Ukuqalisa

I-Chatter in CNC Maching-Maching - Inkinga ejwayelene kakhulu - ingalimaza ingxenye yakho yokuqeda, ilimaze amathuluzi akho, bese unyakazisa umkhiqizo wakho emgogodleni wayo. Ukudlidliza okungafuneki okwenzeka ngesikhathi sokusika, futhi uma uke wakuzwa lokho kuhlafuna, umsindo weqa ngenkathi umshini usebenza, uhlangabezane nakwisibili. Kepha nazi izindaba ezinhle: Chatter akuyona into ethile engenakugwenywa. Ngolwazi olufanele, amathuluzi, namasu, ungayikhahlela ku-curb.

Cabanga ngakho ngale ndlela: I-Chatter iye kwi-CNC Maching Ihlanekezela umyalezo, idala ukungasebenzi kahle, futhi ingenisa amaphutha. Emisebenzini, lawo maphutha ahumusha ezingxenyeni ezi-scrap, impilo yamathuluzi amafushane, nezindleko eziphakeme. Ngakho-ke, ukuqeda i-chatter akuyona nje ukuthuthukisa ikhwalithi - kumayelana nokukhulisa ukusebenza kwakho konke komsebenzi kanye nomugqa ophansi.

Lo mhlahlandlela uzokuthatha ujule kwizimbangela zexove, ungayibona kanjani, futhi, okubaluleke kakhulu, indlela yokukuqeda. Noma ngabe ungumshini onolwazi noma nje ufaka izinyawo zakho emhlabeni we-CNC, lo mbhalo we-step-by-step uzokunika amaqhinga asebenzayo ukuze uthule uxonde futhi ubushelelezi indlela yakho ukunemba.

Ukuqonda i-CNC Chatter

Izincazelo nezinhlobo ze-Chatter

I-CNC Chatter isho ukunyakaza okujabulisayo okwenzeka ngesikhathi senqubo yokusika. Kubonisa njengamagagasi aphindaphindayo endaweni yokusebenza futhi kuvame ukukhiqiza umsindo ophakeme kakhulu. Kunezinhlobo ezimbili ezinkulu:

1. I-Revenerative Chatter - okubangelwa izimbotshana zezimpendulo phakathi kwethuluzi nokusebenza kokusebenza okuvela kuma-pass adlule.

2. I-Mode Coupling Chatter - iphakama lapho kunezindlela ezimbili ezihlukile zokudlidliza (njengokuthandana kwamuva kanye ne-Torsional) ndawonye.

3. Ingxoxo ephoqelelwe yokudlidliza - ebangelwa yizinto zangaphandle ezinjengokungalingani kwezimoto noma izimbotshana ezigugile.

Ngayinye yalezi zinhlobo iletha inselelo eyingqayizivele, kepha bonke banomphumela ojwayelekile: ikhwalithi emishini emishini yehlise futhi yandise ukugqokwa nokudabula kwemishini. Uma ulalela imisele ye-squeal noma yokuqaphela ezingxenyeni zakho, kungenzeka ukuthi usebenzelana nomunye walaba bantu.

Izimbangela ze-Chatter ku-CNC Maching

Manje kungani kwenzeka? Akuyona into eyodwa nje - imvamisa yinhlanganisela yezici:

Amapharamitha wokusika okungalungile : Isivinini esikhulu kakhulu noma isilinganiso sokudla singakhulisa ukudlidliza.

· Bus aughting noma abanikazi : ukuntuleka kokuqina noma ithuluzi elingalungile geometry kungaqala ukunyakaza.

Ukulungiswa okungafanele

Isimo somshini : Imihlahlandlela Exegayo, izikulufo zebhola ezigqokile, kanye nokuphatha kabi konke kunikela.

Izakhiwo ezibonakalayo : Ezinye izinto zokwakha zithambekele kakhulu ekudlidlizelweni kwezinye ngenxa yobulukhuni babo noma ukuqina.

Ukuhlonza imbangela yezimpande kuyisinyathelo sokuqala sokuthulisa umsindo-ngokoqobo nangokomfanekiso. Awukwazi ukulungisa lokho ongakuqondi.

Ingxosha ithinta kanjani imishini ye-CNC

Indawo yomthelela |

Ukufanisa |

Imiphumela |

Qeda phezulu |

Amaphethini we-wavy, amamaki ethuluzi angajwayelekile kwi-workpiece |

Ama-aesthetics ampofu, ingxenye yenqatshwa, ukungalungiswa okungamampunge |

Ukunemba okubucayi |

Ukudlidliza kubangela ukuthi ithuluzi liphambuke endleleni |

Izingxenye eziphuma ngaphandle, ukusebenza okuncishisiwe |

Ukugqokwa kwamathuluzi |

Ukudlidliza okuqhubekayo kuholela ekushayweni okunqenqemeni nokuqhekeka |

Ukufakwa esikhundleni samathuluzi njalo, izindleko eziphakeme zokuthola amathuluzi |

Ukugqokwa komshini |

Ukudluliselwa kwe-Chatter kugcizelela izingxenye zomshini |

Ukulimala, impilo yomshini encishisiwe, ukulungiswa okwandayo |

Isikhathi sokujikeleza |

Amanani Okuphakelayo Okuhamba kancane adingekayo ukugwema ukuxoxa |

Izikhathi ezinde zokukhiqiza, ukusebenza kahle okuncishisiwe |

Izindleko zokukhiqiza |

I-Confsase Scrap, Rework, kanye Ukulimala Kwethuluzi |

Izindleko eziphakeme zokusebenza, imishado yenzuzo encishisiwe |

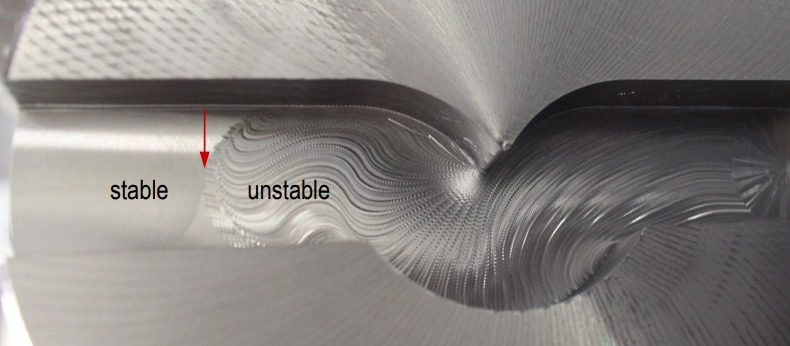

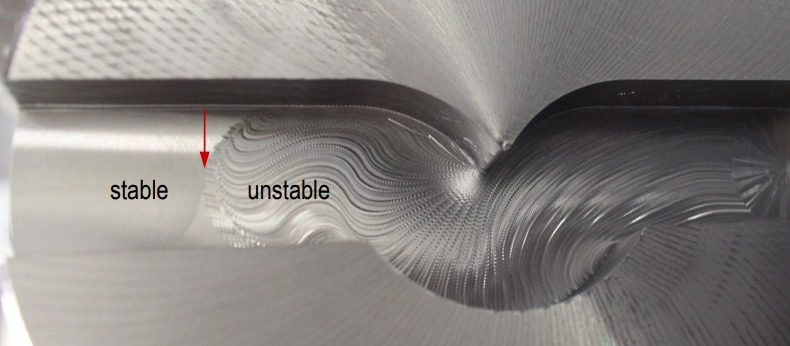

Umthelela ekuqedeni komhlaba kanye nekhwalithi yengxenye

Omunye wemiphumela ebonakalayo ye-chatter kuqediwe okumpofu komhlaba. Cabanga nje uzama ukubhala ngepeni ngenkathi isandla sakho sithuthumela - empeleni yiphi i-chatter eyenza ithuluzi lakho lokusika. Ukudlidliza kubangela izindlela ezingejwayelekile zamathuluzi, ezishiya amaphethini afana nama-wave.

Lokhu kungapheleli akuyona nje i-cosmetic. Bangakwazi ukuyekethisa ukubekezelelana ngokuqinile, bethula ubuthakathaka bezinhlelo, futhi bahole ekulweni nengxenye yenqabe. Ezimbonini ezinjenge-aerospace noma yezokwelapha, lapho ukunemba kuyikho konke, lokho kungumphukeli.

I-chatter ithinta ukunemba kobukhulu. Noma ngabe ingxenye yakho ibukeka ilungile ebusweni, ukungahambi kahle okufihliwe kungaholela ekuphumeni kokusebenza, ikakhulukazi ngaphansi kwengcindezi noma umthwalo.

Ithuluzi Ukugqoka nempilo yomshini

I-chatter ayiyimbi nje engxenyeni - inesihluku ekutholeni kwakho. Ukudlidliza okuqhubekayo kubangela ukuphazamiseka okuncane onqenqemeni lokusika, okuholela ekugqokeni kwethuluzi elisheshayo. Uzozithola uzibuyisela indawo yokugcina noma ukufaka kaninginingi, okunezela ngokushesha.

Futhi masingakhohlwa ngomshini wakho. Ukuchayeka isikhathi eside ku-vibrate kungakhulula ama-bolts, ukulimala, futhi kunciphise impilo yemishini yakho ye-CNC. Izindleko zokulungisa ziyanda, futhi isikhathi esingahlelwanga siba yikhanda elijwayelekile.

Ukusebenza kahle kokukhiqizwa kanye nemiphumela yezindleko

Ekupheleni kosuku, i-Chatter ikushaya lapho kubuhlungu khona kakhulu - isikhwama sakho se-wallet yakho. Amaphetho ampofu aqeda ukucubungula kabusha noma ngisho nezingxenye ezihlekisayo. Amathuluzi adinga ukufaka esikhundleni kaningi. Imishini ibhidliza ngokungazelelwe. Zonke lezi zinto zinomthelela ku:

ezengeziwe Izikhathi zokujikeleza

· Ngendlela engezansi

· Izindleko ezengeziwe zokusebenza

· Iminqamuzo elahlekile

Uma usebenzisa isitolo sevolumu ephezulu, lokhu kulahleka kwehla ngokushesha. Kepha ngisho nokusebenza okuncane, umthelela ubalulekile. Izindleko zokungazinaki i-chatter zihlala ziphakeme kunokutshala imali ekuvinjelweni.

Ukuhlonza ingxoxo ngesikhathi sokusebenza kwe-CNC

Indlela yokuhlonza |

Izinkomba |

Amathuluzi / amasu |

Izimpawu zokucwaninga |

Ukuncipha okubunjiwe okuphezulu, ukukhala, noma umsindo oshelelayo ngesikhathi sokusika |

Ukuzwa kwe-opharetha, izinzwa zokuphuma ze-acoustic |

Ukuhlolwa Okubonakalayo |

Ukuqedwa kwe-Wavy Surface, ama-streaks acwebezelayo, imigqa yokusika engahambisani |

Ukuhlolwa kwengxenye ye-Post-Process |

Ithuluzi Ukugqoka Amaphethini |

Ukugqoka okungajwayelekile njengokuhlanza noma ukushiswa emaphethelweni amathuluzi |

Microscope, ama-lens akhulisayo |

Ukujikeleza |

Ukushisa ngokweqile noma intuthu ngesikhathi sokusika |

Amakhamera we-Thermal, izinzwa ezingenampilo |

Ukulinganisa Ukudlidliza |

Ukuvezwa okulinganiselwe ngaphezulu kwemikhawulo eyamukelekayo |

I-accelerometer, izinzwa zokudlidliza |

Ukusika amandla Impendulo |

Spikes ekusikeni kwamabutho ngesikhathi semishini |

Ukusika amandla Dynamometers, izinzwa ze-torque |

Izinkomba ezibukwayo nezokuzwa

I-chatter ivame ukukhala kakhulu - futhi ayinakuphikwa. Leyo nsimbi ekhuphuke kakhulu, ukugaya, noma umsindo onqenqemeni kuyindlela yomshini wakho ukumemeza usizo. Ungakunaki. Ifulegi elibomvu lento ephumayo.

Kepha akukhona nje ngomsindo. Uzobona futhi:

· Amaphethini angaphezulu we-wavy (evame ukubizwa ngamamaki ')

· Shiny streaks noma izindawo ezishisiwe

· Ithuluzi lokungaphambi kwesikhathi

Ukushisa ngokweqile noma ukubhema ngesikhathi sokusika

Lezi zimpawu zilula ukuzibona uma unaka. Kwenze umkhuba wokuhlola izingxenye ngemuva kokugijima konke, ikakhulukazi ngesikhathi sokuncintisana noma ngejubane eliphezulu.

Amathuluzi Okuxilonga Nezindlela

Uma ufuna ukwedlula amehlo nezindlebe zakho, amathuluzi okuxilonga angumngane wakho omkhulu. Sebenzisa:

ukuze Izikhombisi zokudayela uhlole ukuhanjiswa komshini

· I -acceleromereters ukukala ukudlidliza

· Ukufanekisa ukucabanga ukuthola izindawo zokushisa ngokweqile

· Ukunciphisa izinzwa ze-Forces ukuqonda ukubandakanyeka kwamathuluzi

Lawa mathuluzi akusiza ukuthi ukhombe umthombo wengxoxo ngokunemba okuhlinzayo. Awudingi ukuqagela - uzokwazi kahle ukuthi yini okudingayo.

Kusetshenziswa ukuhlaziya okudlidliza kokutholwa kwengxoxo

Ukuhlaziywa kwe-Vibration kufana ne-MRI ye-CNC yomshini wakho we-CNC. Ngokuhlaziya imvamisa kanye ne-amplitude, ungakhomba ukuthi lokho kwenzeke nje - kodwa kungani.

Isoftware yokusetha okuthuthukile okuxhumeka ezinzwa ku-spindle, umnikazi wamathuluzi, kanye nomsebenzi wokusebenza. Lezi zinhlelo zibala i-vibrate frequencys futhi zixhumane nazo ngemingcele yomshini. Ngale datha, unga:

· Lungisa ijubane lokugwema imvamisa yama-resurant

· Basanganisa i-spindle noma ithuluzi lakho

· Qagela lapho izingxoxo kungenzeka zenzeke

Le ndlela esebenzayo ikuguqula kusuka esicishamlilo kube yingxoxo yokuvimbela amalungelo ngaphambi kokuqala.

Amasu afakazelwe ukuqeda i-chatter

Ukwenza kahle amapharamitha wokusika

Ukuthola amapharamitha wakho wokusika kwesokudla kuyindlela eyodwa ephumelela kakhulu yokuthula. Cabanga ngakho njengokuhlekisa insimbi yomculo: Ukulungiswa okuncane kungenza umehluko umehluko ekutheni yonke into yenza kanjani.

Isivinini sejubane nokulungiswa kwezilinganiso zokuphakelayo

Imvamisa, ukunyakaza kokuqala ukuze kuqedwe. Nazi izinguquko ezincane-ezimbalwa, noma ngo-10%, zingashintsha umsebenzi wakho ngaphandle kwebanga lemvamisa elivuthayo. Kufana nokushaya amabhuleki elokhompi lempendulo elihambile.

Sebenzisa lokho okwaziwa ngokuthi 'spindle speed ukuguquguquka kwejubane Lokhu kuphula isigqi sengxoxo yokuvuselela kabusha, siyivimba ngaphambi kokuba yakhe.

Ngokunjalo, ukwanda noma ukunciphisa izinga lokuphakelayo kunganciphisa nokudlidliza. Uma usika ngokushesha okukhulu, ithuluzi kungenzeka lihlanganyele ngokweqile ngezinto ezibonakalayo, okuholela ekungazinzile. Uma kuhamba kancane, ithuluzi lingalithambisa kunokuba linqume futhi iresiphi yokuxoxa.

Amathiphu asemqoka:

· ' NJALO NJALO IQHAWULWE Ijubane eliphakanyisiwe kanye nokuphakelayo.

Sebenzisa ama-Chip Layitha wokubala ukuze ulondoloze ukuzibandakanya okufanele.

· Ungesabi ukusebenzisa ukusika kokuhlolwa ngokuhlukahluka okuncane.

Ukujula kokuzibandakanya kokusikwa nokuthunyelwa kwamathuluzi

Enye into enkulu esele ngemuva kwengxabano ukujula ngokweqile kokusika (Doc) noma ububanzi bokusika (WOC) . Uma ithuluzi lakho liluma okungaphezu kwalokho okungahlafuna, kuzokhaza ngokoqobo.

Zama lezi zindlela:

· Ukunciphisa i-DOC Complentelly kuze kube yilapho ukudlidliza kuqinisa.

· okubandakanya Sebenza amasu ama-radial-rudial.

· Hlukana nokusikeka okujulile ekudluliseleni okuningi.

Ukulinganisa ukuthi ithuluzi lingena kanjani umsebenzi wokusebenza kubalulekile ukuze uzinze ngemishini ezinzile. Kwesinye isikhathi, ukukhanya kodwa okusheshayo kusebenza kungcono kunokuhamba kancane, okusindayo.

Ukukhetha ukuthobela kanye ne-geometry ye-geometry

Ithuluzi lakho lokusika yi-MVP yokusebenza. Kepha uma luhlobo olungalungile, ukwakheka, noma okuqukethwe, kungakhulisa i-chatter esikhundleni sokucindezela.

Izinto zethuluzi nokugoqa

Izinto ezihlukile zamathuluzi zinikeza ukuqina okuhlukile kanye nezakhiwo ezi-vibration-demponing:

· Amathuluzi we-Carbide aqinile kakhulu kunensimbi ephezulu (HSS), abenze babe ngcono ekuphikiseni i-chatter.

Amathuluzi ahlanganisiwe (njenge-tin noma i-tin noma i-altin) anciphisa ukuxabana, okuthoba ukushisa nokudlidliza.

Kusetshenziswa inhlanganisela efanelekile ngokususelwa kuzinto zakho (i-aluminium vs. titanium, ngokwesibonelo) kungenza wonke umehluko.

Ukulungiswa kwejometri ukuqina

I-geometry ye-geometry yamathuluzi ingaphezu kwamacebo amaningi ayaqaphela. Zama:

· I-helix eguquguqukayo yokuguquguquka ukuze uqhume ukunyakaza kwe-harmoninic.

Ukuhlukaniswa okuyindida okungalingani ukuvikela ukuvumelanisa ukudlidliza.

· Furhangs ethobela ukuqina ngokwengeziwe.

ukwengeza Amadayimane amakhulu aphezulu amandla.

I-3-Flute End Mill enomthelela oguquguqukayo ingahle ihlupheke umtshingo ongama-4 nge-geometry ejwayelekile uma kukhulunywa ngokulawulwa kwengxoxo. Ngokuvamile kuyisivivinyo nephutha, kepha uma usuthole indawo emnandi, uzobona ukuqeda okubushelelezi kanye nokuthula okuthule.

Ukusetha Komshini Nokulungiswa

Ukulungiswa kokumiswa kanye nokusebenza kwe-workpiece

Uma ingxenye yakho ingekho ngokuqinile, izonyakaza. Inkathi. okulungile Ukudla kuyisisekelo semishini yokuxoxa mahhala.

Amathiphu wokuthuthukisa Ukulungiswa:

· Sebenzisa ama-rivid, ama-vibration-demplening ves noma ama-clamps.

· Get the overhang omncane kungenzeka we-workpiepe.

Sebenzisa - amabhlogo wesinyathelo noma ama jigs ngokwezifiso ukuthuthukisa ukuqina.

· Bheka amatafula we-vacuum ezingxenyeni ezifulethi - kepha qinisa amandla abo.

Izingxenye ezibucayi, imihlathi ethambile noma ukulungiswa ngokwezifiso kungadingeka ukuze kuqinisekiswe ukuphepha ngaphandle kwezenkolo.

Ukuqina kwemishini nokuqondanisa

Ngisho namathuluzi amahle kakhulu nezilungiselelo ngeke zisize uma umshini we-CNC uqobo ungawenzi umsebenzi.

Bheka:

· Amaslayidi akhululekile noma izindlela

· Izikulufo zebhola ezigugile

· Spindle misalignment

· Ukudlidliza kwetafula ngesikhathi sokusebenza

Ukuqinisa lezi zindawo kunganciphisa kakhulu ukuhanjiswa okudlidliza futhi kuthuthukise ikhwalithi yazo zonke ukusikwa.

Ukulungiswa Okujwayelekile Nokulinganisa

Musa ukulungisa nje izinto lapho bephuka. Zivimbele ekuphuleni.

Yakha uhlu lokulungiswa okujwayelekile:

· Luthanisa iziqondiso nezikulufa njalo

· Qikelela ama-bolts nokuxhumeka

· Bheka ibhalansi ye-spindle futhi uthwale impilo

· Hlela kabusha izimbazo njalo ezinyangeni ezimbalwa

Umshini ogciniwe kahle ngumshini ongamelana nengxoko. Ukunakekelwa kokuvimbela kungasusa izinkinga ngaphambi kokufinyelela ithuluzi.

Izisombululo ezithuthukile zokuncishiswa kwe-chatter

Ukusetshenziswa kwama-horters athambile

Ama-Hot Hot Hot Balters afana nama-Shock ackfurs amathuluzi akho wokusika. Bamunca amandla kusuka ekudlidlizelweni ngaphambi kokuthi ifinyelele emazingeni abucayi.

Lawa ma-Hellers ajwayele ukuqukatha izinto ezinjenge-polymers noma ama-tuned masteas amaningi ngaphakathi emzimbeni womuntu. Umphumela? Kunciphise kakhulu ukudlidliza, impilo yamathuluzi ende, kanye nokuqedwa okungcono.

Zisebenza kahle kakhulu ekugayeni okujulile ephaketheni nasekufinyeleleni okude lapho amathuluzi ajwayelekile athambekele khona.

I-Pitch eguquguqukayo namathuluzi e-Helix

Amathuluzi ane -pitch eguquguqukayo noma i-helix eguquguqukayo enama-geometries amathambo angalingani ngamabomu. Lokhu kwephula ukuvumelanisa kwamabutho wokusika futhi kuphazamise ukwakhiwa kwe-vibration.

Esikhundleni sayo yonke imibhobho ebandakanya ukwaziswa ngasikhathi esifanayo, isikhala esiguqukayo sisakaza umthwalo we-FOLD. Lokhu kunciphisa ithuba lokuyakha kwe-harmonic futhi kuqeda i-chatter evuselelekayo.

Sebenzisa lezi:

okuphezulu Ukusebenza okusheshayo

· Izingxenye ezingcolile

Izinto zokwakha zebanga le-aerospace

Ama-Vibration Dempaning Systems

Ezinye izinhlelo ze-CNC eziphakeme ze-CNC ziza nezidambi zokudlidliza ezakhelwe ngaphakathi noma zivumela izengezo zangaphandle:

Izinhlelo ezikhulayo ezisebenzayo ezisebenzisa izinzwa nama-actuators

· Ukudonswa kwamandla kazibuthe kwe-spindle associes

· Ukuphazamiseka kwe- mess

Yize kubiza, lezi zinhlelo zibaluleke kakhulu emsebenzini we-Ultra-enengqondo lapho ubuqotho buqede nobunzima obukhulu bubaluleke kakhulu.

Isoftware ye-CAM kanye sekulingisa

Ukubikezela kwe-Chatter nge-software

Isoftware yanamuhla (I-Computer-Emided Edided) Software yenza okungaphezulu kokukhiqiza amathuluzi - manje angabikezela ukuxoxa ngaphambi kokuthi uthinte ucezu lwezinto ezibonakalayo. Kufana nokuthi ube nebhola le-crystal lenqubo yakho yemishini.

Amathuluzi wesoftware athuthukile asebenzisa amamodeli wezibalo kanye nama-Dynamics wemishini wokubikezela lapho kutholakale khona ingxoxo esekwe ku:

· Izinto ezibonakalayo

· Ithuluzi i-geometry

· Ukusika kwamapharamitha

· Umshini umshini

Ngalezi zibikezelo, ungaguqula ukusetha kwakho esigabeni sedijithali, isikhathi sokugcina, impahla, kanye nempilo yamathuluzi. Izinhlelo ezinjenge -cinkinglingcloud , vericut , noma i-NC Simi Simul ziyizintandokazi zezimboni uma kukhulunywa ngokuhlaziywa kwe-chatter kanye nokuvimbela.

Amasu we-Toolttath aptification

Idizayini yeTooltap ngqo ithonya uxoxa. Amaphethini athile angabangelwa ukunyakaza, kanti amanye awazange azinciphise ngokwemvelo.

Nakhu okufanele ukwenze:

· Sebenzisa amasu we-machch-speed high anjenge-adaptive yokususa ukunciphisa ukubandakanyeka kwamathuluzi namandla okuzinza.

· Gwema ushintsho olungazelelwe oluqondisayo noma amakhona abukhali kuma-Tools zakho.

· Usebenzisa amasu wokungenisa amathuluzi aqhubekayo anciphisa ukwehla kwamathuluzi.

Amathuluzi anobuhlakani asho amabutho alinganiselayo alinganiselayo, ahumusha ekuqedeni okubushelelezi, ama-chatter-free.

Ukumbumbuluzwa kwesikhathi sangempela kanye nempendulo

Ezinye izixazululo ze-Cam Solutions zihlanganisa ama-loops wesikhathi sangempela usebenzisa izinzwa ezifakwe emshinini. Lezi zinhlelo ziqapha ukudlidliza, ukusika amandla, kanye nokukhishwa kwe-acoustic ngesikhathi sangempela. Uma u-Chatter uqala ukuthuthukisa, anga:

· Thumela izexwayiso ku-opharetha

· Lungisa ngokuzenzakalela okuphakelayo / isivinini ku-the-fly

· Idatha ye-Log yokuhlaziywa kwenqubo yangemva kwenqubo

Lolu haller olusebenzayo lokulawulwa kokuxoxa luwusizo ikakhulukazi ezindaweni ezizenzakalelayo noma zokukhanya - ukuphuma kwemishini yokuqapha lapho kungahle kube khona ukuqapha okwenziwa ngesandla.

Ukuqeqeshwa opharetha kanye nemikhuba emihle kakhulu

Ukubaluleka kwabasebenza ngamakhono

Ungaba namathuluzi amahle kakhulu, isoftware ehlakaniphe kakhulu, nomshini oqinile wedwala - kepha uma opharetha wakho bengekho isipiliyoni, i-chatter izothola indlela.

Umshini oqeqeshwe kahle angakwazi:

· Yizwa umehluko phakathi kokuncishiswa okuhle nokubi

· FEET EVERLE BIBRRATIONS

· Ukuxilonga izingxoxo ezisuselwa kumamaki e-Tool iyodwa

Opharetha abanamakhono nabo bayazi ukuthi bazongenela nini, bashintshe amathuluzi, noma balungise izilungiselelo ngesikhathi sangempela. Imvelo yabo, yathuthuka ngaphezu kwezinkulungwane zamahora esitezi esitolo, ayinakufinyeleleka.

Khuthaza imfundo eqhubekayo. Tshala imali ekukhuleni kweqembu lakho. U-opharetha we-Smart umucu wakho wokuqala wokuvikela ngokumelene nengxoxo.

Ukufunda okuqhubekayo kanye nama-workshops

Umhlaba wemishini uvela ngokushesha, futhi ukuhlala phambili kudinga ukuqeqeshwa okuqhubekayo. Umgcini noma uya:

Ama -workshops asendlini agxile ekuhlolweni okuxoxisanayo

· Seminars ved-led kumasu amasha okusika

· Izifundo ze-Online kanye nezitifiketi kusuka kumapulatifomu afana ne-Coursera, Tooling u, noma uxhumano lokufunda

Ulwazi lunamandla - nemishini ye-CNC, amandla okunciphisa isikhafu, ukuthuthukisa ikhwalithi, futhi unwebe impilo yomshini.

Izibonelo zomkhakha kanye nezifundo zamacala

Izindaba Zangempela Zomhlaba Wonke

Ake sibheke ukuthi ezinye izinkampani ziqede kanjani ingxoxo futhi zithuthukiswe ngcono:

Umkhiqizi we-Aerospace e-Ohio

Inkinga: Chatter ezingxenyeni ezijulile ze-aluminium

Isixazululo: Kushintshelwe ku-Helix End Mills eguqukayo, kungezwa abanikazi abashayekile

Umphumela: Isikhathi sokujikeleza encishisiwe ngo-30%, ibanga elithuthukisiwe lokuqeda kusuka eRA 6.3 μm kuRa 1.2 μm

Umhlinzeki wezimoto eJalimane

Inkinga: Ithuluzi eleqile lokugqoka kanye nephutha elingaphezulu

Isixazululo: Kusetshenziswe ukuqapha kabusha isikhathi se-Real-Time Vibration nge-Cam Repeedback

Umphumela: 40% ukukhuphuka kwempilo yamathuluzi kanye nezingxenye ezimbalwa ezinqatshelwe

Isitolo Sedivayisi yezokwelapha eCalifornia

Inkinga: Chatter in omncane we-titanium izimila

Isixazululo: Amasu we-Toolttap alungiselelwe, angezelele ukulungiswa okuphezulu okuphezulu

Umphumela: Kutholwe ± ± 0.005 mm ukubekezelela ngokungaguquki

Lezi zibonelo zikhombisa ukuthi noma ngabe imboni noma impahla, ukusebenzisa amasu afanele kuholela ekuthuthukisweni kwangempela, okulinganisekayo.

Izifundo ezifundwe ngabasebenzi be-CNC

Xoxa nanoma yimuphi umshini ongemva kokuvaliwe futhi bazokutshela-i-chatter akuyona nje inkathazo; Kungumbulali wesitolo. Nakhu abakufundile kanzima:

· Ungalokothi ungazinaki izimpawu zokuqala-uChatter uhlala eba mubi kakhulu.

· Ukusetha okuqinile kubaluleke kakhulu kunokusetha okusheshayo.

· Ukusikwa kokuhlolwa kanye nemibhalo kungabangane bakho abakhulu.

Ukusebenzisa ithuluzi eshibhile kukubiza kakhulu ngokuhamba kwesikhathi.

Ukulalela ukuhlakanipha kwesitezi sesitolo kubaluleke kakhulu njengokufunda incwadi. Isipiliyoni sangempela somhlaba yigolide uma kuziwa ekuhlolweni nasekuxazululeni okuxakile.

Amaphutha ajwayelekile ukugwema

Ukulinganiswa komshini ongakunaki

Umshini olinganiselwe kabi ufana nemoto enamasondo anempilo. Impela, kuzohamba - kodwa hhayi kahle. Ukulinganisa okujwayelekile kuqinisekisa ukuthi wonke ama-axses aqondaniswe, i-backlash incishisiwe, futhi izakhi zisebenza ngokuvumelana.

Ama-Missteps ajwayelekile:

· Ukunaka izindaba ezincane zokuqondanisa

· Skrofing ukulungiswa okuhleliwe

· Ukwehluleka ukuphinda kabusha ngemuva kokuphahlazeka kwengxenye

Ngisho nemishini emisha sha ingazuza ekuhlolweni kokulinganisa kokuqala-ungacabangi izilungiselelo zefekthri ziphelele.

Usebenzisa ithuluzi elingafanele

Kusetshenziswa ithuluzi elingalungile kufana nokusebenzisa isando lapho udinga isikulufa-akusikho nje esingaphumeleli, siyalimaza.

Amaphutha Wokuthola Amathuluzi Ejwayelekile:

· Amathuluzi afinyelela amade wokusikeka okungajulile

· Imibhobho eminingi kakhulu yezinto zokwakha ama-gummy

· Ukunaka ukubaluleka kokumbona kwamathuluzi

Ithuluzi elifanelana ne-geometry ngobunzima bezinto ezibonakalayo

Hlala uthintana nomhlinzeki wakho wokuthola amathuluzi noma rep ngaphambi kokusebenzisa umsebenzi omusha. Ucingo lwemizuzu emihlanu lungagcina amahora okusebenza kabusha.

Iqhaza lezobuchwepheshe ekuvinjelweni kwengxoxo

I-IOT ne-Smart Machining Systems

I-Intanethi Yezimboni Yezinto (Iiot) iguqula imishini ye-CNC. Izinzwa ezihlakaniphile ezishumeke ngemishini, izikhala, namathuluzi angaqoqa idatha yesikhathi sangempela ekuvuthweni, okushisa, kanye nokusika amandla.

Le datha yondliwa amadeshibhodi noma amapulatifomu efu, okwenza amandla okuqagela okufana:

· Ukwehliswa kwesivinini lapho ukudlidliza kudlula imikhawulo

· Ukuqwashisa abasebenza ngaphambi kokulimala kwe-chatter kulimaza

· Ukuvala phansi umshini uma kwenzeka kunezimo ezimbi kakhulu

Lezi zinhlelo-smart azitholakali nje ezingxoxweni - zisebenza ngenkuthalo ukuze zivikele.

Amathuluzi wokuqagela wokubikezela

Ukulondolozwa kokubikezela kusebenzisa idatha nama-analytics ukuze kusengaphambili lapho ingxenye yomshini yehluleka. Kungumguquki womdlalo wokulawula ukuxoxa.

Izinzuzo zifaka:

· Ukuhlonza ukugqoka okugqoke ngaphambi kokuthi kuholele ekuvubweni kwe-spindle

Ukuvimbela ukukhululeka emizileni eqondile

· Ukuhlela izikhathi ezingaphazamisi ukukhiqizwa

Ngokubhekana nezinkinga ngaphambi kokuba zibangele ingxoxo, ukunakekelwa kokubikezela kugcina isitolo sakho sisebenza kahle nangokuthula.

Ukwakha Imvelo Yama-CNC E-CHATTERS

Ihlanganisa ukukhiqiza okusondelayo

Ukulawulwa kwengxoxo kufanelana ngokwemvelo ezimisweni zokukhiqiza ezingemuva . Iqondanisa nokunciphisa imfucuza, ukwenza kahle ukuhamba, nokugcina ikhwalithi engaguquki.

Amathuluzi ancike asiza ngengxoxo:

ukuqeda Imicimbi kaKaizen izimbangela zezimpande

· Imiyalo yomsebenzi ojwayelekile wokusetha komshini

zizogcina Izinhlelo ezi-5 indawo ehlanzekile nezinzile

Indawo yokusebenzela, ehleliwe yenhlangano yehlisa izinxushunxushu ezivame ukuzala izimpikiswano.

Izinqubo Zokusebenza Ezijwayelekile (Sops)

Ekugcineni, bhala konke. Dala ama-sops afaka:

· Amapharamitha wokusika okonke entweni ngayinye

· Umshini wokufudumeza wokufudumala kanye nokulinganisa

Uhlu lokuhlola lokukhethwa kwamathuluzi

Wami Imihlahlandlela Yokuhlola Umshini Womshini Womdlalo

Ama-SOPS acacile, atholakalayo asiza bonke abasha - abasha noma abanamathele kwimikhuba emihle kakhulu, ukugcina izingxoxo ezazibange.

Ukugcina

I-chatter ingahle ibe yinkinga ejwayelekile kwimishini ye-CNC, kepha akukude nokungenakugwemeka. Ngokuqonda okucacile kwezimbangela zayo nebhokisi lamathuluzi eligcwele amasu okulungiswa kwamasu-kusuka kumapharamitha wokusika ekuthuthukiseni isoftware kanye ne-Hardware-ungakha imvelo yesitolo esithule, esebenza kahle.

Ungavumeli ukuyekethisa kwe-chatter ukuyekethisa ukunemba kwakho, ukuchitha izinto zakho, noma kukhiphe inzuzo yakho. Yiba namandla, hlala ufundile, futhi uphathe i-Chatter Control njengengxenye yesisekelo yecebo lakho le-CNC.

Amazolumbo

1. Ngazi kanjani ukuthi uma umshini we-CNC wami uhlangabezana nengxoxo?

Funa imisindo emibi kakhulu ngesikhathi sokusika, amaphethini we-wave abonakalayo ku-Workiec yakho, kanye nezimpawu zokugqoka ithuluzi ngokushesha noma ukulimala komhlaba. Izinzwa ze-Real-Time Vibration zingasiza nokuyithola kusenesikhathi.

2. Ungaqedwa ngokuphelele?

Ngenkathi kungahle kungagwemeka ngo-100% kuzo zonke izimo, ukusebenzisa amasu afanele namathuluzi kunganciphisa cishe cishe zero. Ngesipiliyoni kanye nokusetha okulungile, ungagijima izingxenye ngokushelela ngaso sonke isikhathi.

3. Iyiphi indlela ebiza kakhulu yokunciphisa izingxoxo?

Qala ngokulungiswa okulula njengokulungisa amanani okuphakelayo noma ukusebenzisa ithuluzi elifushane. I-Toolttha Popnialization ku-SOFT yakho ye-CAM kanye nokuhlelwa okungcono kuyabiza kepha kusebenza kakhulu.

I-4. Ngabe izinga lokushisa lithinta kanjani ingxoxo kwimishini ye-CNC?

Ukushisa okuphezulu kungaholela ekunwetshisweni okushisayo, okubangela ukungahambi kahle kanye nokwandisa ukudlidliza. Kubalulekile ukugcina ukuqina okushisayo endaweni yakho yokusika.

5. Ngabe kufanele ngishintshe isoftware yami ye-cam ukulungisa i-chatter?

Uma isoftware yakho yamanje iswele ukumbumbuluzwa noma izici zokubikezela zempikiswano, ukuthuthukiswa kungakufanele. Izisombululo zesimanje ze-Cam zinikeza amathuluzi okuhlaziya anamandla asiza ukuvikela ukuxoxa kusuka esigabeni sokuhlela.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu