Ingabe umshini wakho we-CNC wenza imisindo eyinqaba noma ukunemba okuphelelwe yithemba? Lokho okucashile ukudlidliza noma isikhathi esingalindelekile kungakhomba ku-saboteur ethule okuhlala ngaphakathi: amabhere owonakele emotweni yakho ye-spindle. Umonakalo wokuthwala awubonakali ngaso sonke isikhathi, kepha kuyinkinga ebucayi engaholela ekunciphiseni ukunemba, ukugqokwa okwengeziwe kwezinye izinto, ukulungiswa okubizayo, noma ukuhluleka kwe-spindle uma kushiywe kungashintshiwe.

Kulesi umhlahlandlela, sizohlola konke okudingeka ukwazi mayelana nokufaka umonakalo kuma-spindle motors - kusuka ekuboneni izimpawu zokuqala ekuboneni izimbangela nokusebenzisa amasu okuvimbela asebenzayo. Noma ngabe ungumphathi we-CNC, ubuchwepheshe bokulungisa, noma i-hobbyist evikela ukusetha kwakho, lo mthombo uzokusiza ukugcina ama-bearings akho esesimweni esiphezulu, uqinisekise ukusebenza okubushelelezi kanye nempilo yomshini eyengeziwe.

Ake siveze izinsongo ezifihliwe futhi sigcine i-spindle yakho ijikeleze ngokungafanele!

ISINGENISO SOKUVULA ISITOLO

Yini ama-spindle motor bethwar?

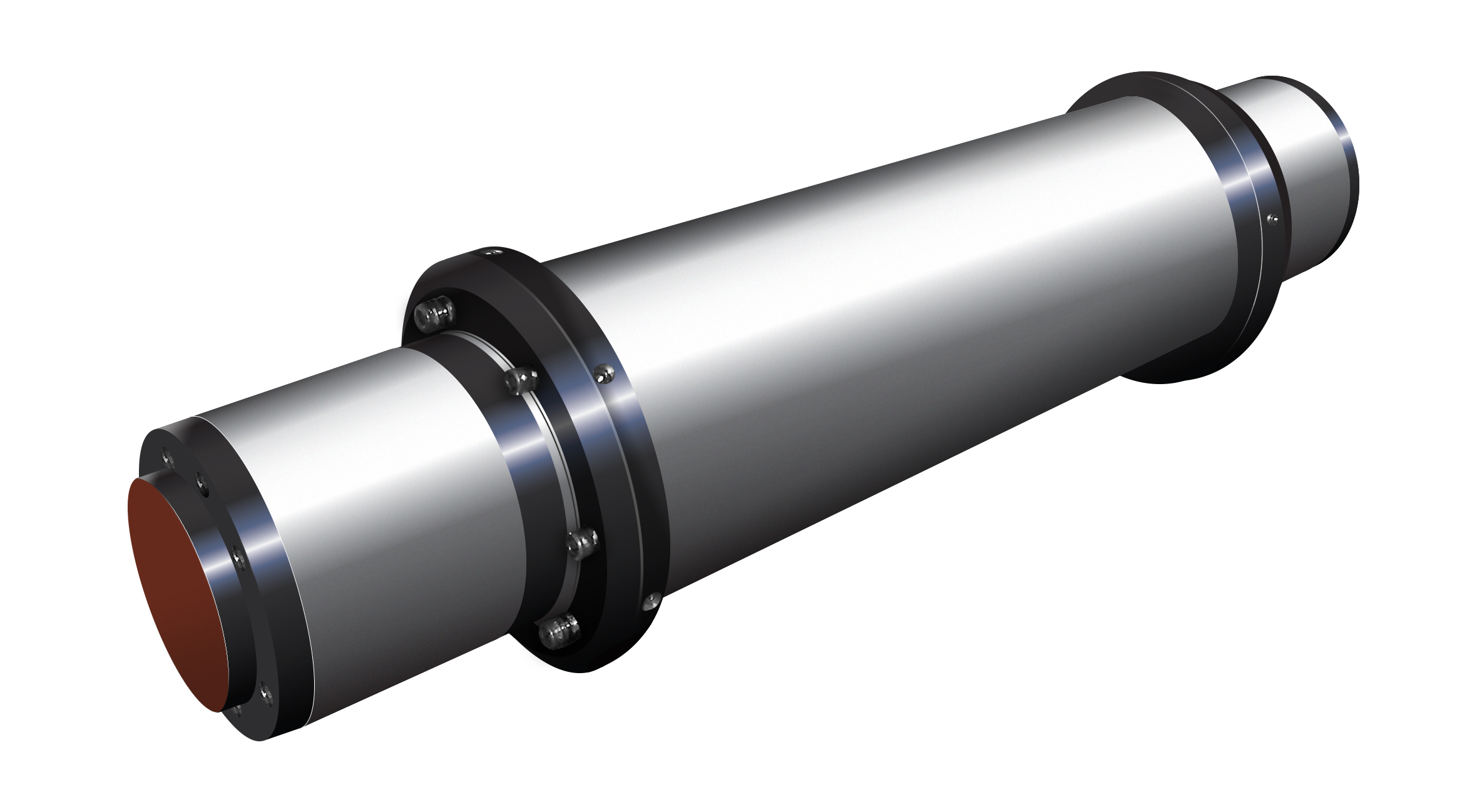

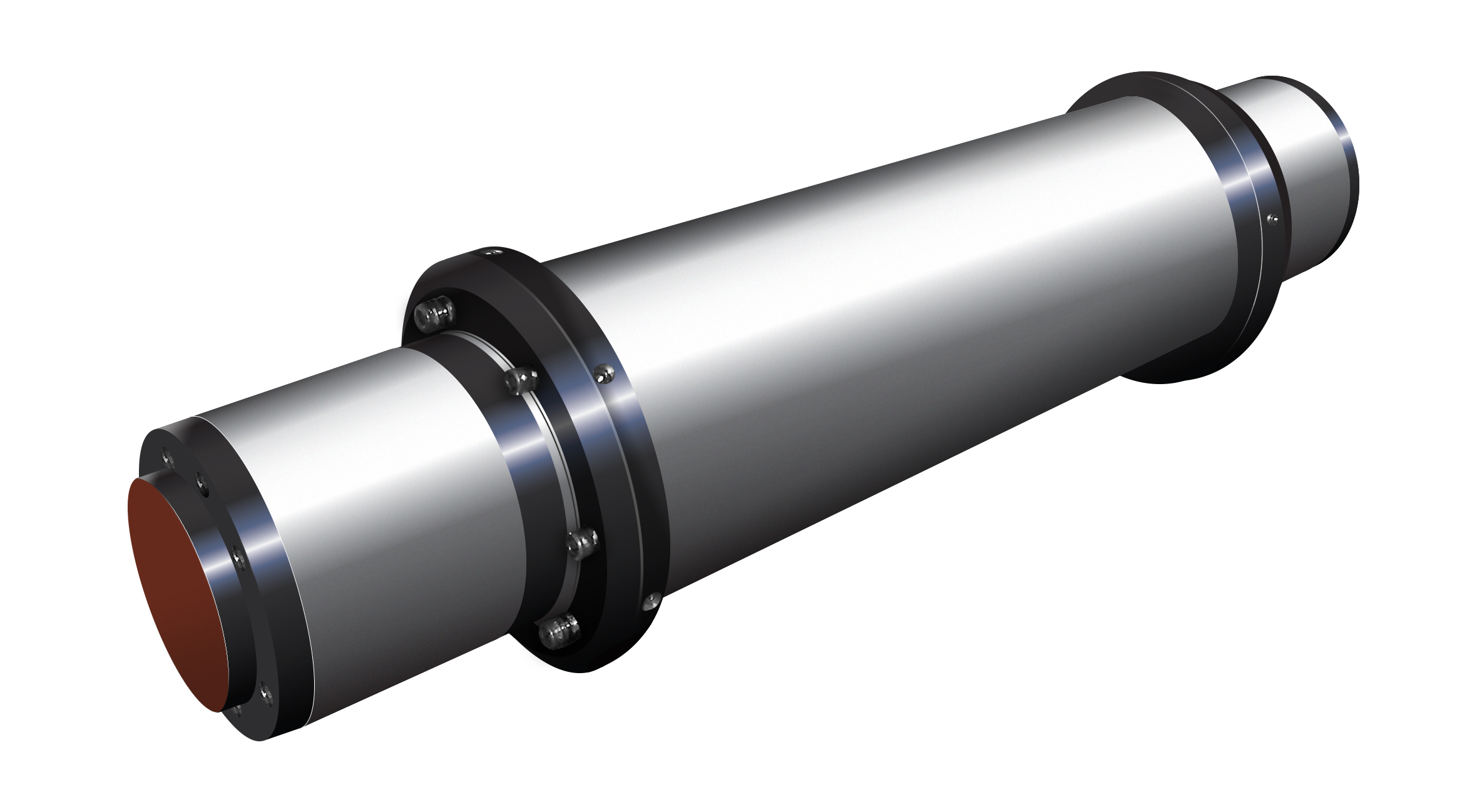

Emgogodleni wazo zonke izimoto ze-spindle kulele iqoqo lezakhi ezinobunjiniyela ezibucayi ezixhasa ishadi elijikelezayo, okwenza isheshe ijubane, ukunyakaza okunembile. Lezi zithwali zinciphisa ukungqubuzana, zidonsa imithwalo, futhi zigcine ukuqondanisa, ukuvumela i-spindle ukuthi iqhube amathuluzi okusika ngokunemba okudingekayo ekubizeni, ukugaya kanye nezinto zokwakha.

I-Bearings iza ezinhlotsheni ezahlukahlukene, njengebhola, i-roller, noma ukuxhumana kwe-angular. Akunandaba noma uhlobo, ama-bearings kumele asebenze ngokubekezelelana okuqinile ukuvikela ukudlidliza, ukwakha ukushisa, nokugqoka.

Zibone ngeso lengqondo amasondo emotweni yokusebenza okuphezulu - uma bexabana noma abamba, lonke uhlelo luhlupheka. Amabhele alonakalisiwe angaholela ekushayweni ngokweqile, ukuphathwa kabi kanye nezinkinga ezishisayo, ukuyekethisa ukusebenza kwe-spindle. Ukuqonda izinhlobo zokuthwala, izidingo zokuthambisa, kanye namakhono okulayisha kukunika umphetho ekutholeni nasekuvimbeleni ukulimala kusenesikhathi.

Ukubaluleka kokuthwala impilo kuma-spindle motors

Ukuthembela kwakho kwe-spindle motor kuhingelwa emibonweni yayo. Lapho ama-bethabu ancipha, akuwona nje ukujikeleza okusengozini; Kungadala ukuphathwa kabi komgodi, ukunwetshwa okwengeziwe kokudlidliza, ukuwonakaliswa kwemisebenzi, ukubambezeleka kokukhiqiza, kanye nezindleko zokulungisa.

Izimpawu zokuqala zomonakalo, njengama-feint vibrations, zingakhuphuka ekuhlulekeni okuphelele uma zinganakwa. Isimo sokuqapha ukubheka sivimbela izingqinamba ezincane ukuthi zibe yizinkinga ezinkulu, zikusindisa ekuvuselelekeni okubizayo.

Ngaphezu kwalokho, ama-bearings alonakele awahlukanisa izinkinga zawo - ahlukumeza ama-windings ezimoto, izinhlelo zokupholisa, kanye nemishini yokushayela. Kungumphumela we-domino okungeyona opharetha efuna ukudala.

Ukuthwala ubuqotho kumayelana okungaphezu kokuphepha kwe-mechanics - ukuphepha, ukusebenza kahle, kanye nokonga olayini ongezansi. Ukukwazisa izimbangela nokuvimbela ukuthwala umonakalo akunakuphikwa ukusebenza okuphezulu.

Izimbangela ezijwayelekile zokufaka umonakalo kuma-spindle motors

| zibangela |

yencazelo |

imiphumela |

imikhuba emihle kakhulu |

| Ukulayisha ngokweqile |

Amabutho angaphezu kwemikhawulo yokuklama kusuka kumakhenishini aqinile machine, ukujula kokusika ngokhahlo, noma amanani okuphakelwa ngokushesha. |

Ukuqhekeka Kokukhathala, Ukuguqulwa Kwezinguquko, Ukukhonjwa Kwangaphambi kwesikhathi / Ukuchitheka, noma ukwehluleka ngokushesha (ukwahlulwa / i-stall). |

Hlela Ukusika Amapharamitha ngezilinganiso zokuthwala; Sebenzisa amathuluzi abukhali nemithwalo enokulinganisela. |

| Ukuthambisa okunganele noma okungcolile |

Amazinga aphansi okugcoba, ama-contaminants (imfucumfucu (imfucumfucu / amanzi), noma izimpawu ezivuzayo ezibangela ukuxhumana okwomile noma isenzo sokuhlukumezeka. |

Ukuguguleka komhlaba, ukupela, ukushisa okwandayo, noma ukuthathwa. |

Sebenzisa izithambisi ezicacisiwe, amazinga okuqapha, buyisela okungcolile, bese uhlola izimpawu. |

| Ukufakwanga misalignment noma ukufakwa okungafanele |

Amaphutha emihlangano, ukunwebeka okushisayo, noma izindawo zokunyusa ezingalingani ezibangela ukushaqeka noma ukuphathwa kabi. |

Ukusatshalaliswa komthwalo okungalingani, ukugqokwa okusheshayo, ukukhathala okuvezwa ukudlidliza, noma ukushisa. |

Sebenzisa amathuluzi wokuqondanisa ngesikhathi sokufakwa, qinisekisa ukusetha ngemuva, bese uhlola njalo. |

| Ukungcola kusuka othulini nasemfuyeni |

Izinhlayiya ezingena ngezimpawu ezingezinhle noma izindawo ezingcolile, okwenza ukugcwala noma ukugqwala. |

Imihuzuko, ama-dents, ukugqwala, noma ukuwohloka. |

Sebenzisa izikhala ezisebenzayo, ukuhlunga komoya, nokuhlanza njalo. |

| Ukudlidliza ngokweqile noma ukungalingani |

Amathuluzi angenakulinganisela noma imvamisa evumayo akhulisa ama-oscillations. |

Ukulimala kwezinhlanga, ukukhathala, noma ukushisa kusuka ekunyakazweni njalo. |

Amathuluzi wokulinganisa, ukuhlukanisa ukudlidliza, nokuqapha ngabahlaziyi. |

| Amazinga okushisa aphezulu |

Izinto zokuthambisa zokushisa, ama-lubring ancipha, noma abangele ukwanda okungalingani. |

Umthamo womthwalo oncishisiwe, ukugcotshwa kokuthambisa, noma ukuqhekeka kokukhathala okushisayo. |

Lungiselela ukupholisa, ukuqapha amazinga okushisa, futhi uvikele ukugcwala ngokweqile. |

| Indima yamanje kagesi |

Ukuqhuma kusuka ekusukeni okumpofu okubangela ukuguguleka komhlaba ngokuphuma kukagesi. |

Ukulimala okungaphezulu kwemiphumela yokuphuma kwemishini kagesi. |

Qinisekisa isisekelo esifanele futhi usebenzise amabhele afakiwe lapho edingeka khona. |

1. Ukulayisha ngokweqile

Ukulayisha ngokweqile kwenzeka lapho izakhi zemishini, ezinjengezinwele ezinde noma imishini ejikelezayo, zibhekwa emandleni adlula umthamo wazo oklanyelwe. Le ndaba igcwele kakhulu ekusebenzeni kwemishini kanye nezimboni lapho amapharamitha okusebenza acindezela imishini engaphezu kwemingcele yawo. Ukulayisha ngokweqile kungaholela ekulimaleni okukhulu, okuncishisiwe kwemishini yokuphila, kanye nesikhathi esibikisayo.

Izimbangela zokulayisha ngokweqile

Amabhele angalayishwa ngokweqile ngenxa yezinto ezahlukahlukene ezisebenzayo nezihlobene nokusetha, kufaka phakathi:

Imishini yokwenza izinto ezinzima ngaphandle kokusetha okufanele:

l Ukucubungula izinto eziminyene noma zamandla aphezulu, njenge-titanium, insimbi engagqwali, noma ezinye izinsolo ezinzima, ikakhulukazi lapho usebenzisa izikhala zomsebenzi ezikhanyayo ezingenzelwe khona imithwalo enjalo.

l Ukusethwa komshini okwanele, njengokukhethwa kwamathuluzi okungafanele noma ukuqina okungafanele kwe-spindle, kukhulisa i-axial (eceleni kwe-axial yokujikeleza) kanye ne-radial (perpendicular eya e-axial) imithwalo.

Ukujula kokusika okunolaka:

l Ukujula ngokweqile kokusika ngesikhathi semishini kubeka amandla amaningi nangobuqili ku-spindle kanye ne-bearings. Le mithwalo ethusa ingadlula umthamo ophethe umthwalo we-bearing, okuholela ekucindezelekeni okusheshayo nomonakalo wesikhathi eside.

l Ukuncishiswa okujulile ngaphandle kwezinyathelo ezifanelekile noma i-Toolpath yoptivation kwandisa amathuba okulayisha ngokweqile.

Amanani Okuphakelwa Okusheshayo Okuthunyelwe kumakhono we-Spindle:

l Amanani aphezulu okuphakelayo angaqondani nokucaciswa kwe-Spindle's Design adale ingcindezi engalingani emibonweni. Lokhu ku-mismatch kudala ukudlidliza okwedlulele nokusebenza okunamandla, okungahlehlisa uhlelo lokuthwala.

l Amanani Okuphakelwa Okusheshayo okuhlanganiswe nethuluzi elingafanele noma ukuhambisana kwe-WorkPiece okunye ukusatshalaliswa kwamandla angalingani.

Umklamo womshini ongafanele noma ukusebenza:

L Usebenzisa ama-bearings noma ama-spindle anele izilinganiso zokulayisha ezinganele zohlelo lokusebenza kungaholela ekuthayisheni ngokweqile noma ngaphansi kwezimo ezijwayelekile zokusebenza.

L amaphutha ohadiwe, njengohlelo olungalungile lwemishini ye-CNC noma ukunganaki ku-akhawunti yezinto ezibonakalayo, zinomthelela kumandla ngokweqile ku-bearings.

Imiphumela yokulayisha ngokweqile

Lapho ama-bearings aphathwe ngaphansi kwemikhawulo yawo yokuklama, athola imiphumela ehlukahlukene enobungozi ebeka phansi ukusebenza nokuqina:

Ukukhathala kuqhekeka emijahweni ephethe:

Ukulayishwa okuphindaphindiwe okuphindaphindiwe kuncenga ukucindezelwa kwe-cyclic emijahweni ethwala (izindandatho zangaphakathi nangaphandle ezihamba ngezinto ezigoqekayo). Ngokuhamba kwesikhathi, lokhu kuholela ekukhathaleni ukuqhekeka, lapho kwakhiwa khona ama-micro-fas.

l Le mifantu iyenza buthaka isakhiwo se-bearing, inciphisa amandla ayo ukusekela imithwalo nokwandisa ingozi yokwehluleka.

Deformation kusuka emithanjeni eyeqile:

l amabutho amaningi angenza ukuguqulwa kwepulasitiki kwezinto ezithwala izinto, njengezinto ezigoqayo (amabhola noma ama-roller) noma izinhlanga. Lokhu kuguquguquka kuguqula i-geometry ye-haring, okuholela ekutheni kuhlaselwe ukuphathwa kabi, ukuxabana okwandayo, nokunciphisa ukucacisa.

l amabhele kanformed nawo angakhiqiza ukushisa ngokweqile, ukusheshisa ukugqokwa.

Ukukhonkotha ngaphambi kwesikhathi noma ukuchitheka:

l ukulayisha ngokweqile kusheshisa ukukhathala okungaphezulu, okuholele ekuphathweni (ama-craters amancane) noma ukuchitha (ukufiphala kwezinto) ezindaweni ezithwala. Lokhu kulimaza ukusebenza okubushelelezi okubushelelezi, kwandise ukudlidliza, futhi ama-hassen anehluleki.

l Ukukhonkotha nokuchitheka kulimaza kakhulu izicelo eziphezulu kakhulu, lapho kungahambisani khona okuncane komhlaba kungathinta ukusebenza.

Ukwehluleka ngokushesha:

l Ezimweni ezinzima, ukulayisha ngokweqile kungadala ukwehluleka okuyinhlekelele, njengokugqwala noma ukugcwala kwesitolo. Ukuthwala okuphukile kungathatha umsebenzi ngokuphelele, ukumisa umshini womshini nokulimaza ezinye izinto.

l Ukwehluleka ngokuzumayo kungafaka nezingozi zokuphepha kubasebenzi futhi kuholele ekulahlekelweni okubalulekile kokukhiqiza.

Imiphumela yokulayisha ngokweqile

Imiphumela yokulayisha ngokweqile i-Bearings ifinyelela ngaphezu komonakalo oseduze kokuzithwala futhi ingaba nemithelela efinyelela kude kanye neyokusebenza kwezezimali:

l Ukuncishiswa kwemishini yokuphila : Ukugcwaliswa okugcwele ngokweqile kugula ngokushesha, kudinga ukufakwa kabusha kwezindleko ezijwayelekile kanye nokwandisa izindleko zokulungiswa.

l Ukukhuphuka kwe-DowTime : Ukuhluleka ukuthwala kuvame ukudinga ukulungiswa okubanzi, okuholela ekuvuselelekeni okungahleliwe nokuphazamiseka kumashejuli wokukhiqiza.

l Ukucacisa okuyekethisiwe : ama-beboings akhubazekile noma alimala anciphisa ukunemba kwezinqubo zemishini, okuholela ezingxenyeni ezingenaphutha nasekuhleleni kabusha.

l Ukusetshenziswa kwamandla okuphezulu : ukuthwala ngokweqile kwandisa ukuxabana, okudinga amandla amaningi ukusebenzisa imishini nokushayela izindleko.

l Izingozi Zokuphepha : Ukwehluleka okusheshayo noma i-spindle stall kungadala izimo eziyingozi, njengemfucumfucu endizayo noma yokuziphatha komshini ongalawulwa.

Imikhuba emihle yokunciphisa

Ukulayisha ngokweqile kuyinkinga engavikeleka evela emikhubeni emishini engafanele, njengokusebenzisa izinto ezingafanele, ukujula kokusika okunolaka, noma amanani okuphakelayo ahlanganisiwe. Ukuqhekeka kokukhathala okuholele, i-deformation, ukukhokha okukhohlisayo, futhi ukwehluleka okungenzeka kube yinhlekelele kungaholela ekunciphiseni i-LifeSpan ye-WIPTEPAS, izindleko ezandisiwe, nezingozi zokuphepha. Ngokuvumelanisa amapharamitha wokusika ngamakhono athela, usebenzisa amathuluzi abukhali, imithwalo yokulinganisa, kanye nokusebenzisa ukulungiswa njalo, abahlinzeki banganciphisa kakhulu ingozi yokulayisha ngokweqile. Lezi zindlela ezisebenzayo ziqinisekisa ukusebenza okuthembekile, zithuthukise ukunemba, futhi zandise impilo yenkonzo yemishini nemishini ehlobene nayo, ekugcineni kufaka ukusebenza ukusebenza kahle kanye nokonga izindleko.

2. Ukunganele noma ukungcoliswa okungcolile

Ukuthambisa kubalulekile ekusebenzeni kahle kanye nokuphila isikhathi eside kwemishini yokujikeleza, njengezindonga, ama-motor, noma ezinye izinhlelo zemishini. Kwehlisa ukungqubuzana phakathi kwezingxenye ezinyakazayo, kuqeda ukushisa, nokuvikela izindawo zokugqoka. Kodwa-ke, ukuthambisa okunganele okunganele noma okungcolile kungaholela ezindabeni ezinzima zokusebenza, ukuyekethisa ukusebenza nokudala ukwehluleka ngaphambi kwesikhathi.

Izimbangela zokuthambisa okunganele noma okungcolile

Ukwehluleka kwe-lubrication kwenzeka ngenxa yezici ezimbalwa eziphazamisa amandla okuthambisa ukwenza imisebenzi yayo ebalulekile:

Amazinga aphansi aphansi:

l Ukugcoba okunganele ohlelweni lokuthwala kuphumela ekuxhumaneni okwomile phakathi kwezindawo ezihambisanayo, njengezinto ezigoqayo nezinhlanga. Lokhu kuntuleka kokuthambisa kwandisa ukungezwani, okuholela ekushayweni (ukuklwebheka noma ama-gouges) ekuvuneni komhlaba.

l Amazinga aphansi angahle aqhamuke ekunakekelweni okungajwayelekile, ukugcwaliswa kokuqala okungafanele, noma ukuncipha kancane kancane ngokuhamba kwesikhathi ngenxa yokuhwamuka noma ukuvuza.

Ukungcola ku-Lubricant:

l imfucumfucu, njengothuli, ukungcola, noma izinhlayiya zensimbi, ingangena ngokuthambisa, ukuyiguqula ibe yindlela yokuhlupha. Lezi zingcoliso zigaya ukuhambisa indawo, ukusheshisa ukugqokwa.

l Imbareress yamanzi, imvamisa ngenxa yokubekwa kahle kokubekwa kahle noma okunomswakama, ukuxubanisa nokuthambisa, ukunciphisa ukubonakala kwayo nokukhuthaza ukugqwala noma ukukhuphula ukusebenza kwe-emulsication.

Izimpawu ezivuzayo noma zeqa imali yesondlo:

Ngigqoke , okulimele, noma okufakwe ngokungafanele

l Ukunganaki amashejuli ejwayelekile wokulungisa, njengokuhluleka ukubheka noma ukuphinda amazinga okuthambisa, kuholela ekuthambekeleni okunganele ngokuhamba kwesikhathi.

Ukusetshenziswa kwezithako ezingalungile:

l Usebenzisa izinto zokugcoba ezingahlangabezani nokucaciswa kwalezi zinto (isib. Ukuvunywa okungalungile, uhlobo, noma izengezo) zingahluleka ukuhlinzeka ngokuvikelwa okwanele, okuholele ekunciphiseni ukungqubuzana nokugqoka.

l Ukuxuba izithambisi ezingahambisani, njengokuhlanganisa amafutha namafutha noma izinhlobo ezahlukahlukene zamafutha, kungadalula ukusebenza futhi kubangele ukwehluleka kokuthambisa.

Imiphumela yokuthambisa okunganele noma okungcolile

Lapho i-lubrication ingenele noma ingcolisiwe, i-beacherings ihlangabezana nemiphumela eyingozi ebeka phansi ukusebenza kwawo:

Ukuguguleka komhlaba kanye nokuphamba:

l Ukuthambekelwa okunganele noma ukungcoliswa okungekho emthethweni kubangela ukuguguleka komhlaba, lapho izinto ezibonakalayo zikhathele kude nezinto ezigoqekayo noma izinhlanga. Lokhu kuholela ekuphaphemeni, okubonakaliswa yi-craters emincane ebusweni, okuphazamisa ukusebenza kahle.

l Ukuphilisa kukhulisa ukudlidliza nomsindo, ukunciphisa ukunemba nokusheshisa okwengeziwe.

Ukwanda ukushisa kusuka ekushayweni:

l Ngaphandle kokuthambisa okufanele, ukungqubuzana phakathi kwezingxenye ezihambayo kwakha ukushisa ngokweqile. Leli lokushisa eliphakeme lingalimaza impahla evunayo, yenze buthaka ukwakheka kwalo, futhi kubangele ukwanda okushisayo, okuholela ekuphatheni kabi noma izindaba zokuthola imvume.

l ama-lubraments angcolisiwe akhulisa isizukulwane sokushisa ngokwazisa izinhlayiya ezikhulisa ukungqubuzana.

Ukuthathwa kwezimo ezimbi kakhulu:

l Ezimweni ezinzima, ukungabikho kokuthambisa okusebenzayo kungadala ukuthwala, lapho izinto ezigoqayo nezinhlanga zivalela ngenxa yokungqubuzana ngokweqile noma ukufudumala kwezinto ezibonakalayo. Ukuhlanza imishini imishini imishini, ngokungathi kudala ukwehluleka kwenhlekelele kanye nomonakalo ezingxenyeni ezizungezile.

l Ukuthathwa kuvame ukuba umphumela wokuxhumana isikhathi eside owomile noma ukungcoliswa okwedlulele.

Imiphumela yokuthambisa okunganele noma okungcolile

Imiphumela yokuhlulela kokuthambisa ukwedlula ukunwebeka ngokwabo, inomthelela ekusebenzeni kohlelo lonke nezindleko zokusebenza:

l Unciphise isikhathi sokuphila esisha : akwanele noma ukungcoliswa okungcolile kusheshisa ukugqokwa, kunciphisa kakhulu impilo yenkonzo yama-bearings kanye nokudinga ukufakwa kabusha njalo.

l Izindleko zokulungiswa zokulungiswa : ukulimala okuvela ekuthambekeni kokuhlunga kwehluleka kuholela ekubizeni okubizayo, kufaka phakathi ukufakwa esikhundleni nesikhathi sokuphumula ukuze kulungiswa.

l sokukhiqizwaIsikhathi

Ukunemba okuyekethisiwe

L Ubungozi Bezokuphepha : Ukuthathwa okuvumayo okusheshayo noma ukwehluleka kungadala izimo eziyingozi, njengokuziphatha okungalawulwa kokuziphatha noma ukulondolozwa kwemfucumfucu, ukubeka ubungozi kubasebenzi.

Imikhuba emihle yokunciphisa

Ukuthambisa okunganele noma okungcolisiwe kubeka engcupheni enkulu yokuthwala ukusebenza, okuholela ekuguguleka komhlaba, okuholela, ukushisa okuphezulu, nokuthathwa okungaba khona. Lezi zinkinga zivela emazingeni aphansi, ukungcoliswa yimfucumfucu noma amanzi, izimpawu ezivuzayo, noma izindlela zokulungisa ezingafanele. Ngokusebenzisa ama-luthayi acacisiwe, amazinga okuqapha, ukufaka esikhundleni izithambisi ezingcolile ngokushesha, futhi enze amasheke ajwayelekile we-Seal, opharetha angavimbela ukwehluleka okuhlobene nokuthambisa. Lezi zindlela ezisebenzayo zithuthukisa ukuthwala ukuthembeka, zinwebe isikhathi sokuphila kwempahla, futhi zinciphise izindleko zokusebenza, ukuqinisekisa ukusebenza okungaguquki kanye nokuphepha ezicelo ezibucayi.

3. Ukufakwa kabi noma ukufakwa okungafanele

Ukuqondanisa kahle kanye nokufakwa kubalulekile ekusebenzeni kahle kanye nokuphila isikhathi eside kwemishini yokujikeleza, njengama-spindle, ama-motors, noma ezinye izinhlelo zemishini. Amabhele enzelwe ukusebenza ngokuqondanisa okuqondile ukuze aqinisekise ngisho nokusatshalaliswa komthwalo nokusebenza okubushelelezi. Ukuphathwa kabi noma ukufakwa okungafanele kungaholela ezindabeni ezibalulekile zokusebenza, ukugqokwa okusheshayo, nokuhluleka ngaphambi kwesikhathi.

Izimbangela zokuphathwa kabi noma ukufakwa okungafanele

Ukuphathwa kabi noma ukufakwa okungafanele kwenzeka lapho ama-bearings akhona kahle noma avikelwe, okuholela ekungasebenzi kahle kokusebenza. Izimbangela ezijwayelekile zifaka:

Amaphutha emihlangano abangela ukutshekelwa komgodi:

l Amaphutha ngesikhathi sokuhlangana, njengokufakwa okungalungile kwama-bearings ama-shaft noma ezindlini, kungaholela ekuhlazekeni kwe-shaft noma ukuphathwa kabi kwe-angular. Lokhu kuhlalisa kabi kuphazamisa amandla okuvuselela ukujikeleza kahle.

Ukusingathwa okungafanele , njengokusebenzisa amandla angalingani ngesikhathi sokufakwa noma ukusebenzisa amathuluzi angafanele, kungadala ukuthwala okungekho emthethweni kusukela ekuqaleni.

Izikhundla ezishintshiwe zokunwebeka:

l Ngesikhathi sokusebenza, izingxenye zemishini zingashisa, zibangele ukwanda okushisayo okususa isikhundla sokuthwala, imicibisholo, noma izindlu. Uma kungenjalo kubalwa ekwakhiweni noma ekufakweni kwenqubo, lokhu kungaholela ekulweni nokungaxhuma.

l Izilungiselelo zokuthola imali ezingafanele noma ezingafanele zokulayisha zingandisa ukungasebenzi kahle okubangelwa ukwanda okushisayo.

Ukubeka endaweni engalingani:

l Ukufaka izimboni ezingalingani noma ezilungiselelwe ngendlela engafanele, njengezindlu ezingezinhle noma izisekelo zomshini we-Misterigned, zethula ukuphathwa kabi kusukela ekuqaleni.

l Ukubekezelela kwemishini engenzi kahle noma ukulungiselela okungafanele komhlaba (isib

Izinqubo zokufaka ezinganele:

l Ukweqa izinyathelo ezibucayi, njengokuqinisekisa ukuqondanisa noma ukucaciswa kwe-torque, ngesikhathi sokufakwa kungaholela ekuhlanjeni kokuhlaseli noma ekuhlaleni okungafanele.

l Ukuntuleka kokuqeqeshwa noma ukwehluleka ukulandela imihlahlandlela yomenzi kuvame ukuba nemiphumela kumaphutha wokufaka ayekethise ukusebenza.

Imiphumela yokuhlanza kabi noma ukufakwa okungafanele

Lapho ama-bearings athunyelwe kabi noma afakwe ngokungafanele, ahlangabezana nemiphumela emibi ebeka phansi ukusebenza kwawo kanye nokuphila isikhathi eside:

Ukusatshalaliswa komthwalo ongalingani:

l Ukuhlanjalazwa kudala ukusatshalaliswa okungalingani kokuqamba ukuthwala, ngezindawo ezithile ezithola imithwalo ngokweqile. Lokhu kusheshisa ukugqoka ezintweni ezigoqayo, izinhlanga, noma amakheji, okuholela ekuhlulekeni ngaphambi kwesikhathi.

l Ukulayisha okungalingani nakho kungadala ukugxila kwengcindezi yasendaweni, okwandisa amathuba okukhathala kwezinto ezibonakalayo.

Ukukhathala okubangelwa ukudlidliza:

l amabhere athunyelwe kabi akhiqiza ukudlidliza ngokweqile ngenxa yokujikeleza okungalingani noma ukuvelela. Lokhu kudlidliza kuncenga ukucindezelwa kwe-cyclic, okuholela ekukhathaleni ukuqhekeka ezintweni ezithwala.

l Ukudlidliza isikhathi eside kungasakaza kwezinye izingxenye zomshini, kubangele ukugqoka okwengeziwe noma ukulimala ohlelweni.

Ukushisa kusuka ekushayweni okwengeziwe:

l Ukungasebenzi kwandisa ukuxabana phakathi kwezakhi, kwakha ukushisa ngokweqile. Lokhu kushisa kungadalula izikombandlela, kuncipha izinto zokwakha, futhi kubangele ukwanda okushisayo, okubhekana nokuhlalisana kabi.

l Amazinga okushisa aphakeme anciphisa ukunemba nokusebenza kahle nokusebenza kahle, okuholela ekutheni kube nokungenzi ngokweqile noma ukwehluleka.

Kuncishisiwe isikhathi sokuphila:

l Imiphumela ehlanganisiwe yokulayisha okungalingani, ukudlidliza, kanye nokwenyuka okuthuthukile kunciphisa kakhulu impilo yokusebenza kwe-bearing, kudinga ukufakwa kabusha kwezindleko ezijwayelekile kanye nokwandisa izindleko zokulungiswa.

Imiphumela yokuhlaziya noma ukufakwa okungafanele

Imiphumela yokuhlaziya noma ukufakwa okungafanele ukunweba ngaphezu kwezibopho ngokwayo, okuthinta ukusebenza kohlelo lonke nezindleko zokusebenza:

l Ukugqokwa okusheshayo nokwehluleka : Imithwalo engalingani kanye nokudlidliza isheshisa ukugqoka, okuholela ekuhlulekeni kwangaphambi kwesikhathi kanye nokunciphisa imishini yokuphila.

l Izindleko zokulungiswa zokulungiswa : Ukulungiswa okuvamisile noma okunye ngenxa yokulimala okuhlobene nokulimazeka kokushayela izindleko zokulungisa.

I-L DowTime : I-Misterigned Bearings ingadala ukwehluleka okungalindelekile, ukumisa ukukhiqizwa kanye nokuphumela kwemali elahlekile noma imali ethosiwe.

l Ukucacisa Okuyekethisiwe : Kuhlelo lokunemba, okufana nemishini ye-CNC noma amarobhothi, ukungasebenzi kahle kunciphisa ukunemba, okuholela emikhiqizweni enesici noma i-Rework.

L Ubungozi Bezokuphepha : Ukwehluleka ngokweqile noma ukwehluleka okungazelelwe kungadala izimo eziyingozi, ezinjengezinto ezihlanganisiwe zezakhi noma zokuziphatha okungalawulwa komshini, ukubeka izingozi kubasebenzi.

Imikhuba emihle yokunciphisa

Ukufakwa okungafanele noma ukufakwa okungafanele kwama-bearings, okubangelwa amaphutha emihlangano, ukunwebeka okushisayo, noma izindawo ezingalingani, kuholela ekusakazweni komthwalo ongalingani, ukukhathala okubangelwa ukudlidliza, kanye nokudinwa okwandayo. Lezi zingqinamba ziholela ekugqokeni okusheshayo, ukuncishiswa kokunemba, kanye nokuhluleka kwemishini, nemiphumela ebalulekile yokusebenza kanye nezezimali. Ngokusebenzisa amathuluzi okuqondanisa, ukuqinisekisa ukuqondanisa kokusetha kokusetha, ukubalwa kwe-accountion kokwanda okushisayo, kanye nokwenza amasheke ajwayelekile, abahlinzeki bangavikela izingqinamba ezihlobene nokuhlehlisa. Lezi zindlela ezisebenzayo ziqinisekisa ukusebenza okuthembekile, zandisa i-WETIW PATESPAN, futhi zithuthukise ukusebenza kahle kokusebenza, ukunciphisa isikhathi sokuphumula nezindleko ezisetshenziselwa ezibucayi.

4. Ukungcoliswa kusuka othulini nasemfuyeni

Ukungcoliswa othulini nasemfuleni kuyinkinga ebalulekile ezindaweni lapho imishini yokunemba khona lapho imishini yokunemba khona, njengezikhala, ama-bearings, noma ezinye izingxenye zemishini, isebenza. Lokhu kungcola, okubandakanya izinhlayiya ezinhle njengothuli, ukungcola, ukushefa kwensimbi, noma ezinye imfucumfucu eyi-microscopic, kungangena emishini ngezindlela ezahlukahlukene, okuholela ekungasebenzi kahle kokusebenza nomonakalo.

Izimbangela Zokungcola

Ukufakwa kothuli kanye nokufakelwa ngokujwayelekile kwenzeka ngenxa yokukodwa noma ngaphezulu kwalezi zinto ezilandelayo:

Izindlela zokubopha ezimpofu:

Izimpawu ezinganele noma ezigugile ezizungeze izingxenye zemishini zivumela izinhlayiya zangaphandle ukungena ezindaweni ezibucayi. Ngokuhamba kwesikhathi, izimpawu zokubopha zingadalula ngenxa yokugqoka, ukufakwa okungafanele, noma ukuvezwa kwezimo ezinokhahlo, ukudala izikhala zokungcola ukuze ungene.

Izimpawu ezingenzelwe ukubekezelela izinselelo ezithile zemvelo, ezinjengamazinga aphezulu uthuli noma amazinga okushisa aphezulu, asengozini ikakhulukazi.

Izindawo ezi-CRET ezisebenzayo:

Imishini esebenza ezindaweni ezinamazinga aphezulu ezinkinga ezindiza, njengokukhiqiza izitshalo, izindawo zokwakha, noma izindawo ezinekhwalithi yomoya empofu, isengozini enkulu yokungcoliswa.

Imikhuba yokugada okungafanele, efana nokwehluleka ukuhlanza izindawo zomsebenzi noma ukuvumela imfucumfucu ukuba iqoqe imishini eduzane, kwandisa inkinga.

Imikhuba yokulungisa engafanele:

Ngesikhathi sokulungiswa noma ukulungisa, amathuluzi, izandla, noma izakhi ezingahlanzwa kahle zingaletha ama-dilanants ohlelweni.

Ukugcotshwa okungcoliswe nezinhlayiya kungasebenza njengendlela yokuletha imfucumfucu emishini.

Abangcoliso bezindiza:

Izinhlayiya ezinhle zimiswe emoyeni, ezinjengempova, uthuli lwezimboni, noma izinsalela zamakhemikhali, zingaxazululwa emishini ngensimbi ngezinhlelo zomoya noma umoya omncane.

Imiphumela yokungcola

Uma usuthuli kanye nodoti imishini yokungena ngaphakathi, kungadala i-cascade yemiphumela elimazayo ebeka phansi i-Perform kanye nokuphila isikhathi eside. Imiphumela emihle ifaka phakathi:

Ukugaya okuhlukumezayo ezindaweni ezikhona:

Uthuli kanye nemfucumfucu, izinhlayiya ezinzima ikakhulukazi ezinjengezingubo zensimbi noma i-silica, yenza njengezimangaliso lapho ziboshelwe phakathi kwezingxenye ezinyakazayo. Lokhu kuholela ekuqothulweni okuncane noma ukugaya ezindaweni ezinjengokuzala, izikhala, noma amagiya.

Ngokuhamba kwesikhathi, lesi senzo sokuhlukumeza sibangela ukugqoka, ukunciphisa ukunemba nokusebenza kahle kwezakhi kanye nokuholela ekuhlaseleni kabi noma ekushayweni okwengeziwe.

Ukugqwala okuqukethwe okuqukethwe okuhlanganisiwe okuhlanganisiwe:

Ukungcola kuvame ukuxubana nomswakama, kungaba okuvela emvelweni noma ekuthayizeni, ukudala indawo eshisayo. Isibonelo, uthuli oluqukethe usawoti noma amakhemikhali lungasheshisa ukwakheka kokugqwala ezindaweni zensimbi.

Ukugqwala kwehlisa izinto, okuholela ekuphaphemeni, okuqhekezayo, noma ukwehluleka kwesakhiwo, okunganciphisa kakhulu isikhathi sokuphila kwemishini.

Izindlela ezivinjelwe:

Uthuli kanye nemfucumfucu ingavala iziteshi zokufuhlakala, kuvimbela ama-lubricant kusuka ekufinyeleleni ezindaweni ezibucayi. Lokhu kuphumela ekuthambezeleni okunganele, okwandayo ukungqubuzana nokushisa kwesizukulwane.

Izindlela ezivinjelwe nazo zingadala ukusatshalaliswa kwe-lubthent, okuholela ekuphumeni ngokweqile okwenziwe ngokweqile noma kwesakhi.

Imihuzuko, ama-dents, kanye nokuqhekeka ekugcineni:

Umphumela wokuqongelela we-abrasion, ukugqwala, nokuthambisa okunganele okunganele kubonakale njengomonakalo obonakalayo, njengokuhlanza, ama-dents, noma okungahambi kahle komhlaba.

Lezi zingqinamba zibeka phansi ubuqotho bezakhiwo zezakhi, okuholela ekugqokeni okusheshayo futhi, ekugcineni, ukwehluleka okuyinhlekelele kwemishini.

Imiphumela yokungcola

Imiphumela yothuli nokungcola kwemfucumfucu yandisa ngaphezu komonakalo osheshayo futhi kungaba nemithelela ebalulekile yokusebenza nezezimali:

l Ukuncishiswa kwemishini yokusebenza : Izingxenye ezingcolisiwe zisebenza kahle kakhulu, kudinga amandla amaningi okwenza imisebenzi efanayo kanye nokwenza izindleko ezisebenzayo.

l Izindleko ezandayo zokulungiswa : Ukulungiswa okuvamisile noma okunye ngenxa yokungcola okuhlobene nokulimala kokushayela izindleko zokulungisa izindleko zokulungisa.

L Dominitime Nokulahleka Kwezokukhiqiza : Ukwehlukahluka okungalindelekile okubangelwa ukungcoliswa kungamisa ukukhiqizwa, okuholele ekuthobekeni okukhawulelwe kanye nemali elahlekile.

L Ikhwalithi Yomkhiqizo Olahlekile : Embonini Yezimboni Eqondile, njenge-Aerospace noma Ukukhiqiza Ngokwe-elekthronikhi, ukungcoliswa kungaholela emikhiqizweni engenaphutha, okuholela ekusetshenzisweni kabusha noma ukunganeliseki kwamakhasimende.

L Izingozi Zokuphepha : Imishini eyonakele noma yokungasebenzi kahle inqwaba yabasebenza kubasebenzi, okuholela ezingozini noma ukulimala.

Imikhuba emihle yokunciphisa

Ukungcola kusuka othulini nasemfuzaneni kubeka engcupheni enkulu ekusebenzeni nasekude kwemishini yokunemba. Ngokuqonda izimbangela - njengezimpawu ezingezinhle nezindawo ezingcolile - nemiphumela ephumelelayo, kufaka phakathi ukugqokwa okuxakile, ukugqwala, kanye nama-blockage, ama-opharetha angathatha izinyathelo ezisebenzayo zokunciphisa ubungozi. Ukusebenzisa imikhuba emihle kakhulu, njengokufaka uphawu okusebenzayo, ukugcwala komoya, nokuhlanza njalo, kunganciphisa kakhulu ukungcoliswa, ukuqinisekisa ukusebenza okuthembekile, ukunciphisa isikhathi sokuphumula, nokunweba impilo yenkonzo yemishini ebucayi. Ngokubeka phambili ukulawulwa kokungcola, amabhizinisi angathuthukisa ukusebenza kahle, anciphise izindleko, futhi alondoloze amazinga aphezulu okusebenza kahle.

5. Ukudlidliza ngokweqile noma ukungalingani

Ukudlidliza okwedlulele noma ukungalingani emishini ejikelezayo, njengezindonga, ama-motors, noma ezinye izinhlelo ezinamabhere, kubeka usongo olukhulu ekusebenzeni okusebenzayo nasengxenyeni ende. Lezi zinkinga zivela lapho amathuluzi, ama-rotors, noma ezinye izinto ezijikelezayo azinakulinganisela noma lapho uhlelo lusebenza khona ngokujwayelekile, okuholela ekucindezelekeni okwenziwe nge-amplonant.

Izimbangela zokudlidliza ngokweqile noma ukungalingani

Ukudlidliza ngokweqile noma ukungalingani emishini ngokuvamile kuphumela ezintweni ezilandelayo:

Amathuluzi noma ama-Rotors angalingani

l Amathuluzi, njengamathuluzi okusika emisebenzini noma kuma-rotors kuma-motors, awona alinganiswe kahle akhiqize amandla angalingani ngesikhathi sokujikeleza. Lokhu kulingana kubangela ama-oscillations athi ukucindezela kwengcindezelo nezinye izinto.

l ukungalingani kungahle kube nomphumela wethuluzi elingalingani, umhlangano ongafanele, noma ukukhiqiza iziphambeko ezintweni ezijikelezayo.

Imvamisa evumayo:

l Lapho imishini isebenza khona noma eduze imvamisa yayo yemvelo yemvelo, ukudlidliza kukhuliswe, kubangele ama-oscillations ngokweqile. Lokhu kwenzeke kungenzeka ngenxa yezilungiselelo zejubane elingafanele noma amaphutha okuklama ohlelweni.

l Izici zangaphandle, njengemishini eseduze noma ukunyakaza kwemvelo, kungajabulisa futhi ama-survency ama-resuncies, akhulise inkinga.

Ukusetha okungafanele noma ukuqondanisa:

Izinto ezithunyelwe kabi, ezinjengemishama noma ukuhlanganisa, zingenisa ukunyakaza ngokwakha ukusatshalaliswa kwamandla angalingani ngesikhathi sokujikeleza.

l Izingxenye ezikhululekile noma ezivikelwe ngokungafanele, ezinjengabanikazi bezithuthi noma ukulungiswa, nazo zingasiza ekungalingani naku-vibration.

Gqoka noma umonakalo ezingxenyeni:

l ukugqokwa, amagiya alimele, noma izingxenye ezingcolile zingadala ukunyakaza okungajwayelekile, okuholele ekuvuthaka okuthuthukile.

l Imfucumfucu eqoqiwe noma ukungcoliswa ohlelweni kungaphazamisa ukulinganisela, ukukhulisa ama-oscillations.

Imiphumela yokudlidliza ngokweqile noma ukungalingani

Lapho imishini ibandakanya ukudlidliza ngokweqile noma ukungalingani, ama-bearings kanye nezinye izakhi zihlupheka ngemiphumela enobungozi:

Ama-Oscillations amplified ukulimaza izinhlanga:

l Ukudlidliza okwedlulele kubangela umthelela ophindaphindile nokulayisha okungalingani emijahweni yokuthwala (izindandatho zangaphakathi nezangaphandle ezihamba ngezinto ezigoqayo). Lokhu kuholela ekulimaleni komhlaba, njengokuqhekeka okuncane noma ukuguquguquka ngokwezinto ezibonakalayo, ukuyekethisa ubuqotho be-haring.

l Oscillations ingasabalalisa nezinye izinto zomshini, ibangele ukugqokwa okusakazekile.

Ukukhathala phezu kwemijikelezo:

l Ukudlidliza okuqhubekayo kudida ukucindezela kwe-cyclic ku-bearings, okuholela ekukhathaleni ukuqhekeka ngokuhamba kwesikhathi. Le mifantu iyenza buthaka isakhiwo se-bearing, yandisa ingozi yokwehluleka.

l Ukulahleka Kokukhathala kuqongelela umjikelezo ngamunye wokusebenza, ukunciphisa kakhulu isikhathi sokuphila kwe-Bearing.

Ukushisa kusuka ekunyakazweni njalo:

I -vibrations yandisa ukungezwani phakathi kwezakhi ezithwala, kwakha ukushisa ngokweqile. Lokhu kushisa kungadalula izithako, kwenza buthaka izinto zokwakha, futhi kubangele ukwanda okushisayo, okwengeziwe okwengeziwe noma izingqinamba zokucacisa.

l Isizukulwane sokushisa isikhathi eside singaholela ekutheni sishise ngokweqile, sinciphise ukusebenza kahle nokunemba.

Ukulimala kwesibili kwemishini:

l Ukudlidliza ngokweqile kungakhulula ama-fasteners, izingxenye zeMisalign, noma ukulimala kwezingxenye eziseduzane, okuholela ekwehlulekeni kohlelo olubanzi.

l Ezimweni ezinzima, ukudlidliza okungalawulwa kungadala ukwehluleka okuyinhlekelele, njengokuphamba noma ukuxabana.

Imiphumela yokudlidliza ngokweqile noma ukungalingani

Imiphumela yokudlidliza ngokweqile noma ukungalingani kwandise ngaphezu kwamabombo, okuthinta ukusebenza kohlelo lonke nezindleko zokusebenza:

L Dissed OWSPAN FUFLPAN FUNDAS : Ama-Vibrations ashekisi ukugqoka, okuholela ekuhlulekeni ngaphambi kwesikhathi kweminye imithwalo kanye nezinye izinto, kudinga ukufakwa kabusha njalo.

l Izindleko zokulungiswa zokulungiswa : Ukulimala kusuka ekuvuthweni kudinga ukulungiswa okubizayo, kufaka phakathi ukufakwa esikhundleni kanye nokulungiswa kabusha kohlelo.

I-L DowTime yokukhiqiza : Ukwehluleka okubangelwa ukudlidliza kungamisa ukukhiqizwa, okuholele ekudeyimeni okudediwe kanye nokulahleka kwezezimali.

: Ukunemba okuyekethisiwe Ukudlidliza ngokweqile kunciphisa ukunemba kwemishini, okuholela emikhiqizweni enesici noma ekusebenzeni kabusha emikhakheni eqondile njenge-aerospace noma ama-elekthronikhi.

L Ubungozi Bezokuphepha : Ukudlidliza okukhulu kungadala ukuqunjelwa kwengxenye, isenzo somshini esingalawulwa, noma ukulondolozwa kwemfucumfucu, ukubeka izingozi kubasebenzi.

Imikhuba emihle yokunciphisa

Ukudlidliza okwedlulele noma ukungalingani, okubangelwa amathuluzi angenakulinganisela, ama-resurance ama-resuncies, noma ukusetha okungafanele, kuholela kuma-oscillations akhuphukile, ukukhathala, kanye nokushisa, ukulimala okulimazayo nezinye izinto. Lezi zingqinamba ziholela ekunciphiseni kwemishini yokuphila, izindleko zokulungiswa kwemali, kanye nokunemba okungekho emthethweni, ngezingozi ezingaba khona zokuphepha. Ngokulinganisa amathuluzi, ukunyakaza okuhlukanisayo, ukuqapha nabahlaziyi, kanye nokuqinisekisa ukusetha okufanele, opharetha banganciphisa lezi zingcuphe. Lezi zindlela ezisebenzayo zenza ngcono ukuthembeka kwemishini, zinwebe impilo yensiza, futhi zilondoloze ukusebenza kahle kokusebenza, ukunciphisa isikhathi sokuphumula nezindleko ezihlelweni ezibucayi.

6. Amazinga okushisa aphezulu aphezulu

Amazinga okushisa aphezulu abeka inselelo ebalulekile ekusebenzeni nasekude kakhulu kwama-bearings kanye nezinye izinto ezijikelezayo zemishini, ezinjengezindonga noma ama-motors. Ukushisa ngokweqile kungadalula izinto zokwehla, kukhandlese, futhi kubangele izinguquko ezibucayi, okuholela ekusebenzeni okungasebenzi kahle kanye nokwehluleka ngaphambi kwesikhathi.

Izimbangela zokushisa okuphezulu kokusebenza

Izinga lokushisa eliphakeme emishini ngokuvamile livela ngokuhlanganiswa kokusebenza, kwezemvelo kanye nokulungiswa okuhlobene nokugcina:

Ukuxabana ngokweqile:

l Ukuxabana okuphezulu phakathi kwezakhi ezithwala, kaningi ngenxa yokuthambisa okunganele, ukuphathwa kabi, noma ukulayisha ngokweqile, kwakha ukushisa okubalulekile.

l Amathuluzi alinganiselayo noma ukudlidliza ngokweqile angakhulisa ukuxabana, okufaka isandla emazingeni okushisa aphakeme.

Ukulayisha ngokweqile noma ukusebenza ngokhahlo:

l Ukusebenza kwemishini esebenza ngaphezu kwamandla awo aklanyelwe umthwalo, njengokusetshenziswa kwemishini okunzima noma ukusebenzisa amapharamitha wokusika anolaka, kwandisa ukulondolozwa kokushisa ngenxa yokucindezela kwemishini.

l Ijubane eliphakeme noma amanani okuphakelayo angabelisa ukukhiqizwa kokushisa, ikakhulukazi ezindlini ezingekho ngaphansi kwezimo.

Izinhlelo ezinganele zokupholisa:

l anele noma ukungasebenzi kahle izinhlelo zokupholisa, ezifana nabalandeli, amaphampu okupholile, noma ukushintshana kokushisa, yehluleka ukuqeda ukushisa ngempumelelo, ukuvumela amazinga okushisa akhuphuke.

l umoya omncane omncane noma amazinga okushisa aphezulu akhona endaweni yokusebenza ekhulisa ukushiswa kokushisa.

Ukugcotshwa kokugcotshwa noma ukukhetha okungafanele:

l Izithambisi ezingalungele izinhlelo zokushisa okuphezulu zingase zinciphise noma zishiye phansi, zinciphise amandla azo okuqeda ukushisa nokuvikela izindawo ezinomthelela.

l Izinto zokuthambisa ezingcolile noma ezonakalisiwe nazo zingasiza ekushayweni okuthuthukile nokushisa kwesizukulwane.

Imithombo yokushisa yangaphandle:

l Imishini esebenza eduze kwemithombo yokushisa yangaphandle, efana namafutha, amahhavini, noma ilanga eliqondile, lingathola amazinga okushisa aphakeme athinta ukusebenza.

l Ukufakwa okunganele noma ukuvikelwa okuvela emithonjeni yokushisa yangaphandle kungahlanganisa inkinga.

Imiphumela yamazinga okushisa aphezulu okusebenza

Lapho ama-bearings kanye nemishini kufakwa ngaphansi kwamazinga okushisa aphezulu, ahlangabezana nemiphumela emibi esonakalisayo ehlehlisa ukusebenza nokuqina:

Umthamo womthwalo oncishisiwe:

l Amazinga okushisa aphezulu athambisa izinto zokuthwala, njengensimbi, anciphise ubulukhuni bawo namandla athwala umthwalo. Lokhu kwenza buthaka kwenza ukubekelwa ukuguquguquka ngokwengeziwe ngaphansi kwemithwalo evamile yokusebenza.

Izinto zokwakha ezithambile azikwazi ukubekezelela ukucindezelwa kwemishini, ukusheshisa ukugqoka nokwehluleka.

Ukuwohloka kwe-Lubrant:

Amazinga okushisa aphakeme akhulisa ama-lufkhonta amancanyana, axize, noma aqhekeze ngamakhemikhali, anciphise ukuhlakanipha nokusebenza kwawo. Lokhu kuholela ekuthambekelweni okunganele, ukuxabana okwandayo, nokuqhubeka kokushisa.

l Izinto zokuthambisa ezingcolile zingakha i-sludge noma ama-varnish, imikhombo yokuthambisa okufuywayo nokukhulisa ukugqoka.

Ukuqhekeka kokukhathala okushisayo:

Ukuchayeka okuphindaphindwayo kumazinga okushisa aphezulu kukhipha ukukhathala okushisayo, lapho ukufudumeza kwe-cyclic nokupholisa kubangela imifantu emincane ekuvuneni izinga. Le mifantu iyasabalalisa ngokuhamba kwesikhathi, yenza buthaka ukuthwala nokwandisa ingozi yokwehluleka kwenhlekelele.

l Ukunwebeka okungekho emthethweni kwezakhi kungandisa ukugxila kwengcindezi, okuholela ekwakhekeni kokuqhekeka.

Izinguquko ezinobukhulu nokungasebenzi kahle:

Ukushisa okuphezulu kubangela ukwanda okungalingani kwama-bearings, ama-shaft, noma izindlu, okuholela ekutheni kuhlaselwe ukuphathwa kabusha, ukudlidliza okungekho emthethweni, nokusatshalaliswa komthwalo ongalingani.

l Lezi zinguquko ezinobukhulu zinganciphisa ukuvumela imvume, kubangele ukubopha noma ukuxabana okwandayo.

Imiphumela yamazinga okushisa aphezulu

Imiphumela yokushisa ngokweqile idlulisela ngaphesheya kwama-bearings, okuthinta ukusebenza kwesistimu kanye nezindleko zokusebenza:

l ancishisiwe imishini yokuphila : izinto ezithambisayo kanye nokudla okuvuthayo okuthambisayo ukugqoka, ukunciphisa kakhulu ukuthwala kanye nemishini yokuphila.

l Izindleko zokulungiswa kwanyuselwa : Ukulungiswa okuvamisile noma okunye ngenxa yokulimala okuhlobene nokushisa kokushayela izindleko zokulungisa.

I-L DowTime yokukhiqiza : Ukwehluleka okubangelwa ukushisa okuphezulu kungamisa ukukhiqizwa, okuholele ekunciphiseni okuphuthelwe kanye nokulahleka kwezezimali.

Ukunemba okuyekethisiwe

l Izingozi Zokuphepha : Izakhi ezigcwele ngokweqile zingahluleka ngokuzumayo, zakha izimo eziyingozi njengokuthathwa kokuthathwa, ukuboshwa kwengxenye, noma ubungozi bomlilo ezimweni ezimbi kakhulu.

Imikhuba emihle yokunciphisa

Amazinga okushisa aphezulu, adalwa ukungqubuzana ngokweqile, ukulayisha ngokweqile, ukupholisa okunganele, noma izinto zokuthambisa ezingafanele, ukuholela ekunciphiseni umthamo womthwalo, ukugcotshwa kokuthambekela, kanye nokuqhekeka kokukhathala okushisayo. Lezi zingqinamba zinciphisa i-Imishini Lifespan, zikhulisa izindleko zokulungiswa, futhi ziyekethise ukunemba, ngezingozi zokuphepha ezingaba khona. Ngokwenza kahle amasistimu wokupholisa, amazinga okushisa, ukugwema ukulayisha ngokweqile, kanye nokukhetha ama-lubrices afanele, ama-opharetha anganciphisa ubungozi obuhlobene nokushisa. Lezi zindlela ezisebenzayo ziqinisekisa ukusebenza kwemishini ethembekile, zandisa impilo yensiza, futhi zinciphise isikhathi sokuphumula nezindleko ezihlelweni ezibucayi.

7. Indima yamanje kagesi

Indima yamanje kagesi ngokusebenzisa ama-bearings, imvamisa okubangelwa izisekelo ezingezinhle noma ezidukayo, kungaholela kumonakalo omkhulu ekujikelezeni imishini efana nama-motors, ama-spindle, noma ama-generator. Lesi simo, esinqunyelwe ukukhishwa kwemishini kagesi (EDM), i-Erodes ithwala izindawo zazo.

Izimbangela zendima yamanje kagesi

Indima yamanje kagesi yenzeka lapho ama-currics kagesi engahlosiwe agelezela ngamabhere, ngokuvamile ngenxa yalezi zinto ezilandelayo:

Ukuphathwa kabi:

l Ukungafanele noma okungama-Impreate noma okungafanele kweMishini kuvumela ama-curmical kagesi aphambuke agelezele ama-bearings, afune indlela yokumelana nokuncane okuncane emhlabathini.

l Ukuphathwa kabi kungahle kube nomphumela we-wiring enephutha, ukuxhumeka okukhohlakele, noma izinhlelo ezinganele ezisekelwe emshinini noma esikhungweni.

Imisipha elahlekile kusuka ezinhlelweni zikagesi:

l Imisinga elahlekile ingavela kuma-effect frequency drives (VFFS), ama-inverters, noma ezinye izakhi zikagesi ezisetshenziswa kakhulu emishini yanamuhla, ikakhulukazi kumandla aphezulu noma ngejubane eliphezulu.

l Ukuphazanyiswa kwe-Electromagnetic (EMI) noma ama-voltages adonsele ama-voltages avela kumathuluzi kagesi aseduze nawo angenza ama-currings adlule amabhere.

I-Static Electricity Daild:

l Izindleko ze-Static zinganqwabelana ngezinto ezijikelezayo, ikakhulukazi ezindaweni ezomile noma eziphakeme, okuholela ekulahlekelweni ngokusebenzisa amabhere.

l Lokhu kujwayelekile kuzinhlelo zokusebenza ezibandakanya izinto ezingezona ezenziwa noma amabhande akhiqiza ugesi ovumayo.

Ukufakwa okungafanele noma ukuvikela:

l Ukuntuleka kokufakelwa okufanelekile kuma-bearings noma izingxenye ezizungezile kuvumela ama-currics kagesi ukuba ageleze izindlela ezingahlosiwe.

l Ukuvikelwa okulayini okumelene nezinkundla ze-electromagnetic kungandisa ukuhamba kwamanje emishini ebucayi.

Imiphumela yendima yamanje kagesi

Lapho ama-currical kagesi adlula ebhethri, adala imiphumela enobungozi, ngokuyinhloko ngokuqhuma kwemishini yokuphuma kwemishini (edm)

Ukuguguleka komhlaba ngokweqile nge-arcing:

l Ukuqhuma kukagesi phakathi kwezakhi ezithwala (isib. Izici ezigoqekayo nezinhlanga) kwakha izinhlansi zasendaweni ezakhiwe izinto, ezifana ne-EDM. Lokhu kuphumela ekuphambungqeni, okushayayo, noma amaphethini aqanjiwe ekuvuneni kwaphezulu.

l Lawa mahle anciphise ukusebenza okubushelelezi, andise ukuxabana, futhi asheshise ukugqoka.

Ama-craters amancane nokuwohloka kwezinto ezibonakalayo:

l Ukuphoqelela kukhiqiza ama-craters amancane noma amamaki ashise izindawo ezinemininingwane, anciphise ngokwehlisa impahla futhi anciphise umthamo ophethe umthwalo wawo.

Ngaleso sikhathi, la ma-micro-craters aholela ekuchithekeni (ukufiphala kwezinto ezibonakalayo), ukwehlisa ubuqotho be-haring.

Ukwanda kokudlidliza nomsindo:

l Ukulimala okungaphezulu kwe-arching kubangela ukujikeleza okungalingani, okuholela ekuthuthukiseni ukudlidliza nomsindo ngesikhathi sokusebenza.

l Ukudlidliza kungasakaza kwezinye izingxenye zomshini, kubangele ukugqoka okwengeziwe noma ukuphathwa kabi.

Ukugcotshwa kwe-grucinant:

l Ukuphonsa kwakha ukushisa ezindaweni zokuxhumana, ezinganciphisa noma zivutha ama-lubrics, zinciphisa ukusebenza kwazo futhi ziholele ekuqhekekeni nasekugqokeni.

l Ukuthambisa okungcolisiwe noma kwe-carbonised kungahle kube okuxakayo, okukhulisa ukulimala komhlaba.

Ukuhluleka ngaphambi kwesikhathi:

l Imiphumela emihle yokuguguleka komhlaba, ukudlidliza, futhi ukuwohloka okuthokozelayo okuqinile kunciphisa kakhulu isikhathi sokuphila, okuholela ekuhlulekeni ngaphambi kwesikhathi.

l Ezimweni ezinzima, ukuqeda kungadala ukwehluleka noma ukwehluleka okuyinhlekelele.

Imiphumela yendima yamanje kagesi

Imiphumela yendima yamanje kagesi yandisa ngaphezu kwamabombo, okuthinta ukusebenza kohlelo kanye nezindleko zokusebenza:

l ancishisiwe imishini yokuphila yempilo

l Izindleko zokulungiswa zokulungiswa : Ukulimala kusuka ekuphoqelweni kudinga ukulungiswa okubizayo, kufaka phakathi ukufakwa esikhundleni kanye nesikhathi sesistimu.

I-L Dowtime Isikhathi sokukhiqiza : Ukwehluleka okubangelwa ukulimala kukagesi kungamisa ukukhiqizwa, okuholele ekunciphiseni okukhawulelwe kanye nokulahleka kwezezimali.

Ukunemba okuyekethisiwe

l Ubungozi Bezokuphepha : Ukwehluleka okusheshayo noma ukudlidliza ngokweqile kungadala izimo eziyingozi, ezinjengezembatho zengxenye noma izingozi zikagesi, ukubeka ubungozi kubasebenzi.

Imikhuba emihle yokunciphisa

Indima yamanje kagesi, evame ukubangelwa yindawo empofu, i-curns elahlekile, noma ugesi ophelele, izinhlanzi ezithwala izindawo zokuphonsa, okuholela ekukhohlisayo, ukudlidliza nokukhohlisa. Le miphumela inciphisa isikhathi sokuphila, yandise izindleko zokulungiswa, futhi iyekethise ukunemba okusebenzayo, ngezingozi zokuphepha ezingaba khona. Ngokuqinisekisa ukuthi kunesisekelo esifanele, kusetshenziswa ama-beagedings afakwe, anciphise imisinga elahlekile, futhi enze ukuhlola okujwayelekile, abahlinzeki bangavimbela ukulimala kukagesi. Lezi zindlela ezisebenzayo zenza ngcono ukuthembeka kwemishini, zandise impilo yensiza, futhi zinciphise isikhathi sokuphumula nezindleko ezisetshenziselwa ezibucayi.

Izimpawu nezimpawu ze-CNC Spindle Overheating

I-Spindle Motors iyizakhi ezibucayi emishini yokunemba, efana nemishini ye-CNC, ama-Lases, kanye nemishini yokugaya, lapho ama-bearings adlala indima ebaluleke kakhulu ekuqinisekiseni ukusebenza kahle, okunembile, nokusebenza kahle. Ukulwa nomonakalo, uma kungatholakali, kungaholela ekuvuseleleni izindleko, kuncishisiwe ikhwalithi yemishini, kanye nokwehluleka kwenhlekelele kwemoto ye-spindle. Ukutholwa kusenesikhathi kubalulekile ukuze unciphise lezi zingozi futhi unwebe isikhathi sokuphila kwemishini.

Imisindo engajwayelekile

Enye yezimpawu zokuqala futhi ezibonakalayo zomonakalo onobukhona bokuthi imisindo engajwayelekile isuka kwi-spindle motor ngesikhathi sokusebenza. Le misindo ivame ukukhombisa izingqinamba ezingaphansi, uma zinganakwa, zingakhuphuka zibe nomonakalo omkhulu. Imisindo ejwayelekile yokungajwayelekile ifaka:

l Ukukhala noma okubunjiwe okumisiwe : I-high-putched highsing averaily iphakamisa ukungqubuzana okungaphezulu komthelela, imvamisa ngenxa yokuthambisa okunganele, ukugqokwa kwezindawo zokuthwala, noma ukungcoliswa kwemfucumfucu enjengezinhlayiya zothuli noma zensimbi. Lo msindo ungaqina njengoba ukuthwala kuwohloka kakhulu.

l Ukugaya noma imisindo yokuklabalasa : Imisindo yokugaya ikhona ngokugqokwa okubalulekile noma ukulimala komhlaba, njengokuphamba noma ukuchitha izinhlanga ezivumayo noma izinto ezihlanganayo. Lokhu kungenzeka lapho ukuthwala kufakwa emithanjeni ngokweqile, ukuphathwa kabi, noma ukusebenza isikhathi eside ngaphandle kokulungiswa okufanele.

l Ukuchofoza noma Ukuphapha : Ukuchofoza okukodwa noma imisindo yokuphawula kungakhomba ezingxenyeni ezivulekile, njengekheji elimele noma izinto ezisolayo ezingasahambi kahle. Lokhu kungakhombisa ukukhathala kwesiteji sokuqala noma indawo engafanele yokukhokha emhlanganweni wokuthwala.

Kungani kubalulekile : Le misindo ivame ukuba yizinkomba zokuqala ezizwakalayo zokuthwala usizi. Njengokwenyuka kwengxabano nokugqokwa, imisindo iba kakhulu futhi yabizwa kakhudlwana, ukusayina ukuthi ukuthwala kusondela kokwehluleka. Ukuhlolwa okusheshayo kubalulekile ukuthola imbangela yempande - noma ngabe kungukungcola, ukuphathwa kabi, noma ukukhathala ngezinto ezibonakalayo - futhi ukuvimba okwengeziwe ngemoto ye-spindle.

Izinyathelo Zokusebenza : Sebenzisa i-stethoscope noma amathuluzi wokuhlaziya wokudlidliza ukukhomba umthombo womsindo. Bheka amazinga okuthambisa okuthambisa nekhwalithi, hlola ukungcoliswa, futhi uqinisekise ukuqondanisa. Uma umsindo uphikelela, cabanga ngenhlanganisela i-spindle ukuze ihlolwe kahle.

Ukudlidliza okwandisiwe

Ukudlidliza ngokweqile kungenye uphawu lomonakalo obhekene nomonakalo kuma-spindle motors. Ngenkathi elinye izinga lokudlidliza lijwayelekile ekushintsheni kwemishini, ukwanda okubonakalayo noma ushintsho kumaphethini okudlidliza kungakhombisa izingqinamba ezinkulu ngaphakathi komhlangano othwala. Izici ezibalulekile zifaka:

L Imbalince : Ukugqoka okungalingani noma ukulimala kumthwali kungenza ukuthi i-rotor ingaba nokungcola, okuholela ekunyisweni ngokweqile. Lokhu kuvame ukuzwakala njengesigqi noma ukudlidliza ngokuhamba ngesikhathi sokusebenza.

l Ukulimala okukhohlisayo noma okuphezulu kwendawo Lezi ziphutha zingavela ekukhathazekeni, ukulayishwa ngokweqile, noma ukungcoliswa.

l Ukukhubazeka okungalungile noma okwenziwa okuxekethile : amabhere ahleliwe noma i-hardware ekhuphukayo angakhulisa ukudlidliza, abeke ingcindezi eyengeziwe ekuvuneni nasekusheshiseni.

Kungani kubalulekile : ukukhuphuka kokudlidliza akubonisi ukudala umonakalo kodwa futhi kuthinta nokusebenza okuphelele kwemoto ye-spindle. Ukuthuthukiswa ngokweqile kungaholela ekuqopheni kahle kwemishini, ingxoxo yamathuluzi, kanye nomonakalo kwezinye izinto, njengezimpawu noma izindlu. Ngokuhamba kwesikhathi, ukudlidliza okungalawulwa kungadala ukwehluleka okuyinhlekelele.

Izinyathelo Zokusebenza : Qamba ama-vibration analyzers ukuze anciphise amazinga okuvvyration futhi akhombe amaza athile ahambisana namaphutha (isib. Imvamisa yebhola noma imvamisa ye-Ball). Ukuqapha njalo kungasiza ekutholeni izitayela zokudlidliza ezikhuphukayo, okubonisa ukuthuthuka okuthuthukayo. Uma ukudlidliza okuphakeme kutholwa, hlola ukuthwala ukugqoka, hlola ukuqondanisa, futhi uqinisekise ukuthi i-rotor ilinganiselwe. Ukungenelela kusenesikhathi kungavimba ukuwohloka okwengeziwe.

Ukuwohloka kokusebenza

Ukulwa nomonakalo kuvame ukubonakaliswa njengokwehla kokusebenza kokusebenza kwe-spindle motor, kuthinta amandla alo okugcina ukunemba, ukushesha namandla. Izimpawu ezijwayelekile zifaka:

l Ukulahleka kokunemba : Amabhere owonakele angadala i-spindle ku-webble noma iphambuke endleleni yayo okuhlosiwe, okuholela ekusebenzeni kwemishini noma yokusika. Lokhu kubaluleke kakhulu kwizinhlelo zokusebenza ezinengqondo eziphakeme njengemishini ye-CNC, lapho ukuphambuka okuncane kungalimaza khona imisebenzi yokusebenza.

l Ukushintshashintsha kwesivinini : ama-bearings agugile noma alimala angadala ukumelana okungahambisani, okwenza ukuthi le moto ye-spindle ilwele ukulondolozwa isivinini sokujikeleza esingaguquki. Lokhu kungaholela ekusebenzeni okungalingani noma ukusebenza kokugaya.

l Ama-WOW DIps noma ukulayisha ngokweqile : Njengoba ama-bearings awohloka, ukukhuphuka kwemvunulo kudinga amandla amaningi ukugcina umsebenzi, okuholela ekusetshenzisweni kwamandla okuphezulu noma amaconsi aphakathi kwamandla. Ezimweni ezinzima, imoto ingatatazela noma yehluleke ukuqala ngokuphelele.

Kungani kubalulekile : Ukuwohloka kokusebenza kube nomthelela ngqo kwikhwalithi yokuphuma kanye nokusebenza kwemishini. Ezimboni ezithembele ngokunemba nokuvumelana, njenge-aerospace noma ukukhiqiza izimoto, ngisho nezinkinga ezincane zokusebenza kungaholela ekulahlekelweni kwemali okubalulekile noma ukukhathazeka ngokuphepha.

Izinyathelo Zokusebenza : Qapha ama-spindle performance metric, njengokuqina kwesivinini kanye nokusetshenziswa kwamandla, usebenzisa amathuluzi okuxilonga noma amasistimu wokulawula umshini. Uma ukucekelwa phansi kubhekwa, hlola amabele okugqoka, hlola ukuthambisa, bese uqinisekisa ukuthi i-spindle ilinganiselwe kahle. Ukubhekana nalezi zingqinamba kusenesikhathi kungabuyisela ukusebenza futhi kuvikele ukulimala okwengeziwe.

I-Discoloration noma iphunga

Izinguquko ezibonakalayo ezingxenyeni ezithwala noma ezizungezile, njenge-discoloration noma iphunga elingajwayelekile, ziyizimpawu ezibalulekile eziyisixwayiso zokuthwala usizi, okuvame ukuxhunyaniswa nokuhlukunyezwa ngokweqile noma ngokwehluleka ngokwezinto ezibonakalayo. Lezi zimpawu zifaka:

l Ukudilizwa (ukufiphala noma browning) : I-Beheated Overheated Eahele Lokhu kungenzeka lapho ukungqubuzana kukhuphuka ngenxa yokuthambisa okunganele, imithwalo ephezulu, noma ukusebenza isikhathi eside ngejubane eliphakeme. I-Discoloration isibonakaliso esicacile sokuthi izinto ezithinta ukucindezela zibhekene nengcindezi eshisayo, enganciphisa isakhiwo sayo.

l ACRID noma iphunga elishisiwe : Iphunga elibukhali, elibukhali lingakhombisa ukuthi i-libricant evuthayo iyavutha noma ibhidliza phansi ngenxa yokushisa ngokweqile. Kwezinye izimo, iphunga lingaqhamuka ezintweni ezivumayo ngokwalo njengoba liqala ukungcola noma ezingxenyeni eziseduze ezithintwe ukushisa.

Kungani Kubaluleke : I-Discoloration and Odors Signal ukuthi ukuthwala kusebenza ngaphansi kwezimo ezedlulele, ezingasheshisa ukugqoka nokuholela ekuhlulekeni okuseduze. Ukushiswa ngokweqile kungalimaza nezinto eziseduze, njengezimpawu zokwenziwa, imisele, noma izindlu, izindleko zokulungisa zokulungisa kanye nesikhathi sokuphumula.

Izinyathelo Zokusebenza : Uma kutholwa ukuguqulwa noma amaphunga, vala ngokushesha le moto ye-spindle ukuvikela okwengeziwe. Hlola izimboni zezimpawu zokushisa ngokweqile, hlola isimo sokuthambisa (isib. Ukuvota), bese uhlola izimo zokusebenza (isib., Isivinini, umthwalo, amasistimu wokupholisa). Faka esikhundleni izibopho ezilimele futhi ugcwalise kabusha noma uthuthukise ukuthambisa ukuvikela ukuphindeka.

Izindlela zokuvimbela kanye nemikhuba emihle kakhulu

Ukunciphisa ubungozi bokunikeza umonakalo futhi kunwebe isikhathi sokuphila kwama-spindle motors, cabanga ngemikhuba emihle elandelayo:

l Ukulondolozwa Okujwayelekile : Sebenzisa uhlelo lokulungisa okujwayelekile okubandakanya amasheke okufuhlazeka, ukuqinisekiswa kokuqondanisa, nokuhlola ukuthwala. Sebenzisa ama-lubrip akhwalithi aphezulu afanelekele ezimweni zokusebenza ze-spindle.

l Ukuqapha Ukuqapha : Faka izinzwa zokudlidliza noma usebenzise ama-analyzers aphathekayo ukulandelela amazinga okudlidliza ngokuhamba kwesikhathi. Setha imibundu ukuze ivuse izexwayiso lapho ukudlidliza kudlula imikhawulo eyamukelekayo.

l Ukuphathwa kwe-lubrication : Qinisekisa ukuthambisa okulungile ngokubheka amazinga we-lubricant nekhwalithi. Sebenzisa uhlobo lokuthambisa okungumenzi-enconyiwe kanye nezikhawu zokuvuselela ukunciphisa ukungqubuzana nokugqoka.

l Ukulawulwa Kwezemvelo : Nciphisa ukungcoliswa ngokugcina indawo yokusebenza ehlanzekile nokusebenzisa izimpawu ezisebenzayo ukuvikela ama-bearings kusuka othulini, emfucumfuni, noma umswakama.

l Ukuqeqeshwa Nokuqwashisa : Abasebenzisi bezitimela kanye nabasebenzi bezokugcina ukubona izimpawu zakuqala zomonakalo, njengemisindo engajwayelekile noma izinguquko zokusebenza, futhi zibike ngokushesha.

Ukulimazeka kuma-spindle motors kungaba nemiphumela ebalulekile, kepha ukutholwa kusenesikhathi kungasindisa zombili izikhala nemishini yamandla. Ngokuhlala uphapheme ngezimpawu ezinjengomsindo ongajwayelekile, ukudlidliza okungekho emthethweni, ukuwohloka kokusebenza, kanye nokonakalisa noma iphunga noma iphunga, ama-opharetha angakhomba izingqinamba ngaphambi kokuba zikhule. Ukuqapha njalo, ukulungiswa okufanele, kanye nezenzo ezisheshayo ziwukhiye ekuqinisekiseni ukuthembeka nokuphila isikhathi eside kwama-spindle motors. Uma noma yiziphi zalezi zimpawu zibonwa, yenza ngokushesha ukuze uhlole futhi ubhekane nenkinga, ukubonisana nochwepheshe bethela noma umenzi we-spindle njengoba kudingeka ukubuyisela ukusebenza okuhle.

Ukugcina

Umonakalo ophethe ama-spindle motors ungosongo oshubile ongaholela ekwehlulekeni, isikhathi sokuphumula, nezindleko ezibalulekile uma kushiywe kungalawulwa. Ngokuqonda izimbangela-ngokweqile, ukungcoliswa, kanye nokunganakwa - futhi usebenzisa amathuluzi athuthukile njengobuhlakani be-vibration kanye nobuchwepheshe bokufanela, opharetha bangabona izingqinamba kusenesikhathi futhi bathathe izinyathelo zokulungisa. Ukunamathela kuzinkombandlela zokugcina kanye nokusebenzisa izilawuli zezemvelo kuvikeleke futhi kuvinjelwe ukulimala, ukuqinisekisa ukusebenza nokunemba okungaguquki. Amandla anika amandla i-spindle motor, futhi ebakhulisa ngokusebenzisa ukunakekelwa okusebenzayo namasu anolwazi kubalulekile ekubekezeleleni ukuthembeka. Ngezixazululo ezifanele, thintana nabakhiqizi be-bearing noma ongoti be-spindle ukwenza ngcono ukukhetha nokulungiswa kwesicelo sakho esithile.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu