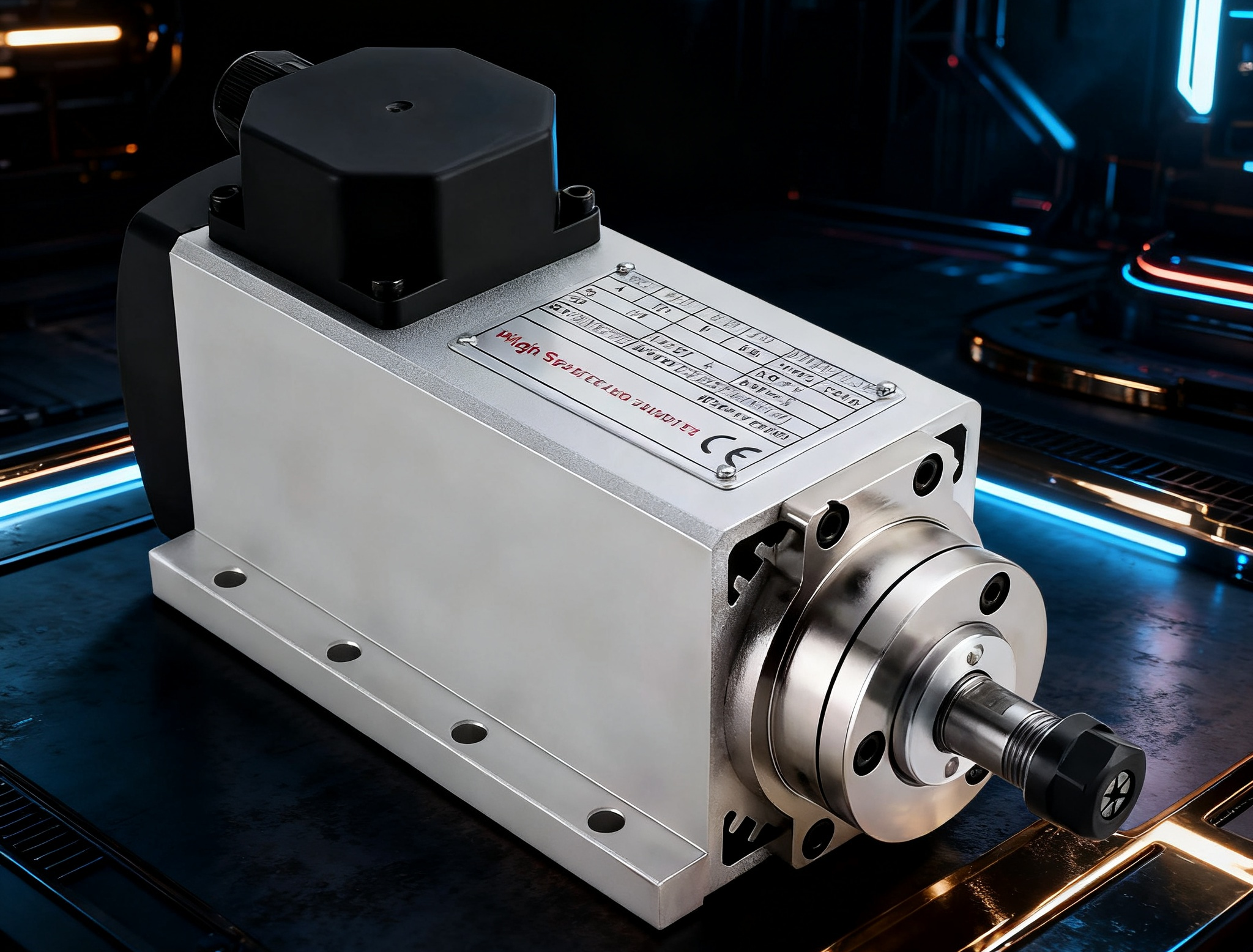

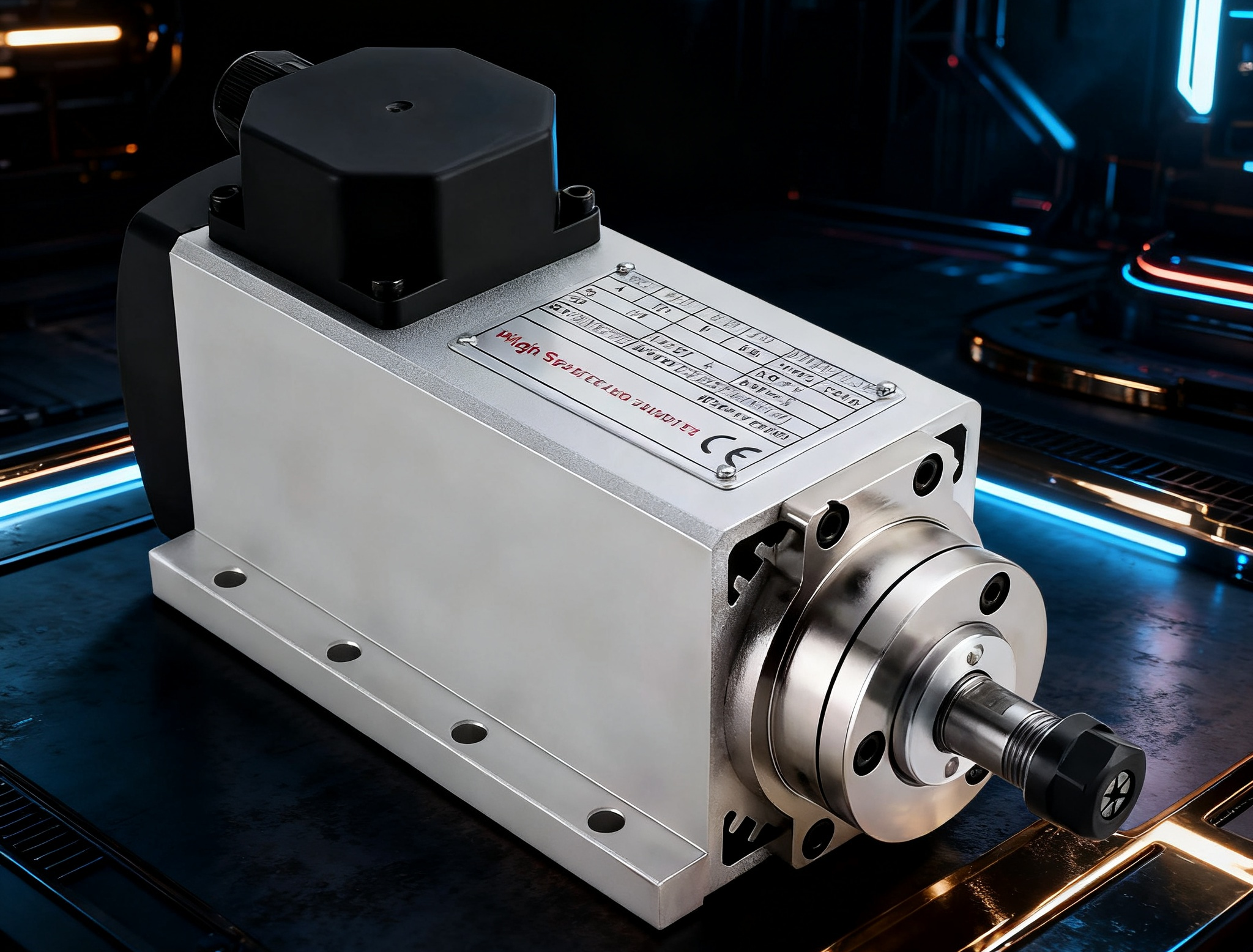

Spindle motors sune ƙirar injin lantarki na musamman don fitar da yankan, milling, kayatarwa na kwamfuta) injunansu ta hanyar juyawa kayan yankan. Kamar yadda gidan yanar gizon CNC na CNC, Motar Motar ta ba da ƙarfi da ƙarfin aiki, suna sa su ci gaba da cimma matsara da ake so, gama, da daidaito a cikin ayyukan da ke tattare da su. Ba kamar Motors Servo ba, wanda ke da hankali kan ingantaccen iko, da motocin motsi ana inganta su don ci gaba, juyawa mai sauri don isar da daidaitaccen iko ga kayan aiki ko kayan aiki. An tsara su don magance kayan ƙasa da yawa, daga wood mai laushi zuwa ga ƙarfe mai laushi, kuma suna da alaƙa ga aikace-aikace a masana'antu kamar masana'antu, da aikin ƙarfe

Mabuɗin Kayan Motoci na Motors

Ana gina motores masu hanawa tare da takamaiman halaye waɗanda ke ba su fice a ɗakunan ayyukan da ke buƙatar manyan hanyoyin juyawa da kuma isar da wutar lantarki. A ƙasa akwai abubuwan da suke amfani da aikinsu da rarrabe su daga wasu nau'ikan motoci, kamar su Servo Motors:

Motar da aka yi da sauri-sauri-hanzari

an tsara su don yin aiki a babban recentutions a minti (RPM), yawanci suna fitowa daga 6,000 zuwa 60,000 rpm ko sama da haka, dangane da aikace-aikacen. Wannan ikon da ya girma yana ba su damar yin ayyuka kamar yin zane, micro-qarshe, inda yankan tsayayyen kayan aiki yana da mahimmanci don daidaitawa da finafinan sauri. Misali, motar da ke gudana a rpm 4,000 da ta dace da sigogin da ke cikin baƙin ƙarfe ko filastik 6,000,000 rpm) suka dace da ayyukan yankan karfe.

Isar da wutar lantarki

Babban fifikon ƙwallan Mota shine don isar da isasshen Torque da ƙarfi don cire abu yadda yakamata a lokacin injin. Akwai shi a cikin kewayon iko na wutar lantarki (0.5-15 kW ko 0.67-29 HP), spindle motocin da aka zaba bisa ga taurin abu da kuma aikin da aka yi amfani da shi. High-Power Spindles samar da Torque da ake buƙata don yankan kayan m kamar titanium, yayin da ƙananan wuta ya isa ga kayan Softer kamar itace ko kumfa. Wannan mai da hankali kan isar da wutar lantarki yana tabbatar da daidaitaccen aiki a karkashin launuka daban-daban.

Bude-madauki ko rufewa-madauki

da yawa motors suna aiki a cikin tsarin madaukai, inda aka sarrafa saurin ta hanyar ƙira. Wannan ya isa ga aikace-aikace inda saurin jujjuyawa ya fi mahimmanci fiye da matsayin matsayi. Koyaya, spindles mai ci gaba na iya amfani da ikon rufewa tare da na'urorin ra'ayoyi (misali, ogoders) don kula da saurin saurin a ƙarƙashin ayyuka daban-daban, inganta aiki a cikin manyan ayyuka. Tsarin Loop ɗin yana da sauki kuma mafi tsada-tsada, yayin da tsarin rufewa-loop yana ba da mafi inganci ga aikace-aikacen neman.

Tsarin sanyaya

kayan sanyaya yana haifar da motsi mai tsananin zafi a lokacin tsawan aiki, musamman a babban gudu ko ƙarƙashin nauyin kaya masu nauyi. Don gudanar da wannan, suna sanye da tsarin sanyaya:

Air-cooled : Yi amfani da magoya baya ko iska mai yanayi don hana zafin rana, ya dace da ɗawainiya ko matsakaici-aiki kamar aikin itace. Suna da sauki kuma suna da araha amma ba su da tasiri don ci gaba da aiki.

Ruwa-sanyaya : Yi amfani da sanyaya ruwa mai sauƙi don kula da yanayin zafi sosai, daidai ga babban gudu ko ayyuka na dogon lokaci kamar sassaƙa na ƙarfe. Suna ba da isasshen dissifar zafi da kuma aiki na kashe amma suna buƙatar ƙarin kulawa don tsarin coolant. Inganci mai sanyi yana hana fadada zafi, kuma yana kare kayan ciki, kuma ya tsawaita motar.

Karɓar karfafa gwiwa na kayan aiki

suna sanye da masu riƙe da kayan aiki, kamar su er comets, BT, ko HSK, amintattun kayan aikin yankan, drills, ko kuma zanen ragi. Nau'in mai riƙe kayan aiki na tantance kewayon kayan aikin da spindle zai iya ɗaukar kuma yana shafar daidaici da daidaito da ƙiyayya. Misali, er clets ne mai mahimmanci ga janar-manufa Catcys don manyan masu riƙewa, aikace-aikacen masana'antu saboda matsakaicin ƙwayoyin su. Karɓar wuri tare da tsarin canjin kayan aikin CNC shima yana da mahimmanci don aiki mai ƙarfi.

Matsayi a cikin injayen CNC

A cikin tsarin CNC, motocin motocin suna da alhakin juyawa kayan aiki ko, a wasu yanayi, aikin aikin yi ayyukan sarrafawa. Misali:

A cikin na'ura mai amfani da CNC, motar da ke jujjuyawa tana jujjuya kayan aiki don sassaƙa sassaƙa a kan katako ko filastik.

A cikin injin mil mil mil, yana fitar da injin ƙare don cire abu daga kayan aikin ƙarfe, ƙirƙirar ƙwararrun gemuetries.

A cikin CNC Lathat, injin da aka shafa na iya juya aikin kayan aiki akan kayan aiki na tsayayye don kunna ayyukan. Ikonsu na ci gaba da saurin saurin da ƙarfi na tabbatar da ingancin kayan aiki, yana sa su mahimmanci don ayyuka masu nauyi daga ɗakuna masu nauyi zuwa gajiya.

M la'akari

Lokacin zaɓi ko amfani da Motors a aikace-aikacen CNC, la'akari da masu zuwa:

Gudanar da ƙarfi da sarrafawa : Yi daidai da rpm da ƙimar wutar lantarki zuwa kayan da aiki (misali, babban-sauri don yin zane, high-torque don yankan ƙarfe).

Bukatar sanyaya : Zabi mai sanyaya-sanyaya don ingantaccen farashi, amfani da ruwa ko spindles mai sanyaya don ci gaba, ayyukan da suka yi.

Karfin da ya dace da kayan aiki : Tabbatar da mai riƙe kayan aikin kayan aikin na Spindle yana tallafawa kayan aikin da ake buƙata kuma ya dace da saitin injin.

Kulawa : A kai a kai tsaftace tsarin sanyaya, saka idanu na sanyaya, da kuma bincika abubuwan da zasu hana matsaloli, rawar jiki, ko bel din batutuwan.

Ta hanyar ɗaukar juyawa mai sauri, isar da wutar lantarki, da kuma ƙirar ƙwararrun Motors, ingantattun masu inganci wanda aka bayar.

Bambancin bambance-bambance tsakanin Motors Servo da Spindle Mota

Motors Servo da Spindle Motors sune kayan masarufi ne a cikin CNC (na ƙididdigar kwamfuta na kwamfuta), amma suna ba da takamaiman dalilai, tare da halaye daban-daban waɗanda aka sarrafa su zuwa takamaiman aikinsu. Yayin da Motoro na Servo fice A cikin sarrafawa na Motsa don sanya kayan aikin injin, wanda aka inganta motores an inganta shi don juyawa mai sauri don fitar da yankan yankan ko tafiyar matakai. Fahimtar bambance-bambancen su a duk faɗin mahimman abubuwan ingantattu-na farko, saurin sarrafawa, saurin sarrafawa don zabar motar dama don tsarin tsarin CNC da ingantaccen aiki. A ƙasa, mun kwatanta waɗannan nau'ikan motocin guda biyu daki-daki, muna biye da misalai masu amfani don nuna matsayinsu na injin CNC.

1. Aikin farko

Motors : Motors Servor an tsara su ne don sarrafa matsayin, gudu, da motsi na inji mai inji tare da babban daidaitacce. A cikin injunan CNC, suna fitar da layi ko motsi na motsi na kayan mashin (misali, x, y, z), sanya shi), sanya shi), sanya shi), sanya kayan aiki ko aiki daidai gwargwadon umarnin. Babban abin da suke mayar da martani shine kan sarrafa motsi maimakon isar da wutar lantarki.

Spindle Motors : Spindle motors ana samun injiniya don juya kayan aikin yankan yankan yankan yankan yankan yankan yankan yankuna masu zuwa da yankan, milling, hakowa, ko zane. Suna mai da hankali kan isar da wuta da saurin da ake buƙata don cire kayan abu ko gyarawa, fifikon fifikon daidaito akan daidaito.

Bambancin Bambanci : Moto na Moto Servors suna sarrafa matsayin da motsi na kayan aikin, yayin da spindle motores ke fitar da ƙarfin juyawa don tafiyar matakai don tafiyar matakai.

2. Tsarin sarrafawa

Motors : Yi aiki a cikin tsarin sarrafawa na rufewa, ta amfani da na'urorin ra'ayoyi kamar raxoli ko sake fasalin don saka idanu wuri, saurin, da Torque a cikin ainihin lokaci. Mai kula da CNC ya kwatanta ainihin aikin motar don ƙimar da ake so kuma yana daidaita shigarwar don gyara kowane karkata, tabbatar da babban inganci da maimaitawa.

Spindle Motors : Yawanci amfani da tsarin sarrafawa-loop, inda aka tsara saurin ta hanyar mitar mita (VFD) ba tare da ci gaba da amsa ba. Motar da suka fi dacewa da Motar ta haɗa kai rufaffiyar madaidaiciya tare da tsarin hanzari a karkashin tsari daban-daban, amma wannan ya zama ruwan dare gama gari kuma bai zama masu gamsarwa ba kuma ba mai da hankali ne a kan iko.

Bambancin Bambanci : Motor Motor Rely dogara da kulawar rufe-ƙasa don madaidaici Tsarin kasawa, tare da zaɓin rufaffiyar hanya don aikace-aikacen rufewa.

3. Sauri da Torque

Motar Motor : Bayar da saurin canzawa da kuma babban torque, musamman a ƙananan gudu, yana yin su da kyau ga motsin motsi na buƙatar saurin hanzari da kuma yaudara. Yawancin lokaci suna aiki a ƙananan rpms (misali, 1,000-6,000 rpm) idan aka kwatanta da spindle motores, fifiko kan sarrafawa sama da saurin.

Spindle motors : wanda aka tsara don juyawa-sauri, tare da rpms jere daga 6,000 zuwa 60,000 ko sama, dangane da aikace-aikacen. Suna ba da daidaitattun ƙwalaƙen katako don yankan ko nika, tare da yin dacewar aiki don kula da sauri a cikin daidaitawa maimakon daidaitaccen daidaitawa.

Motar maɓallin : Moti na Servo sun fi fifita mai yawa a ƙananan gudu na motsi, yayin da suke da motsawar da ke da kyau a kan ayyukan da ke da kyau don ɗakunan sarrafawa.

4. Aikace-aikace

Motar Servo : An yi amfani da su don injin CNC, robotics, masu firintocin 3, da kuma tsarin sarrafa kansa mai mahimmanci. Misalai sun haɗa da matsar da kayan aiki a cikin hanyar sadarwa ta CNC, tana sarrafa Z-Axis a cikin injin milling, ko kuma ku ɗauki makamai a cikin babban taro na sarrafa kansa.

Spindle Motors : aiki a cikin hanyoyin sarrafawa kamar milling, hako, da juyawa, da juya, da juya, da juyawa, inda aikin farko yake cire ko gyaran farko. Ana samun su a cikin hanyoyin shiga CNC, injunan miliyoyin miliyoyin, injunan ƙasa, da kayan aikin tuki don aikace-aikacen katako, aikin ƙwallon ƙafa, ko masana'antar PCB.

Ana amfani da maɓallin banbanci : Motor Motors ana amfani da su don daidaitattun tsarin CNC da tsarin atomatik, yayin da yake hanzarta fitar da yankan ko gyara hanyoyin cikin aikace-aikacen komputa.

5. Tsara da gini

Motar Motor : Karamin da Haske mai nauyi, wanda aka tsara don hanzarta hanzari a tsarin da yawa axis. Suna haɗa kayan aikin da aka haɗa da su (misali, maƙiyi) kuma an gina su ne don rage ƙwayar cuta don motsi mai mayar da martani. Ginin da aka tsara daidaito da kuma mai tsauri.

Spindle motors : mafi girma kuma mafi ƙarfi, wanda aka gina don tsayayya da saurin juyawa da ci gaba da kaya a lokacin injin. Sun haɗa tsarin sanyaya (sanyaya iska ko ruwa-sananniyar ruwa) don sarrafa zafi da masu riƙe da kayan aiki (misali, er clets, yana ƙarfafa tsararraki da isar da iko.

Bambancin Bambanci : Moto na Servo sune babban motsi, daidai motocin, yayin da yake hanzarta motsi tare da tsarin sanyaya mai sanyaya da injin mai tsayi.

6. Bukatun Wuta

Motorce Motors : Yawanci suna buƙatar ƙananan iko, tare da kimantawa daga ɗan wattat 'yan wattats (misali, 0.1-5 kW), gwargwadon aikace-aikacen. An tsara su don ayyukan sarrafa motsi waɗanda ke buƙatar ƙasa da ƙarancin wuta amma babban daidaitacce.

Spindle motors : suna da babban darajar iko, yawanci 0.5 kw zuwa 15 kW ko fiye da (0.67-20 HP), katako, ko kayan aiki. Abubuwan da aka buƙaci ikonsu suna nuna buƙata don ingantaccen makamashi don cire abu yadda ya kamata.

Bambancin Bambanci : Motoci Motlor suna amfani da ƙananan iko don iko na motsi, yayin da hanji ke buƙatar mafi girman iko ga cirewar abu da injinan.

7. Inshorar sakamako

Motors Servo : Koyaushe sun haɗa da hanyoyin amfani da ra'ayi, kamar su masu bi ko sakewa, don samar da bayanai na hakika a matsayi, saurin, da Torque. Wannan martanin yana tabbatar da tsari daidai da gyaran kuskure, mai mahimmanci don riƙe mai haƙuri a cikin ayyukan CNC.

Spindle motors : Mayu ko bazai hada da hanyoyin ra'ayoyi ba. Mutane da yawa suna aiki ba tare da mai amfani ba a cikin tsarin buɗe-wurare, suna dogaro da VFDs don sarrafa saurin. Za a iya amfani da hanyoyin haɓaka don ƙa'idodin rufaffiyar madaidaiciya, amma ra'ayoyi na yanayi yawanci ba shi da mahimmanci tun lokacin da su sake juyawa, ba matsayin.

Bambancin key : Motoran Motors koyaushe suna amfani da ra'ayi don sarrafawa, yayin da yake hanzarta dogaro da tsarin buɗe ido, tare da baƙon abu don takamaiman aikace-aikace.

Misalai masu amfani a cikin injunan CNC

Don ba da misali da ayyukan da aka gamawa da Motors, la'akari da ayyukansu a cikin injin mil milling na CNC.

Motors : sarrafa motsi na teburin injin ko kayan aiki tare da x, y, da z axes. Misali, Motors Motors sanya kayan aiki daidai sama da kayan aikin ƙarfe, bayan kayan aikin kayan aikin don tabbatar da ingantaccen cuts. A cikin injin CNC na 5-Axis, Moto na Servo na ɗaukar rikicewar ƙwayar cuta, ba da damar haɗe da geomet.

Motar Fiye da Motsa : Raulasa tsintsiyar Milling a babbar gudun (misali, 20,000 rpm) don cire abu daga kayan aiki. Horar da ke da zafi ta kawo wutar da saurin da ake buƙata zuwa ƙarfe, tabbatar da ingantacciyar abu na cire abubuwa da kuma santsi a farfajiya.

Misali Yanayin : Lokacin milling Aerospace ta fito da kayan aiki zuwa madaidaicin shirye-shiryen da yawa, tabbatar da abun yanka ya biyo madaidaiciyar hanya madaidaiciya. Lokaci guda, motar da ke da zafi spins da yankan kayan yankan yankakken a 20,000 rpm don cire kayan, tare da saurin da aka sarrafa ta VFD ya dace da kayan abu da bukatun yankan. Tare, waɗannan motocin suna ba da injin don samar da wani hadadden sashi, babban aiki.

Zabi tsakanin Servo da Spindle Mota

Zabi hanyar motar da ta dace don tsarin CNC (Kamfanin Kamfanin Kwamfuta) ko Aikace-aikacen Injiniyanci na Kamfanin yana buƙatar fahimtar mahimman mahara na Motors da kuma motors. Kowane nau'in motar an tsara shi ne don takamaiman ayyuka a cikin injin CNC, tare da Motors Excelling a cikin madaidaici mai sarrafawa da kuma cire motocin. A mafi yawan tsarin CNC, waɗannan motocin ba su da bambanci amma suna aiki tare don cimma daidaito kuma wadataccen injin. Zabi tsakanin Servo da spindle Motolor-ko shawarar haɗa gwiwa da takamaiman buƙatun aikace-aikacen ku, da kayan, da tsarin da aka buƙata, da tsarin daidaitawa. A ƙasa, muna bayyanawa mahimmin la'akari tsakanin Servo da spindle Moors kuma bayyana yadda ake amfani da su a cikin injunan CNC.

Zabi Motors Servo

Motors Server sune zaɓin da ya dace lokacin da aikace-aikacenku ya buƙaci iko da iko akan matsayi, gudu, da Torque. Tsarin Gudanarwarsu na rufewa, wanda ya dogara da na'urorin ra'ayoyi kamar baƙi, tabbatar da su da mahimmanci don ayyuka na buƙatar sarrafawa mai tsauri.

Lokacin da za a zabi Motors Servo:

Ana amfani da motocin CNC : Servo Motors suna amfani da su don fitar da x, y, z, ko ƙarin axes (misali tsarin cnc, saka kayan aiki ko babban aiki tare da babban daidaito. Misali, a cikin hanyar sadarwa mai amfani da CNC, servo Mota motsa gantry zuwa ainihin daidaitawa don yankan ko zane.

Robotics : A cikin makamai na robotic, Mototic Motlor, Server Motors Corces ƙungiyoyi, kunna madaidaici amfani da ayyuka, waldi, ko kuma wuraren aiki.

Tsarin aiki da kai : Motors Motors ana amfani dasu a cikin injin atomatik, kamar tsarin firinta na 3D, inda madaidaicin matsayi ko kuma sarrafa saurin aiki.

Aikace-aikace na buƙatar ƙananan gyare-gyare : ɗawainiya kamar zaren, mai ban sha'awa, ko amfani da injin motsi na Motsa na Servo don yin daidaitattun gyare-gyare.

Key la'akari:

Bukatar Medica : Zabi Servo Motlor tare da babban ƙabilanci (misali, 10,000) don neman yarda, kamar Aerospace ko masana'antu na na'urar.

TorQue da sauri : Tabbatar da ma'aunin wasan kwaikwayon servo da kuma hanzarin sittin da suka dace da kaya da kuma ƙarfin bukatun na injin. Misali, aikin aiki masu nauyi na iya buƙatar ƙarin motors mafi girma.

Yarda da daidaituwa ta Kulawa : Tabbatar da cewa motar servo ta dace da mai kula da CNC ko PLC, tabbatar da haɗin kai na CLN tare da software na injin.

Kulawa : Yi shiri don dubawa na yau da kullun da hanyoyin lantarki don hana batutuwan aiki, kamar misalin rashin daidaituwa ko kurakurai masu yawa.

Misali : A cikin injin mil 5 na CN 5, Servo Moors sanya kayan aiki da kuma daidaitaccen aiki tare da daidaito-millimita tare da daidaitattun Geometries don kayan haɗin Aerospace.

Zabi Motsa Mota

Motar Mottoci sune zabin zabi lokacin da aikace-aikacen ku ya mai da hankali kan mai saurin juyawa don fitar da yankan, hako, ko ƙirƙira. Wadannan motores an tsara su ne don isar da karfi da saurin cire abu, yana sa su m don ayyukan da inji a cikin kayan da yawa.

Lokacin da za a zaɓi Spindle Motors:

Yankan da Milling : Spindle Moors Motsi Drive yankan kayan kwalliya kamar ƙarshen Mills don cire kayan daga injiniyoyi masu wucewa da injunan CNC.

Hilling : Suna juyawa rami na huɗun don ƙirƙirar ramuka a cikin kayan ko kayan ƙarfe, don kayan aiki ko kayan aiki.

Yin zane : Ana amfani da motocin da aka girka don cikakken aiki, kamar zane mai kyau akan kayan ado, sa hannu, ko buga allon allo (kwaya).

Juya : A cikin Lates na CNC, spinle Moors juyawa da kayan aiki da wani aiki kayan aiki don tsara sassan silinda, kamar shafs ko kayan shiga.

Key la'akari:

Abu da aiki : Zaɓi motar da aka shafa tare da isasshen iko (misali, 0.5-15 kW) da sauri (misali, 6,0000,000 rpm) don kayan da aiki. Misali, babban iko, spinded ruwa-sanyaya ruwa suna da kyau don yankan ƙarfe, yayin da spindles da sanyin iska suka dace da katako.

Tsarin sanyaya : Zabi mai sanyaya-sananniyar ayyuka don ɗakunan ruwa ko gurbataccen ruwa don ci gaba, ayyukan da suka dace don sarrafa zafi yadda ya kamata.

Karancin kayan aiki : Tabbatar da mai riƙe kayan aikin kayan aikin na Spindle, HSK) yana goyan bayan kayan aikin da ake buƙata kuma ya dace da tsarin canjin kayan aikin.

Kulawa : A kai a kai tsaftace tsarin, a kai a kai tsaftace tsarin sanyaya, da lubricate beings don hana batutuwan kamar bel ɗin da baƙon lantarki.

Misali : A cikin na'urori na CNC mai ruwa, mai ruwa 3 kw mai sanyaya motoci mai guba yana juyawa wani abu mai guba a cikin kayan aikinta don samar da kayan daki.

Hada amfani da injunan CNC

A yawancin injunan CNC, Motors Sern da Spindle suna amfani da su, suna levingging su hade don cimma adali kuma ingantacciyar injiniya:

Motors Servors don sarrafawa : Motar Motors ta sanya kayan aiki ko aikin injin, tabbatar da kayan aikin yankan yana bi da kayan aikin yankan da ke biye da daidaito. Misali, sun motsa Gantry a cikin hanyar sadarwa ta CNC ko daidaita kusurwar kayan aiki a cikin injin 5-axis.

Spindle Motlors ga Machining : Spindle Motors juyawa kayan aiki ko kuma aikin aiki a saurin da ake buƙata, hayaki mafi ingancin yankan, hayaki, ko zane mafi kyau.

Misali Yanayin : A cikin injin mil mil mil, Motos, Motos ya fitar da x, y, da kuma motar ta zube da kayan aikin da ke ƙarƙashin koshin da ke ƙasa, ƙirƙirar kayan aikin. Motoran wasan kwaikwayon Servo Tabbatar da kayan aikin ya biyo madaidaiciyar hanya, yayin da motar ta kawo wutar da ake buƙata don yankan.

Ci gaba da kiyayewa

Motar da ta dace da servo da spindle motors suna da mahimmanci don tabbatar da amincin, daidai, da kuma tsawon lokacin sarrafawa) injunan CNC (inji kwamfuta). Duk nau'ikan motocin suna ba da sabis na Motles na Servo don ɗaukar hoto da ke haifar da lalacewa na yau da kullun don hana al'amura. Ta wajen aiwatar da ayyukan gyara da aka yi niyya, masu aiki na iya tsawaita lokacin, ci gaba da daidaito na inji, kuma mika saukewa na wadannan kayan aikin. A ƙasa, muna bayyana takamaiman sabuntawa don Motors na Servo da kuma motors, suna daidaita matakai don kiyaye su cikin kyakkyawan yanayi.

Moti na Servo

Motors na Servo, da ke da alhakin ingantaccen iko a cikin injunan CNC, sun dogara da tsarin rufaffiyar hanyoyin tare da na'urorin ra'ayoyi don kula da daidaito. Kulawa na yau da kullun yana tabbatar da aikinsu ya yi daidai, yana hana al'amurran da zasu iya yin jigilar motsi ko daidaitaccen motsi ko daidai.

Bincike akai-akai da na'urorin amsawa na yau da kullun (misali, maƙasudi)

Servo Moors Yi amfani da na'urorin da ke son matsayi, saurin, da Torque a cikin ainihin lokaci. Babu shakka, datti, ko sutura a cikin waɗannan na'urori na iya haifar da rashin daidaituwa ko kurakuran sarrafawa.

Ayyuka:

Goge Excoders ko sake fasalin don ƙura, tarkace, ko lalacewar jiki wanda zai iya tsoma baki da daidaito daidai. Tsaftace tare da zane-zane mai kyau da tsabtace mai tsabtace.

Na'urorin bincike na kwatankwatacce lokaci-lokaci ta amfani da software mai mahimmanci ko kayan aiki don tabbatar da jeri tare da mai sarrafa CNC.

Bincika nazarin eborder don sutura ko haɗi.

Mita : duba da tsaftacewa kowane watanni 3-6 ko 500-1,000 optate awowi; Calibrate kamar yadda ke jagororin masana'antu, yawanci shekara ko bayan manya.

Fa'idodi : Yana kula da daidaito mai daidaitawa, yana hana kashin sarrafawa, kuma yana tabbatar da aiwatarwa a cikin ayyuka kamar injinan da yawa ko robotics.

Duba don sa a cikin b beedings da lubricate kamar yadda ake buƙata

Bears a Serving Motors rage tashin hankali yayin saurin cosips, amma sutura na iya haifar da ƙara muni, amo, ko rage daidaito. Yawan lubrication da yakamata ayi kuma yana kula da ingantaccen aiki.

Ayyuka:

Saurari kararrawa mai ban mamaki (misali, niƙa ko hyming) ko amfani da mai ƙididdigar rawar jiki don gano suturar sa. Vistrivearancin girgiza yana nuna buƙatar dubawa ko sauyawa.

Aiwatar da masana'anta-shawarar (misali, man shafawa ko mai) don ɗauka, wanda zai iya jawo wajan tarkace ko haifar da dafar ruwa. Wasu Motors na Servo suna amfani da abubuwan da aka rufe da aka rufe waɗanda ba su buƙatar lubrication amma ya kamata a bincika sawa.

Sauya Buyings da sauri don hana lalacewar hanyar motar motar ko mai rotor.

Mita : duba kudade kowane watanni 6 ko 1,000 da yake aiki; Sa sa a kowane bayani dalla-dalla, yawanci kowane sa'o'i 500,000 don begenings da ba a rufe ba.

Fa'idodi : rage tashin hankali, yana hana lalacewa mai lalacewa, kuma ya shimfida gidansa.

Saka saka idanu akan haɗin lantarki don hana asarar sigina ko shiga cikin

motocin Siragoranci don dogaro da haɗi da watsa bayanai zuwa mai sarrafawa da na'urorin saƙo. A sako-sako, ko haɗin haɗi mai lalacewa na iya haifar da asarar sigina, tsangwama, ko kurakuran lantarki kamar gajeren da'irori.

Ayyuka:

Bincike ikon da igiyoyin siginar don fray, lalata, ko sararin samaniya. One endara haɗin gwiwa kuma maye gurbin igiyoyi masu lalacewa.

Yi amfani da multimeter don bincika ƙarfin lantarki da ci gaba a cikin wiring don tabbatar da isar da wutar lantarki.

Gidajen siginar hannu daga tsangwama na lantarki (EMI) ta hanyar ɗaukar su daga manyan abubuwa masu ƙarfi kamar ƙwayoyin soja ko vfds.

Mitar : bincika hanyoyin haɗin wata ko kowane ɗayan sa'o'i 500; yi cikakken bincike yayin hanyoyin kulawa na yau da kullun.

Fa'idodi : Yana hana asarar sigina, rage haɗarin kurakuran lantarki, kuma yana tabbatar da ingantaccen sadarwa tare da mai sarrafa CNC.

Spindle motors

Motar Mottoci, waɗanda aka tsara don juyawa-hanzari da kuma cirewar abu don sarrafa zafi, rawar jiki, da batutuwa masu alaƙa da kayan aiki. Kulawar da ya dace yana hana lalata da lalacewar aiki, kamar gajerun da'irori ko lalacewa ta zamani.

Masu riƙe da kayan aiki masu tsabta da kuma suna hana

masu riƙe kayan aikin kayan aiki (misali, er classets, BT, HSK) da kuma tattara kayan kayan lambu. Rnit, tarkace, ko lalacewa na iya haifar da runtout na kayan aiki (Wobbling), yana haifar da ingancin injin da ke da ƙarfi, ko damuwa a kan spindle.

Ayyuka:

Masu riƙe kayan aiki na tsabta bayan kowane canji na kayan aiki ta amfani da zane mai-lint-foshin kyauta don cire ragowar da ba mai tsabta, kwakwalwan kwamfuta, ko ƙura.

Yi bincike don sutura, dents, ko kazanta a kan mai riƙe kayan aiki ko collet, wanda zai haifar da kuskure. Sauya abubuwan da suka lalace nan da nan.

Yi amfani da mai nuna alamar kira don auna tseren kayan aiki bayan shigarwa; Runout wuce 0.01 mm yana nuna matsala buƙatar gyara.

Mita : tsabta bayan kowane canji na kayan aiki ko yau da kullun yayin amfani mai nauyi; Yi bincike don sa kowane wata ko kowane ɗayan sa'o'i 500.

Fa'idodi : Kula da daidaitaccen daidai, yana rage rawar jiki, kuma yana hana suttura da kayan aiki da kayan aiki.

Kula da tsarin sanyaya-ruwa (iska ko ruwa) don hana

zubar da ruwa na ruwa a lokacin babban aiki ko kuma faɗakarwa mai tasiri don hana lalata ko gazawar ƙasa.

Ayyuka:

Don spindless-sanyaya-sanyaya : abune mai tsabta masu sanyaya da magoya bayan kullun don cire ƙura ko tarkace wanda ke hana tazflow. Tabbatar da iska a bayyane yake don kula da ingancin sanyaya.

Don ruwan da aka sanyaya ruwa mai sanyaya : saka idanu matakan matakan a cikin tafki, toping tare da ruwa-mai amfani. Bincika Hoses, Fitings, da jaket ɗin sanyi don leaks ko lalata. Sanya tsarin kowane watanni 6-12 don cire lewa ko algae.

Yi amfani da Hoto na zafi don gano wuraren zafi, suna nuna tsarin sanyaya sanyaya.

Mitar : bincika tsarin Air-sanyaya-sati; Saka idanu tsarin da aka sanyaya tsarin ruwa a sati don matakan sanyaya da wata-wata don leaks; Flush ruwan ruwa-sananniyar tsarin kowane 6-12 watanni.

Fa'idodi : Yana hana zafi mai zafi, yana rage damuwar thermal a kan iska da kuma saƙo, kuma ya shimfida mai sa rai.

Saka idanu beings don rawar jiki ko amo, wanda ke nuna yiwuwar sa

waken fata, sau da yawa yumbu ko karfe, goyan bayan juyawa-sauri. Wear ko rashin daidaituwa na iya haifar da matsanancin tashin hankali ko amo, yana haifar da rage daidai, bel bel da lalacewa, ko lalacewar motar.

Ayyuka:

Saurari noties na mahaukaci (misali, niƙa, rataye, rataye) yayin aiki, yana nuna ɗaukar sa maye ko kuskure.

Yi amfani da mai amfani da tsaki don auna ɗaukar matakan rigakafin matsananciyar ruwa, kwatanta su zuwa manyan tarihin masana'antar da wuri.

Lubricate Bears a kowace jagororin mai samar da kayayyaki (idan ba a rufe shi ba), ta amfani da ƙayyadadden maiko ko mai. Sauya Buyings da sauri don hana lalacewa ga sararin samaniya ko mai rotor.

Mitar mita : saka idanu a kullun ko mako-mako yayin aiki; Yi cikakken bayani game da bincike a kowace watanni 3-6 ko 500-1,000 optate awowi.

Fa'idodi : Yana hana gazawar injiniya, rike daidaito na inji, kuma rage haɗarin gyara.

Ƙarshe

Motors Servo da Spindle Mottoci sune abubuwan da ba za a iya amfani dasu ba a cikin CNC (comprical Complical Production) da daidaitattun kayan aikin injiniya, kowannensu yana yin aiki da aikin waɗannan tsarin. Motor Motlos Frevicep Freel Finalmasashen Ikon Moraka Gudanarwa, suna ba da cikakken matsayin wurin injin ko abubuwan haɗin Cikin Cikakkun CNC, Robotics, da Robotics, da kuma Robotics. A bambanta, spindle motores ana da injiniya don babban-gudun, juyawa mai girma, samar da karfi da ake buƙata kamar milling, hayaki, ko zane. Ta hanyar fahimtar mabuɗin iko-sarrafawa, aikace-aikace, ƙira, saurin da kuma masu aiki na iya yin shawarwari don inganta aikin CCC da kuma samun sakamako mai inganci.

A halin da ke tsakanin Servo da Spindle Moors shi ne abin da ke sa injin CTN na CNC don haka da tasiri. Mota Servo tabbatar da cewa shugaban kayan aiki ko kayan aiki an sanya shi tare da daidaito na nuna, yayin da aka fitar da motores ɗin da ya wajaba don cirewar abu ko gulla. Misali, a cikin injin mil milic, Moto Motors sarrafa X, Y, da Z ya juya kayan aikin yankan da ke saurin samar da santsi, cikakken bangare. Zaɓin da ya dace da kiyayewa na nau'ikan motocin suna da mahimmanci don guje wa batutuwa kamar sarin belin, ko gazawar masarufi, don tabbatar da daidaitawa da dogaro.

Ga waɗancan gini, haɓakawa, ko tsarin CNC na aiki, a hankali la'akari da takamaiman buƙatun aikace-aikacenku - kamar a tsaye, da kuma motsa jiki-lokacin zabar servo da spindle. Zaɓi Servo motors tare da Torque mai dacewa, da kuma karfin kulawa da iko, saurin, da tsarin sanyaya don dacewa da ayyukanka. Kulawa na yau da kullun, gami da tsaftacewa, lubrication, na'urar na'urar amfani da Motors, yana da mahimmanci don ci gaba da aiwatarwa da kuma mashin Livespan. Ta hanyar leverarging da karfi na Sirvo da spindle Mottoci da aiwatar da sakamako masu amfani da aiki da ayyukan atomatik, da tabbatar da inganci, daidai, da tsoratar a ayyukan CNC.

Danna nan don saukar da kundin adireshin Zhong Hua Jiang's.

Zhong Hua Jiang Catalog 2025.pdf

Zhong Hua Jiang Catalog 2025.pdf

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu